Aluminum alloy gravity casting die with good cooling effect

A cooling effect, gravity casting technology, applied in manufacturing tools, casting equipment, casting molding equipment, etc., can solve the problems of small area and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

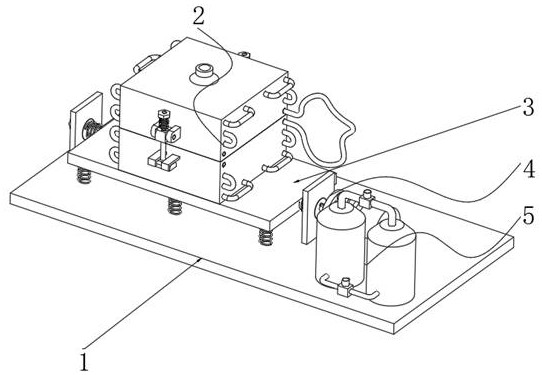

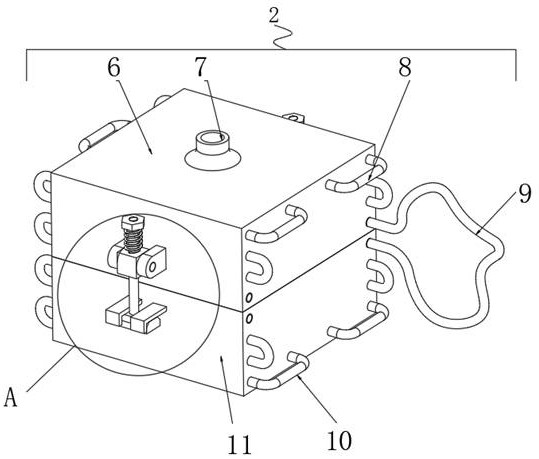

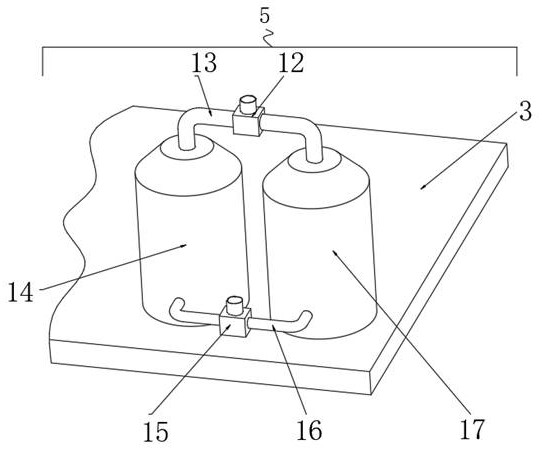

[0038] An aluminum alloy gravity casting mold with good cooling effect, such as Figure 1-3, 8, including a base 1 and a support base 3, the top of the support base 3 is provided with an upper and lower die assembly 2, and the top of the base 1 is provided with an auxiliary assembly 5, and the upper and lower die assembly 2 includes an upper die 6 and The lower mold 11, the upper mold 6 and the inner walls of the remaining three sides of the lower mold 11 on the non-opening side are respectively embedded with a multi-section "U" tube combination tube 1 8 and a multi-section "U" tube combination tube 2 10, and the multi-section "U" tube combination tube 2 10 is respectively embedded. One of the openings of the "pipe combination pipe one 8 and the multi-section "U" pipe combination pipe two 10 is communicated through the connecting pipe 9, and the auxiliary assembly 5 includes an electric heating oil tank 14 and a cooling water bucket 17, and the electric heating oil tank 14 and...

Embodiment 2

[0043] An aluminum alloy gravity casting mold with good cooling effect, such as figure 1 , 5 , 6, and 7, in order to solve the problem of insufficient gravity casting; this embodiment makes the following improvements on the basis of embodiment 1: the top outer wall of the base 1 is fixed with two support plates 26 by bolts, and the support seat Both sides outer walls of 3 are welded with shaft two 31, and shaft two 31 is slidably connected with shaft sleeve 32 through two torque transmission protrusions 30 provided thereon, and shaft sleeve 32 is rotatably connected on the inner wall of support plate 26.

[0044] The outer wall of the second shaft 31 is sleeved with a spring three 29 .

[0045] Two springs 27 are welded to both bottom outer walls of the support base 3 , and the other end of the second spring 27 is welded to the top outer wall of the base 1 .

[0046] The top outer wall of the base 1 is provided with a drive assembly 4, the drive assembly 4 includes a motor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com