Gas pressure reduction valve

A valve and gas technology, used in safety valves, balance valves, valve devices, etc., can solve the problems of low pressure regulation accuracy, poor operating stability, and small pressure regulation range, and achieve convenient uniformity, simple structure, and controllable points. many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

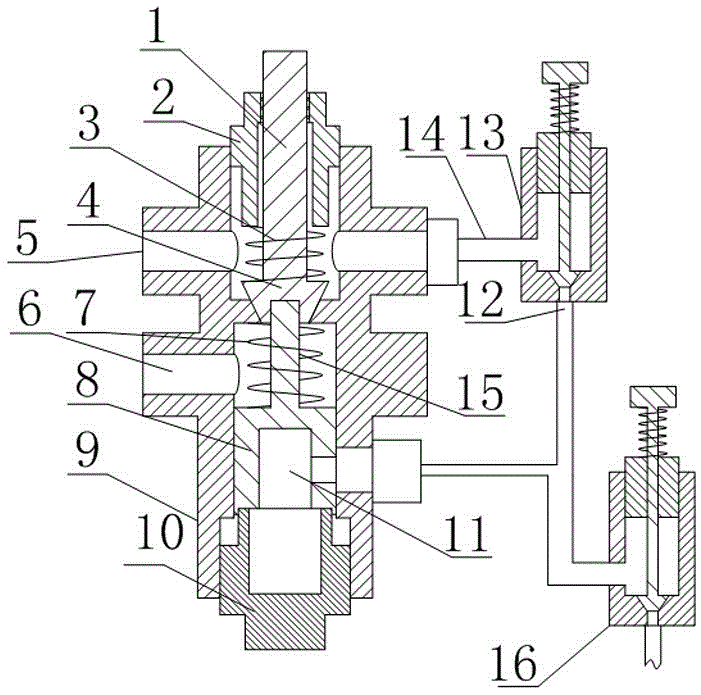

[0025] Such as figure 1 As shown, a gas decompression valve includes a valve body 9, an inlet passage 5 and an outlet passage 6 are arranged on the valve body 9, and a decompression part communicating with the inlet passage 5 and the outlet passage 6 is arranged in the valve body 9, so The decompression part includes a valve core 4 and a valve seat arranged on the valve body 9, the valve body 9 is also screwed with a pressure seat 2, and a first spring 3 is arranged between the pressure seat 2 and the valve core 4, and also includes an adjustment The valve and the piston chamber 11 arranged in the valve body 9, the piston chamber 11 is arranged on the side of the decompression part close to the outlet passage 6, the piston chamber 11 is also provided with a piston 8, and the piston 8 is near the side of the valve core 4 One side is provided with a connecting rod 15 for fixedly connecting the piston 8 and the valve core 4, the intake end of the regulating valve communicates wit...

Embodiment 2

[0032] The present embodiment is further limited on the basis of embodiment 1, as figure 1 As shown, in order to reduce the change speed of the channel area for gas flow between the valve core 4 and the valve seat during the movement of the valve core 4, that is, to improve the controllability of the flow channel area, the valve seat and the valve core 4 The sections are conical, and the valve seat and the larger end of the valve core 4 are close to the inlet channel 5 . The above structure also facilitates the sealing of the valve core 4 and the valve seat in the shut-off state of the present invention.

[0033] In order to improve the uniformity of the force on the valve core 4 and further ensure and improve the output pressure accuracy of the present invention, the axis of the first spring 3 is collinear with the axis of the guide rod 1 .

[0034] In order to facilitate the processing, assembly and maintenance of the present invention, the valve body 9 is provided with a s...

Embodiment 3

[0037] This embodiment is further limited on the basis of the above embodiments, as figure 1 As shown, in order to optimize the flow adjustment performance of the pressure regulating valve 13 and the relief valve 16, both the regulating valve and the relief valve 16 are cut-off valves.

[0038] In order to further optimize the above-mentioned flow adjustment performance, the sealing surface of the cut-off valve is tapered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com