A method for separating C4 olefins from ultramicroporous ion-hybrid porous materials

A porous material and ultra-microporous technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low selectivity and separation selectivity, and achieve simple preparation methods, easy-to-obtain raw materials, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] NiSiF was synthesized by solvothermal method 6 ·6H 2 O and pyrazine were dissolved in methanol solvent and reacted for 3 days to obtain crystals. The obtained crystals were vacuum-dried at 120°C for 6 hours, washed with methanol, and filtered with suction. The obtained product was vacuum desorbed at 100°C for 12 hours to obtain SIFSIX-3-Ni material.

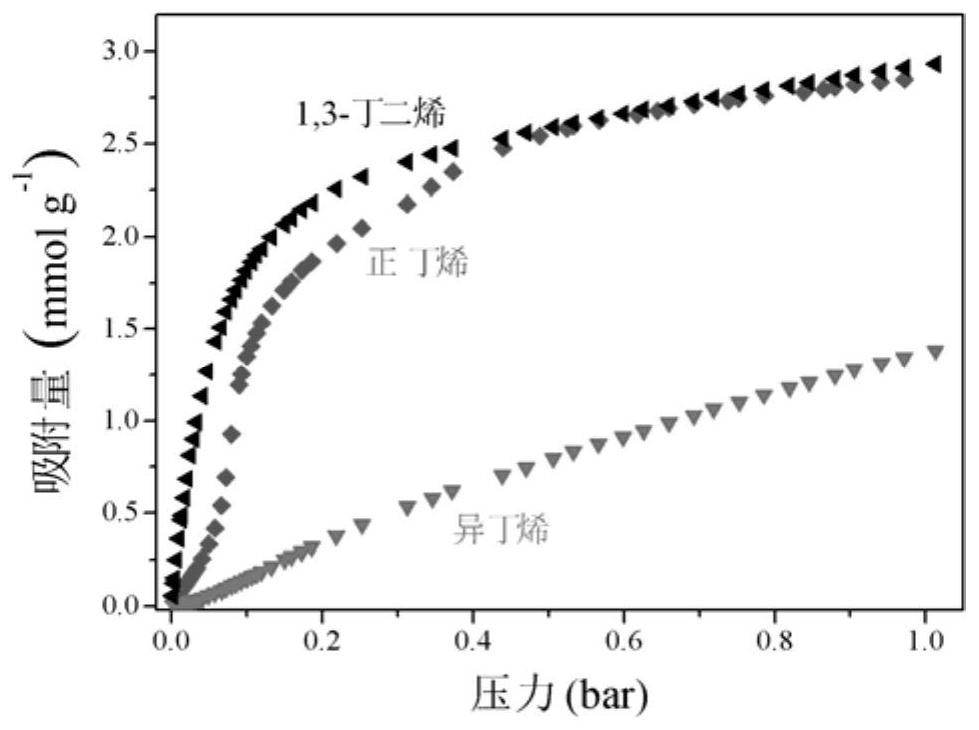

[0055] The adsorption isotherms of SIFSIX-3-Ni material to 1,3-butadiene, 1-butene and isobutene at 298K are as follows: figure 1 shown.

Embodiment 2

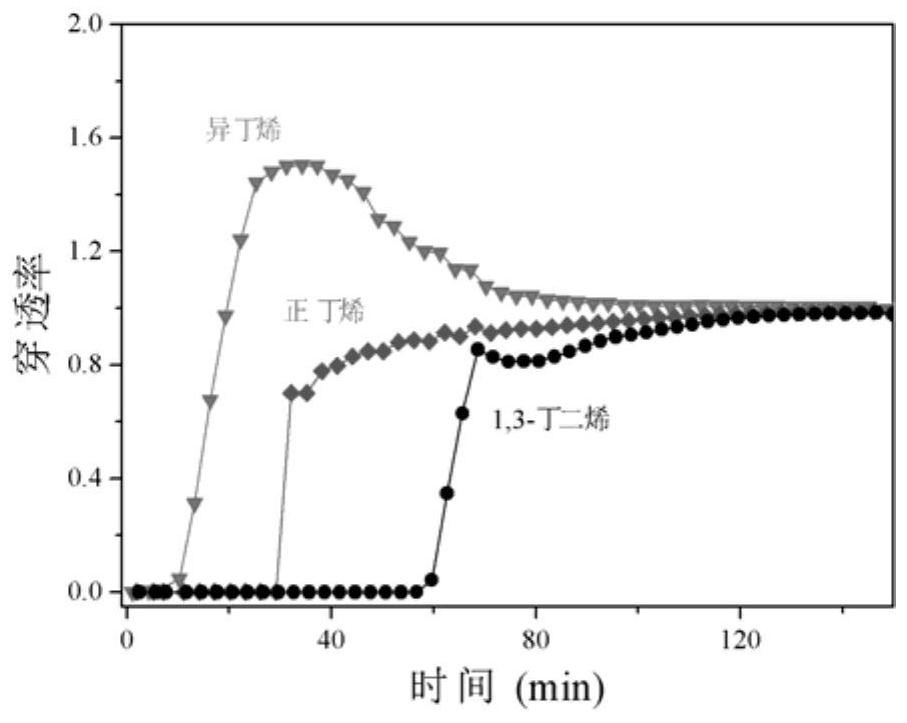

[0057] The SIFSIX-3-Ni material obtained in Example 1 was filled into a 5cm adsorption column, and 0.1Mpa of isobutene: 1-butene: 1,3-butadiene: He (30: 15: 50: 5 ) mixed gas is passed into the adsorption column at 0.5mL / min, high-purity isobutene (greater than 99.999%) gas can be obtained in the effluent gas, and when 1,3-butadiene breaks through, the adsorption is stopped. The adsorption column adopts vacuum desorption at 80°C to obtain a mixed gas of 1,3-butadiene and 1-butene, and the adsorption column can be recycled. Breakthrough curves such as figure 2 shown.

Embodiment 3

[0059] At 10°C, 1,3-butadiene: isobutene (50:50) mixed gas was introduced into the adsorption column of Example 2 at 1 mL / min, and high-purity isobutene (greater than 99.999%) gas could be obtained in the effluent gas. When 1, When 3-butadiene breaks through, the adsorption stops. The adsorption column adopts vacuum desorption at 100° C. to obtain 1,3-butadiene (greater than 90%), and the adsorption column can be recycled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com