Plenum chamber capable of achieving balanced ventilation

A static pressure box and uniform technology, applied in the direction of pipeline arrangement, can solve the problems of uneven airflow, disordered airflow organization, low air uniformity, etc., and achieve the effect of improving the air supply jet distance, weakening the mixing ability, and improving the uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

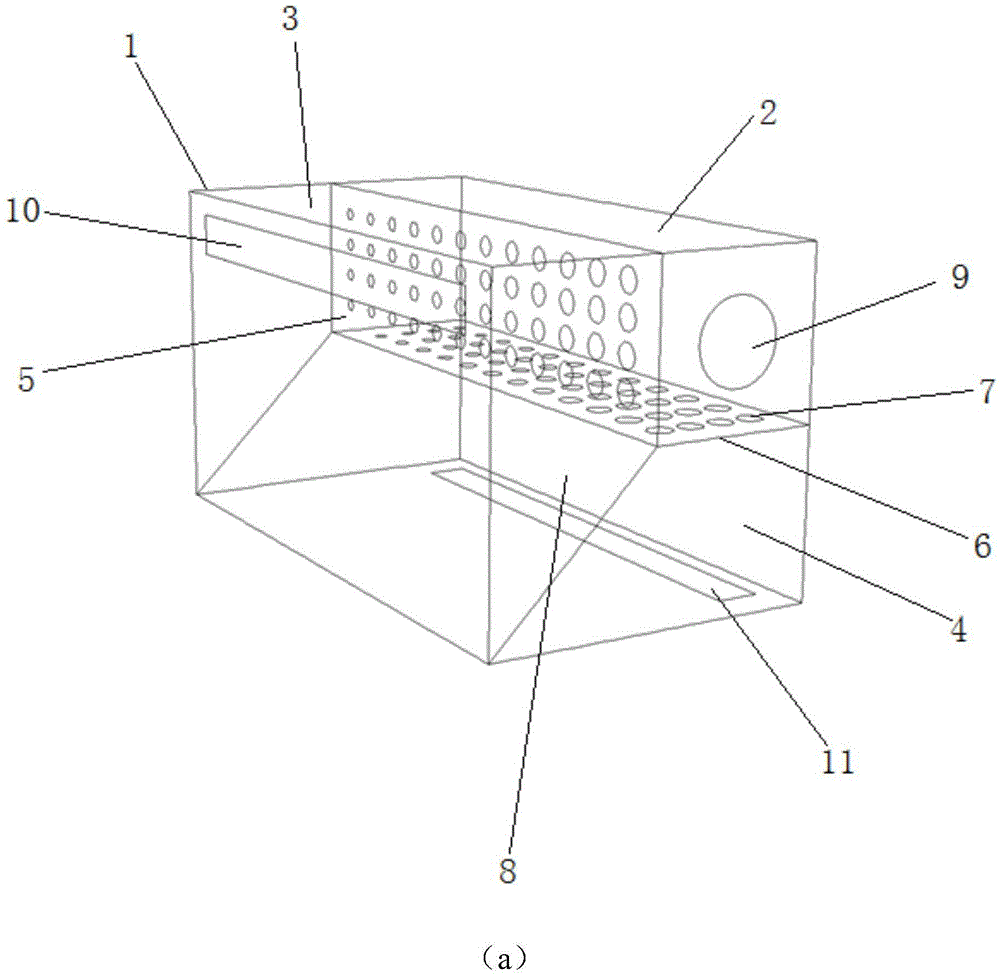

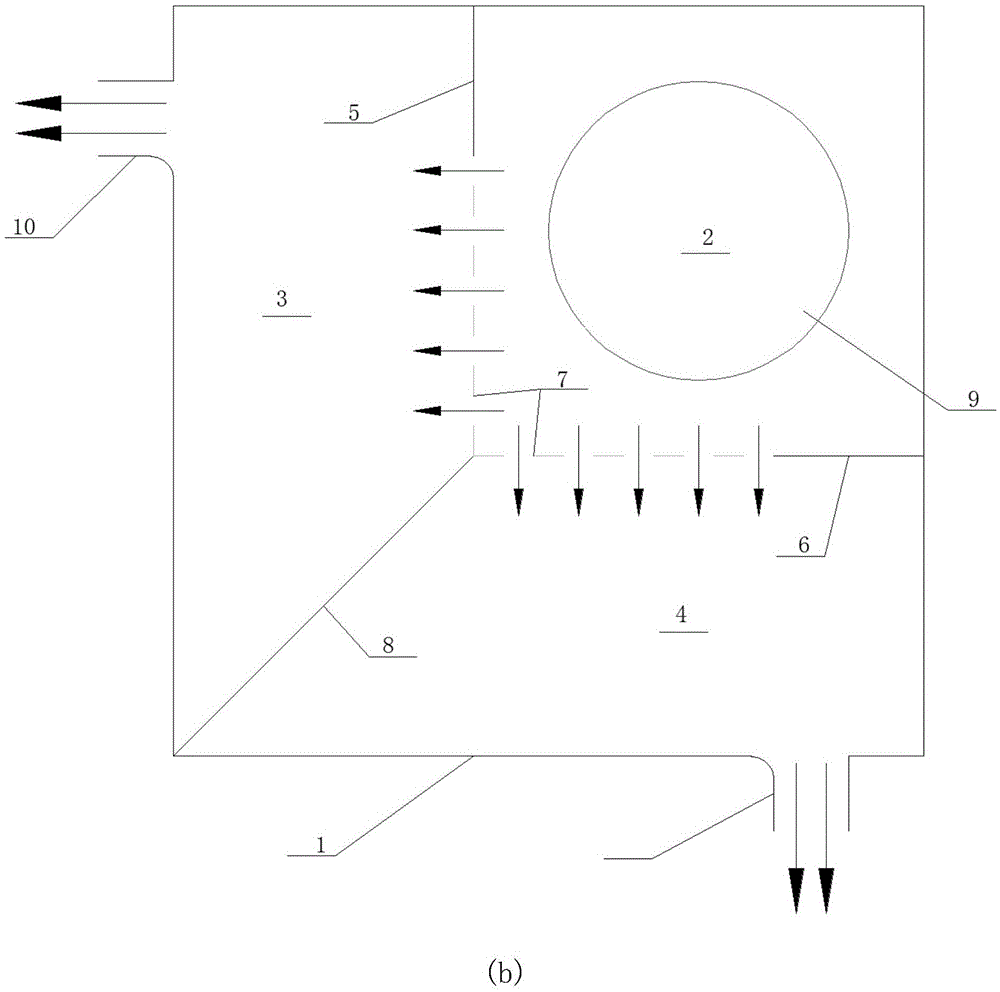

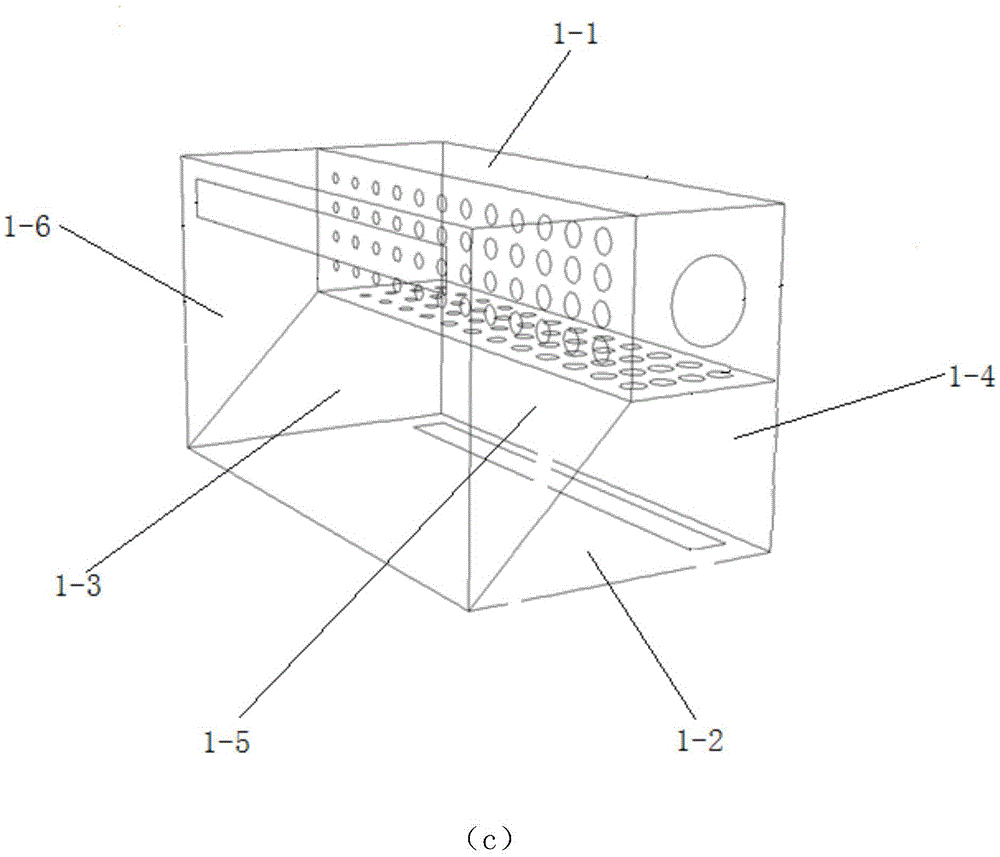

[0074] The numerical calculation model of the plenum box is established according to the actual use conditions. The size of the plenum box shell is 1500×800×800mm in length×width×height; The porosity is 14.95%, such as figure 1 Shown; partition length × height is The upper edge coincides with the two orifice plate edges, and the lower edge coincides with the lower left corner of the static pressure box; the length of the vertical air outlet 11 and the horizontal air outlet 10 are both 1300 mm, and the width is 100 mm; the air inlet 9 is a round hole with a diameter of 200 mm. The wind speed at tuyere 9 is 4m / s, that is, the air intake is 450m 3 / h. It can be calculated from the above steps that the size of the orifice 7 decreases sequentially from the end of the air inlet 9, respectively 28.0mm, 28.0mm, 27.1mm, 26.2mm, 25.4mm, 24.6mm, 23.8mm, 23.0mm, 22.3mm mm, 21.6mm, 20.9mm, 20.0mm, the quantity distribution is as follows Figure 4 shown.

[0075] The box body 1, the h...

Embodiment 2

[0081] Others are identical with embodiment 1, and air inlet 9 wind speeds are 6m / s, and promptly air intake is 680m 3 / h. Figure 8 , 9 respectively represent the central axis velocity distribution of the plenum of the present invention and the horizontal air outlet 10 and the vertical air outlet 11 of the traditional plenum.

[0082] When the plenum box of the present invention is adopted, the maximum speed difference of the central axis of the horizontal air outlet 10 and the vertical air outlet 11 is 41.54% and 36.89% respectively; The maximum velocity differences of the central axis of the straight air outlet 11 are 97.81% and 68.74% respectively. Compared with the latter, the wind volatility of the former is respectively reduced by 135.48% and 86.35%.

[0083] In terms of the uniformity of air outlets from the horizontal air outlet 10 and the vertical air outlet 11, the unevenness of the horizontal air outlet 10 and the vertical air outlet 11 is respectively 9.20% and ...

Embodiment 3

[0085] Others are identical with embodiment 1, and air inlet 9 wind speeds are 8m / s, and promptly air intake is 900m 3 / h. Figure 10 , 11 respectively represent the central axis velocity distribution of the plenum of the present invention and the horizontal air outlet 10 and the vertical air outlet 11 of the traditional plenum.

[0086] When using the plenum box of the present invention, the maximum speed difference of the central axis of the horizontal air outlet 10 and the vertical air outlet 11 is 32.62% and 33.96% respectively; The maximum speed difference of the central axis of the vertical air outlet 11 is 82.96% and 95.93% respectively. Compared with the latter, the wind volatility of the former is respectively reduced by 154.36% and 182.48%.

[0087] In terms of the uniformity of air outlets from the horizontal air outlet 10 and the vertical air outlet 11, the unevenness of the horizontal air outlet 10 and the vertical air outlet 11 is 7.90% and 8.36% respectively w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com