Treatment technique for pollutants in sinter fume and spraying and absorbing tower thereof

A technology of spraying absorption tower and sintering flue gas, which is applied in the fields of chemical industry and environmental protection. It can solve the problems of no obvious reduction in investment costs, unstable system operation, and large loss of equipment resistance, so as to improve the treatment quantity or quality, install and manufacture Convenience and small resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

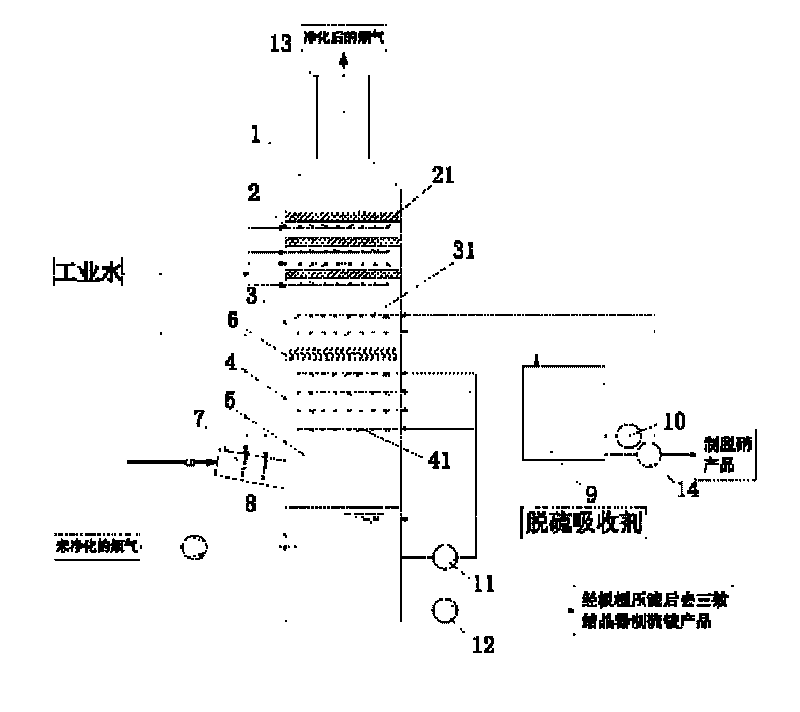

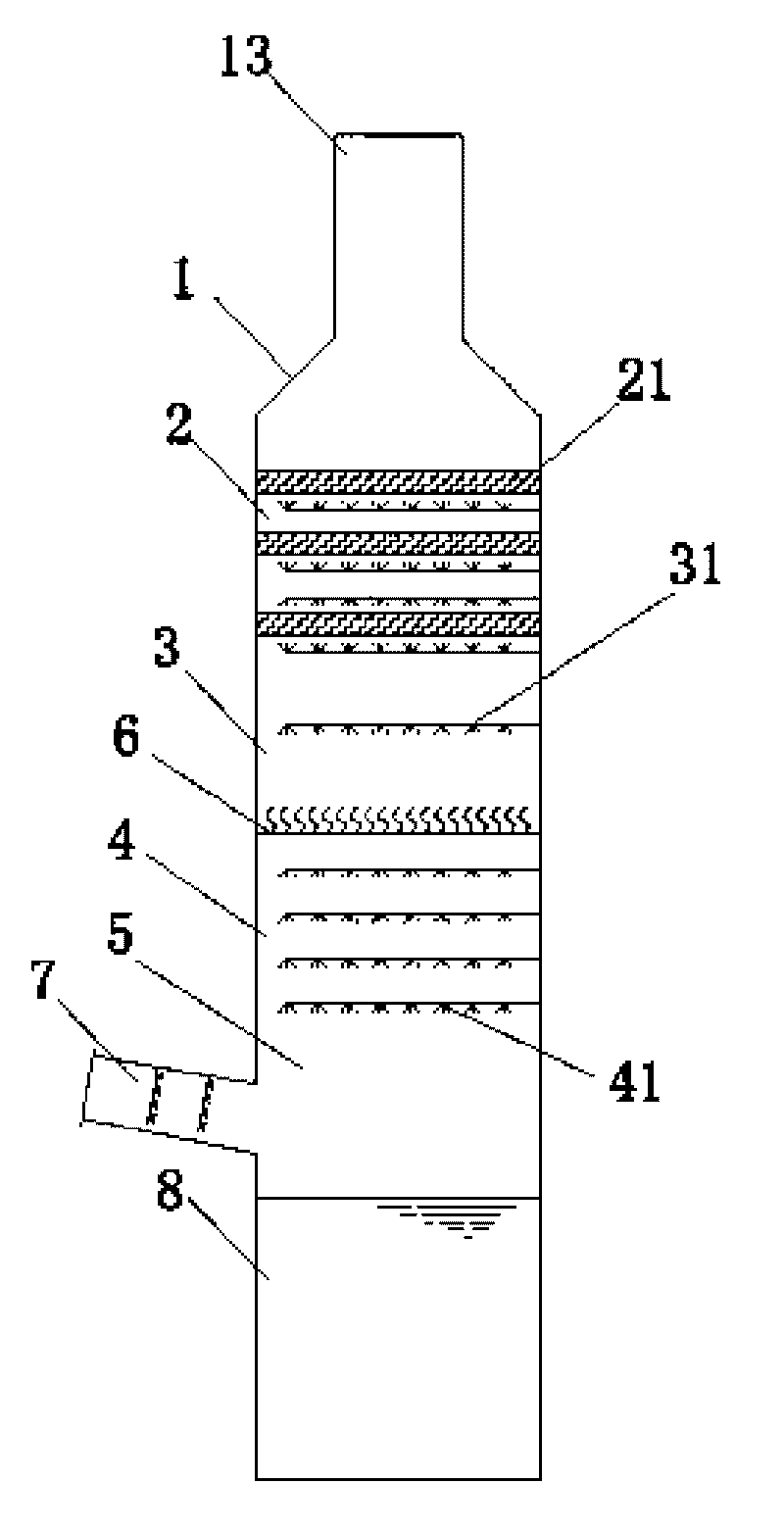

[0038] Embodiment 1: as figure 1 As shown, taking the simultaneous treatment of sulfur dioxide and nitrogen oxides in the sintering flue gas as an example, the spray absorption section in the spray absorption tower includes desulfurization section 4 and denitrification section 3, and the sintering flue gas passes through the desulfurization section first 4. Desulfurization section 4 adopts wet desulfurization process. Wet desulfurization process includes limestone-gypsum method, ammonia-ammonium sulfate method, double alkali method and other processes. In this process, the SO in the sintering flue gas 2 Dissolve in the absorbing liquid, react with the absorbing liquid for desulfurization, and the residual dust in the sintering flue gas is also captured to complete the desulfurization and dust removal. 4 recycling; the flue gas after passing through the desulfurization section 4 enters the denitration section 3, and the denitration section 3 adopts a wet method for denitrificat...

Embodiment 2

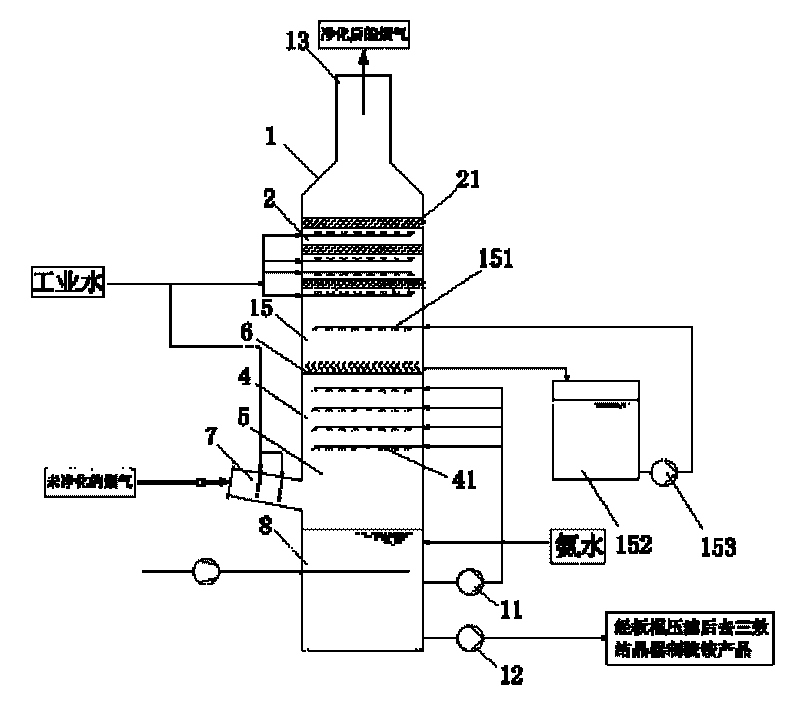

[0067] Embodiment 2: as figure 2 As shown, taking the treatment of sulfur dioxide in the sintering flue gas with two spray absorption sections as an example, the sintering flue gas first passes through the desulfurization section 4, and the desulfurization section 4 adopts the ammonia-ammonium sulfate wet desulfurization process. SO in flue gas 2 Dissolve in the absorbing liquid, react with the absorbing liquid for desulfurization, and the residual dust in the sintering flue gas is also captured to complete the desulfurization and dust removal. 4 Recycling; the airflow passing through the desulfurization section 4 enters the cleaning and spraying section 15, and the cleaning and spraying section 15 cleans the airflow with clean water or an absorption liquid with a low pH value. After passing through all the spray absorption sections, the air flow is discharged from the top of the spray absorption tower after demisting treatment.

[0068] see figure 2 , applied to the spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com