Crankshaft balance weight fan blade chamfering mechanism

A technology of chamfering mechanism and counterweight, which is applied in the field of chamfering mechanism and crankshaft counterweight fan blade chamfering, which can solve the problem of dimensional accuracy and surface roughness of crankshaft workpieces that are difficult to meet requirements, increase production costs, and large tool loss, etc. Problems, to achieve significant economic benefits, simple installation, high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

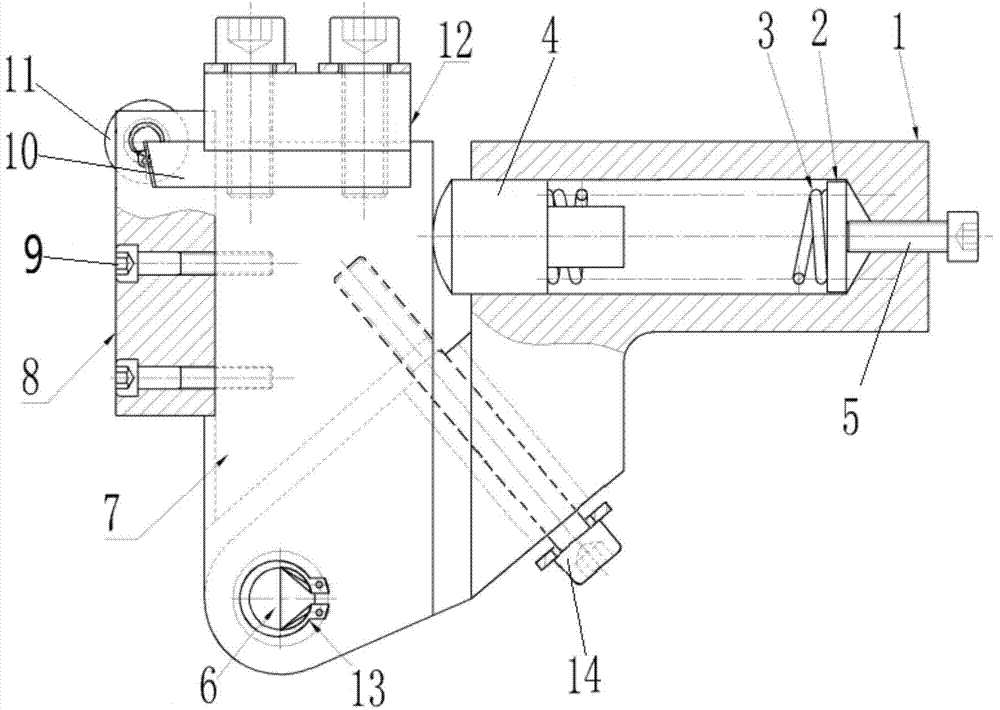

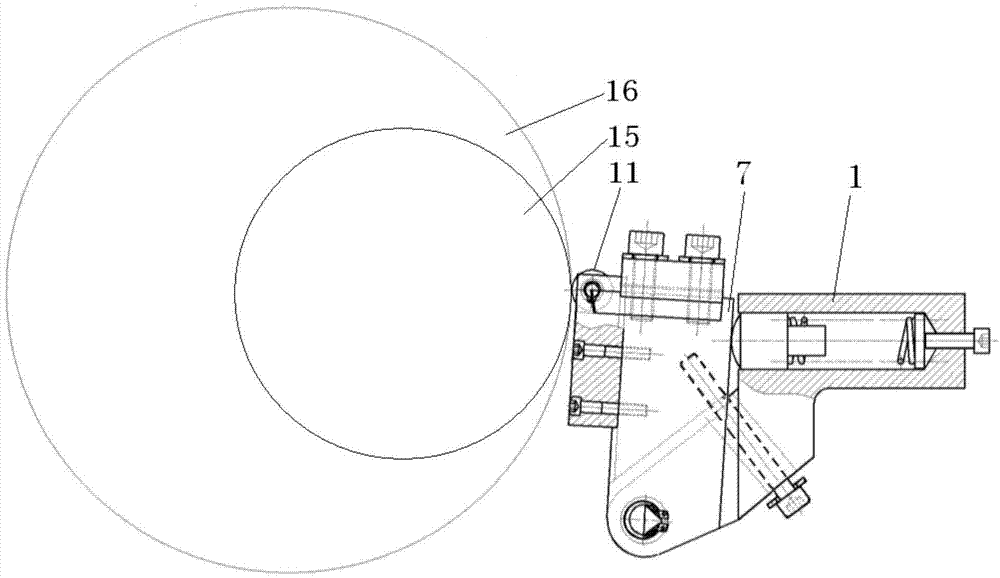

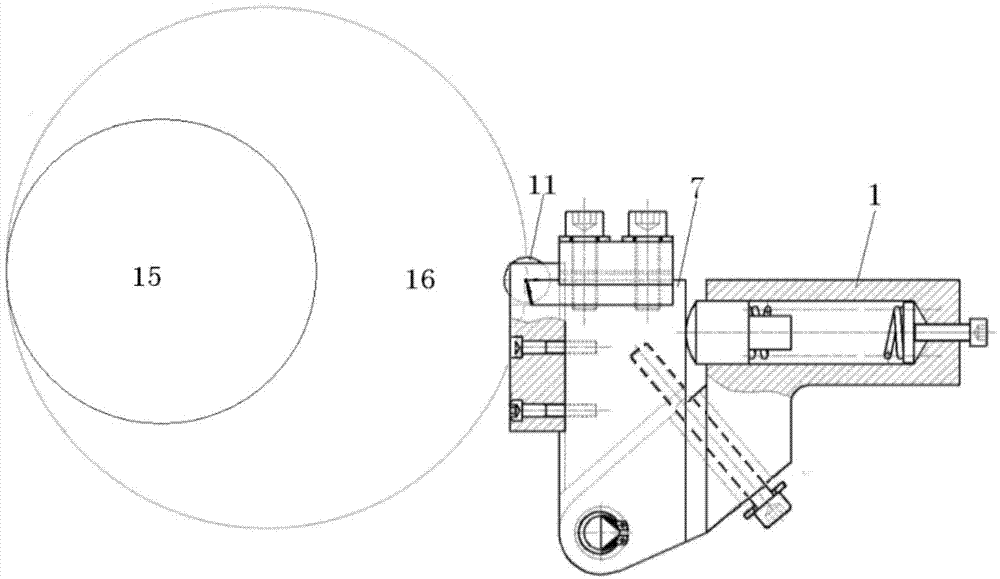

[0018] The crankshaft counterweight fan blade chamfering mechanism provided by the invention has a structure such as figure 1 As shown, it includes a cutting unit and a flexible tool letting unit located behind the cutting unit. The cutting unit includes a tool body 7, a positioning block 8, two knives 10, a pressing block 12 and a rolling member 11 installed in the positioning block. The parts are rollers or rolling bearings. The cutter body is in the shape of a square column. The pressure block 12 is fixed on the top of the cutter body by screws 9. The two cutters are symmetrically fixed on the bottom surface of the pressure block along the horizontal direction and are located on the upper part of the left and right sides of the cutter body. , the positioning block is a square column type, the positioning block 8 is fixed on the front side of the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com