Zero-discharge purifying treatment method for mine wastewater and mine domestic sewage

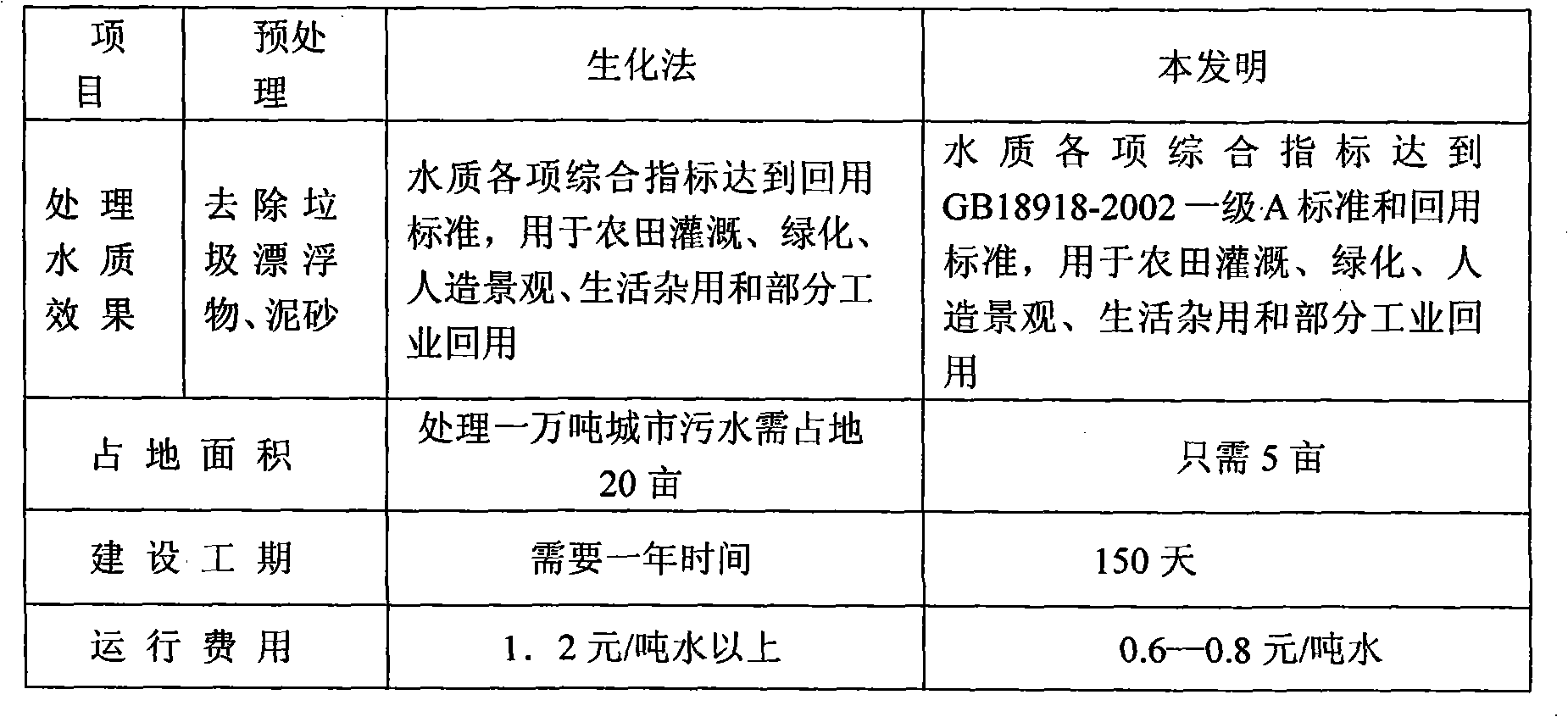

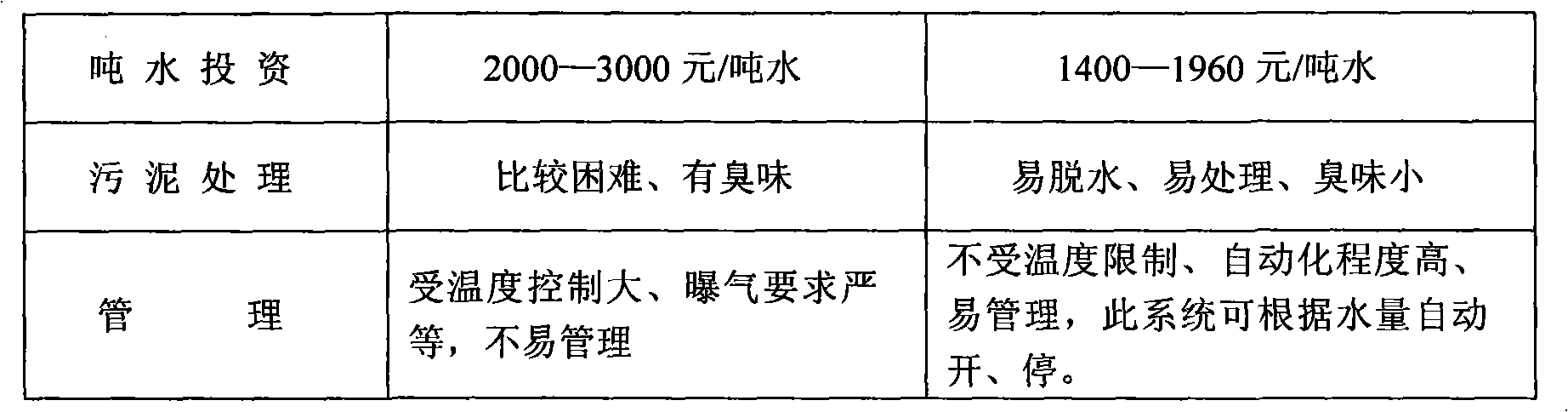

A technology for domestic sewage and purification treatment, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sewage multi-stage treatment, etc. To solve problems such as large land area, it can achieve the effect of ensuring physical adsorption and electrochemical adsorption performance, reducing power consumption and operating costs, and reducing floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] to handle 1200M 3 The Daping Coal Mine of / d coal mine wastewater is taken as an example to illustrate the present invention.

[0031] A zero-discharge purification treatment method for mine wastewater and mine domestic sewage. Its process steps are as follows:

[0032] 1) Pretreatment: The sewage flowing out of the septic tank enters the sewage treatment plant, and after passing through the grid, the larger floating matter and mud and sand are separated out, and the supernatant enters the regulating tank, which adopts a reinforced concrete structure, and stays After 2 to 4 hours, after mixing, adjusting and clarifying, it enters the purifier lifting pump pool;

[0033] The grid plate is a PVC plate with a hole diameter of 5mm.

[0034] 2) Primary treatment: The pretreated sewage enters the purifier lifting pump pool, and the purifier lifting pump pool adopts reinforced concrete structure. When the sewage water level in the purifier lifting pump pool rises to the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com