Heat treatment method of spiral bevel gear of cargo truck on double-row rare earth carburization equipment

A heat treatment method and technology for trucks, which is applied in the field of heat treatment of spiral bevel gears of trucks, can solve the problems of carburizing and quenching, thermal distortion of gears, high energy consumption, and high production costs, so as to improve carburizing speed, reduce exhaust gas emissions, The effect of metallographic structure and surface hardness optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

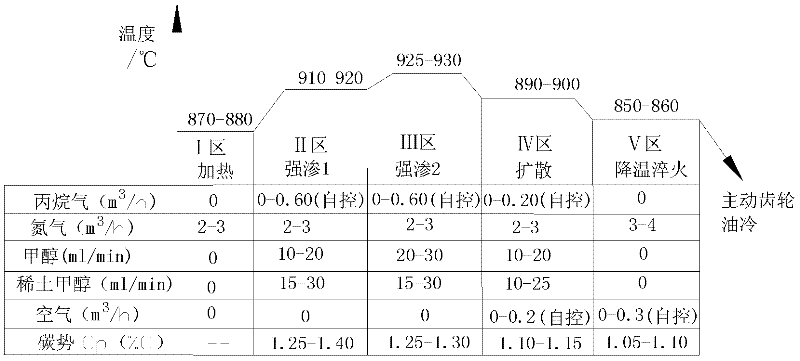

[0015] Specific implementation mode one: combine figure 1 The present embodiment will be described. The steps of this embodiment method are as follows:

[0016] The rare earth carburizing product is CA457 "Jiefang" truck rear axle main and driven spiral bevel gears, both of which are made of 20CrMnTiH steel; the hardenability of the material is J9=36~42HRC.

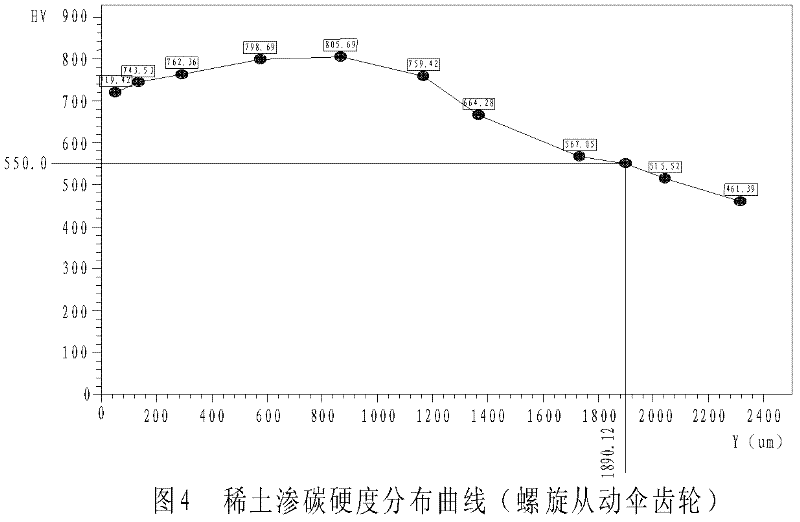

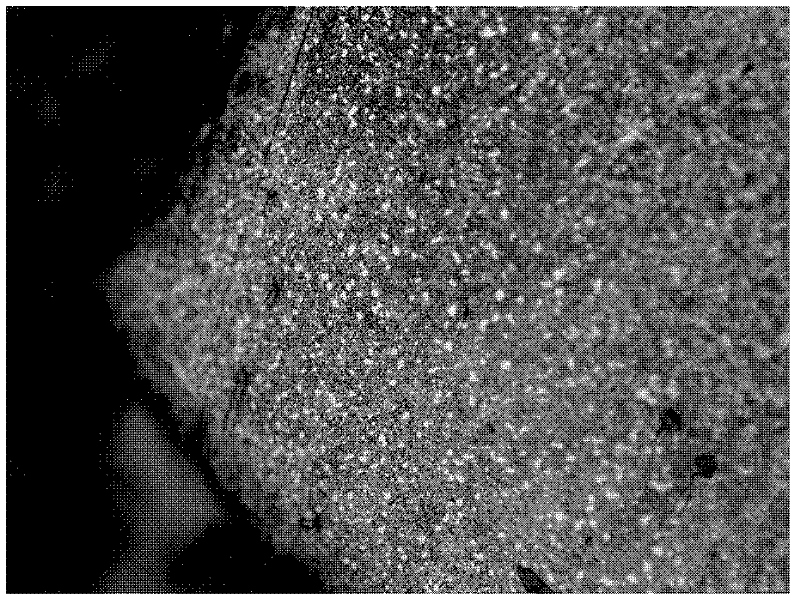

[0017] The effective hardened layer depth requirement of carburizing and quenching for driving and driven spiral bevel gears is 1.70-2.10mm; metallographic structure, carbide grade 1-5, martensite and retained austenite grade 1-5; gear surface and core The hardness requirements are 58~63HRC and 35~40HRC respectively; the depth of non-martensitic layer is ≤20um, and the inspection shall be carried out according to the standard of QC / T262-1999 "Metallographic Inspection of Automobile Carburized Gears".

[0018] Step 1. Put the spiral bevel gear on the washing machine, wash it for 5-6 minutes at the temperature of alkaline...

specific Embodiment approach 2

[0024]Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, pretreatment is carried out under the condition that the temperature of the pretreatment furnace on the double-row rare earth carburizing equipment is 480 ° C, and the pretreatment time is 120 minutes; step two The temperature in the middle heating zone is preheated under the condition of 870°C, and the preheating time is 300 minutes. At this time, 2 cubic meters of nitrogen gas per hour is input into the furnace; The temperature of the zone is 910°C for pre-carburization, and the pre-carburization time is 300 minutes. At this time, the carbon potential Cp is 1.35%C, propane gas is input at 0.5 cubic meters per hour, nitrogen is input at 2 cubic meters per hour, and methanol per hour 20 milliliters per minute, 25 milliliters per minute of rare earth methanol; in step 4, carburizing is carried out at a temperature of 930° C. after pre-carburizing in step 3 and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com