Separation method of isomerized oil

A separation method and technology for isomerizing oil, which are applied in the field of chemical engineering to achieve the effects of high adsorption and separation selectivity, good application prospects and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

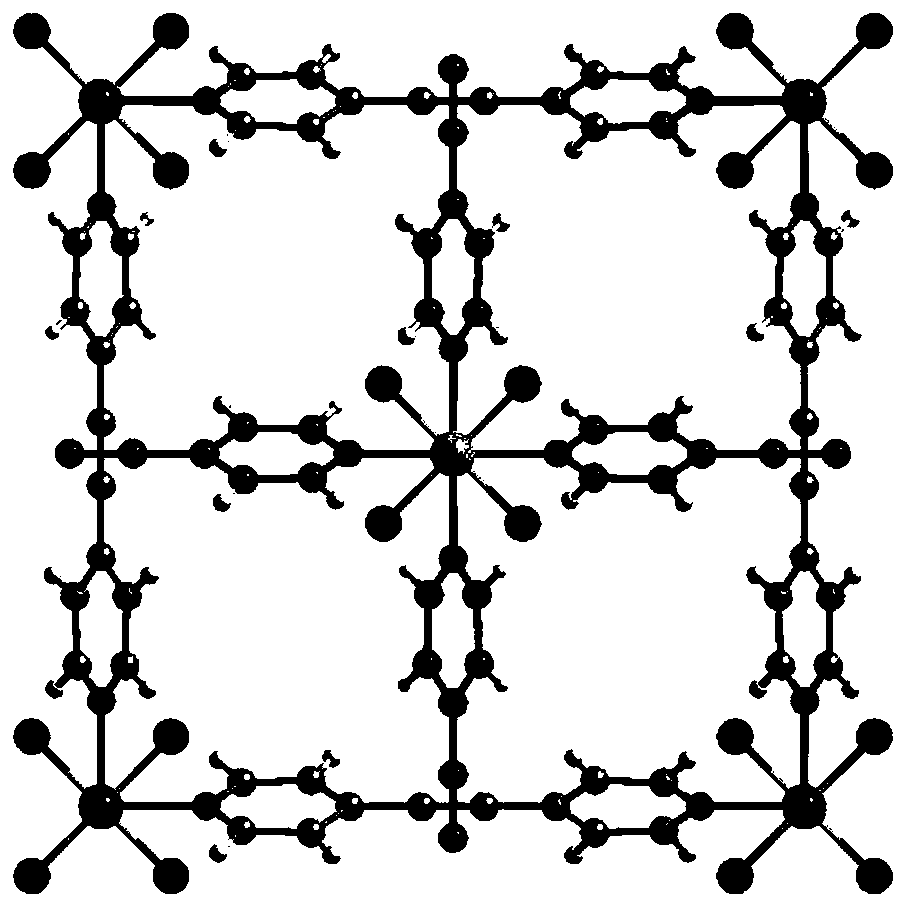

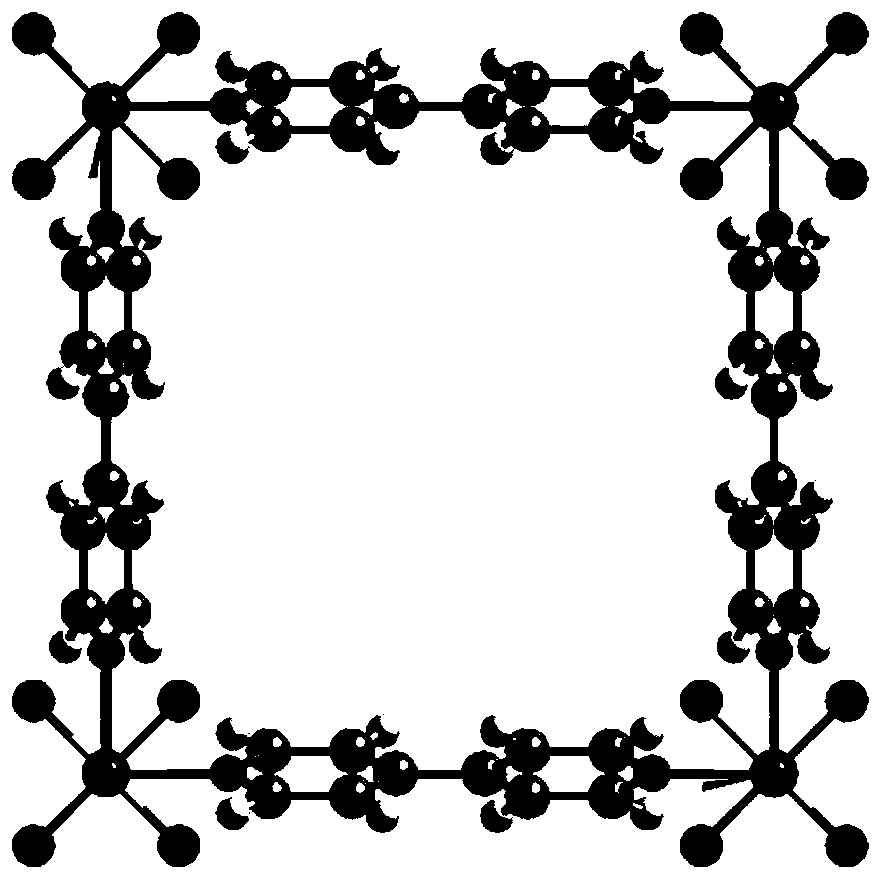

[0059] 1mmol Cu(BF 4 ) 2 , 1mmol (NH 4 ) 2 SnF 6 Dissolve 1.5mmol of 1,2-dipyridineacetylene in 10mL of methanol, mix the two in 10mL of water, and stir at 80°C for 24h. After suction filtration, activate the slurry at 80°C for 24h under vacuum conditions to obtain flexible functional The fluorine-containing anion hybrid porous material SnFSIX-2-Cu-i.

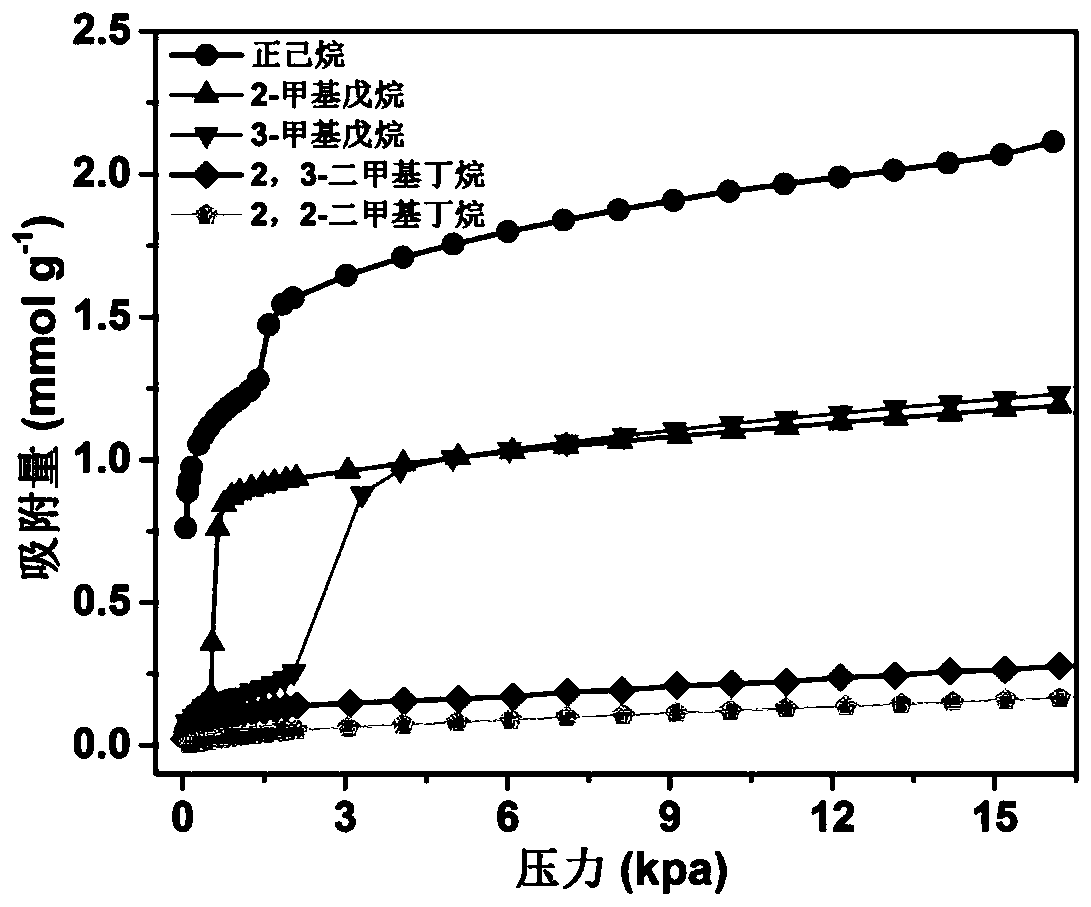

[0060] Measurement of SnFSIX-2-Cu-i material at 298K for n-hexane, 2-methylpentane, 3-methylpentane, 2,2-dimethylbutane and 2,3-dimethylbutane The adsorption isotherm of a single component, the results are as follows image 3 shown.

[0061] The obtained SnFSIX-2-Cu-i was filled into a 5cm adsorption column, and n-hexane, 2-methylpentane, 3-methylpentane, 2,2-dimethylbutane and 2, The mixed vapor of 3-dimethylbutane (molar ratio 1:1:1:1:1) is passed into the adsorption column at 2mL / min, and the breakthrough curve is as follows: Figure 5 As shown, high-purity 2,2-dimethylbutane and 2,3-dimethylbutane can be obtained in...

Embodiment 2

[0063] 1mmol ZnZrF 6 Dissolve 1.5mmol of 1,2-dipyridineacetylene in 10mL of methanol, mix the two at room temperature and stir for 24h, the resulting slurry is filtered and activated at room temperature for 24h under vacuum to obtain a flexible function containing Fluoride anion hybrid porous material ZrFSIX-2-Zn-i.

[0064] The obtained ZrFSIX-2-Zn-i was filled into a 5cm adsorption column, and n-pentane, 2-methylbutane, n-hexane, 2-methylpentane, 3-methylpentane, 2 , 2-dimethylbutane and 2,3-dimethylbutane (molar ratio 1:1:1:1:1:1:1) mixed vapor into the adsorption column at 2mL / min, the effluent gas can Obtain high-purity 2,2-dimethylbutane and 2,3-dimethylbutane. When n-hexane breaks through, the adsorption is stopped. Afterwards, switch nitrogen to purge the adsorption column at room temperature, the flow rate is 3.0mL / min, and the adsorption column can be recycled.

Embodiment 3

[0066] 1mmol CuZrF 6 Dissolve 1.5mmol of 1,2-dipyridineacetylene in 10mL of methanol, mix the two at room temperature and stir for 24h, the resulting slurry is filtered and activated at room temperature for 24h under vacuum to obtain a flexible function containing Fluoride anion hybrid porous material ZrFSIX-2-Cu-i.

[0067] Fill the obtained ZrFSIX-2-Cu-i into a 5cm adsorption column, and add n-hexane, 2-methylpentane, 3-methylpentane, 2,2-dimethylbutane, n-heptane The mixed vapor of alkanes, 2-methylhexane and 2,2 dimethylpentane (molar ratio 1:1:1:1:1:1:1) is passed into the adsorption column at 2mL / min, and the effluent gas can be obtained High purity 2,2-dimethylbutane and 2,2-dimethylpentane. When n-heptane breaks through, the adsorption is stopped. Afterwards, switch nitrogen to purge the adsorption column at room temperature, the flow rate is 3.0mL / min, and the adsorption column can be recycled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com