Extrusion pressing puffing apparatus capable of removing fibre in materials

A technology of extruding puffing and fiber, which is applied in the field of mechanical devices, can solve the problems of increasing the wear of blades and templates, greatly affecting the smooth surface of puffed particles, and scratching the surface of puffed particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

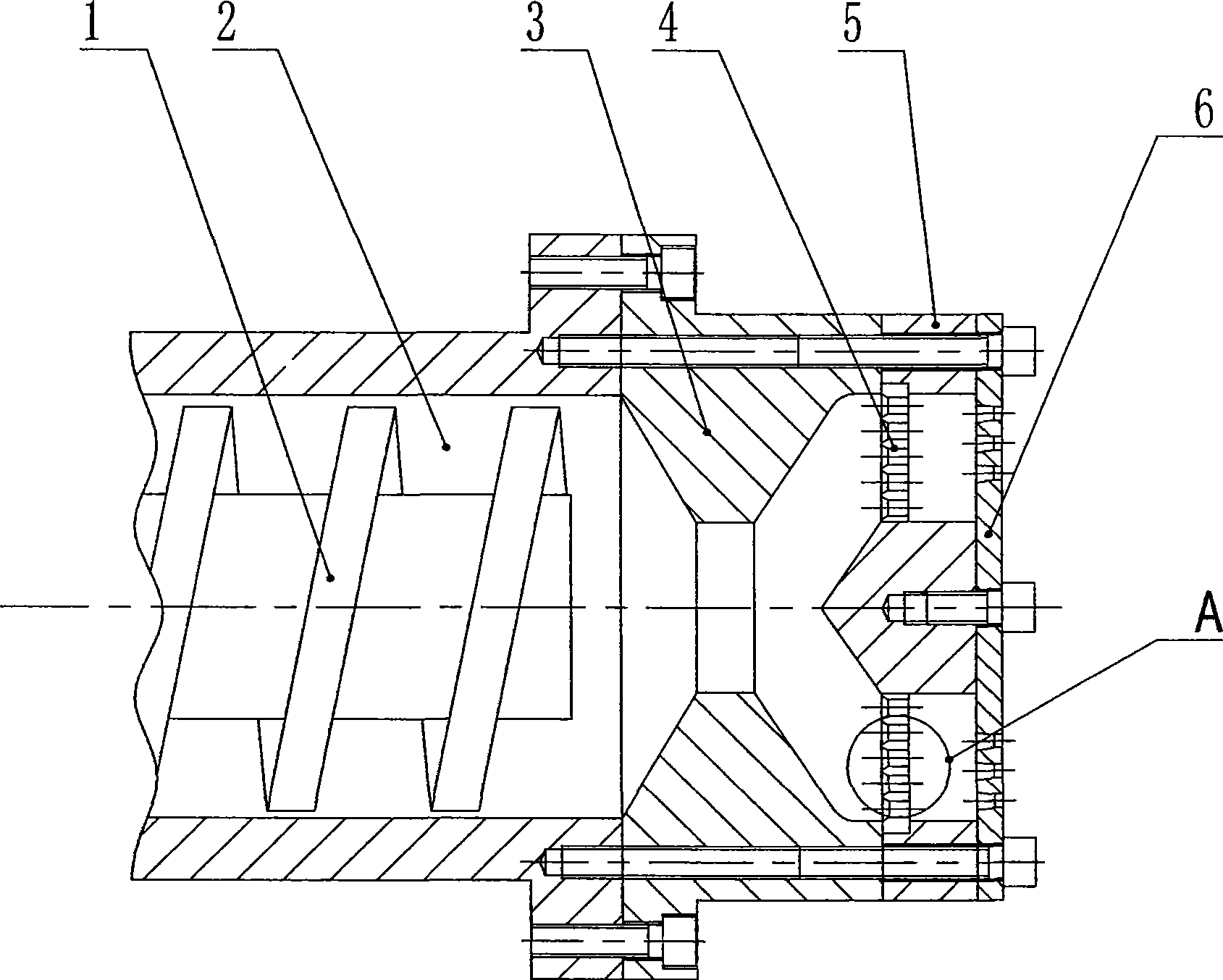

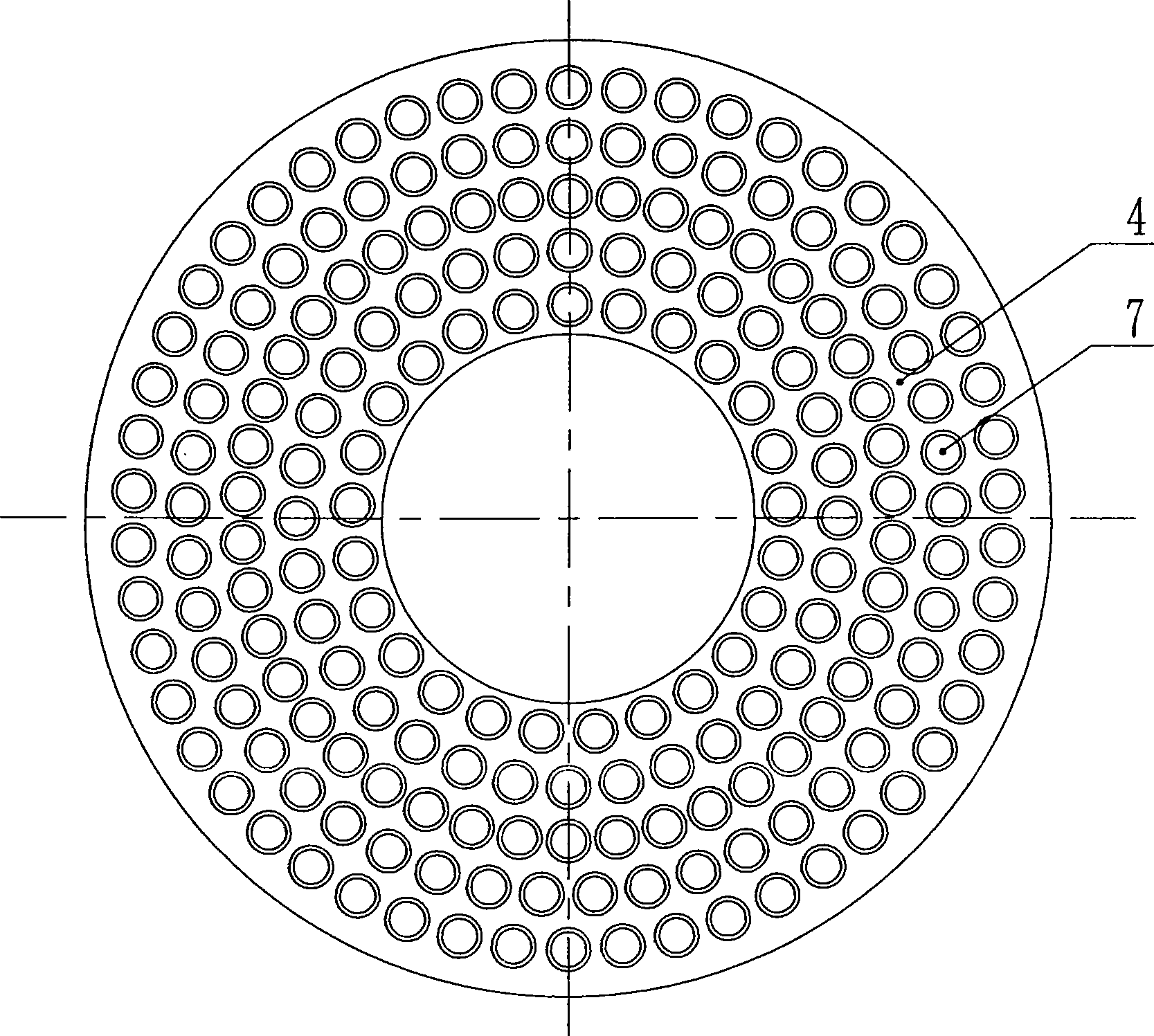

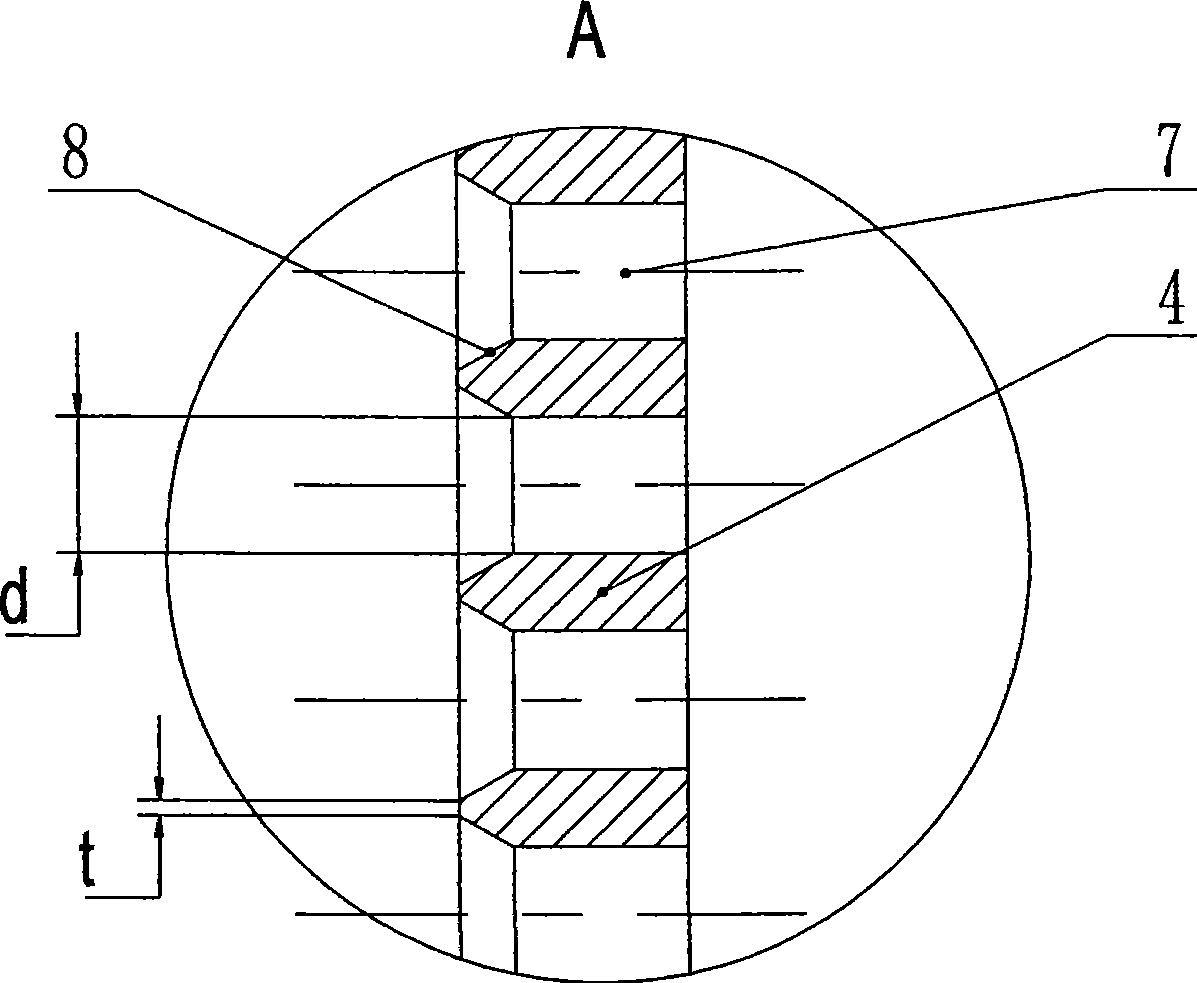

[0014] Such as figure 1 -3, is an extrusion puffing device that can remove fibers in the material, including an extrusion chamber 2, and a screw 1 is arranged in the extrusion chamber 2, and the screw 1 can be provided with one, two or three screws, correspondingly forming a single-screw extruder For presses, twin-screw extruders and three-screw extruders, a template frame 5 is provided at the outlet end of the extrusion chamber 2, and a discharge template 6 is installed on the template frame 5, and a number of through discharge templates are arranged on the discharge template 6. 6 die holes, the die holes communicate with the extrusion cavity 2, and a blade is provided on the outside of the discharge template 6; a hanging fiber template 4 is provided in the passage between the discharge template 6 and the extrusion cavity 2, and a There are several fiber-hanging holes 7, and the side of the fiber-hanging holes 7 facing the extrusion cavity 2 is provided with an inner chamfer ...

Embodiment 2

[0016] Such as Figure 4 , is another kind of extruding puffing device that can remove the fiber in the material, including extrusion chamber 2, screw rod 1 is arranged in extrusion chamber 2, the outlet end of extrusion chamber 2 is directly connected with a template frame 5, and the template frame 5 is installed There is a discharge template 6, and the discharge template 6 is provided with a plurality of die holes that run through the discharge template 6, and the die holes communicate with the extrusion chamber 2, and a blade is provided on the outside of the discharge template 6; the discharge template 6 and The channel between the extrusion chambers 2 is provided with a fiber-hanging formwork 4, the fiber-hanging formwork 4 is provided with a number of fiber-hanging holes 7, and the side of the fiber-hanging holes 7 facing the extrusion chamber 2 is provided with an inner chamfer 8.

[0017] When the material is extruded, the hanging fiber template 4 is like a filter net ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com