Oil smoke filtering device

A technology for oil fume filtration and oil fume, which is applied in the direction of oil fume removal, household heating, heating methods, etc., can solve problems such as large resistance loss, increase maintenance cycle, improve oil fume separation efficiency, and improve the effect of oil fume separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

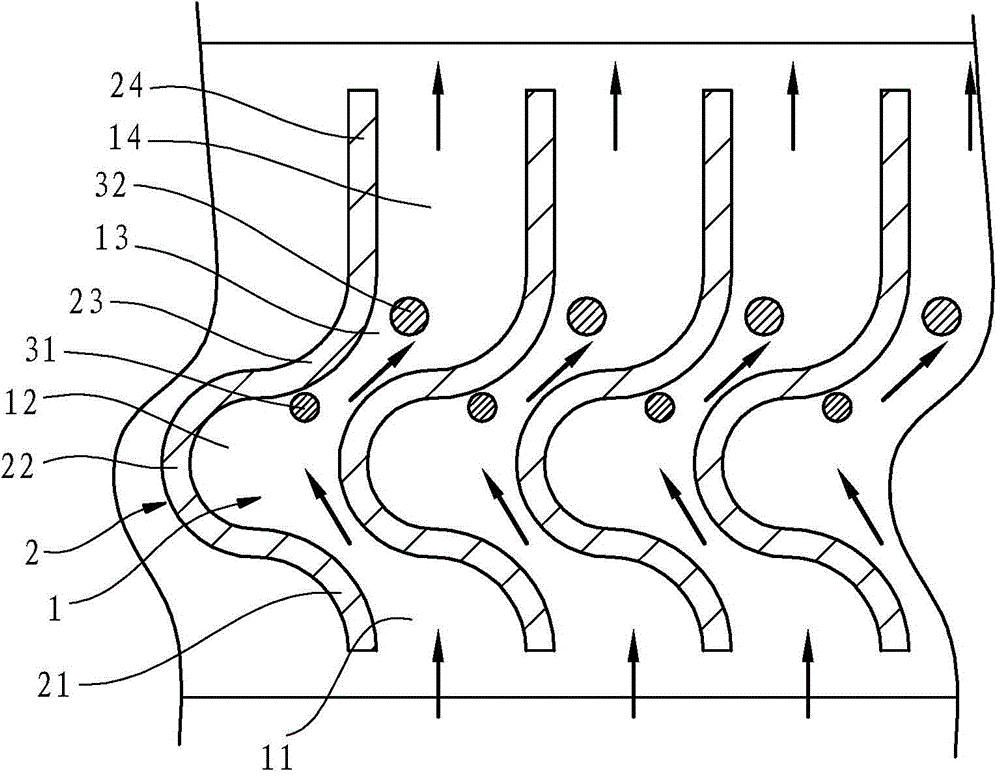

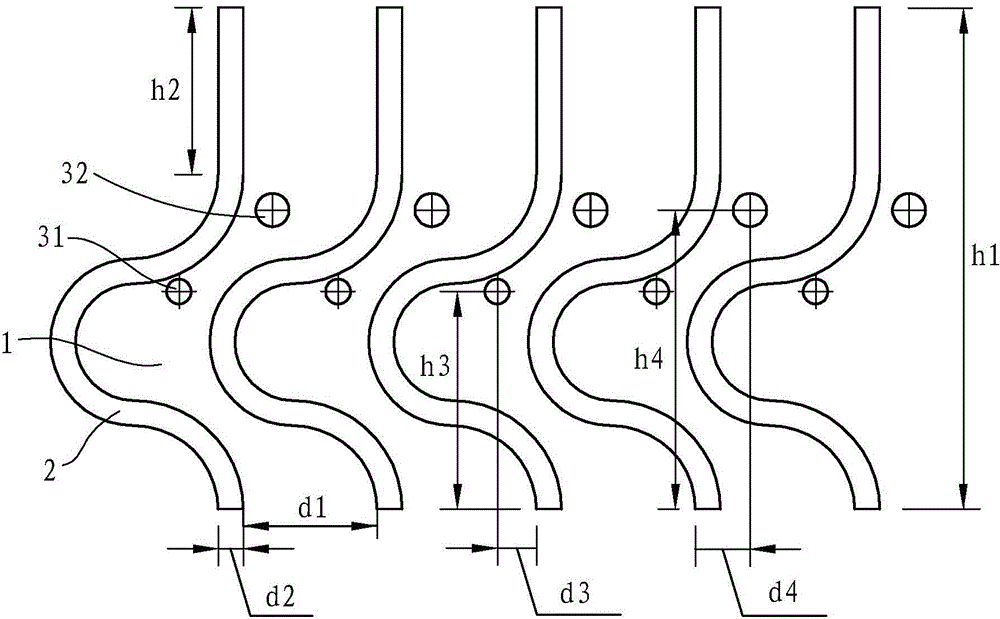

[0038] Such as figure 1 with figure 2 As shown, the oil fume filter device in this embodiment includes a plurality of filter channels arranged vertically and arranged side by side in the horizontal direction, and only four of the filter channels 1 are shown in the figure, and the arrows in the filter channels 1 indicate the flow direction of oil fume. In this embodiment, each filter channel 1 is an arc-shaped zigzag channel and is formed by adjacent vertical partitions 2 respectively. The filter channel 1 is the air intake area 11 from bottom to top, where the oil fume concentrates and collides. The filter area 12 and the air outlet area 13, where the oily fume concentrates and collides with the filter area 12, is the zigzag part of the zigzag channel. In this embodiment, each partition plate 2 has the same shape and is an integral structure. The cross section of the partition plate 2 includes a first arc segment 21, a second arc segment 22 and a third arc segment connected ...

Embodiment 2

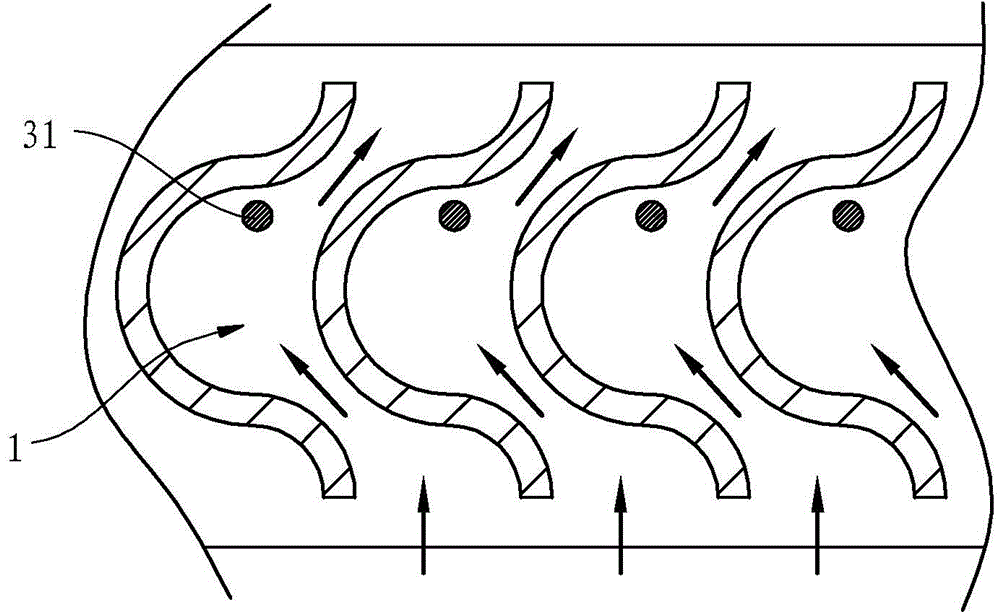

[0059] Such as image 3 As shown, compared with the structure in Embodiment 1, the oil fume filtering device in this embodiment omits the linear rectification channel and the second oil fume blocking member, and the first oil fume blocking member 31 in the filtering channel 1 continues to remain. The rest of the structure is the same as that in Embodiment 1, and will not be described here.

Embodiment 3

[0061] Such as Figure 4 As shown, the filter channel in this embodiment is a bent filter channel 10, the air inlet rectifying channel 101 is located below the bent filter channel 10, and the air outlet rectifying channel 102 is located above the bent filter channel 10. Inside the filter channel 10 are provided two rod-shaped oil fume stoppers, namely a lower stopper 33 at the bottom and an upper stopper 34 at the top. The cross sections of the lower stopper 33 and the upper stopper 34 are circular. Each bent partition 20 is formed by bending the straight section 201 up and down sequentially, and the combination of the curved parts of two adjacent bent partitions 20 makes the filtering channel appear as a zigzag channel. The bending angle between adjacent straight segments 201 constituting the cross-section of the bending portion is 60-90 degrees. In this embodiment, the cross-section of the bending part includes three straight segments 201, the total height of the bending pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com