Multi-filter cylinder automatic backwashing filter apparatus

A backwash filtration and automatic technology, which is applied in the direction of fixed filter elements, filtration separation, chemical instruments and methods, etc., can solve the problems of unavoidable contamination of dirt, bacteria, shortened filter life, small effective filtration area, etc., to achieve Perfect function, avoid relative friction, clean and thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

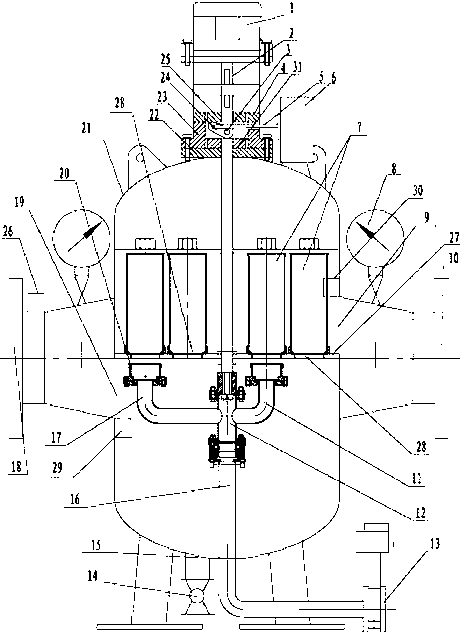

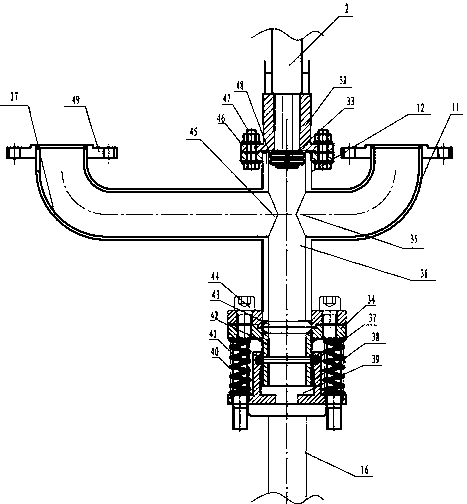

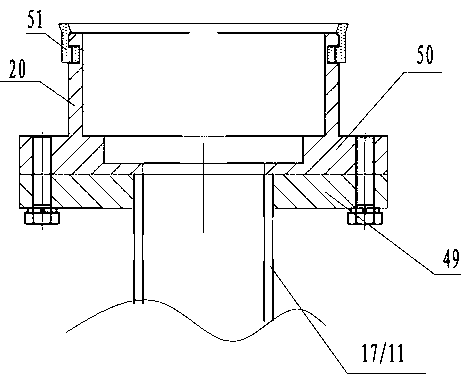

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, this embodiment includes a closed housing 21, a filter mechanism, a backwash mechanism, a high frequency oscillator 26 and a control system.

[0024] The filter mechanism includes partitions and 24 filter cartridges. The inside of the housing 21 is divided into upper and lower chambers by the partition 27. The partition 27 has water inlets 28 distributed in the manner of two concentric circles, 16 water inlets 28 are distributed on the outer concentric circle, and 8 water inlets 28 are distributed on the inner concentric circle. A filter cartridge 7 is installed on each water inlet 28 at the upper end of the partition 27. A sewage inlet 19 is opened on the side wall of the housing at the lower end of the partition 27, and a clean water outlet 9 is opened on the housing side wall at the upper end of the partition 27. The sewage inlet 19 and the clean water outlet 9 are respectively in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com