Air outlet pipe assembly, machining method thereof, liquid storage device and machining method of liquid storage device

A processing method and a technology for an outlet pipe, which are applied in the field of fluid machinery, can solve the problems of deterioration of the resistance loss along the path of the refrigerant, the reduction of the volumetric efficiency of the compressor, and the poor welding quality of the outlet pipe, and achieve good operability and accessibility. , The effect of reducing processing cost and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

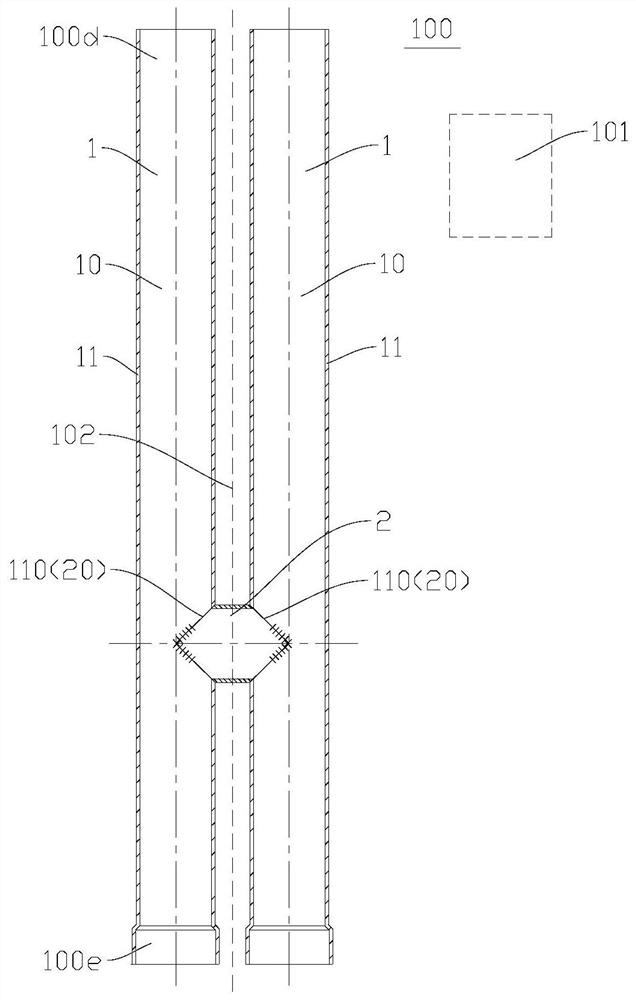

[0075]In this embodiment, iffigure 1 withfigure 2 As shown, the material of the air pipe assembly 100 is steel. The air tube assembly 100 includes an air tube 1 and a connecting tube 2, and the air tube 1 is two, and the two air pipes are spaced apart, each of which is formed as a circular tube, and the central axis of each of the ventilation tube 1. The linear extension, the two ventilation 1 parallel, that is, the central axis of the two air tubes 1 is arranged in parallel, that is, the central axis of the two air pipes 1 can define the first preset plane 101 (eg,,figure 1 The paper surface in which the structure is located); the connecting pipe 2 is a circular tube, and the connecting tube 2 is connected between the two air pipes 1, and the central axis of the connecting pipe 2 extends in line, connecting tube 2 The central axis of the center axis is perpendicular to the central axis of the vent, and the central axis of the connecting pipe 2 is also within the first preset plane ...

Embodiment 2

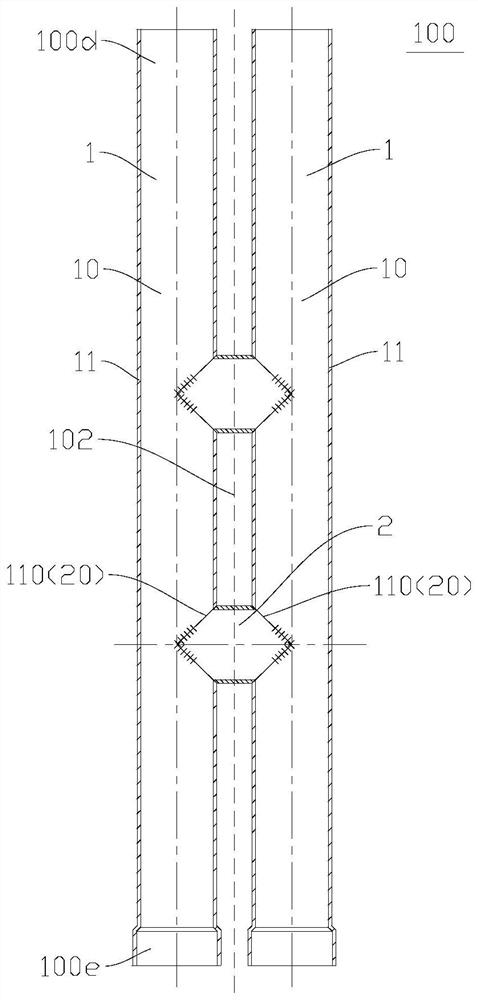

[0080]Such asimage 3 As shown, the present embodiment is substantially the same as that of the embodiment, wherein the same components are identical to the same reference numerals, the connection tube 2 is two, and the two connecting pipes 2 along the axial direction of the air tube 1. The intervals are arranged, each connecting tube 2 is coupled between the two extravasants 1, so that the two vent tubes 1 communicate through two connecting tubes 2. Among them, the two connecting pipes 2 extend along linear, the central axis of the two connecting tubes 2 is parallel, and the central axis of the two connecting tubes 2 is coplanar with the central axis of the two air pipes 1. The air pipe assembly 100 has eight solder joint sections 100a, and the air tube assembly 100 has sixteen continuous weld 100f.

Embodiment 3

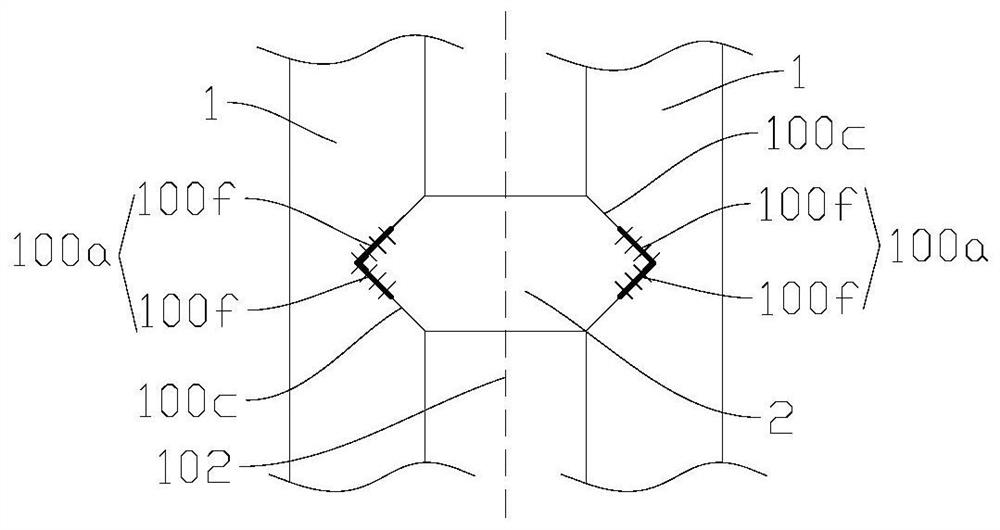

[0082]Such asFigure 4 withFigure 5 As shown, the present embodiment is substantially the same as that of the embodiment, wherein the same components are identical to the same reference numerals, and the disc 2 is: the pipe diameter of the connecting tube 2 is less than the pipe diameter of the ventilator 1, then in the first pre- On the plane 101, the positive projection of the end nozzle 20 is substantially formed as an arc stage such as an arc segment, and in the first preset plane 101, the positive projection of the connection opening 110 is also generally formed as an arc segment.

[0083]The air pipe assembly 100 has four weld joint sections 100a, each of which includes a continuous weld 100f, i.e., the air tube assembly 100 has four consecutive welds 100F, four continuous weld 100F respect to the first pre- The plane 101 and the second preset plane 102 are arranged symmetrically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com