Efficient roll forming method for large medium-thickness-plate conical cylinder

A forming method and rolling forming technology, applied in the field of steel structure, can solve the problems of non-rolling, low production efficiency, difficult operation, etc., and achieve the effect of small curvature radius and dimensional error, improved production efficiency, and easy alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

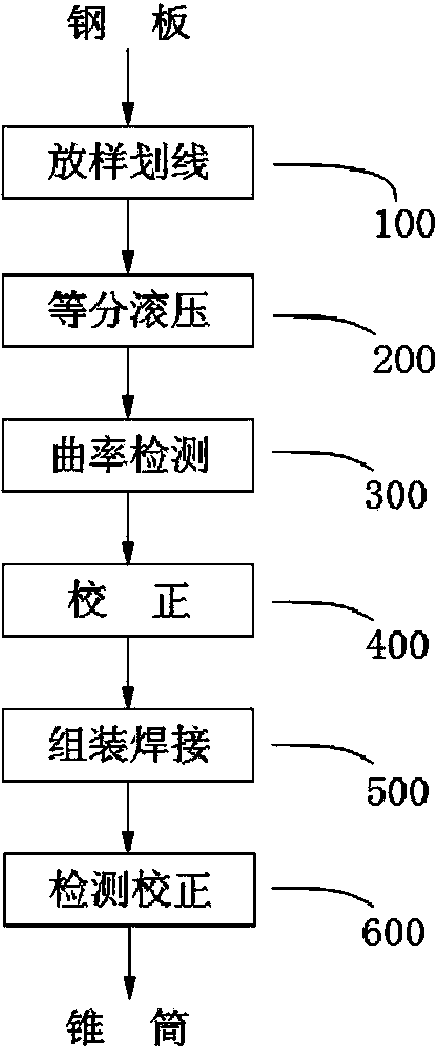

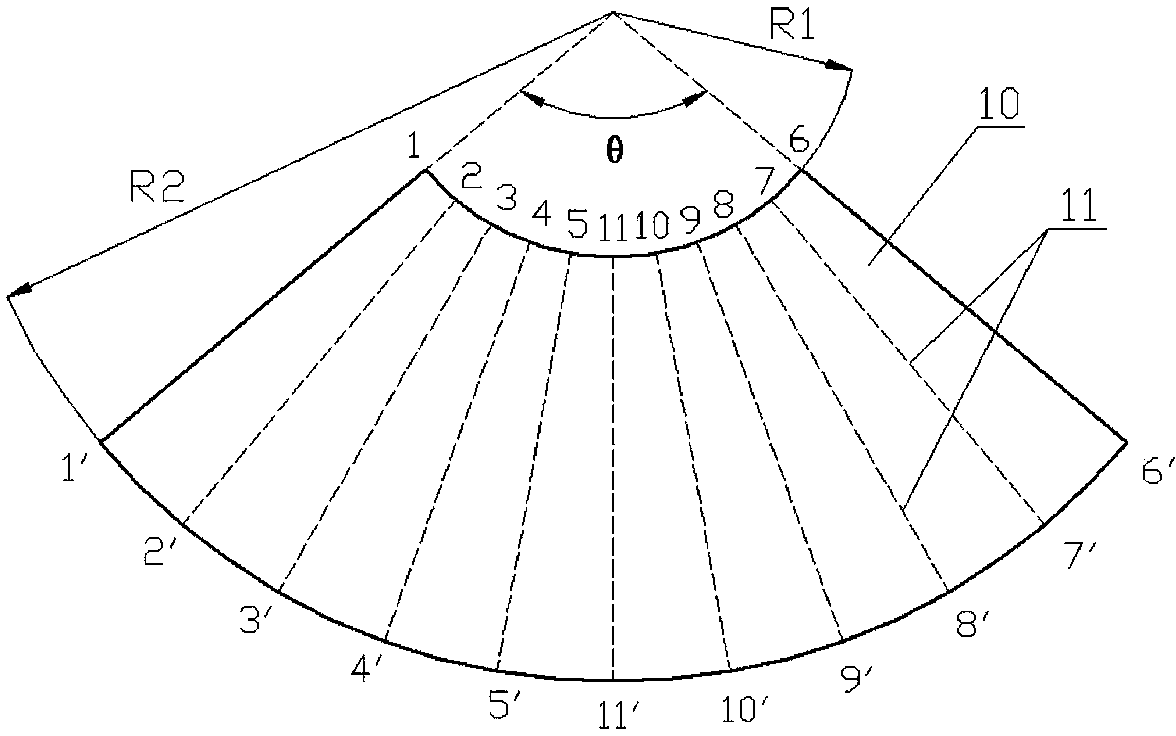

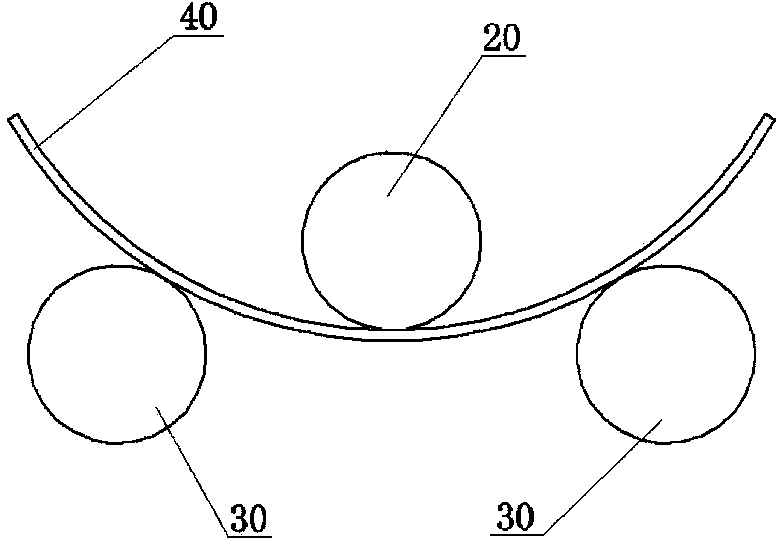

[0042] Such as figure 2As shown, the fan-shaped cone angle θ of the fan-shaped steel plate 10 is calculated according to the neutral plane of the cone product structure diagram, the inner circular arc R1 and the outer circular arc R2 are expanded, and two fan-shaped steel plates 10 are obtained by blanking the steel plate, and the cone cylinder is used for lofting Expand the structural element line to divide the inner arc R1 and the outer arc R2 into 10 equal parts, and then connect the equal element line to the corresponding connecting line (such as 1-1', 2-2'...11-11'), as drawn The line also reflects the actual length of the generatrix expanded by the lofting of the conical cylinder, and the expanded part is the size of the neutral plane of the product. Such as image 3 Shown are the three rollers of the down-pressing type plate rolling machine, the upper middle one is the upper pressing roller 20, the lower left and right sides are two lower rollers 30, and the fan-shape...

Embodiment 2

[0044] According to the calculation of Example 1, the lofting and blanking are used to obtain 4 fan-shaped steel plates 10, and each fan-shaped steel plate 10 is divided into 6 equal divisions (such as 1-1', 2-2' ... 7-7'). Place the sector-shaped steel plate 10 after scribing between the upper pressure roller 20 and the lower roller 30, adjust the angle included between the axis of the upper pressure roller 20 and the axis of the backup roller to be 1.02 times the half cone angle θ / 2 of the cone cylinder, and center the upper The bus bar of the pressure roller 20 and the marking line 11 of the fan-shaped steel plate 10, use the main oil cylinder of the plate rolling machine to press down on the marking line 11 through the upper pressing roller 20, and then use the marking line when the pressure is applied as the center, and the left and right adjacent marking lines as the boundary, Carry out equal pressure rolling on the fan-shaped steel plate 10; repeat the above and below pr...

Embodiment 3

[0046] As in Example 1, the sector-shaped workpiece 40 is molded and welded to form a conical cylinder, and the curvature is further checked by using the inner and outer circular arc templates. If there is an error, it can be corrected twice until it is qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com