Coal mine underground self-suction abrasive jet flow drill bit and drilling method

An abrasive jet and self-priming technology, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of drill bit wear and low drilling efficiency, and achieve the effects of small resistance loss, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

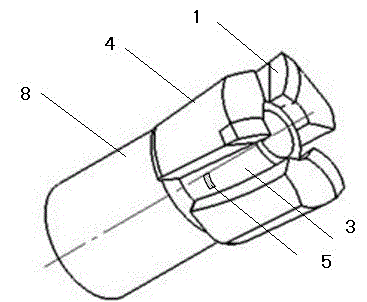

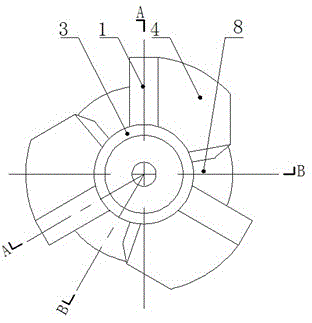

[0025] The following combination Figure 1 to Figure 5 Embodiments of the present invention are described:

[0026] combine figure 1 It can be seen that the front end of the drill bit body 8 of the drill bit is the main crushing structure, which is composed of three cutting blades 1 and three-lobe crushing teeth 4, the three-lobe crushing teeth 4 are arranged around the central cavity 3, and the three cutting blades 1 are fixed by brazing At the front end of the three-lobe broken tooth 4.

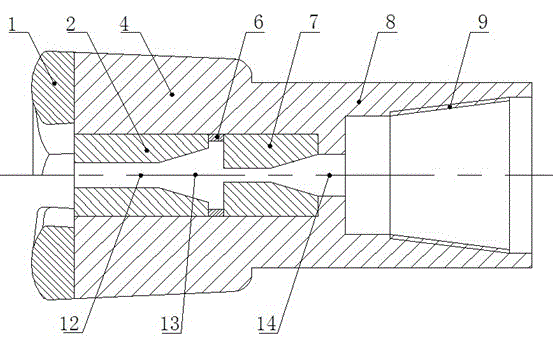

[0027] combine figure 2 It can be seen that the drill body 8 of the self-priming abrasive jet drill bit is a front-to-rear through structure with a central cavity 3, and the rear end of the drill body 8 is a drill pipe connection end 9 with an interface with an internal thread.

[0028] The abrasive jet nozzle 2 is installed in the front part of the central cavity 3, the front end pipe diameter is small, which is the acceleration chamber 12, and the rear end pipe diameter is trumpet-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com