Anti-oxidation high pressure seal stuffing box component

A high-pressure sealing and stuffing box technology, which is applied in shaft seals, engine seals, engine components, etc., can solve problems such as increasing the friction coefficient between packing and valve stem, accelerating valve stem wear, and technical difficulty, achieving self-lubricating properties Good, maintain sealing reliability, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

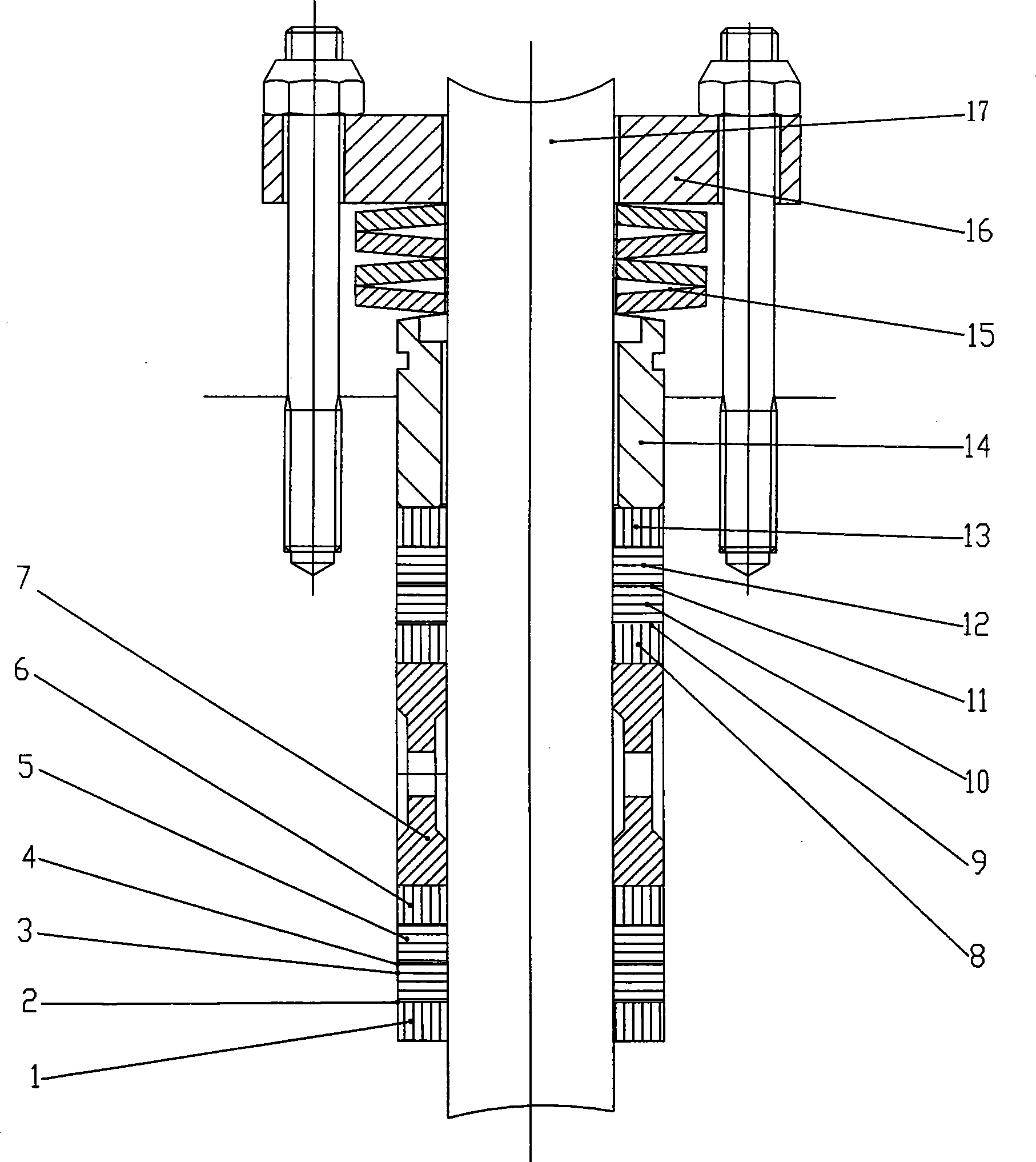

[0018] Such as Figure 1 ~ Figure 3 As shown, it includes the first filiform filler 1, the first zinc flake 2, the first flake filler 3, the second zinc flake 4, the second flake filler 5, the second filiform filler 6, the spacer 7, the third Filiform filler 8, third zinc flake 9, third flake filler 10, fourth zinc flake 11, fourth flake filler 12, fourth filiform filler 13, packing gland 14, disc spring 15, gland Flange 16 and valve stem 17.

[0019] The invention consists of two parts: a sealing main body and a compensating mechanism. When assembling, the sealing main body is installed on the valve stem 17, and the sealing main body is composed of the first filiform packing 1, the first zinc sheet 2, the first sheet packing 3, the second zinc sheet 4, the second sheet packing 5, The second filiform packing 6, the spacer 7, the third filiform packi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com