Ball screw pair failure testing experiment table

A ball screw pair and fault testing technology, which is applied in the testing of mechanical parts, machine/structural parts testing, measuring devices, etc., can solve the problem of weakening the vibration signal of the ball screw pair, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

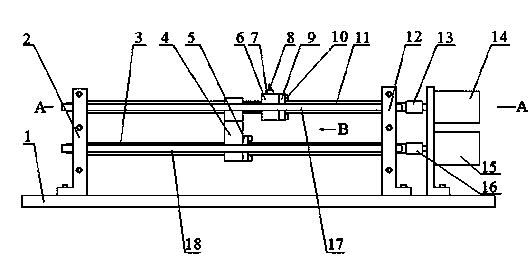

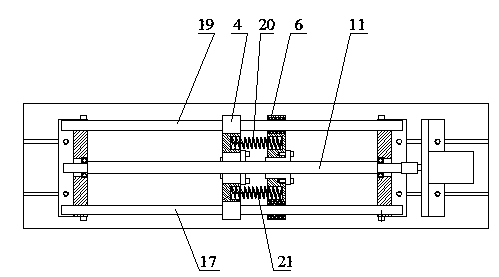

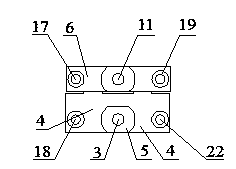

[0018] refer to figure 1 , 2 , 3 and 4, the ball screw pair failure test bench of the present invention includes: a machine base 1, a first support seat 2 and a second support seat 12 are arranged on the machine base 1, and a standard ball nut is provided between the two The supporting seat 4 and the ball nut supporting seat 6 to be tested; the first guide rail sliding hole 28, the second guiding rail sliding hole 30 and the first guiding rail sliding hole 28 and the second guiding rail sliding hole 30 are arranged on the standard ball nut supporting seat 4 The standard ball nut mounting holes 29 between them are respectively provided with the first guide rail 18 and the second guide rail 22 in the slide holes of the two guide rails, and the two ends of the two guide rails are respectively connected with the first support seat 2 and the second support seat 12, The standard ball nut mounting hole 29 is provided with a standard ball nut 5, the internal thread of the standard ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com