Method for determining blade adjustment frequency of variable-angle optimized operation of large fully-adjustable water pump station

A technology for blade adjustment and optimized operation, which is applied in pump control, non-variable pumps, machines/engines, etc., and can solve problems such as the frequency of blade adjustment that has not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Adopting the technical scheme of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and cases, but this case should not be construed as a limitation to the present invention.

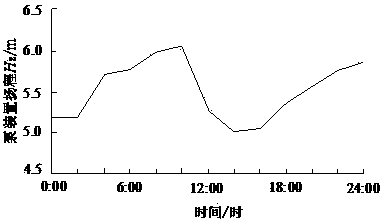

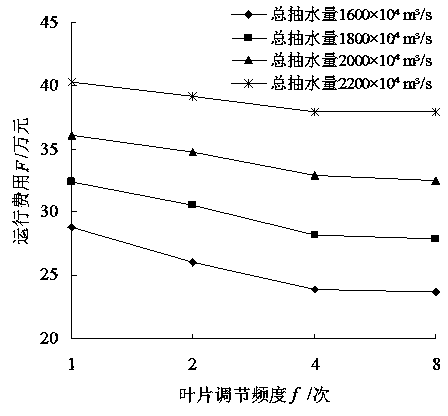

[0034] A large pumping station installed 7 sets of 2900ZLQ30-7.8 vane full-adjustable axial flow pumps, with a single flow rate of 30m 3 / s, stand-alone power 3400kW, design head 7.8m, design annual running time 5000h. The forebay of the pumping station is affected by the tidal water level of the water source, and the head of the pumping station changes frequently and in a large range. According to the water level data monitored and recorded every 2 hours in a typical day of the pumping station, the change rule of the head of the pump device at different times in the pumping station is as follows: figure 1 shown. According to the time-of-use electricity price regulations for general industrial peaks and valleys of 100kVA an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com