Demister for desulfurization tower

A technology of demister and desulfurization tower, which is applied in the field of environmental protection and desulfurization, can solve the problems of increasing tower body height and manufacturing cost, multi-level installation space of multi-stage demister, increasing investment cost, etc., so as to increase demisting effect and reduce The effect of reducing investment cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

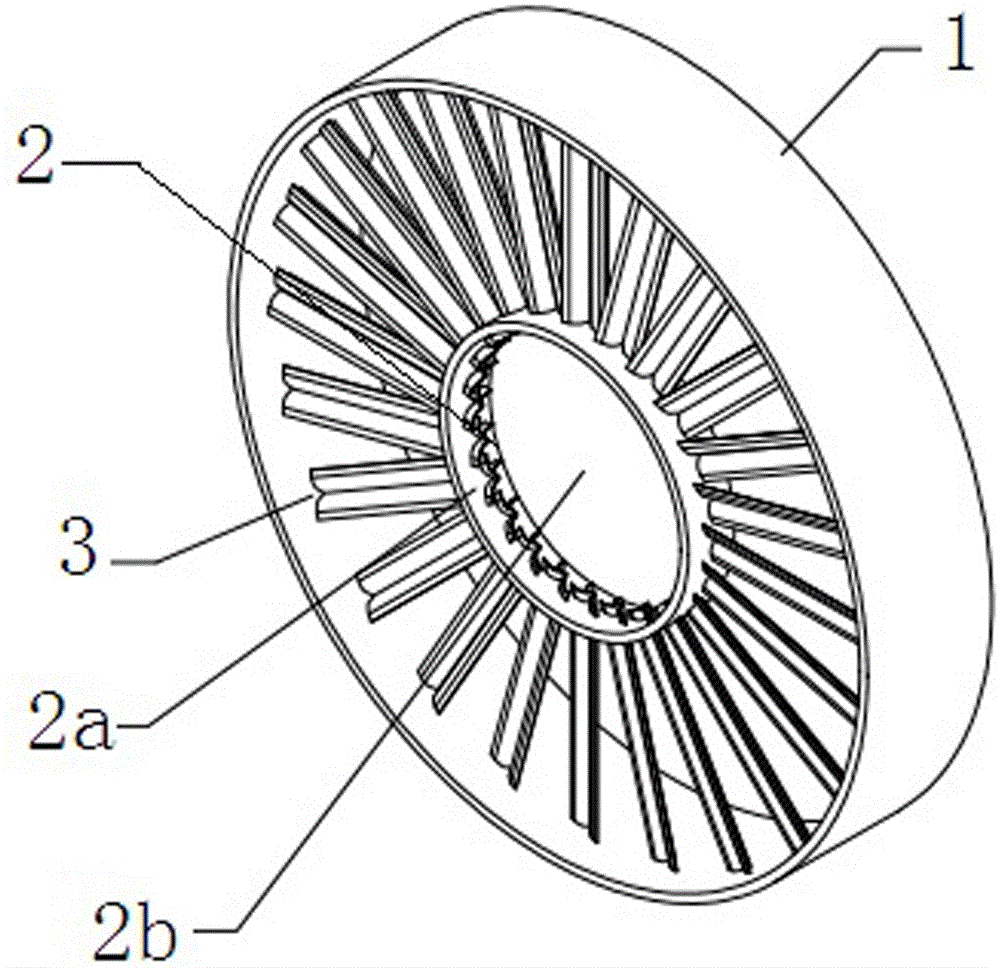

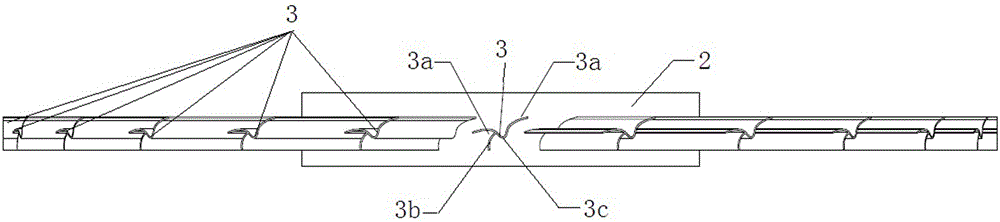

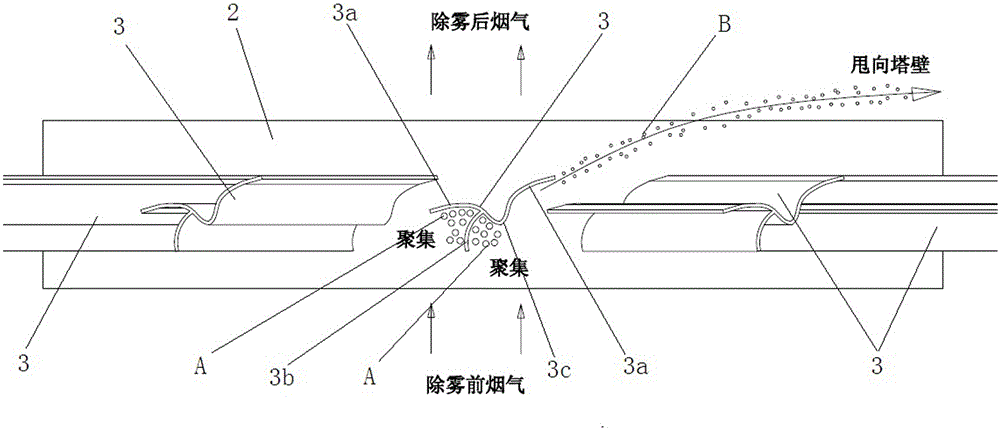

[0017] As shown in the figure, the present invention includes a support ring 1, a support shaft 2 located in the middle of the support ring 1, and several blades 3 distributed around the support shaft 2 and welded and fixed between the support ring 1 and the support shaft 2. The blades 3 include The two connected blade units 3a with an upwardly convex arc shape and the hook blade 3b bent outwards and downwards under one of the blade units 3a are welded and fixedly connected, and the blade 3 is along one of the blade units connected with the hook blade 3b 3a to the direction of the other vane unit 3a is inclined upwards.

[0018] The support shaft 2 includes a cylinder 2a and a blind plate 2b that closes the through hole in the middle of the cylinder 2a.

[0019] The connecting part of the two blade units 3a is a bending portion 3c, and the two blade units...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com