Manufacturing method of airplane chemical milling skin three-dimensional chemical milling sample plate

A technology for milling a template and a manufacturing method, which is applied in the directions of aircraft parts, transportation and packaging, etc., can solve the problems of large machining error of three-dimensional milling template, poor scribing accuracy of mold tire and template forming accuracy, manual carving error, etc. Achieve the effect of improving the marking accuracy of the mold tire, improving the forming accuracy of the template, and reducing the size error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

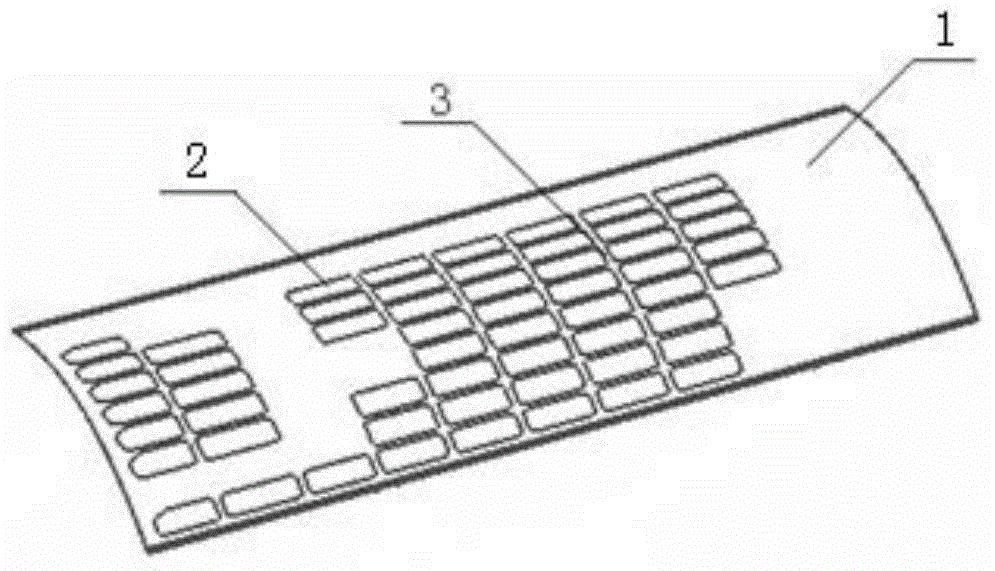

[0032] Such as figure 1 The shown chemical milling skin part has a length of 6065mm and a width of 2306mm, among which there are 57 quadrilateral chemical milling areas, each of which is 46mm long and 28mm wide, and the material thickness of the part is δ=2.5mm.

[0033] Establish a digital-analog data set for a standard model process.

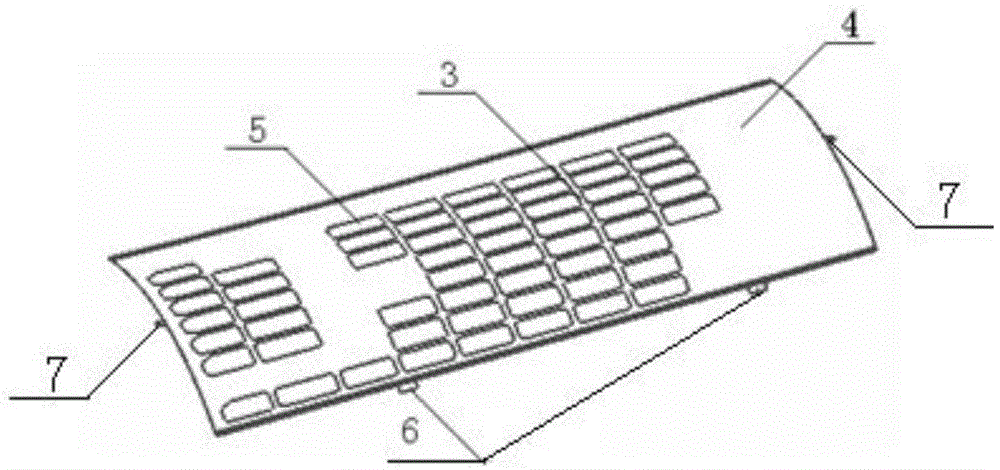

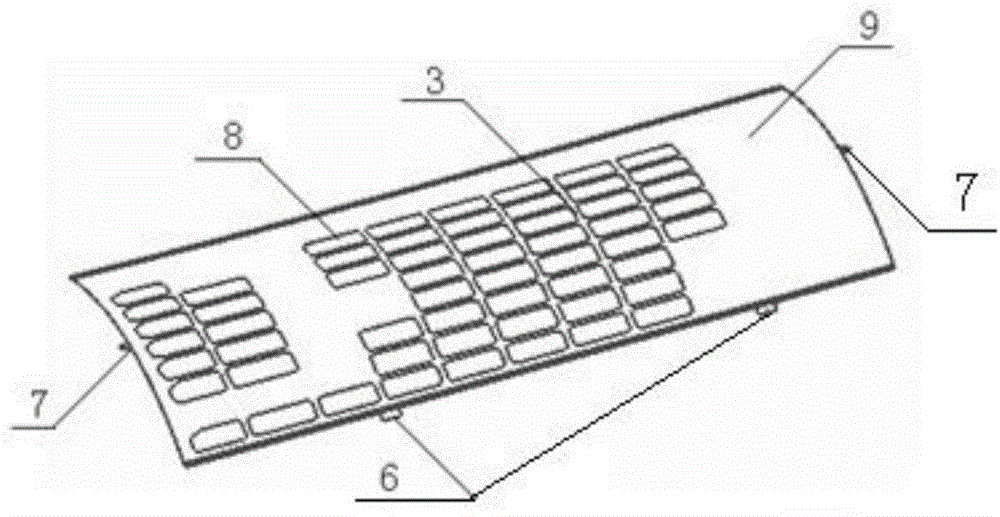

[0034] Firstly, based on the digital model of the aircraft milling skin, use CATIA software to establish a digital model data set of a standard model process, and use the shape of the digital model to offset the material thickness of the aircraft milling skin to δ2.5mm inwards, and establish the digital model data of the standard model process Set, in the digital-analog data set of the standard model process, there are 57 perspective openings in the normal direction of the grooves that need to be milled in the aircraft milling skin, and the size of each perspective opening is 46mm in length and 28mm in width. Set 2 chemical milling positionin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com