Thrust plate reliability test device

A test device and reliability technology, applied in the field of thrust plate reliability test device, can solve the problems of no oil or dry friction on the thrust surface of the crankshaft, quality control consistency error, accelerated wear of the thrust plate, etc. The effect of adjustable size, simple installation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in combination with specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

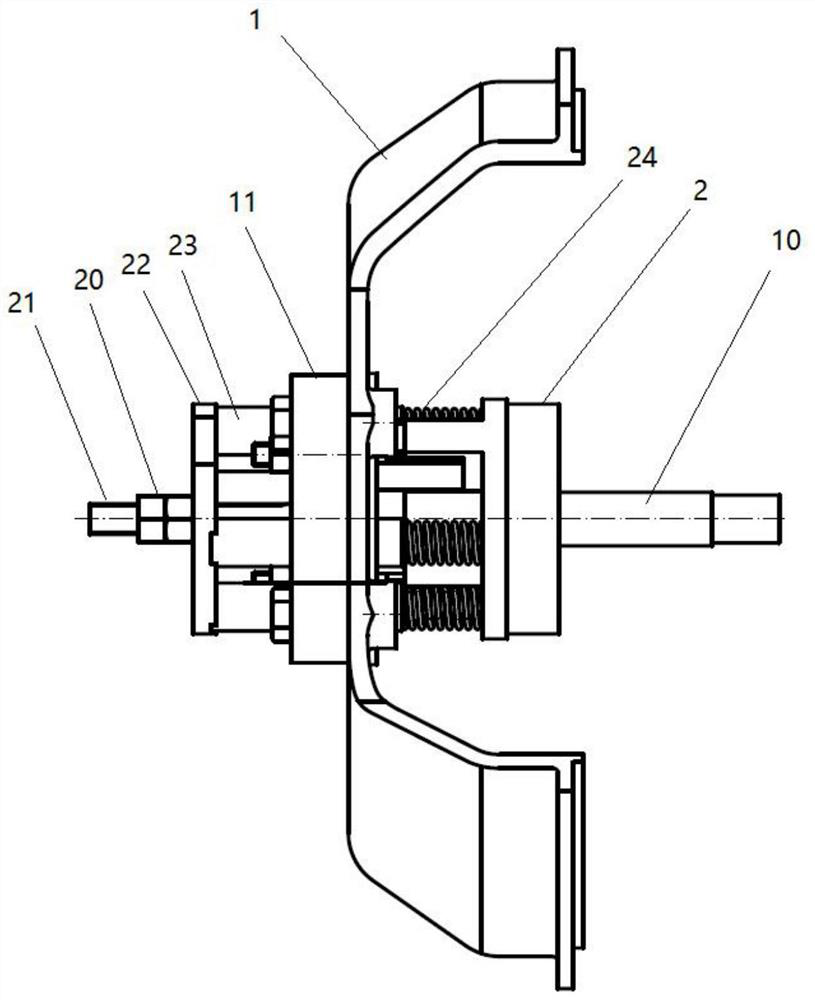

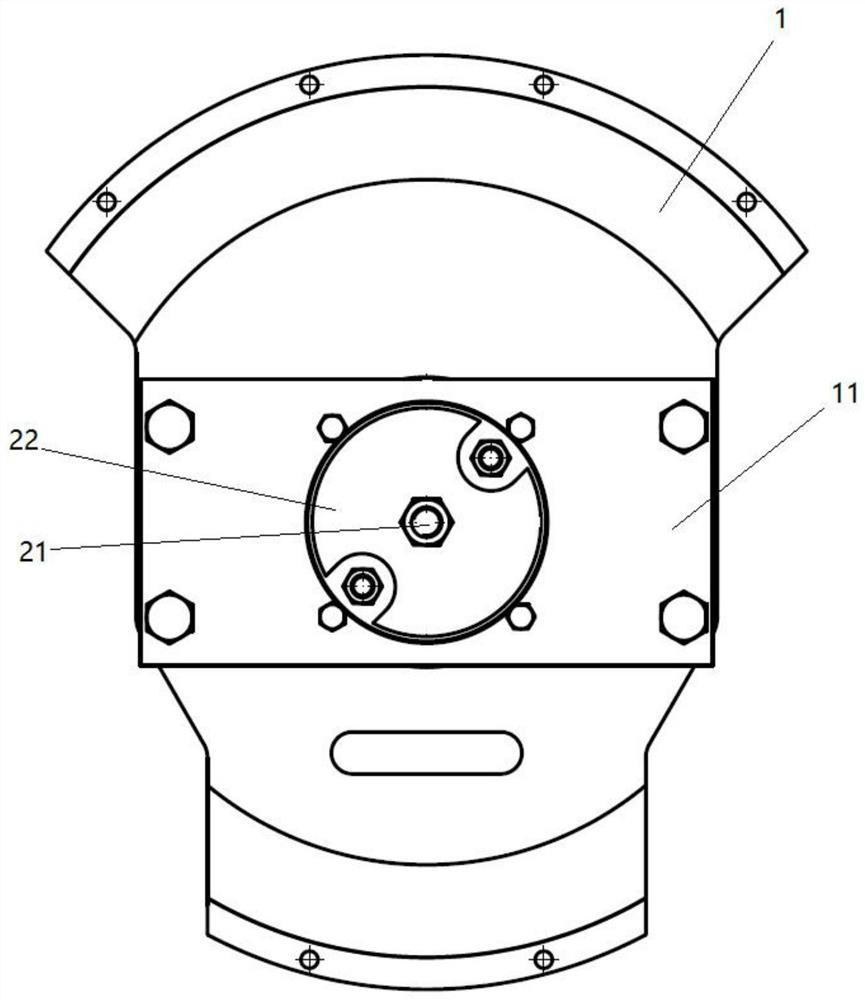

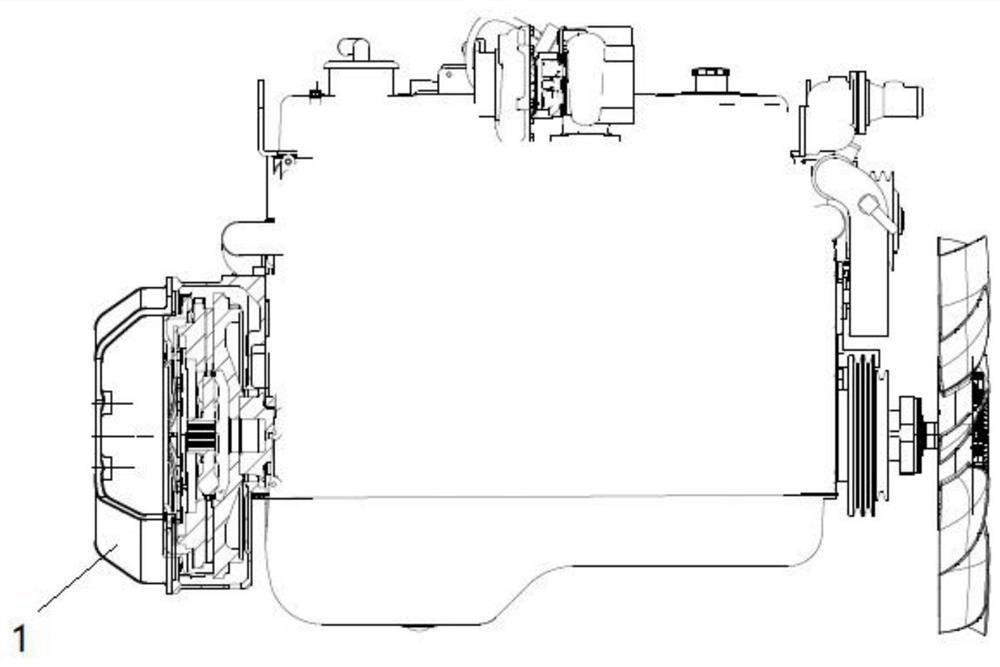

[0028] Such as Figure 1-12 As shown, the thrust plate reliability test device is characterized in that it includes a tooling clutch cover 1, a release bearing assembly 2, a positioning component 3, and a thrust adjustment component 4, and the middle part of the tooling clutch cover 1 is provided with a The positioning hole 5 is used for positioning the positioning assembly 3, and there are notches 6 on both sides of the tooling clutch cover 1, which is convenient for installation and observation of the device; the center of the release bearing assembly 2 is provided with a round hole 7, and the release bearing One end of the assembly 2 is provided with two symmetrical limit ends 8 and four symmetrical spring circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com