Full-automatic ion exchange resin pretreatment device for laboratory

A technology of ion exchange resin and pretreatment device, which is applied in the direction of ion exchange column/bed method, ion exchange mediation/control, etc. It can solve the problems of liquid bias flow, resin cannot contact regeneration liquid, affect pretreatment effect, etc., and achieve optimal experiment The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

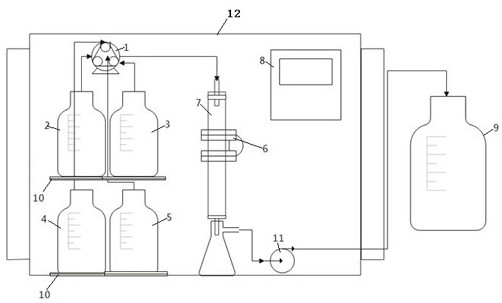

[0025] see figure 1 .

[0026] This embodiment discloses a fully automatic ion exchange resin pretreatment device for laboratory use, which includes a liquid bottle, a peristaltic pump 1, an exchange column 7, a control system 8, a waste liquid bottle 9, a waste liquid pump 11 and a test bench 12 The peristaltic pump 1, the exchange column 7, the control system 8 and the waste liquid pump 11 are all installed on the test bench 12, and the exchange column 7 is installed on the test bench 12 through the fixing buckle 6. A placement platform 10 for placing liquid bottles is also installed on the test bench 12, and the placement platform 10 has a groove. The exchange column 7 adopts an organic glass exchange column or a glass exchange column.

[0027] In this embodiment, the peristaltic pump 1 is a multi-channel peristaltic metering pump, for example, a three-, four-, or six-channel peristaltic metering pump, depending on the experimental conditions. There are multiple liquid b...

experiment example 1

[0031] 1. Adopt the above-mentioned fully automatic ion exchange resin pretreatment device for the laboratory as the experimental equipment;

[0032] 2. Use the standard "Cation Exchange Resin Exchange Capacity Determination Method" DL / T 519-2014 to detect 001×7 cation resin (required to be converted to hydrogen form);

[0033] 3. The exchange column uses a glass exchange column. Take 25ml of the resin sample after removing the external water, add tap water, use glass rods to stir the bubbles in the resin, and fix the glass exchange column on the test bench;

[0034] 4. Add 500ml of hydrochloric acid solution with a concentration of 1mol / L to the first polytetrafluoroethylene bottle, add desalted water to the second polytetrafluoroethylene bottle, and set the program to control the first channel of the peristaltic pump to 1mol / L The flow rate of hydrochloric acid solution is 6mL / min, the liquid volume is 375ml, the flow rate of the second channel is desalted water is 6mL / min, ...

experiment example 2

[0038] 1. Adopt the above-mentioned fully automatic ion exchange resin pretreatment device for the laboratory as the experimental equipment;

[0039] 2. Use the standard "Cation Exchange Resin Exchange Capacity Determination Method" DL / T 519-2014 to detect the 201×7 anion resin (required to be converted to hydrogen-oxygen type);

[0040] 3. The exchange column uses a plexiglass exchange column. Take 25ml of the resin sample after removing the external water, add tap water, use glass rods to stir the bubbles in the resin, and fix the glass exchange column on the test bench;

[0041] 4. Add 500ml of sulfuric acid solution with a concentration of 0.5 mol / L to the first PTFE bottle, add demineralized water to the second PTFE bottle, and add 700ml, Sodium hydroxide solution with a concentration of 1 mol / L, add 700ml of sodium hydroxide solution with a concentration of 2 mol / L to the fourth polytetrafluoroethylene bottle, set the program to control the first channel of the peristalt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com