Method for automatically compensating numerical control machining size error based on fractional order

A technology of machining dimensions and automatic compensation, applied in the field of error compensation, can solve the problems of large amount of calculation, inability to compensate for dimensional errors, imperfect error compensation technology, etc., to achieve obvious error compensation effect, increase workpiece qualification rate, and reduce dimensional errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

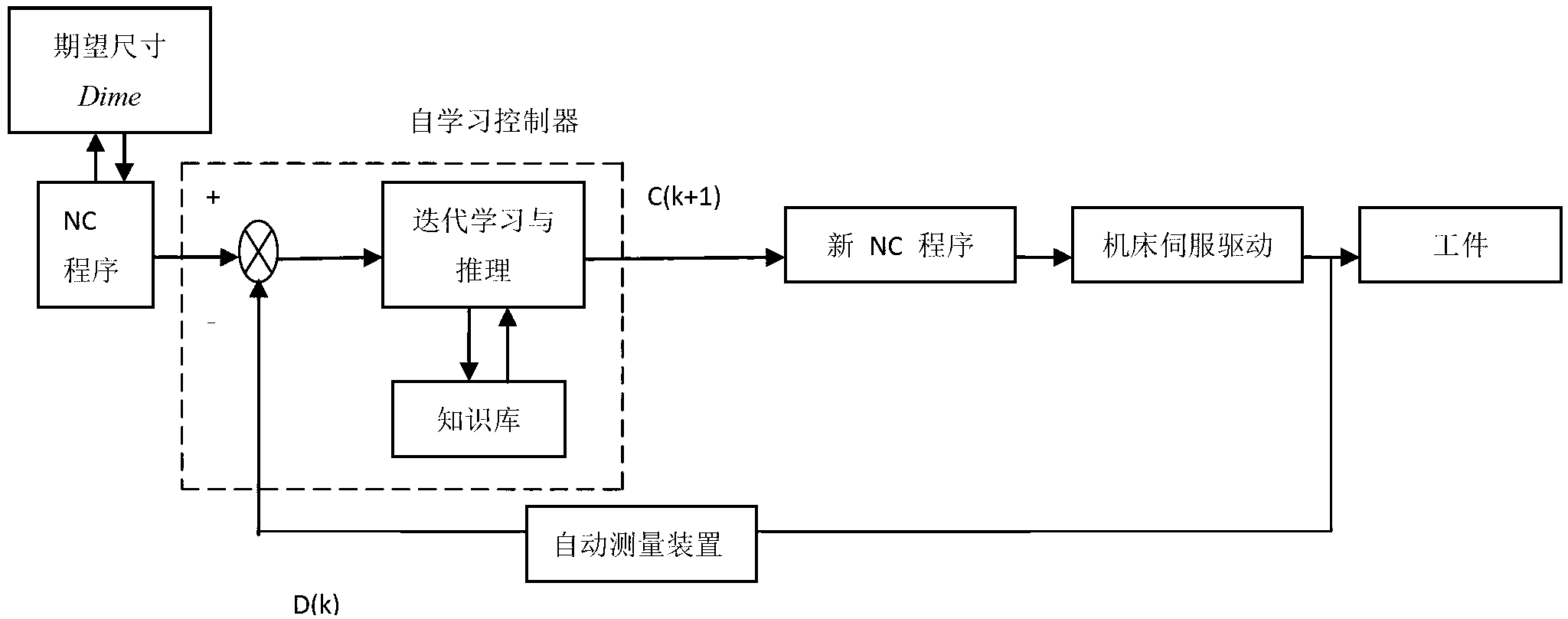

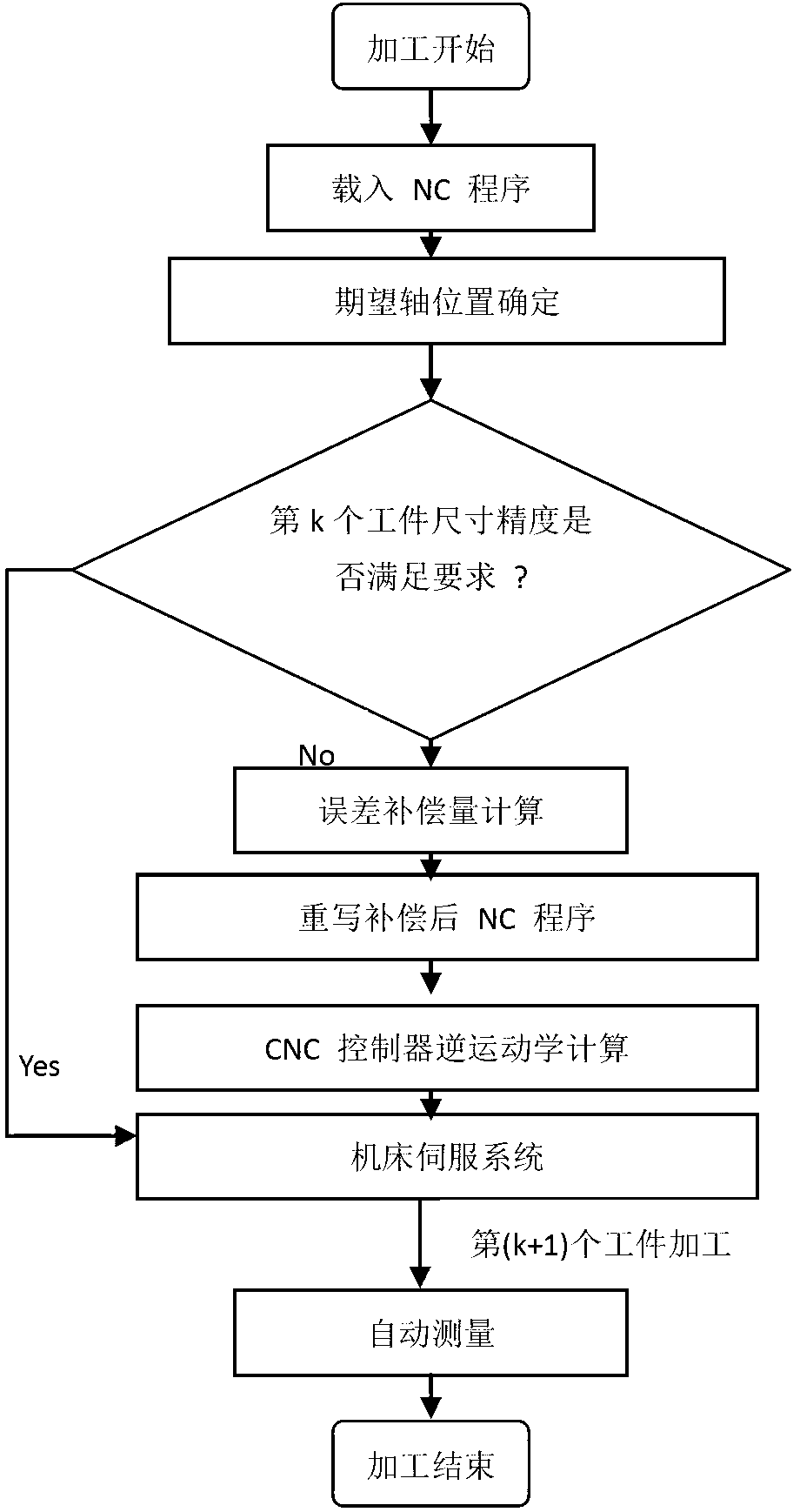

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0045] Step 1 is as follows: measure the size of the opposite side of the workpiece to obtain the measured size data; calculate the size error value of this set of data through the formula (a), and observe the change trend of the size error; the change trend of the size error is nonlinear on the whole Non-monotonic increasing;

[0046] e(k)=Dime-D(k) (a)

[0047] In the formula: e(k)——dimension error of the kth workpiece

[0048] Dime - desired size

[0049] D(k)——measured size of the kth workpiece

[0050] Calculate the arithmetic mean value of a group of workpiece dimensional errors as a parameter for system order identification, as shown in formula (b). Solve the average size error of a group of processed workpieces. This parameter is not only a parameter of system order identification but also an indicator of whether the identification is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com