Oil well sand washing pump and using method thereof

A technology for sand washing and oil wells, applied in the direction of pumps, jet pumps, earthwork drilling and production, etc., can solve problems such as no jet formation, no filter structure, and pump inoperability, so as to avoid parts falling off, smooth liquid flow, and reduce edge The effect of stroke resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

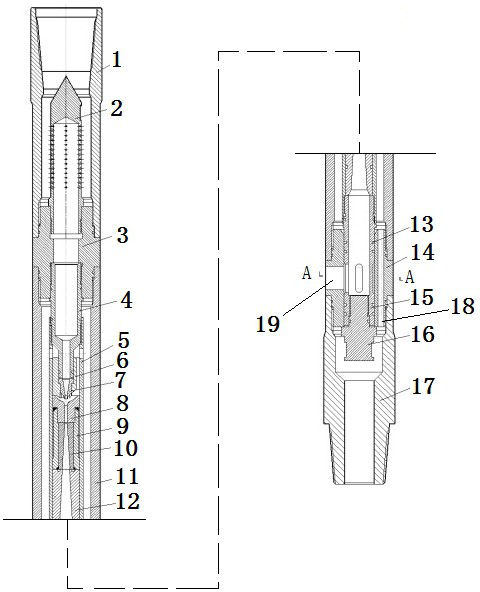

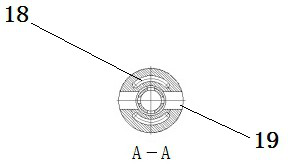

[0029] see figure 1 and figure 2 . An oil well sand flushing pump, comprising an upper joint 1, an upper sealing joint 3, an outer cylinder 11, a lower sealing joint 14, a lower joint 17, a filter cylinder 2, a high-pressure introduction joint 4, an inner sleeve 5, a nozzle 7, a nozzle support 6, Throat pipe 8, transition pipe 10, fixed sleeve 9, diffuser pipe 12, water outlet joint 15 and plug 16. The upper joint 1 is connected with the drill pipe or the oil pipe through the upper box, and the lower box of the upper joint 1 is engaged with the upper pin of the upper sealing joint 3 . The female button at the upper end of the outer cylinder 11 is engaged with the male button at the lower end of the upper sealing joint 3 , and the female button at the lower end of the outer cylinder 11 is engaged with the male button at the upper end of the lower sealing joint 14 . The female buckle at the upper end of the lower joint 17 is engaged with the male buckle at the lower end of t...

Embodiment 2

[0031] see figure 1 and figure 2. An oil well sand flushing pump, comprising an upper joint 1, an upper sealing joint 3, an outer cylinder 11, a lower sealing joint 14, a lower joint 17, a filter cylinder 2, a high-pressure introduction joint 4, an inner sleeve 5, a nozzle 7, a nozzle support 6, Throat pipe 8, transition pipe 10, fixed sleeve 9, diffuser pipe 12, water outlet joint 15 and plug 16. The upper joint 1 is connected with the drill pipe or the oil pipe through the upper box, and the lower box of the upper joint 1 is engaged with the upper pin of the upper sealing joint 3 . The female button at the upper end of the outer cylinder 11 is engaged with the male button at the lower end of the upper sealing joint 3 , and the female button at the lower end of the outer cylinder 11 is engaged with the male button at the upper end of the lower sealing joint 14 . The female buckle at the upper end of the lower joint 17 is engaged with the male buckle at the lower end of th...

Embodiment 3

[0034] see figure 1 and figure 2 . An oil well sand flushing pump, comprising an upper joint 1, an upper sealing joint 3, an outer cylinder 11, a lower sealing joint 14, a lower joint 17, a filter cylinder 2, a high-pressure introduction joint 4, an inner sleeve 5, a nozzle 7, a nozzle support 6, Throat pipe 8, transition pipe 10, fixed sleeve 9, diffuser pipe 12, water outlet joint 15 and plug 16. The upper joint 1 is connected with the drill pipe or the oil pipe through the upper box, and the lower box of the upper joint 1 is engaged with the upper pin of the upper sealing joint 3 . The female button at the upper end of the outer cylinder 11 is engaged with the male button at the lower end of the upper sealing joint 3 , and the female button at the lower end of the outer cylinder 11 is engaged with the male button at the upper end of the lower sealing joint 14 . The female buckle at the upper end of the lower joint 17 is engaged with the male buckle at the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com