Laminated ceramic capacitor and manufacturing method therefor

一种陶瓷电容器、制造方法的技术,应用在电容器制造、叠层电容器、电容器等方向,能够解决增加工序、瓷坯片受损、制造工序复杂化等问题,达到简化制造工序、防止片材受冲击的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]

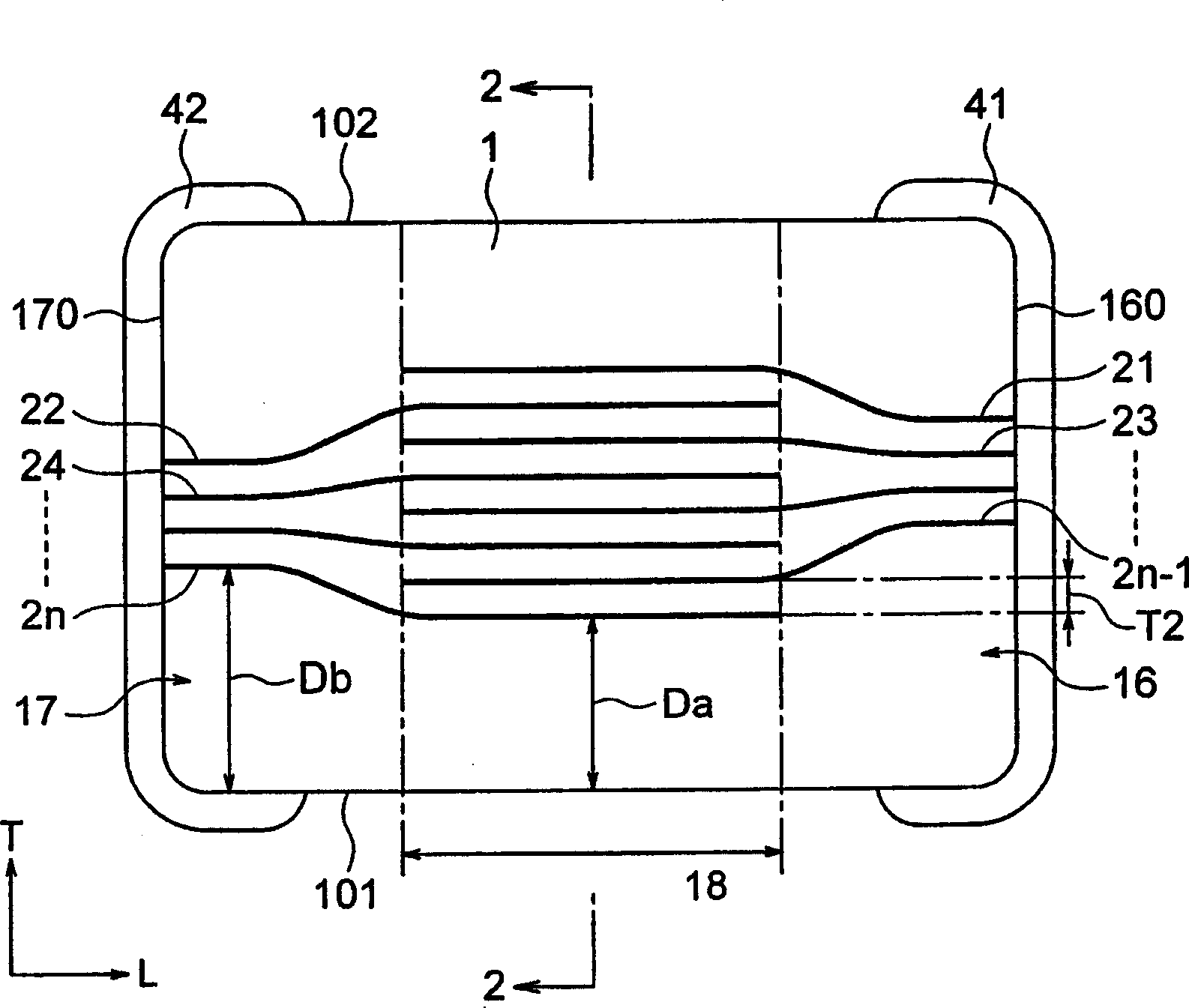

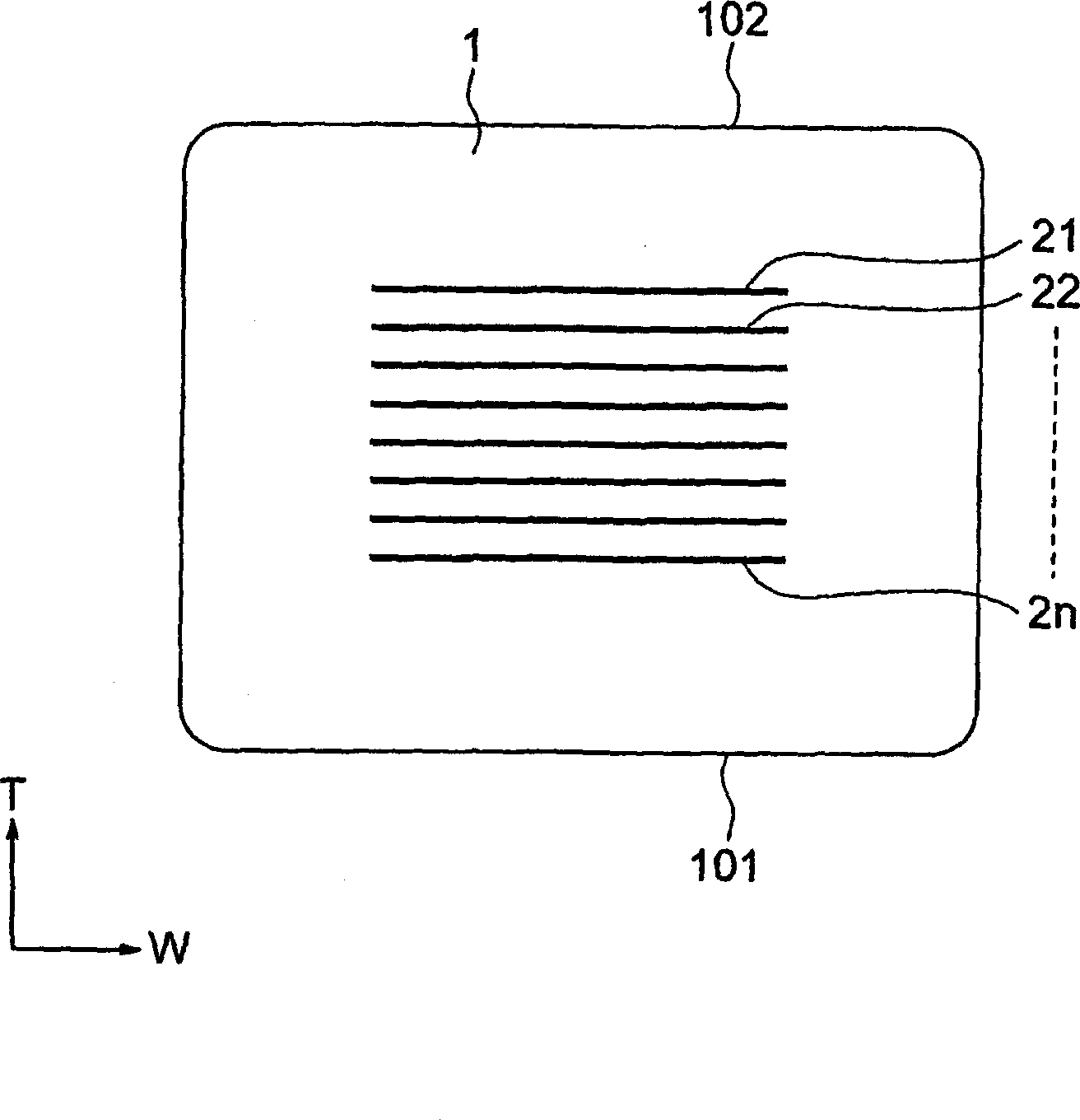

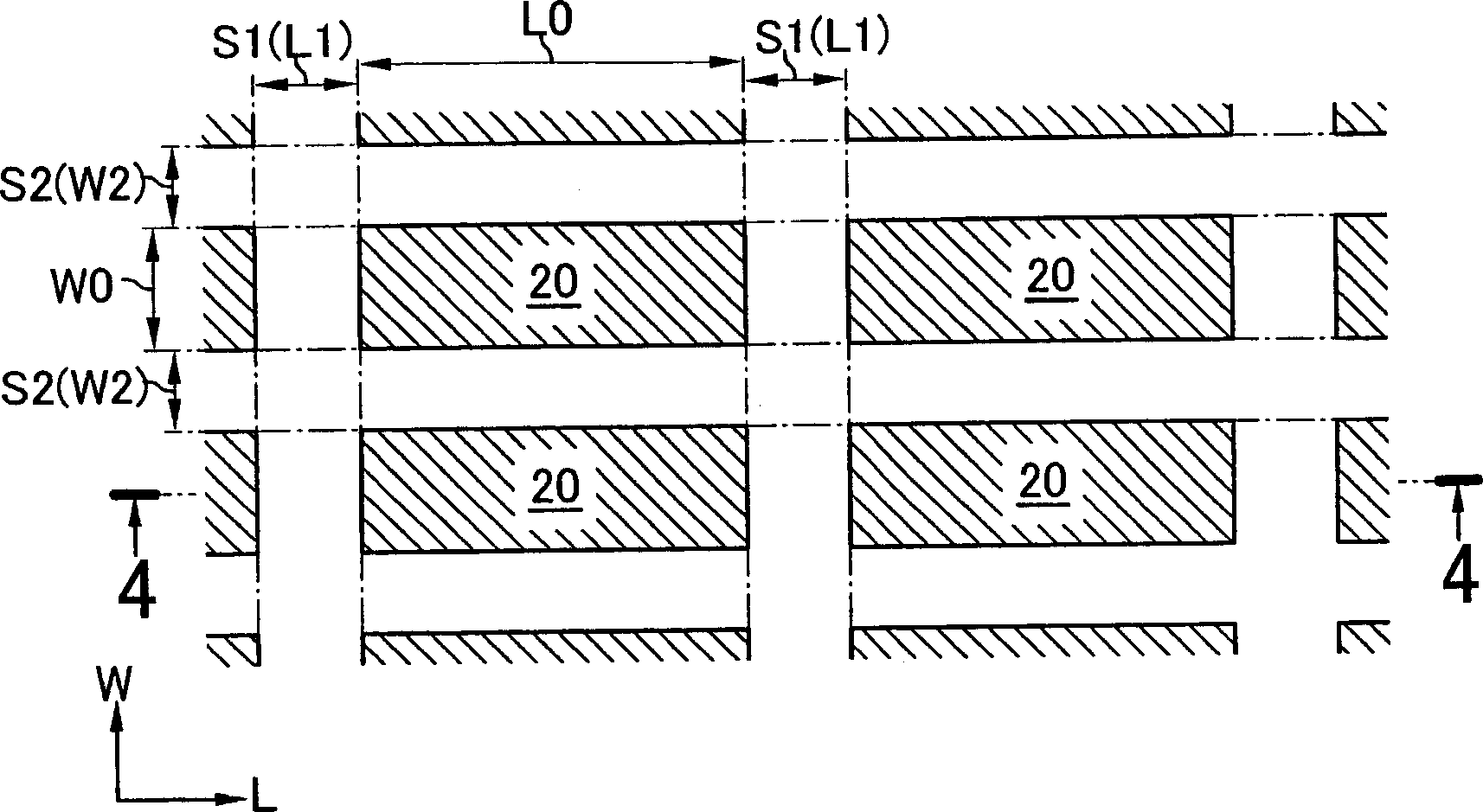

[0032] figure 1 It is a sectional view showing an embodiment of the multilayer ceramic capacitor according to the present invention. figure 2 is along figure 1 A sectional view of the 2-2 line. As shown in the figure, the multilayer ceramic capacitor according to the present invention has a ceramic base 1 and n-layer internal electrodes 21 to 2n.

[0033] The ceramic base 1 is made of, for example, a dielectric material mainly composed of barium titanate. The ceramic base 1 is a shape defined by a length direction L, a width direction W, and a thickness direction T. Specifically, the ceramic base 1 has a substantially rectangular parallelepiped shape having a length direction L, a width direction W, and a thickness direction T. As shown in FIG. Regarding the dimensions of the ceramic base 1, numerical values thereof are exemplified as follows. The length dimension, width dimension and thickness dimension are 3.2mm, 1.6mm and 1.6mm, respectively.

[0034] On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com