Patents

Literature

71results about How to "No outflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

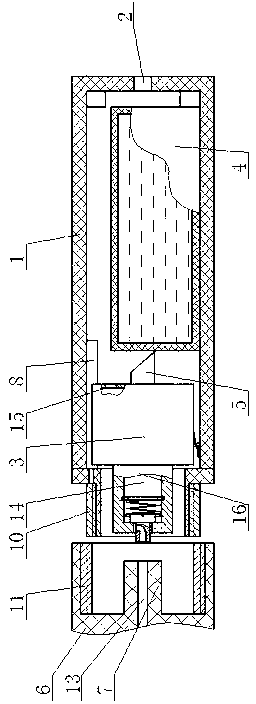

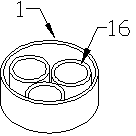

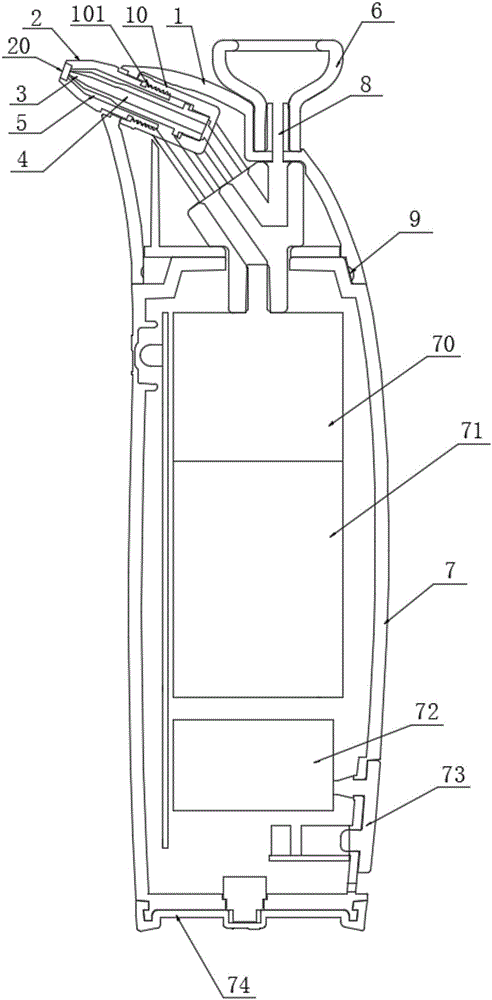

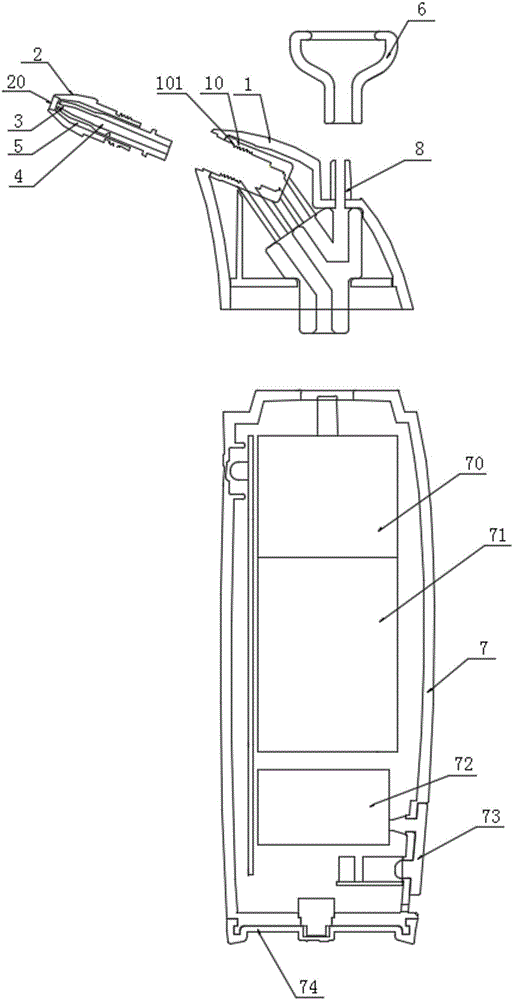

Screw-driven sliding piercing type electronic smoking set

ActiveCN103315402ANo outflowAvoid pollutionTobacco devicesMedical atomisersEngineeringMechanical engineering

The invention provides a screw-driven sliding piercing type electronic smoking set comprising a smoking set shell. A cigarette liquid capsule and an atomizer are mounted in the smoking set shell, an air inlet passage is formed in the atomizer, a smoking orifice is formed in the side wall of the shell, the atomizer is mounted on the other side of the shell, a piercing liquid guide frame on the atomizer is positioned on one side of the cigarette liquid capsule, and a thread is arranged on the inner or outer peripheral wall, at one end of the atomizer, of the shell. A guide block is mounted on the inner wall of one end, provided with the atomizer, of the smoking set shell axially, and a guide groove is formed in the outer wall of the atomizer and matches with the guide block. The atomizer can be completely isolated from the outside when not used, impurities are thoroughly prevented from being ignited by a heating wire to generate naked flame after dust and the impurities enter the atomizer, and harmful substances in the impurities are prevented from being inhaled into human bodies; the atomizer is prevented from being separated from the cigarette liquid capsule, so that sealing reliability between the atomizer and the cigarette liquid capsule is further kept.

Owner:SHENZHEN BUDDY TECH DEV CO LTD

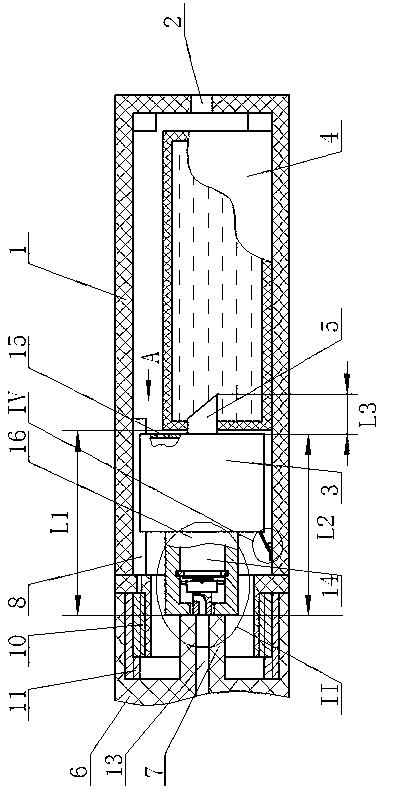

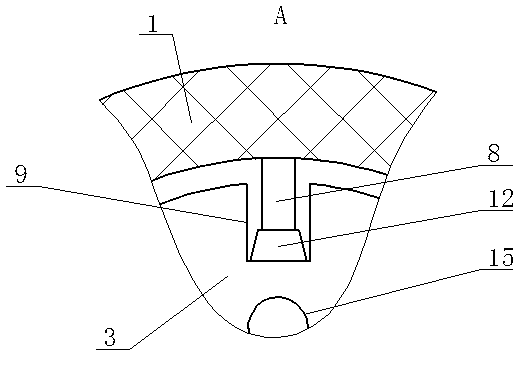

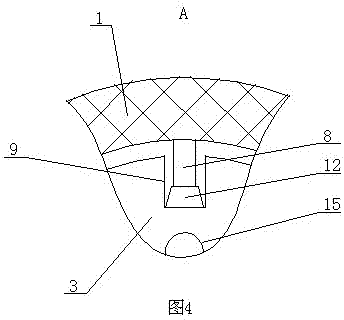

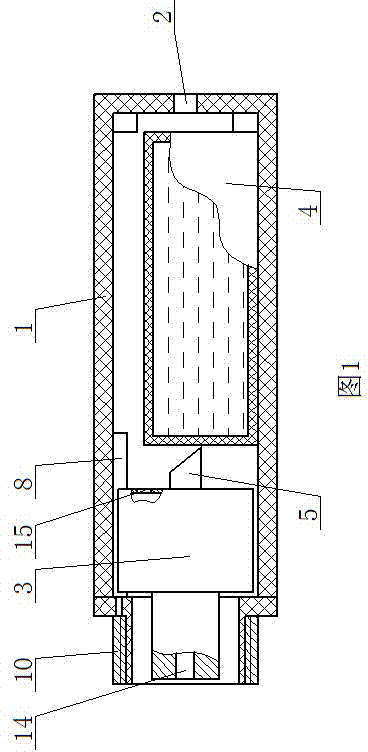

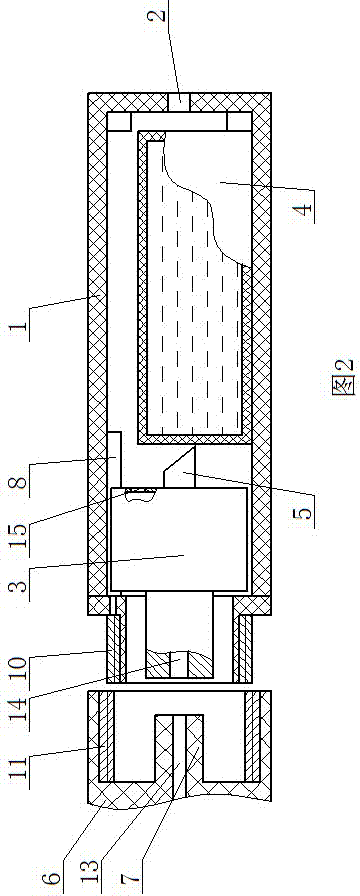

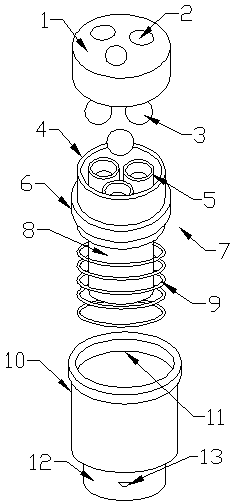

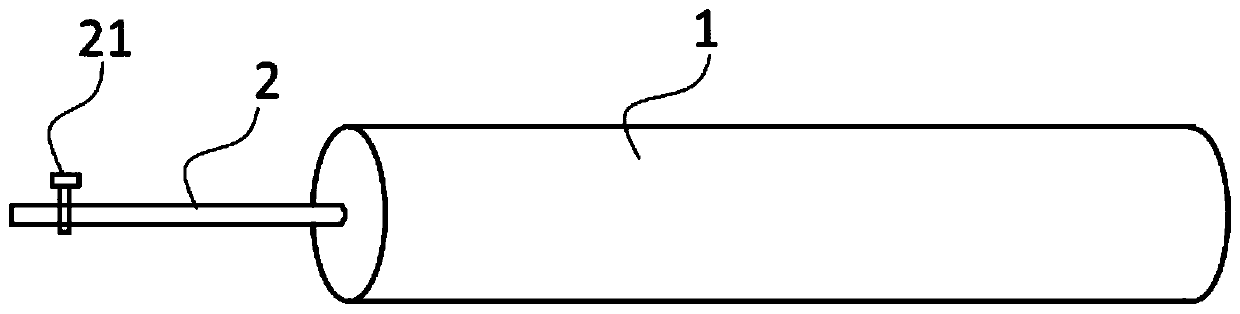

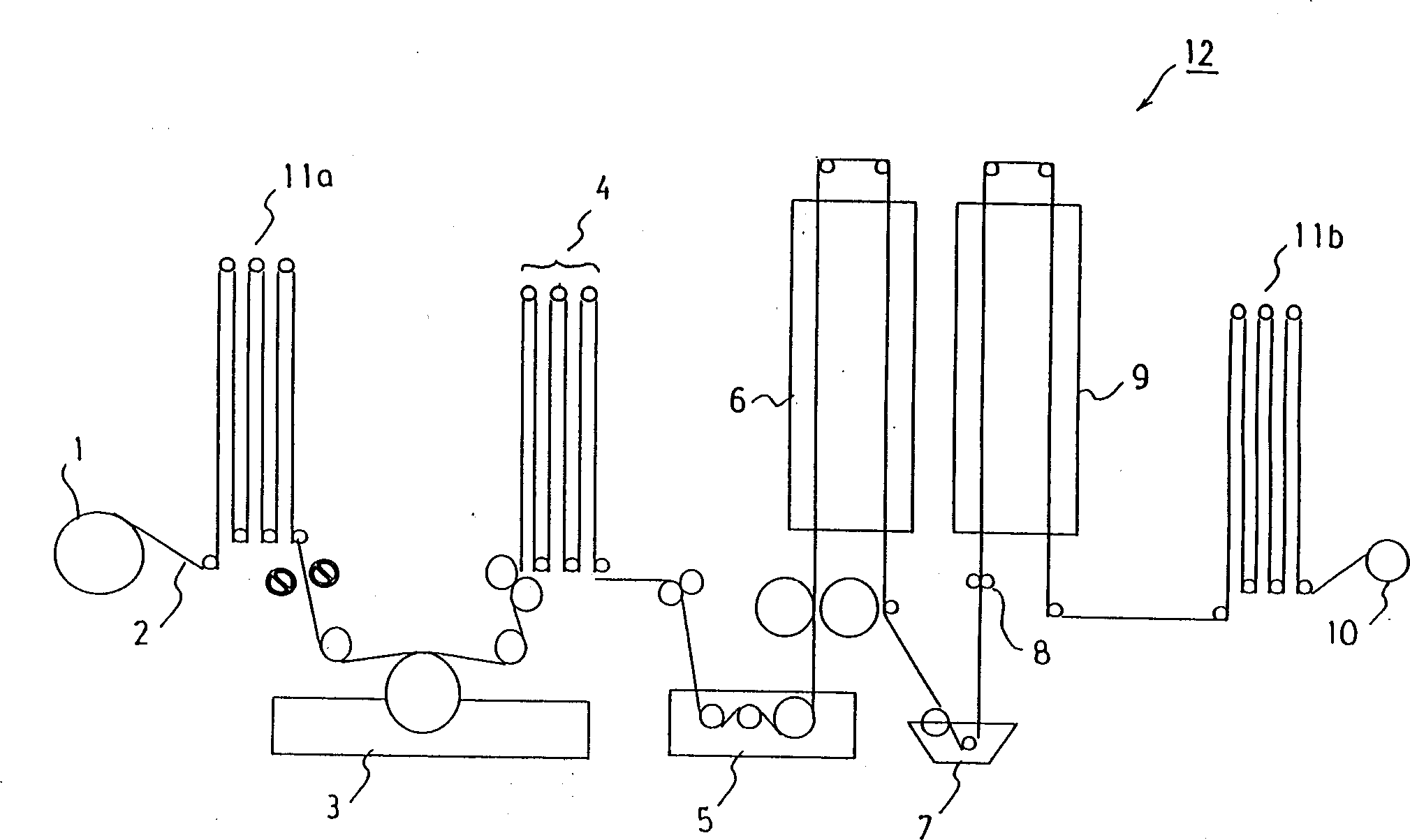

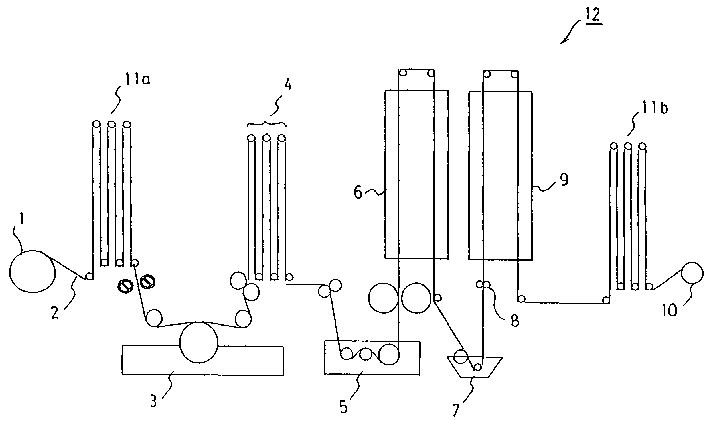

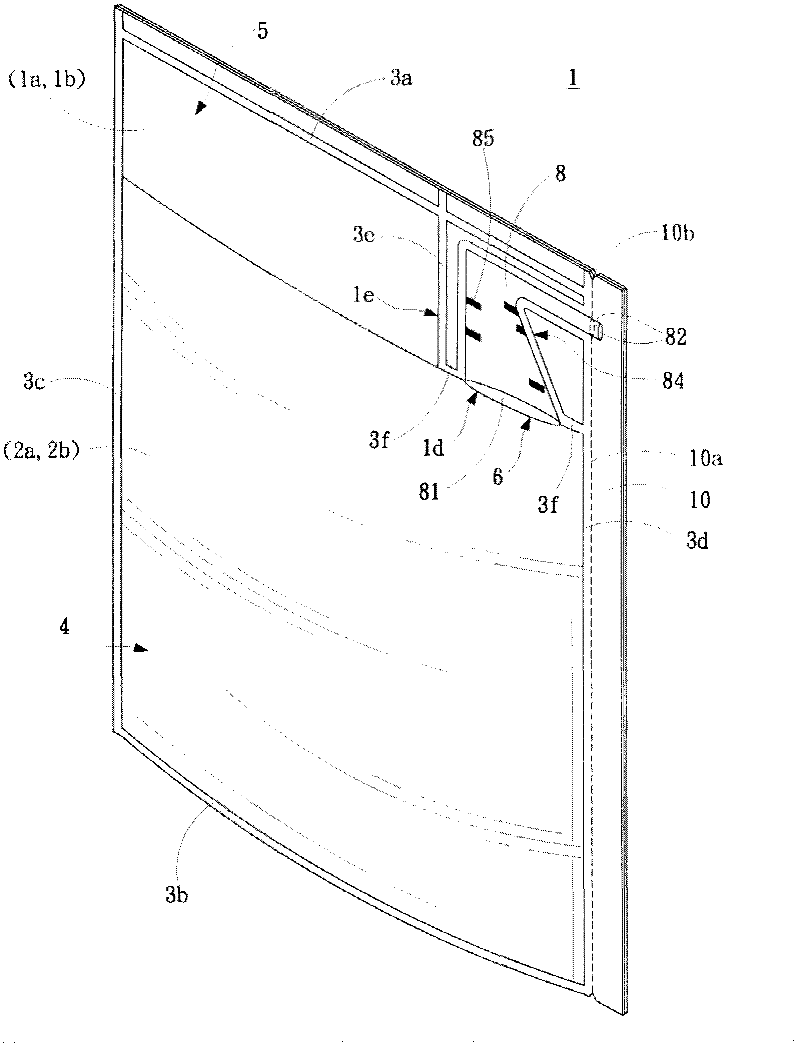

Spirally-driven slidably-punctured electronic smoking set

InactiveCN102894486AAccurate piercing operationEffective piercing operationTobacco devicesMedical atomisersEngineeringDriving mode

The invention provides a spirally-driven slidably-punctured electronic smoking set, which comprises a smoking set shell, wherein a gas suction hole is formed in one end of the smoking set shell, and threads are arranged on the inner wall or outer wall of the smoking set shell; a tobacco juice atomizer and a tobacco juice capsule are arranged in the smoking set shell; a puncturing liquid guide frame is arranged on one side, which is close to the tobacco juice capsule, of the tobacco juice atomizer; and the tobacco juice atomizer slides in the smoking set shell along the axial direction of the smoking set shell. By the spirally-driven slidably-punctured electronic smoking set, the puncturing liquid guide frame on the tobacco juice atomizer can puncture the tobacco juice capsule in a sliding mode under the driving of a spirally-driven mode, the puncture direction and puncture force of the puncturing liquid guide frame during the puncture of the tobacco juice capsule are not needed to be mastered by users, and after the users screw the threads, the puncturing liquid guide frame can puncture the tobacco juice capsule according to the accurate direction and force; and after the puncturing liquid guide frame punctures the tobacco juice capsule, the tobacco juice capsule can keep high tightness except for tobacco juice which is led out slowly along the puncturing liquid guide frame, so that the using time of the tobacco juice capsule can be prolonged, and the tobacco juice can be prevented from being polluted.

Owner:修运强

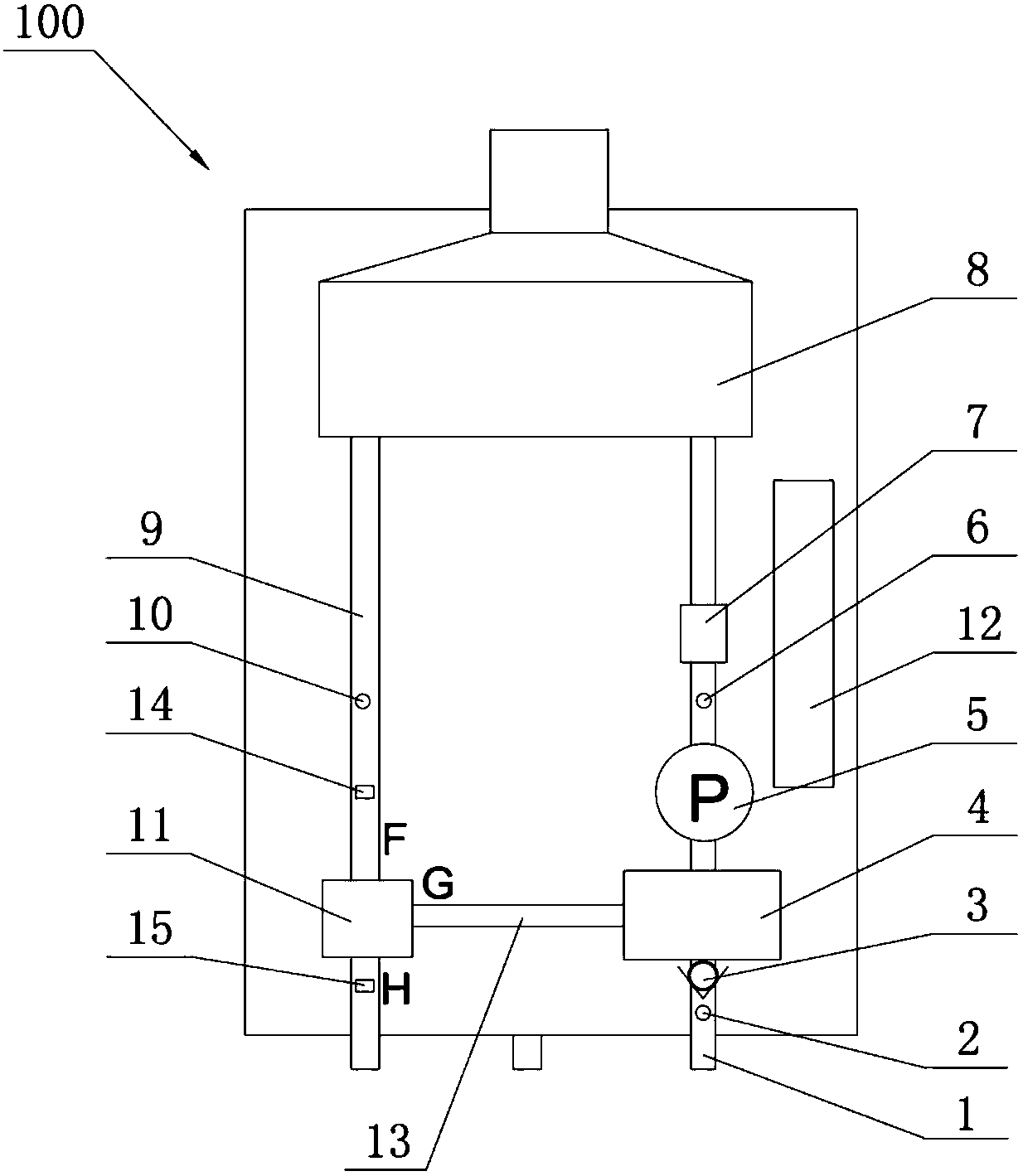

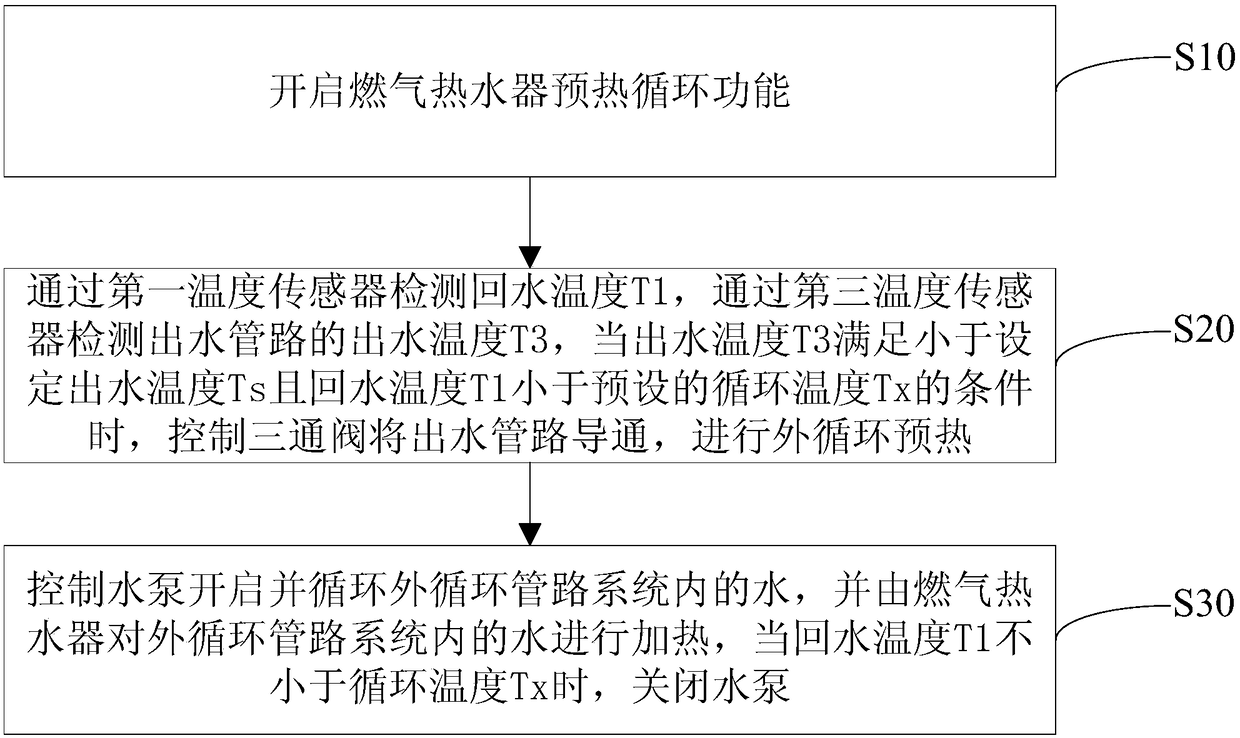

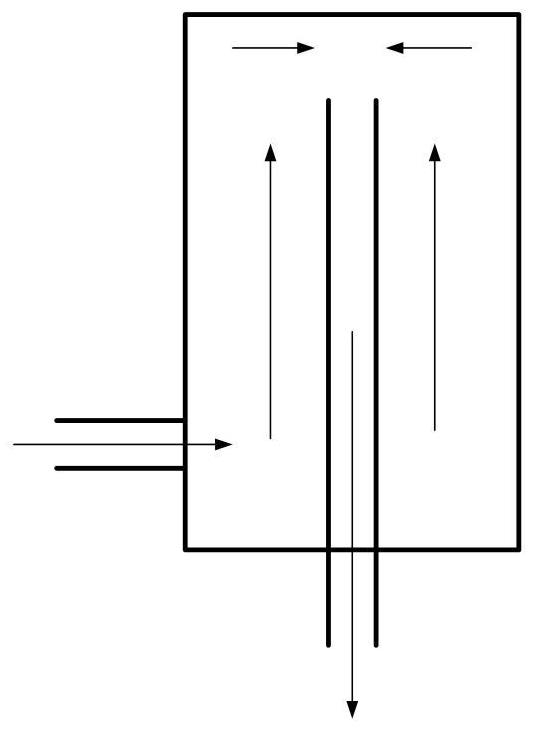

Intelligent preheating circulation gas water heater, preheating circulation system and control method

InactiveCN109297180AImprove use comfort performanceNo outflowWater heatersWater storage tankEngineering

The invention belongs to the field of water heaters, and discloses an intelligent preheating circulation gas water heater, a preheating circulation system and a control method. A water storage tank and a water pump are arranged on a water inlet pipeline; a three-way valve is arranged on a water outlet pipeline; a heat exchanger is arranged between the water inlet pipeline and the water outlet pipeline; the three-way valve communicates with the water storage tank through a bypass line; when a preheating circulation function is started, the conducting of the three-way valve and the bypass line is controlled; an inner circulation pipeline system is formed among the water inlet pipeline, the water pump, the heat exchanger, the water outlet pipeline, the three-way valve, the bypass line and thewater storage tank; and when the water outlet temperature T2 of the water storage tank is smaller than the preset circulation temperature Tx, the water pump circulates water in the inner circulationpipeline system, and water is heated to the temperature which is not less than the circulation temperature Tx. When a user uses hot water, water in the water storage tank is heated to the temperaturewhich is not less than the circulation temperature Tx and firstly flows out; and after hot water in the water storage tank flows out, entered cold water can be stably heated through the gas water heater so as to reach to the preset temperature required by the user.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

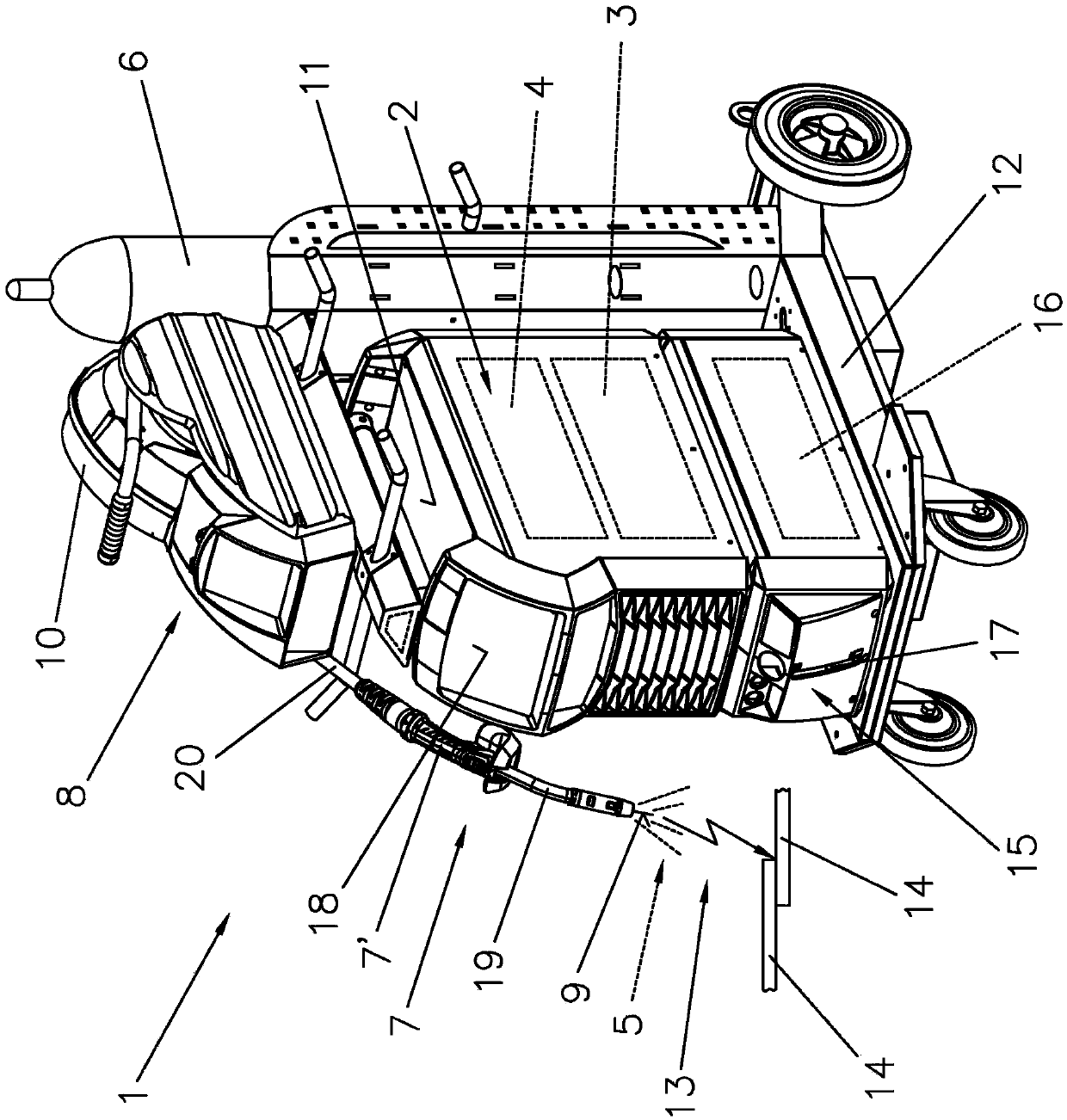

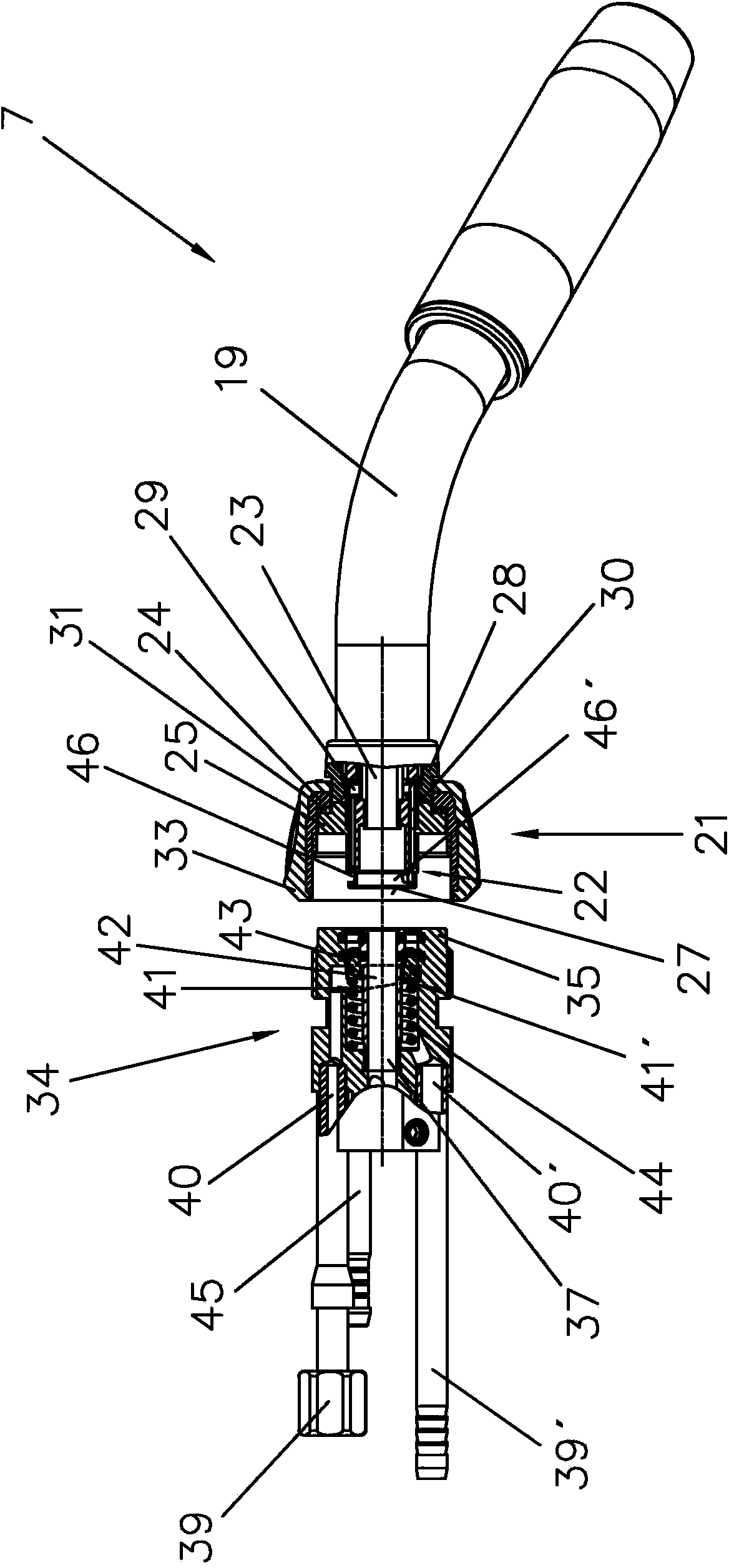

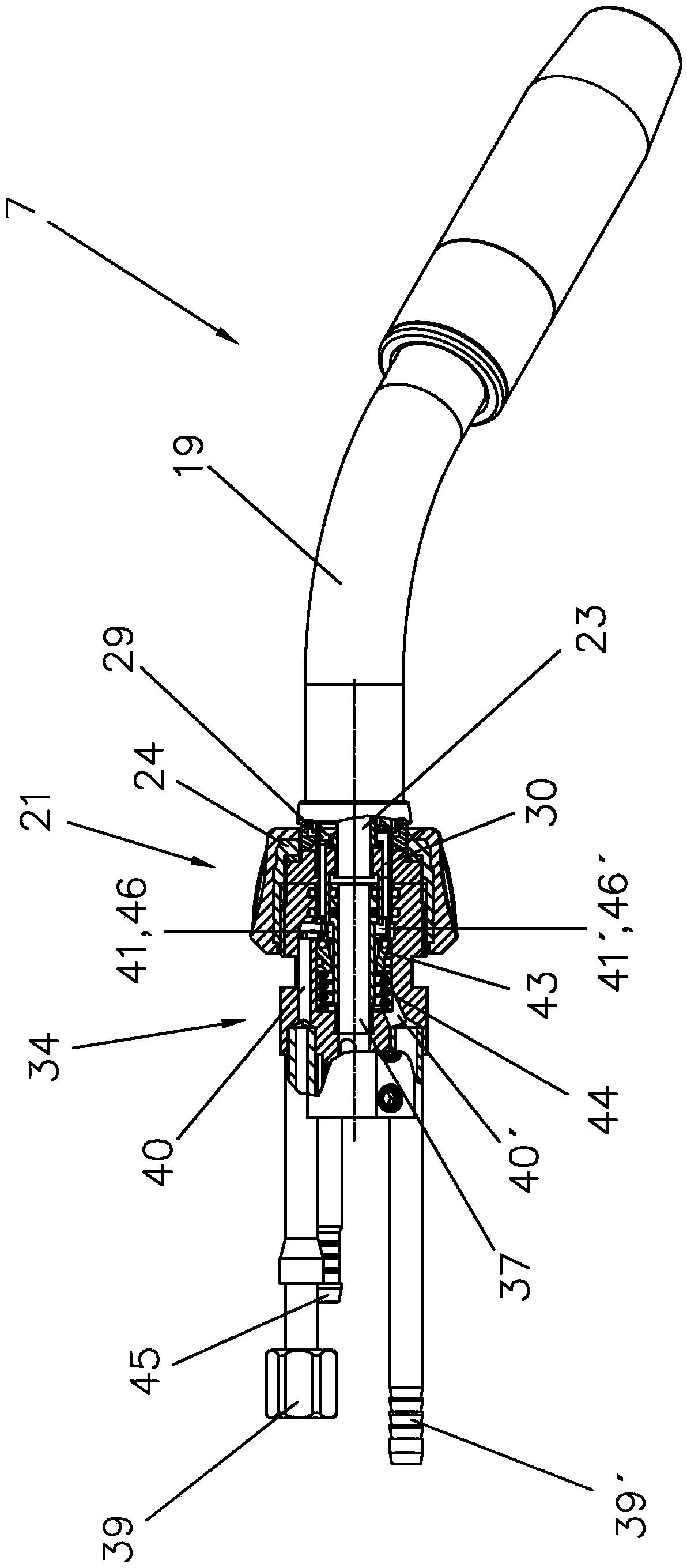

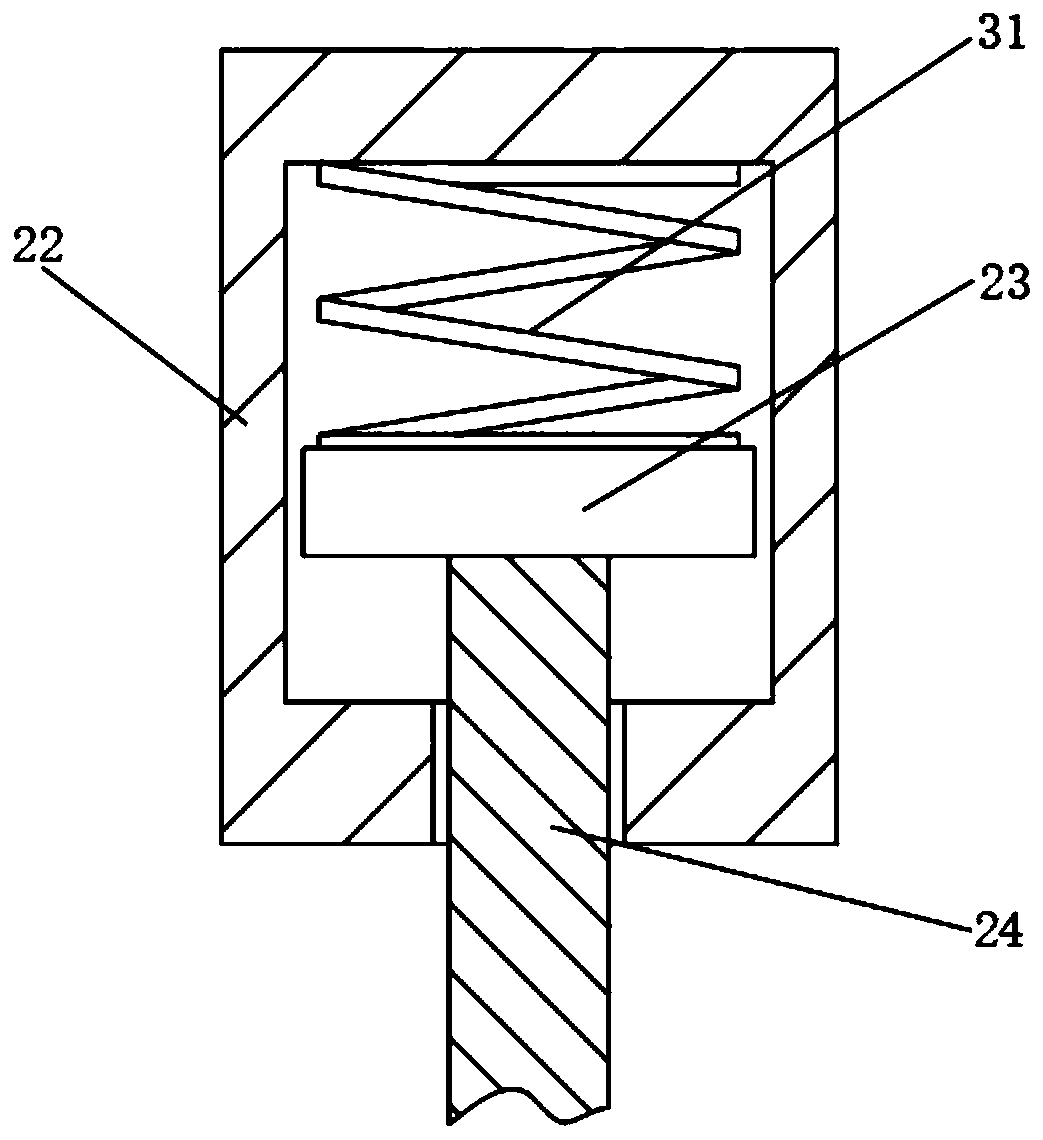

Plug part and socket part for detachably connecting pipe elbow of water-cooled welding torch and connecting device

ActiveCN104185530ANo outflowIncrease flexibilityElectrically conductive connectionsCoupling device detailsShielding gasEngineering

The invention relates to a plug part (21) for detachably connecting a pipe elbow (19) of a water-cooled welding torch (7) to a socket part (34) arranged on a hose package (20), having a cylindrical pipe element (22) with an axially running channel (23) for a welding rod (9) and a protective gas (5) and having at least two cooling channels (29, 30) for supplying and returning a cooling fluid, and a union nut (24) rotatably arranged on the pipe element (22), said union nut having an internal thread for connection to a mating external thread on the socket part (34), said invention further relating to such a socket part (34). In order to produce an optimal connection between the pipe elbow (19) and the hose package (20), a flange (25) having at least one receiving opening for receiving a pin-like element (36) of the socket part (34) is arranged on the pipe element (22) of the plug part (21) in order to fix at least one angular position of the pipe elbow (19).

Owner:FRONIUS INTERNATIONAL GMBH

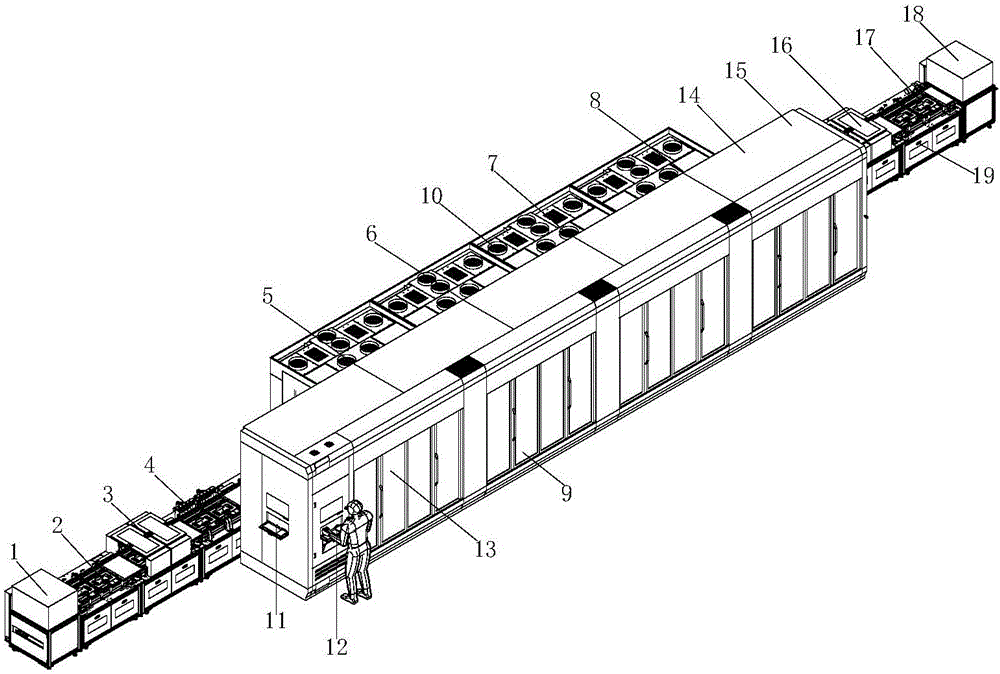

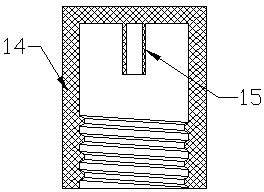

Electronic product automatic detection and automatic aging system

InactiveCN106053997AReduce work intensityReduce labor costsEnvironmental/reliability testsProduction lineThird age

The invention discloses an electronic product automatic detection and automatic aging system comprising an inlet carrier elevator. A finished product installing position is fixedly connected at one side of the inlet carrier elevator, and a finished product preliminary detection position and an aging feeding standby position are fixedly connected at one side, which is away from the inlet carrier elevator, of the finished product installing position in turn. A first aging unit is fixedly connected at one side of the front surface of the aging feeding standby position, and a second aging unit, a third aging unit and a fourth aging unit are fixedly connected at the right side of the first aging unit in turn. According to the electronic product automatic detection and automatic aging system, test and aging work personnel are reduced, enterprise labor cost is reduced, production efficiency is enhanced, the fraud and omission phenomena of the test and aging process of production line manual work are avoided and labor intensity of manual carrying of a support plate is reduced so that field management is enabled to be more standard and beautiful, and the aging effectiveness is ensured by constant temperature aging.

Owner:GUANGDONG STIGER ELECTRONICS

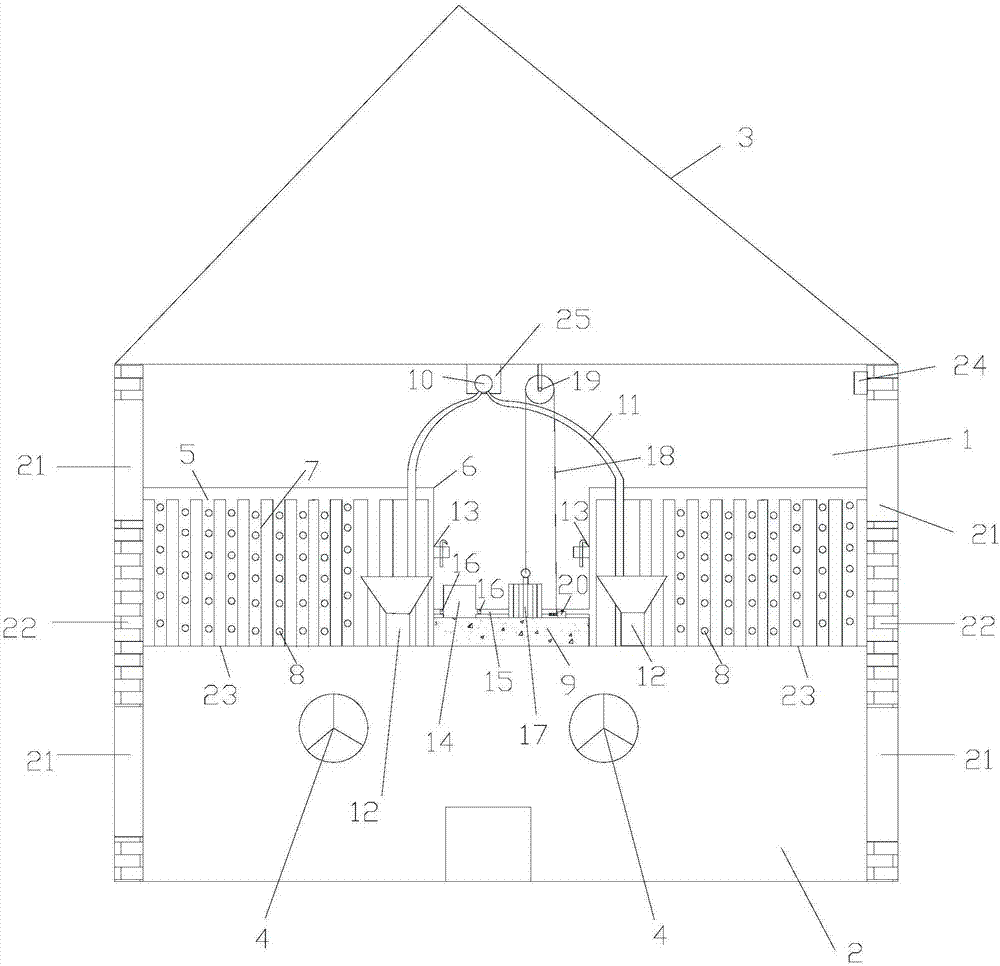

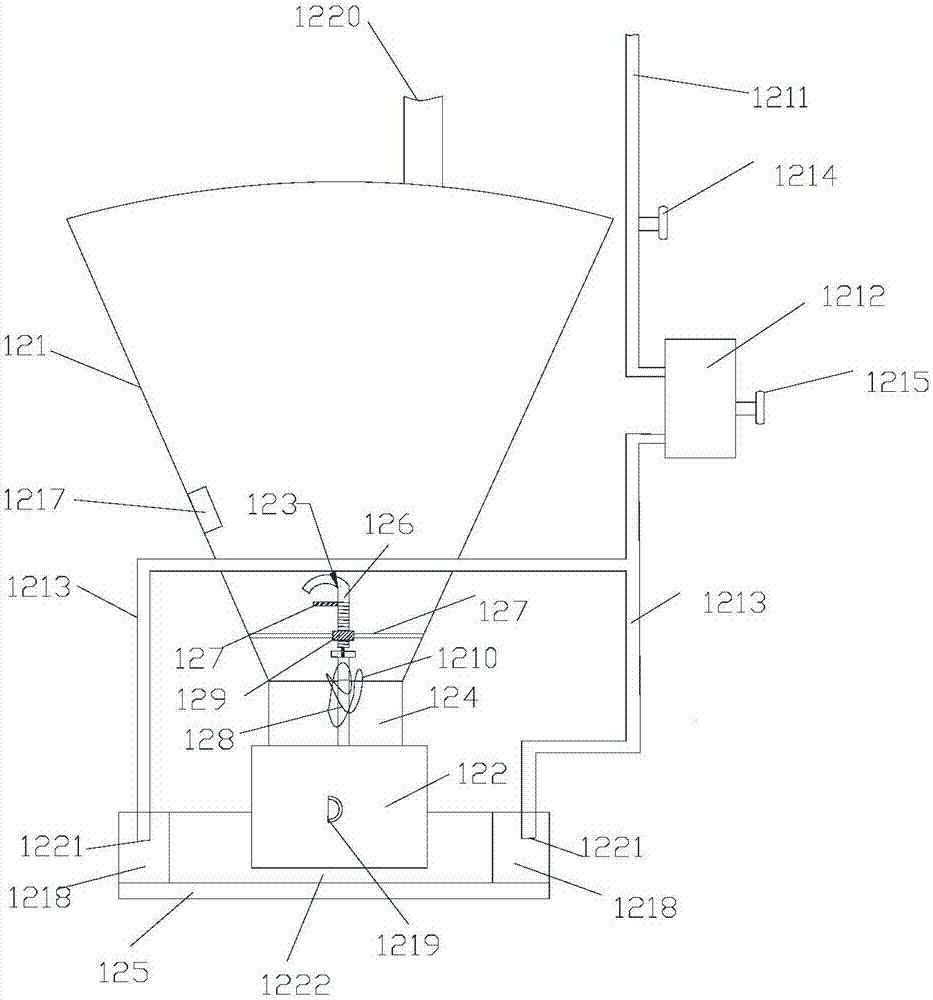

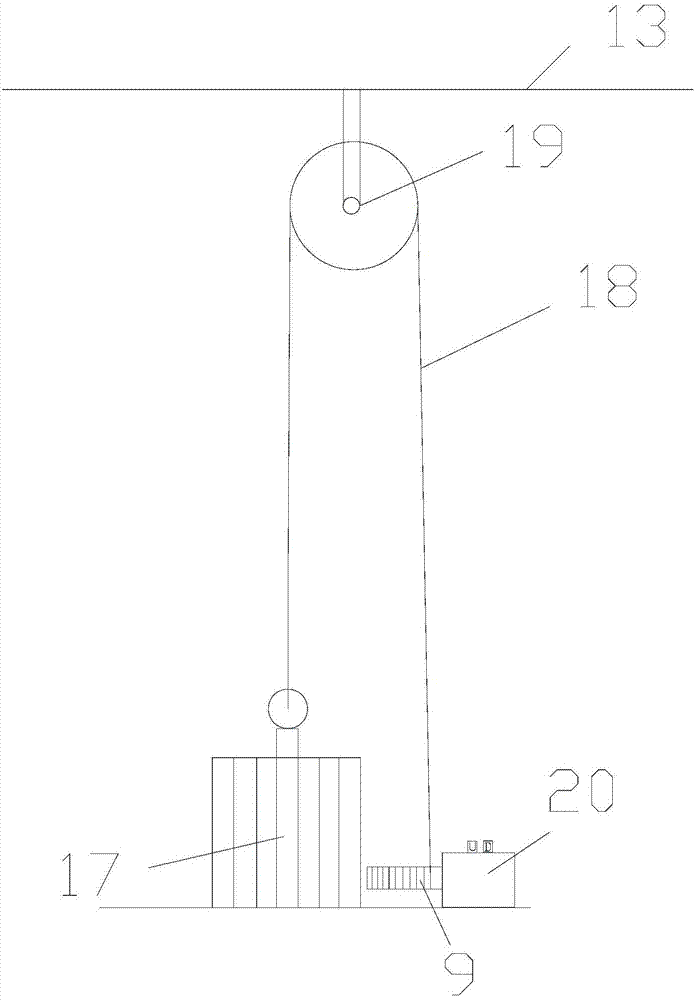

Pig house

ActiveCN106922542AReduce usageImprove the living environmentAnimal feeding devicesLifting devicesAnimal fecesDrive motor

The invention relates to the technical field of hog breeding and provides a pig house. The pig house comprises a first floor feces collecting room, a second floor feces collecting room, a roof and a pedestrian path. The pedestrian path is additionally provided with a pressurizing and storage tank, a pipeline, a lifting mechanism and a lifting channel communicating upper and lower floors. Left and right sides of the pedestrian path are provided with multiple pigsties spaced by pig fences. The pig fences are made by hollow pipes which communicate and are connected. The hollow pipes are provided with multiple spray openings. The pressurizing and storage tank communicates with the pipeline. The joint between the pressurizing and storage tank and the pipeline is provided with an electromagnetic valve which communicates and is connected with the pipeline. Therefore, liquid in the pressurizing and storage tank can spray out of the spray openings. The lifting mechanism comprises a cage, a rope, a pulley and a driving motor. The rope is sleeved on the pulley. One end of the rope is connected with the top of the cage. The other end of the rope is connected with the driving motor so that the rope can be wounded on the driving motor, driving the cage to lift up and down. The pig house can be moved up and down. Meanwhile, the pig house can be disinfected, deodorized and cleaned. Labor force is saved.

Owner:广西聚银牧业集团有限公司

Intelligent nano-silver hydrogel

InactiveCN103126977APreparation raw materials are cheapEasy to prepareAntibacterial agentsInorganic active ingredientsHydroxypropylmethyl celluloseMethyl cellulose

The invention discloses intelligent nano-silver hydrogel. A preparation process of the intelligent nano-silver hydrogel comprises the following steps of: 1, dissolving silver nitrate and hydroxypropyl methyl cellulose used as raw materials into purified water to prepare a hydroxypropyl methyl cellulose-silver nitrate complex; and 2, on the basis of taking a complex solution as a precursor, reducing silver ions in the precursor solution by using hydrate electrons and free radicals produced by ultraviolet irradiation to prepare nano-silver gel, coating nano-silver by the hydroxypropyl methyl cellulose through the action of sulfydryl and silver, and forming hydrogel by amino and carboxylic acid of the hydroxypropyl methyl cellulose as hydrophilic residue network water molecules to prepare the nano-silver hydrogel. Compared with the nano-silver hydrogel prepared by using the traditional method, the intelligent nano-silver hydrogel disclosed by the invention has the advantages of few raw materials, simple preparation method, good antibacterial effect, good stability and the like and can have no remarkable change after being exposed in air for one year.

Owner:WUHAN WORLDNER UNITED PHARMA

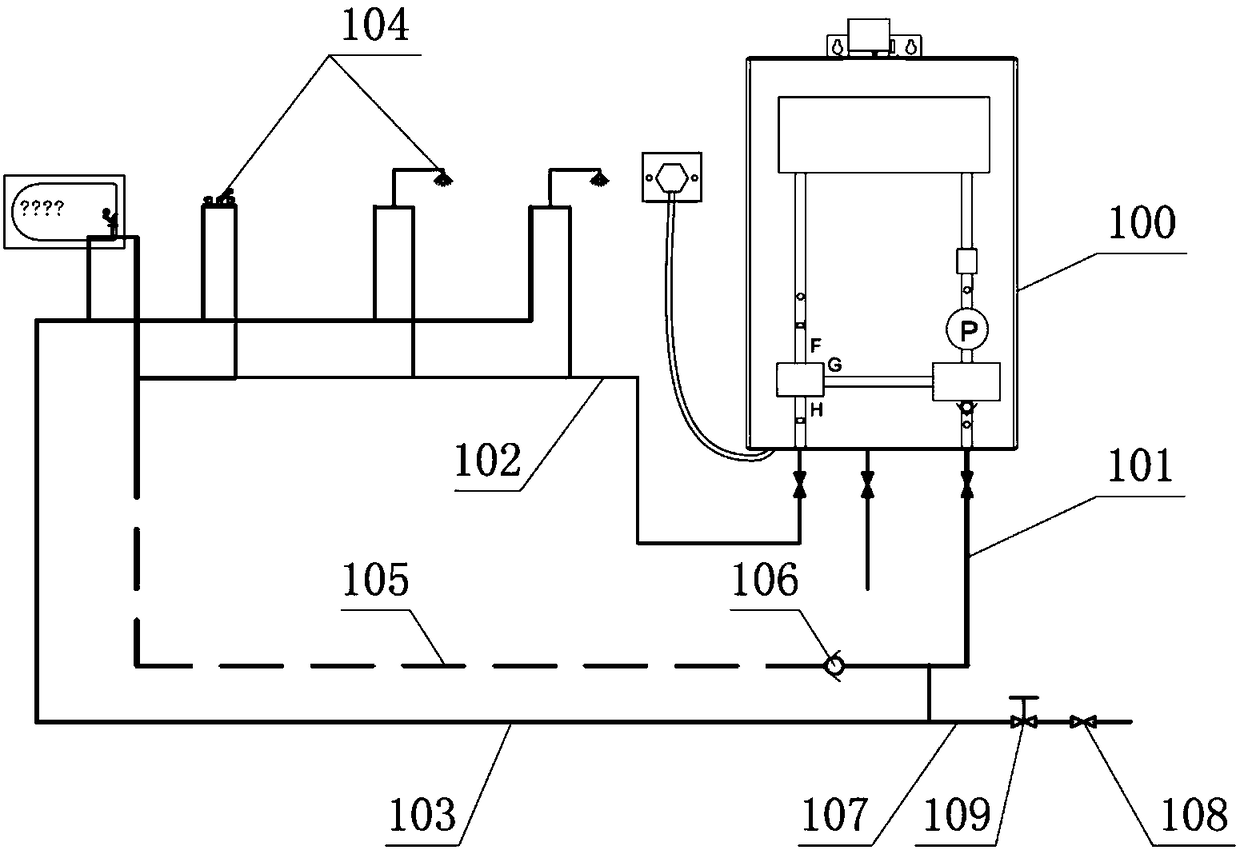

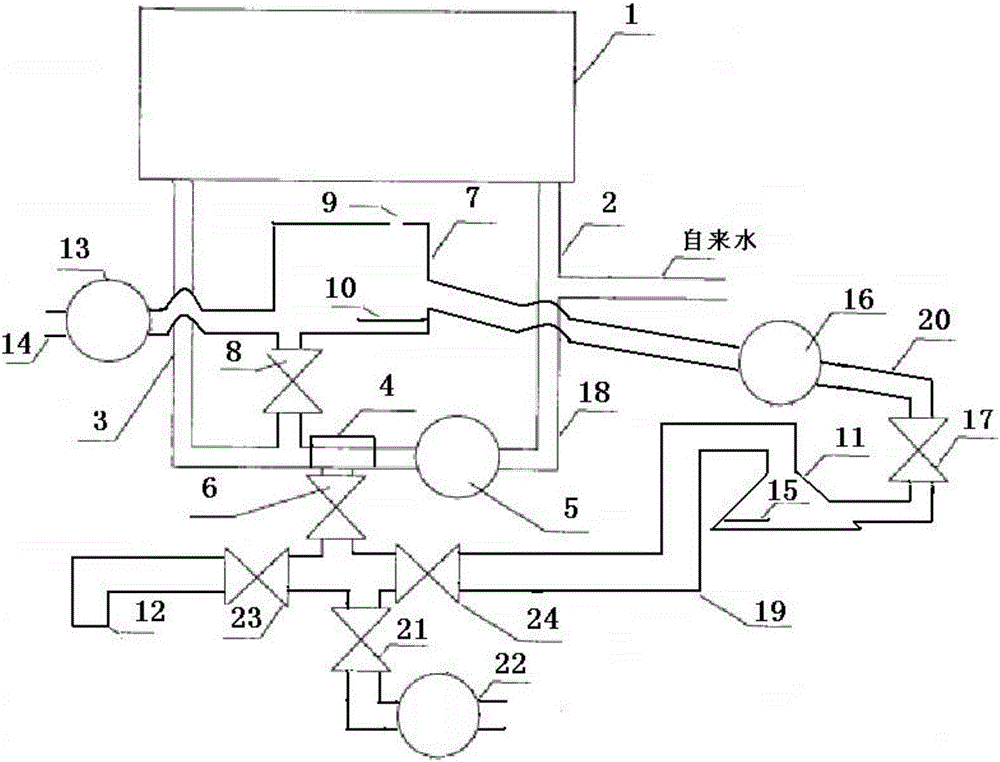

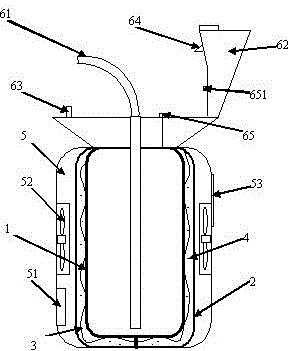

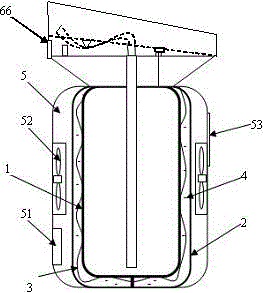

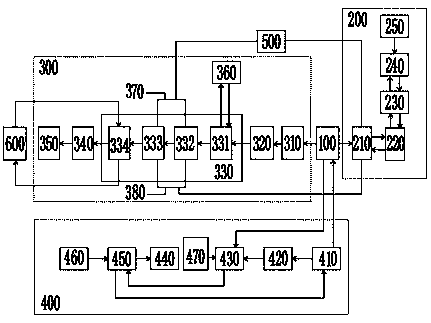

Shower system for recovering hot water without cold water and control method thereof

The invention discloses a shower system for recovering hot water without cold water and a control method thereof. The shower system comprises a controller, a sprinkler switch, a water heater, a water heater water inlet pipe, a water heater water outlet pipe, a first temperature sensor, a first pump, a first electromagnetic valve, a water tank, a second electromagnetic valve, a ventilation hole, a second temperature sensor, a sprinkler, a tap hot water inlet, a second pump, a connecting pipe, a third temperature sensor, a third pump, a third electromagnetic valve, a water return pipe, a sprinkler water inlet pipe, a sprinkler return pipe, a fourth electromagnetic valve, a fourth pump, a fifth electromagnetic valve, a sixth electromagnetic valve and the like. The shower system can really guarantee no flowing out of the cold water from the sprinkler (11), has no need to worry about users to catch a cold caused by lower water temperature, meanwhile, realizes recovery of afterheat water after use of the hot water, and achieves the effects of energy saving and water saving.

Owner:ZHENGZHOU TECHN COLLEGE

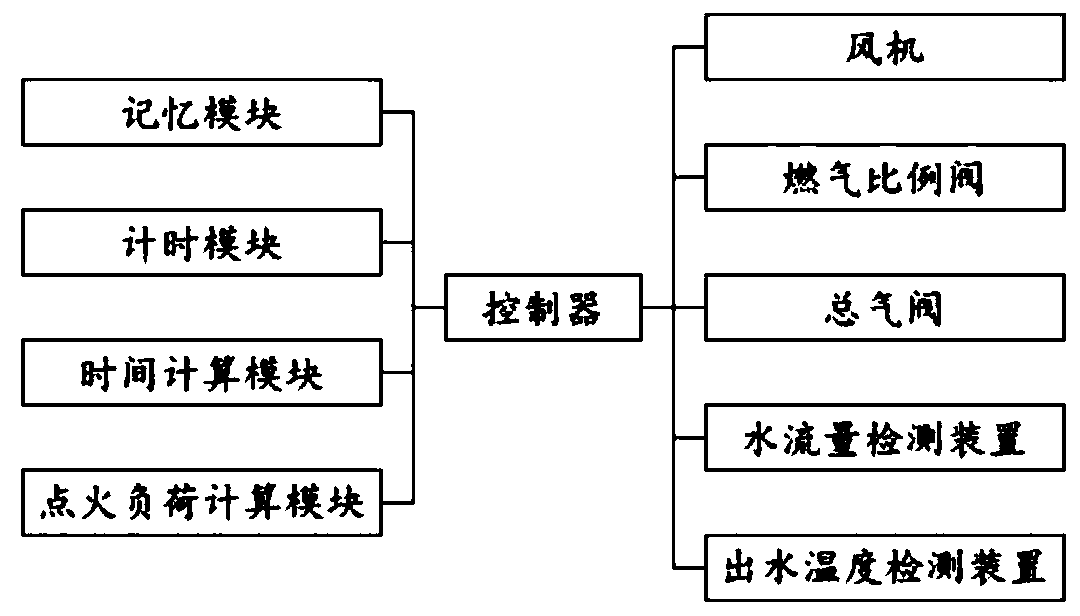

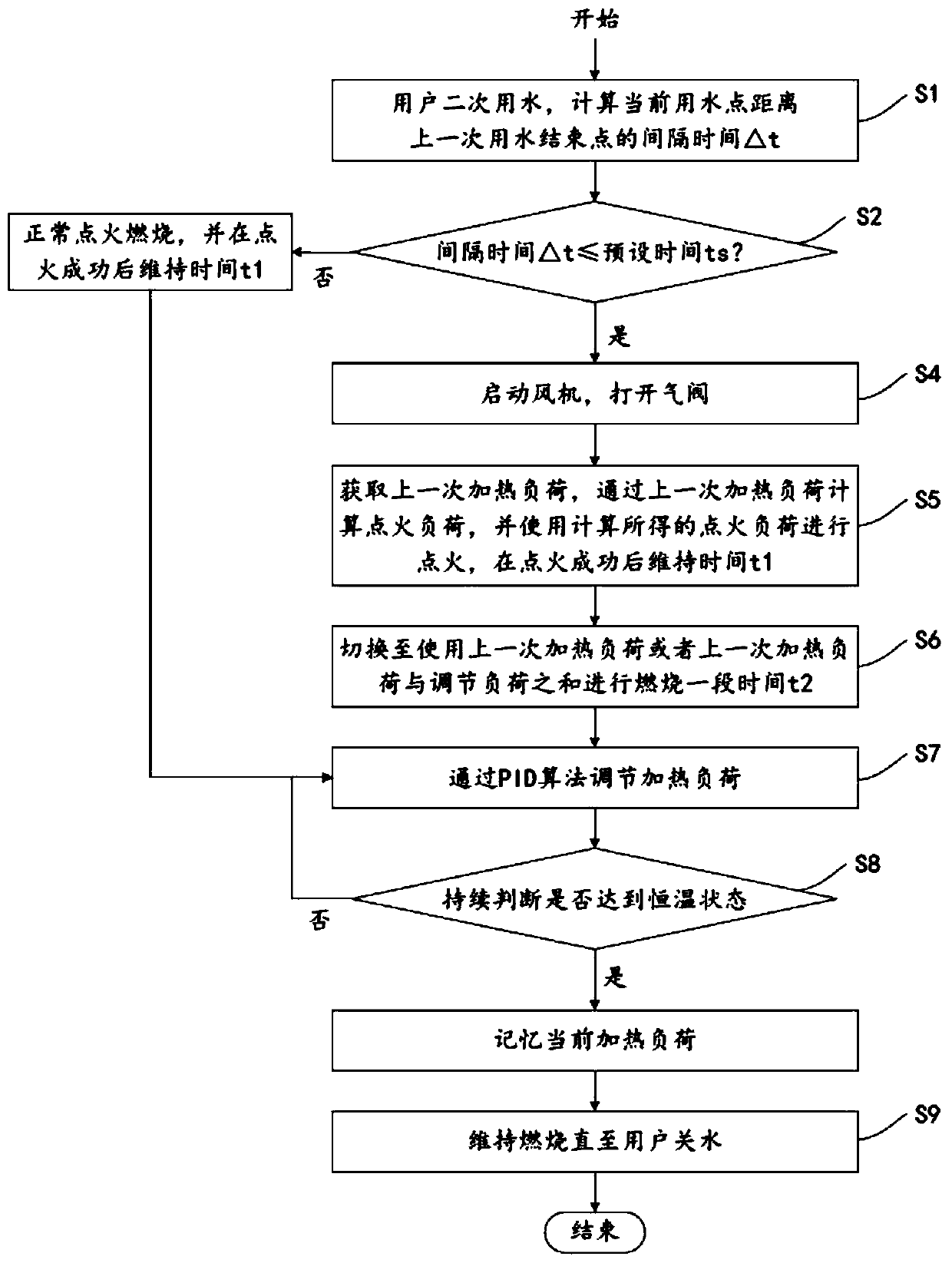

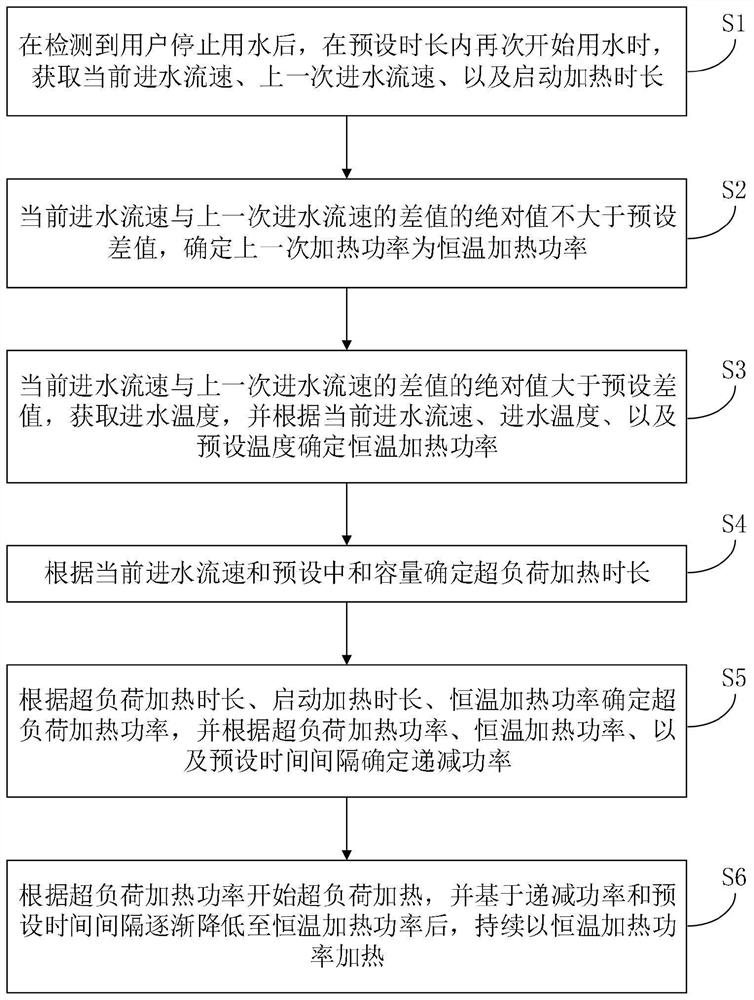

Quick constant-temperature control method for secondary water use of gas water heater

The invention discloses a quick constant-temperature control method for secondary water use of a gas water heater, which comprises the following steps: S1, in the case of secondary water use of a user, the interval time deltat between a current water use point and a last water use end point is calculated; S2, whether the interval time deltat is smaller than or equal to preset time ts or not is judged; S4, a fan is started, and an air valve is opened; S5, the last heating load is obtained, the ignition load is calculated through the last heating load, ignition is conducted through the ignitionload obtained through calculation, and the maintaining time is t1 after ignition succeeds; S6, switching to use the last heating load or the sum of the last heating load and the adjusting load is conducted for combustion for a period of time t2; S7, the heating load is adjusted through a PID algorithm; S8, whether a constant-temperature state is reached or not is judged continuously, if so, the current heating load is memorized and the step S9 is carried out, if not, the step S7 is returned; and S9, combustion is maintained until a user turns off water. By means of the technical scheme, rapidignition heating can be achieved, and the user bath experience is improved.

Owner:VATTI CORP LTD

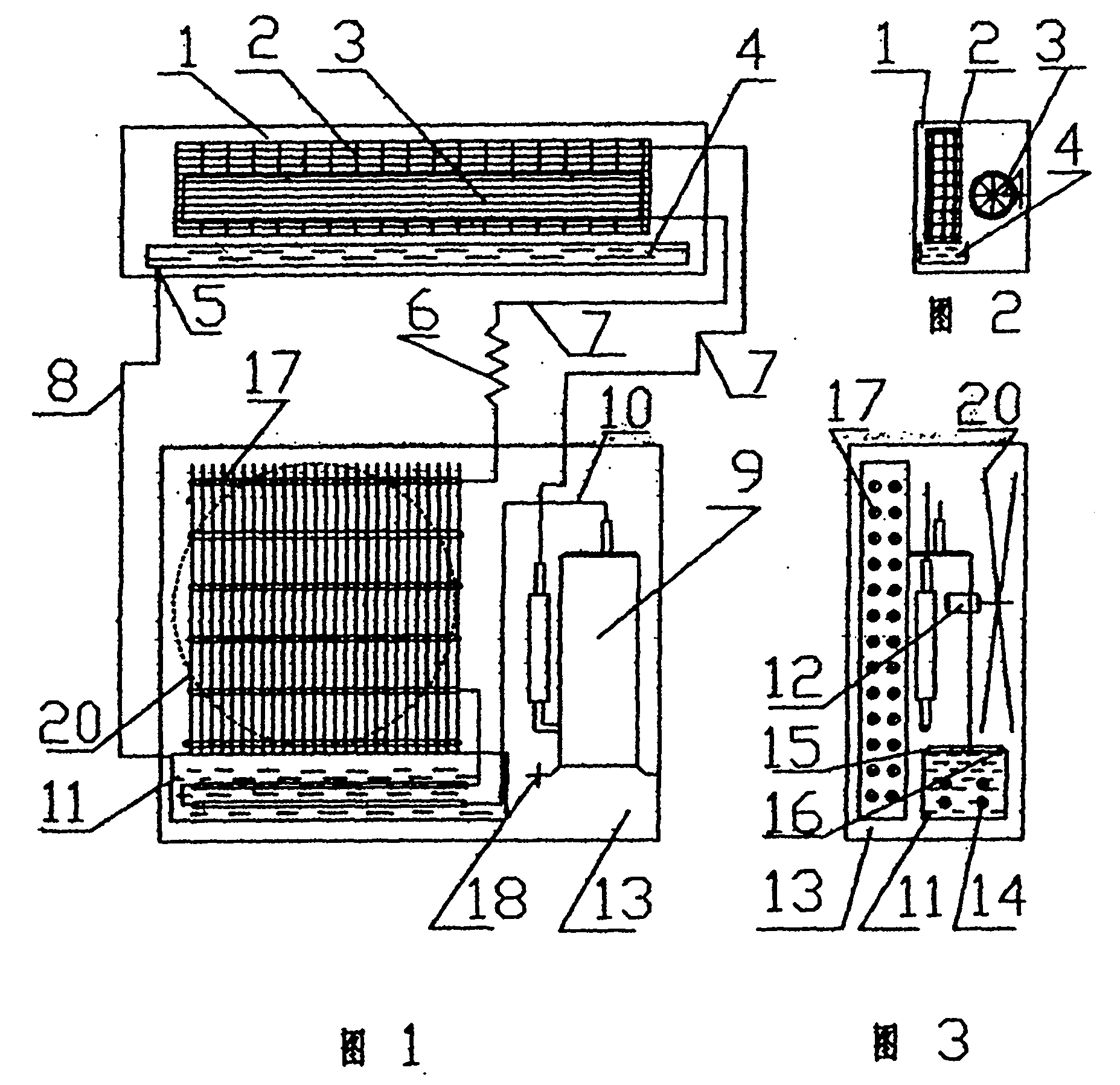

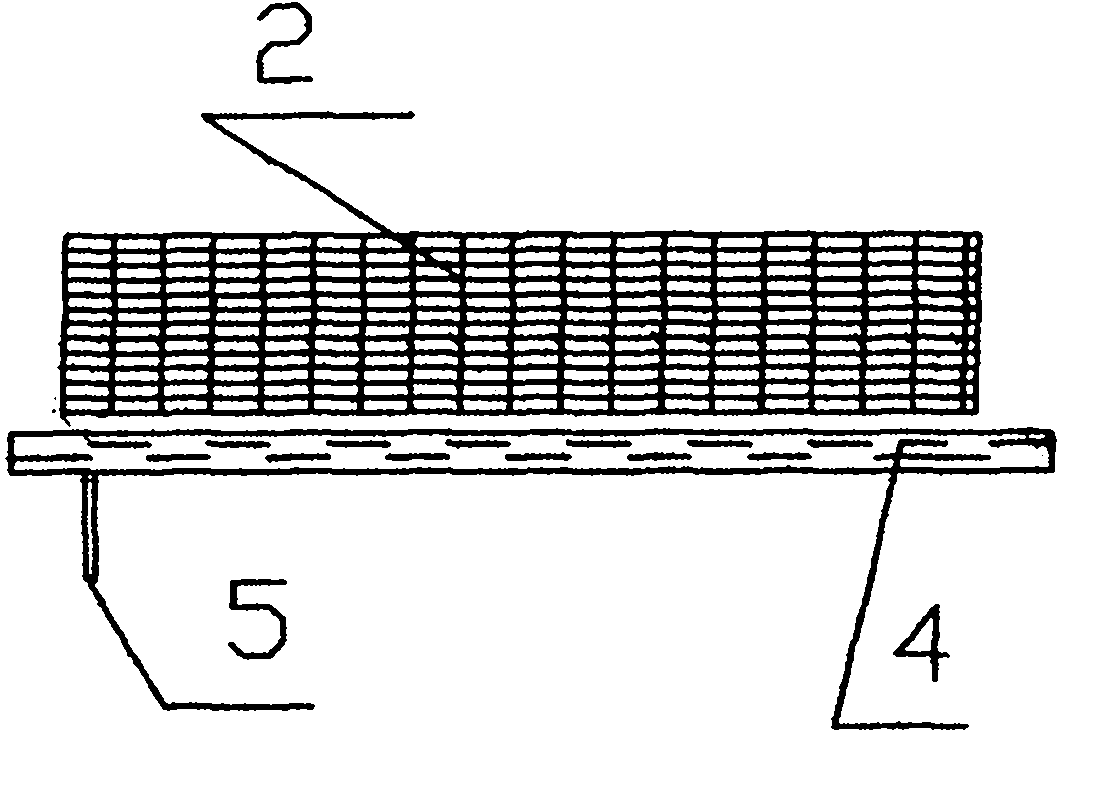

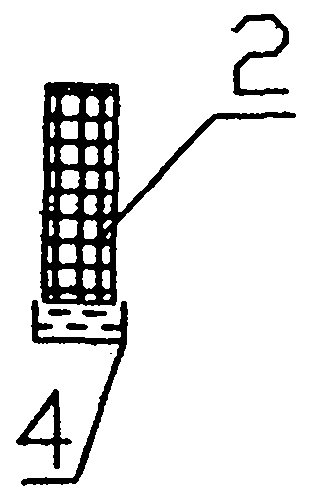

Water-leakage-free air conditioner

InactiveCN102434912ANo outflow phenomenonNo outflowCondensate preventionLighting and heating apparatusPipingRefrigerant

The invention discloses a water-leakage-free air conditioner and relates to the innovation of air conditioner structures. The air conditioner is an environment-friendly air conditioner which has the advantages of saving electric energy, reducing heat discharge capacity, improving refrigerating capacity and prolonging the service life of the air conditioner and does not leak water. The air conditioner comprises an indoor unit and an outdoor unit, wherein the indoor unit is provided with an evaporator, a fan, a water collecting disk and a water guide pipe; the outdoor unit is provided with a fan, a condenser and a compressor; and the compressor is connected with the evaporator, a capillary pipe and a condenser through pipelines respectively and is filled with a refrigerant. The air conditioner has structural features that the water collecting disk is arranged below the evaporator and is connected with an evaporation water tank in the indoor unit through the water guide pipe; a high-pressure exhaust pipe of the compressor is partially arranged in the evaporation water tank; and a front wind shield and a rear wind shield are arranged at the edge of the evaporation water tank.

Owner:路野

Cornus officinalis processing method

InactiveCN101317875AAdvantages of processing methodHigh content of active ingredientsDigestive systemUrinary disorderCooking & bakingCornus officinalis

The present invention relates to a processing method for cornels. The rinsed cornels are put into a hothouse and baked at the temperature ranging from 50 to 60 DEG C with water to separate cores. The cores are mechanically removed after being cooled, and then the cornels without cores are put into the hothouse and the temperature is controlled below 70 DEG C. The finished product is obtained after the cornels are dried for 5 to 6h. The sarcocarps and cores are separated by adopting the baking technology in the processing method of cornel of the present invention. Content of active ingredient of the processed cornel can be improved by 30%; The baking dryness technology is adopted and the dried finished product is bright in color and good in taste with mild medicine incense. By adopting the processing method of the present invention, the fresh fruit collected on the day can be dried and warehoused 10 hours later. The processing method is timesaving and labor saving. Furthermore, primary taste of active ingredient of the product is guaranteed.

Owner:JINCHENG SHANZHUYU DEV

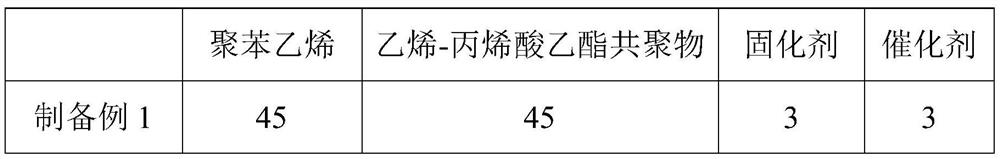

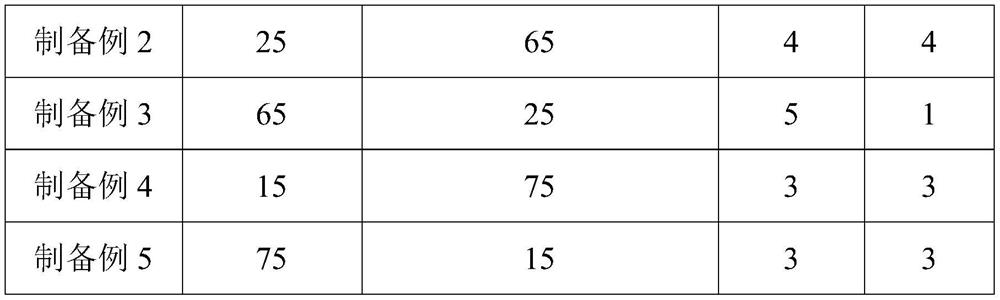

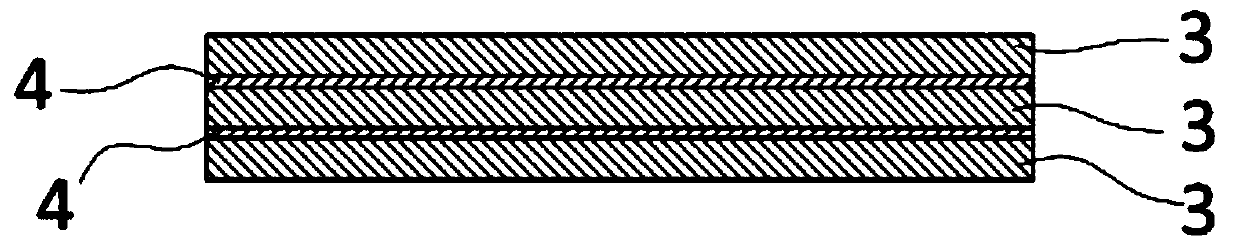

High-temperature-resistant composite expansion film as well as preparation method and application thereof

PendingCN112646505AGuaranteed high temperature performanceImprove temperature resistanceLamination ancillary operationsFilm/foil adhesivesElectrolytic agentPolystyrene

The invention provides a high-temperature-resistant composite expansion film as well as a preparation method and application thereof. The high-temperature-resistant composite expansion film comprises an expansion layer, a first bonding layer, a temperature-resistant layer and a second bonding layer which are sequentially arranged; and the temperature-resistant layer is made of a combination of polystyrene and an ethylene-ethyl acrylate copolymer. By selecting the combination of polystyrene and ethylene-ethyl acrylate copolymer with better expansion effect and temperature resistance as the temperature-resistant layer, the high-temperature-resistant composite expansion film has excellent expansion performance and high-temperature resistance, and can fill the gap between the battery cell and the shell after being soaked in an electrolyte and expanded, and the anti-vibration and anti-shaking stability of the battery is improved; and no shrinkage is generated under high-temperature baking at 90 DEG C, so that the safety of the battery can be ensured.

Owner:EVE HYPERPOWER BATTERIES INC +1

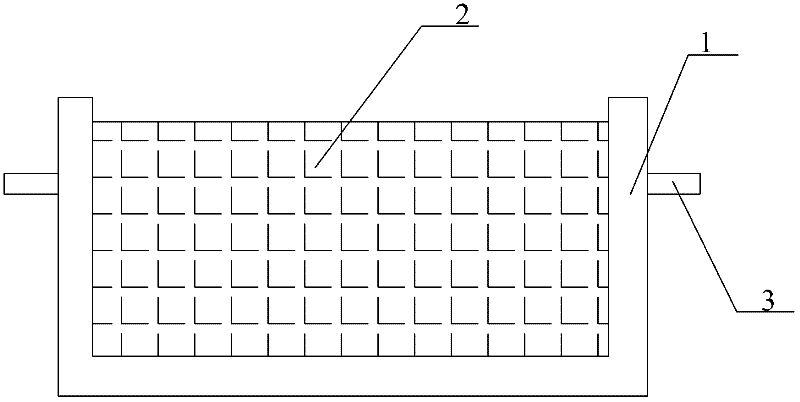

Integrated remediation device for heavy metal contaminated soil

InactiveCN107649509AEasy to collectNo wasteContaminated soil reclamationDrying gas arrangementsElutionEngineering

The invention discloses an integrated remediation device for heavy metal contaminated soil. The integrated remediation device comprises an elution box, a containing box, a spraying box, a liquid storage box, a drying box and a water collection box. The elution box is of a rectangular box-shaped structure without an upper surface. The upper end of the elution box is provided with the spraying box.The left end and the right end of the spraying box are fixedly provided with clamping edges correspondingly. The bottom face of the spraying box is provided with a plurality of spraying holes which are in same size and are arrayed at equal intervals. The integrated remediation device is internally provided with a filtering box separation device for muddy water, cleanout fluid and soil in the muddywater can be respectively discharged after being separated, the cleanout fluid and the soil in the muddy water are collected easily, and waste cannot be caused; a filtering plate below the containingbox of the device replaces quartz sand, the filtering plate can remove metal substances in the muddy water, the phenomenon that the quartz sand flows out along with the muddy water cannot occur, thewashing effect is relatively good; and the containing box is fixed to the elution box through a fixing plate, mounting and dismounting are convenient, soil can be put in and taken out conveniently, using is convenient, and the device is suitable for being popularized.

Owner:冯志强

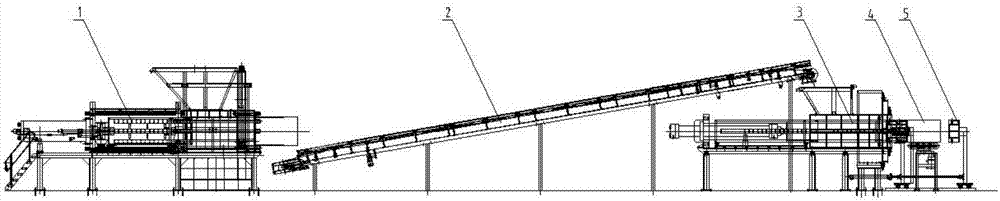

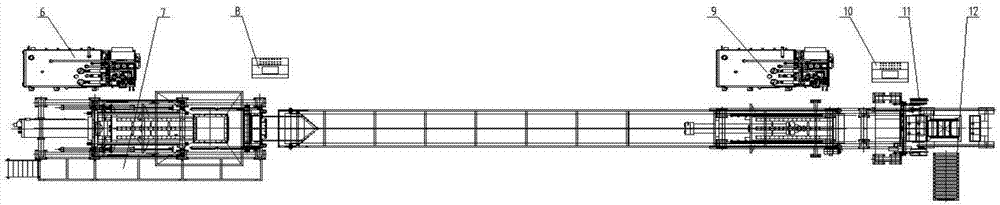

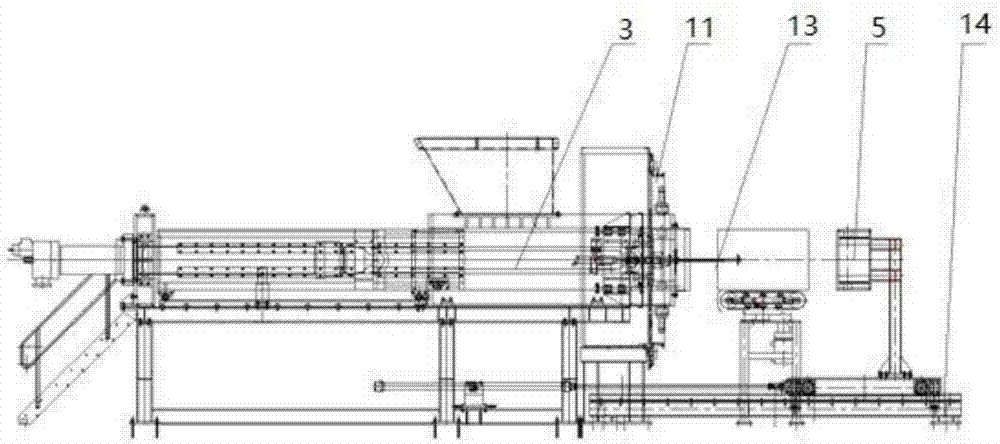

Extrusion forming and packaging machine and system for forming and packaging garbage

PendingCN107487011AGood workshop environmentReduce moisture contentWrapping material feeding apparatusWeb rotation wrappingBack pressureExtrusion

The invention provides an extrusion forming and packaging machine and system for forming and packaging garbage. The extrusion forming and packaging machine comprises a garbage forming machine and a wrapping film packaging machine body; a back pressure head capable of moving in the axial direction of the garbage forming machine is arranged at an outlet of an extrusion cavity of the garbage forming machine, and the back pressure head can be locked at or moved away from the outlet of the extrusion cavity of the garbage forming machine; and the back pressure head, an extrusion head and a wrapping head are matched to package a garbage bag from vertical faces, and the wrapping head and a belt conveyor are matched to package the garbage bag from planes. The extrusion forming and packaging machine and system for forming and packaging garbage have the beneficial effects that the unique design of the back pressure head and the extrusion head of the extrusion forming and packaging machine ensures packaging of the garbage bag and prevents the garbage bag from scattering; and meanwhile through accurate action cooperation of the back pressure head, the extrusion head and a film wrapping system, the garbage bag is discharged and packaged at the same time after being formed, scattering is avoided in the packaging process, and a wrapping film completely seals garbage blocks.

Owner:EGUARD NEW ENERGY AUTOMOBILE CO LTD

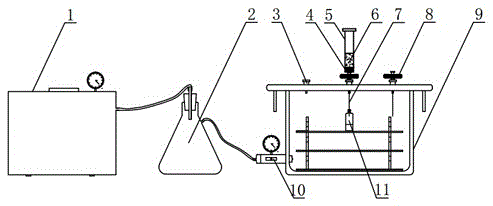

Desorption device for saxitoxin in macroporous resin and method of desorption device

ActiveCN105651575AAvoid residuePrevent dumpingPreparing sample for investigationDesorptionFiltration

The invention relates to a desorption device for saxitoxin in macroporous resin and a method of the desorption device. The desorption device comprises a vacuum pump and a solid-phase extraction instrument which are connected to the two ends of a transition bottle. A small column joint of the solid phase extraction instrument is connected with a microporus filter. A glass syringe is installed on the microporus filter. A filtering material layer is arranged at the bottom of the glass syringe. By means of the filtering material layer, macroporous resin can be effectively prevented from blocking the syringe. The method mainly includes the steps of flushing, moisture filtering, stirring, desorption, desorption solution collection and the like, filtering is completed at the same time during desorption, operation is easy, convenient and rapid, the time consumption is low, the steps of filtration and concentration can be omitted, and the use amount of a desorption solution can be effectively decreased.

Owner:ZHEJIANG UNIV

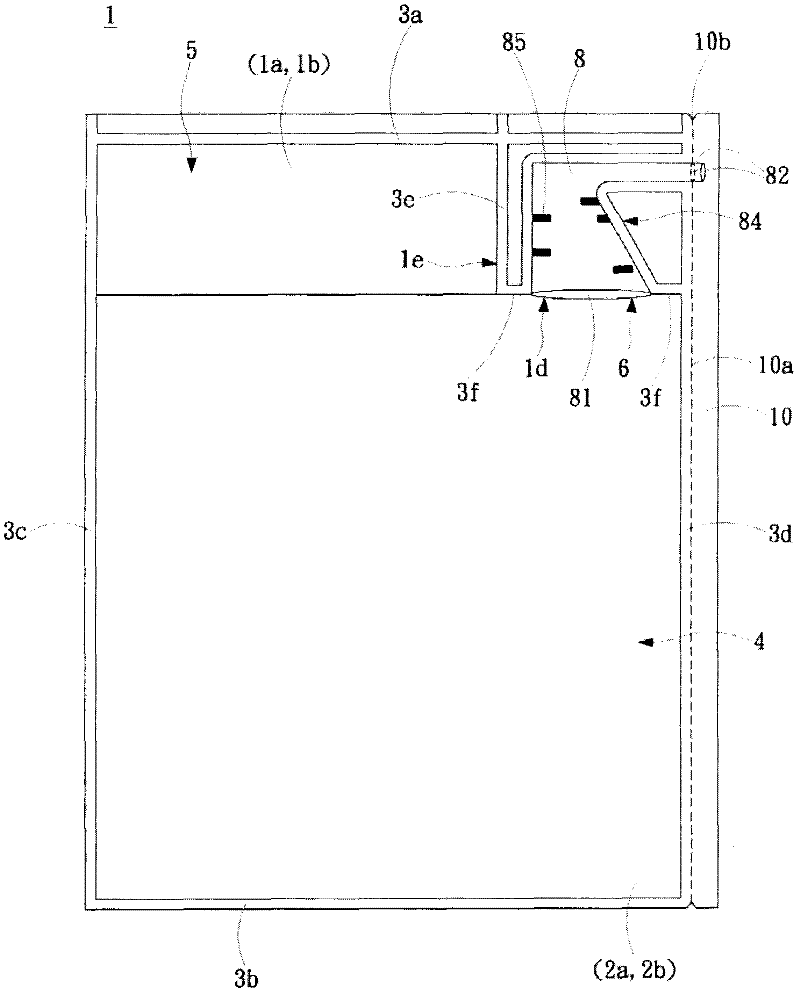

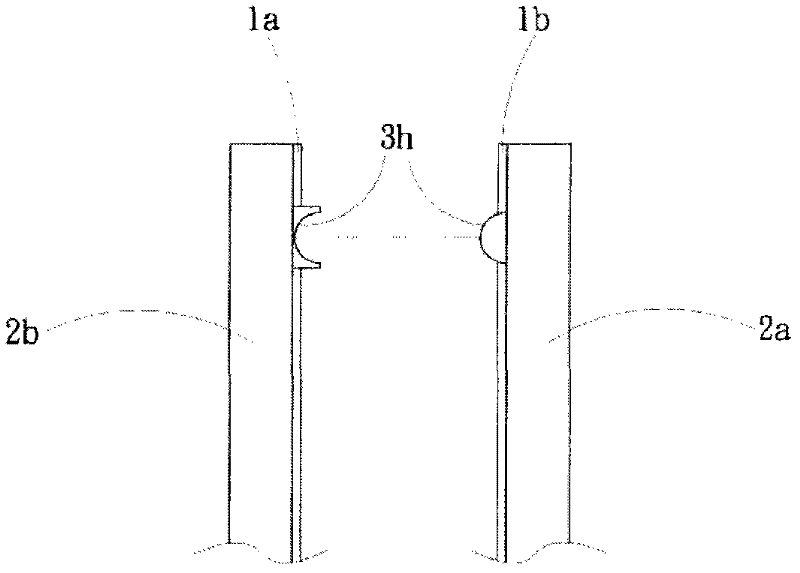

Cosmetics container with roll ball head

InactiveCN103190762AGood environmental stabilityNo outflowPackaging toiletriesPackaging cosmeticsCouplingEngineering

The invention discloses a cosmetics container with a roll ball head. The cosmetics container comprises a soft bag, wherein a coupling head is movably arranged in an opening of the soft bag; the outer end part of the coupling head is provided with a roll ball; a housing for limiting the position of the roll ball is coupled to the outer end part of the coupling head; the roll ball protrudes to the outer side of the outer end surface of the housing; and a runner for communicating the roll ball with the soft bag is arranged between the roll ball and the soft bag. The cosmetics container is characterized in that a spring enabling the coupling head to extend to the outer side of the opening of the soft bag is arranged in the opening of the soft bag; the coupling head in an extending state enables the runner to be in an unblocked state; the cosmetics container also comprises an end cap; the end cap is coupled at the opening of the soft bag and is capable of overcoming the elastic force of the spring so as to be used for pressing the coupling head towards the inner side of the opening of the soft bag; and the pressed coupling head enables the runner to be in a blocked state. According to the cosmetics container, cosmetics can not leak when the cosmetics container is carried, and therefore, the cosmetics can be conveniently carried when a user goes out.

Owner:郑春根

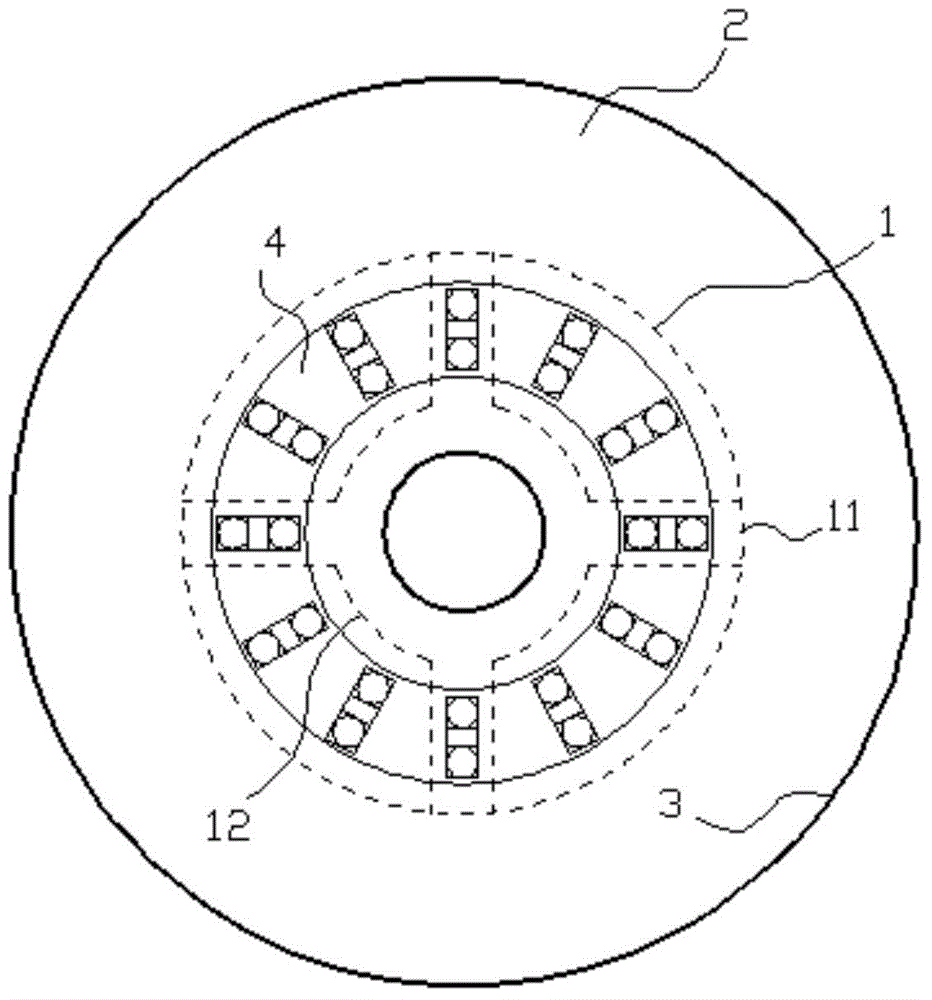

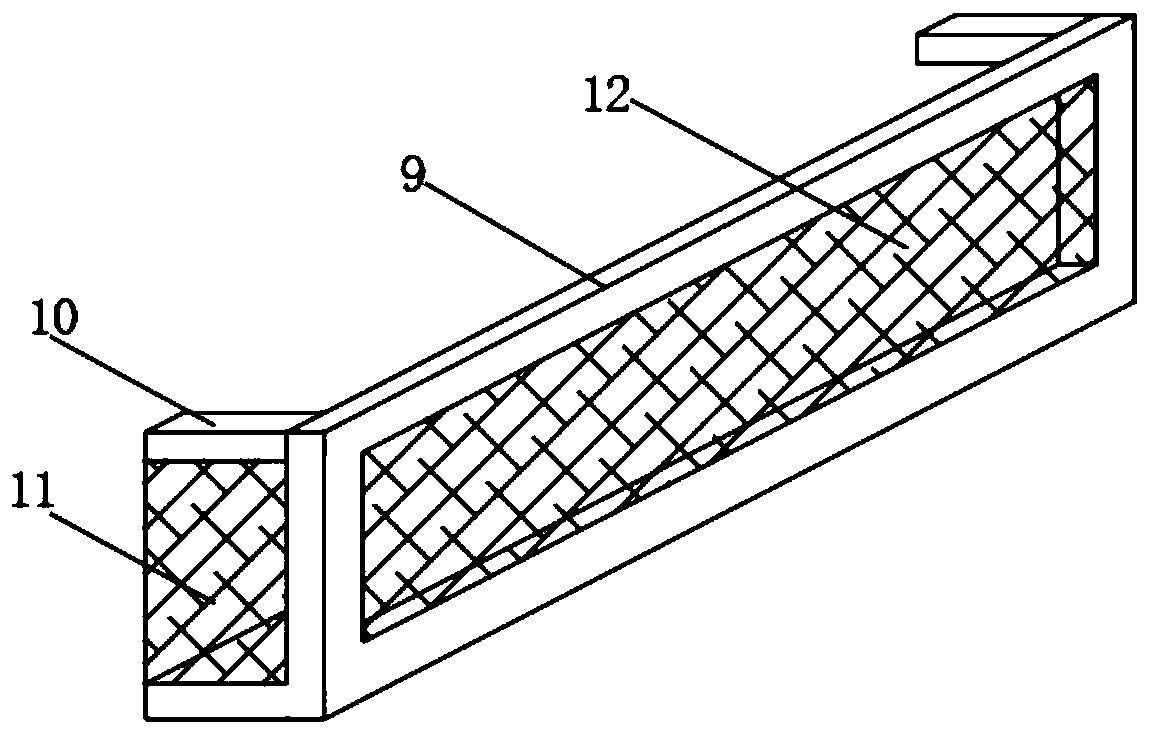

Dust removal ring of electric hand drill

ActiveCN104626071AGuaranteed circulationNo outflowPortable power-driven toolsPortable drilling machinesRubber ringEngineering

The invention relates to a dust removal ring of an electric hand drill. The dust removal ring of the electric hand drill mainly comprises a rotary ring and a hollow-inside dust collection ring, the dust collection ring is sleeved with the outer peripheral wall of the rotary ring, and the outer peripheral wall of the rotary ring is formed of a hard dustproof mesh. A rubber ring is attached to the inner peripheral wall of the rotary ring, and the internal diameter of the rubber ring is matched with the size of an electric hand drill bit. Centrifugal holes extending along the rotary ring axially are distributed on the circumference of the rotary ring at equal distance, the centrifugal holes penetrate the rubber ring and the outer peripheral wall of the rotary ring and communicated with the internal cavity of the dust collection ring, and the diameter of the centrifugal holes is not smaller than the width of a threaded groove of the drill bit. The dust removal ring is simple in structure, convenient to mount and free of external power source, chippings and dust of drill holes can be efficiently collected, and dust can be prevented from polluting the environment.

Owner:河北鸿嘉环保设备有限公司

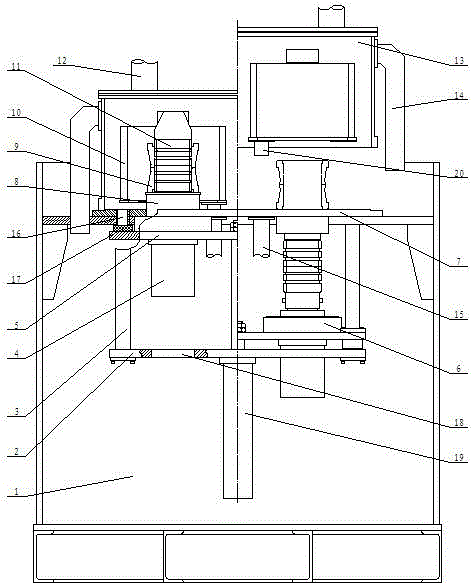

Railway bearing inner race mold retaining quenching device

ActiveCN104357624AReasonable structureIncrease the level of automationFurnace typesHeat treatment furnacesProduction lineFuel tank

The invention relates to a quenching device, and particularly to a railway bearing inner race mold retaining quenching device. The device comprises an oil tank, a worktable mounted inside the oil tank, a quenching mold mounted on the worktable and an quenching oil cover mounted at the upper part of the oil tank, and is characterized in that a fixing plate, a guiding rod and a supporting plate form an overall frame below the worktable; the quenching mold is mounted on the supporting plate; the quenching mold moves up to be inserted into an inner hole of a quenched workpiece and is used for implementing a quenching process in a closed quenching space formed by the quenching oil cover and the worktable. The quenching mold can move up to the surface of the worktable, so the mold is quite convenient, safe, clean and rapid to install and regulate, and the mold installation and regulation time is greatly shortened; compared with the prior art, the device can be used for reducing the production assistance time by more than 80%; meanwhile, no oil liquid overflows during the quenching process, and the device is environmentally friendly and quite applicable to ancillary use of large-batch thermal treatment production lines.

Owner:NINGXIA MACHINERY RES INST

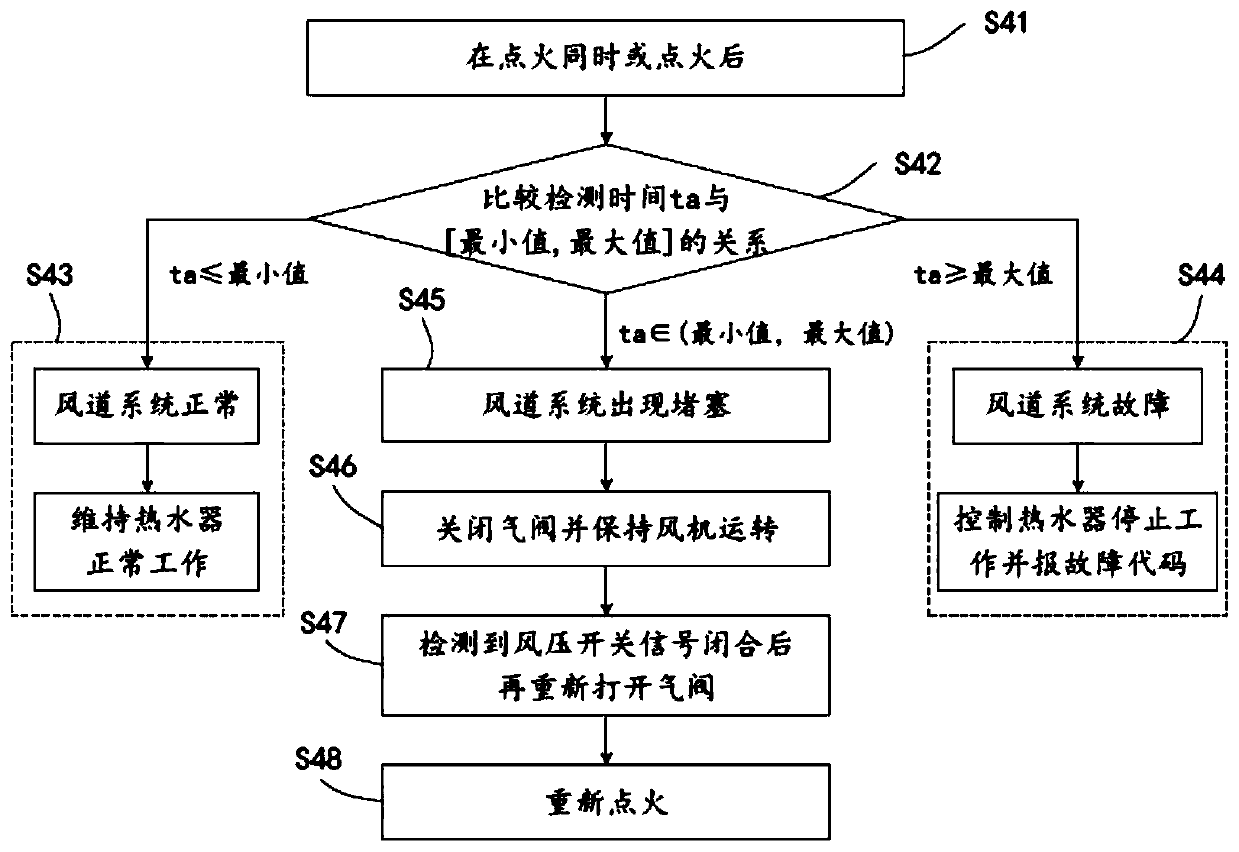

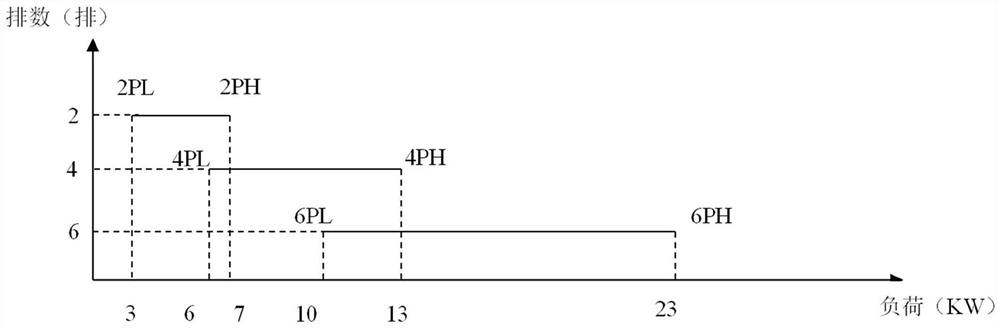

Gas water heater and control method thereof

ActiveCN113983696AEnhance bathing experienceNo outflowControl of fluid heatersWater useThermodynamics

The invention relates to a gas water heater and a control method thereof. The method comprises the steps that after it is detected that a user stops using water, when water is started again within a preset duration, the current water inlet flow speed, the last water inlet flow speed and the heating starting duration are obtained; the constant-temperature heating power is determined according to the difference value between the current water inlet flow speed and the last water inlet flow speed; the overload heating duration is determined according to the current water inlet flow speed and the preset neutralization capacity; the overload heating power is determined according to the overload heating duration, the starting heating duration and the constant-temperature heating power, and the decreasing power is determined according to the overload heating power, the constant-temperature heating power and a preset time interval; and overload heating is started according to the overload heating power, the power is gradually reduced to constant-temperature heating power based on the decreasing power and the preset time interval, and continuous heating is performed at the constant-temperature heating power. According to the embodiment of the invention, heating is carried out in the overload heating stage and the power is decreased progressively, so that the constant-temperature time of starting and the water outlet temperature fluctuation are reduced.

Owner:VATTI CORP LTD

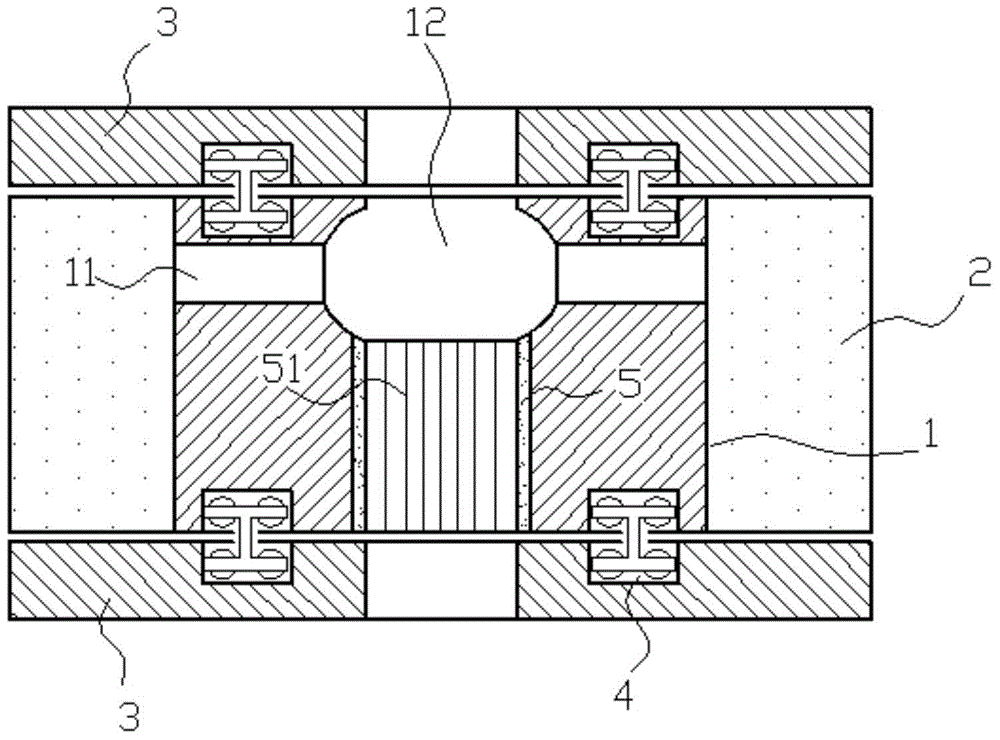

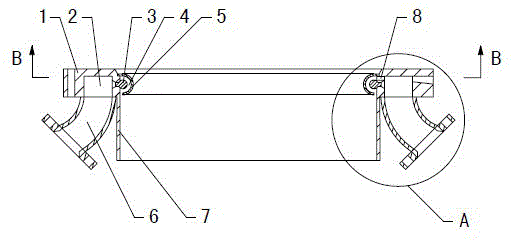

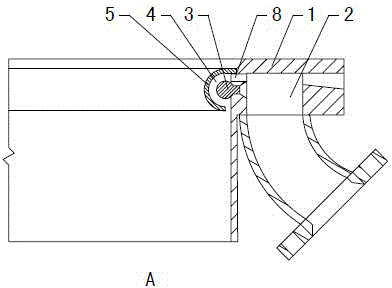

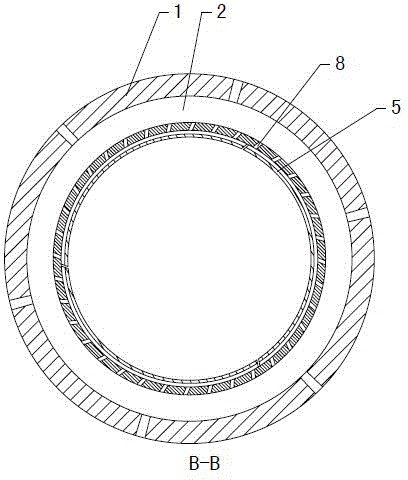

Processing method of gasification furnace quenching ring

ActiveCN105316045AHigh hardnessImprove erosion resistanceCombustible gas productionSpray coatingAlloy

A processing method of a gasification furnace quenching ring. The invention relates to the processing method of a coal water slurry gasification furnace quenching ring. The processing method includes the steps of: (A) firstly producing an outer ring tube (5), a chamber base (1), a water distribution inner ring (3) and a cylinder body (7) and fixedly connecting the chamber base (1), the water distribution inner ring (3) and the cylinder body (7), wherein a plurality of water distribution holes (8) are formed in the chamber base (1) above the water distribution inner ring (3); (B) spray-coating a hard alloy material onto the inner surface of the outer ring tube (5), the outer surface of the water distribution inner ring (3), and a water outlet on the water distribution inner ring (3) to form spray coating layers; (C) cutting the outer ring tube (5) into at least three parts; and (D) sleeving the water distribution inner ring (3) by the outer ring tube (5) on the inner side in the radial direction and welding the outer ring tube (5) to the inner ring on the chamber base (1). The method improves anti-erosion property and increases service life of the quenching ring, reduces shut down times, overcomes waste of loss of raw materials due to shut down maintenance and change of a new quenching ring in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP

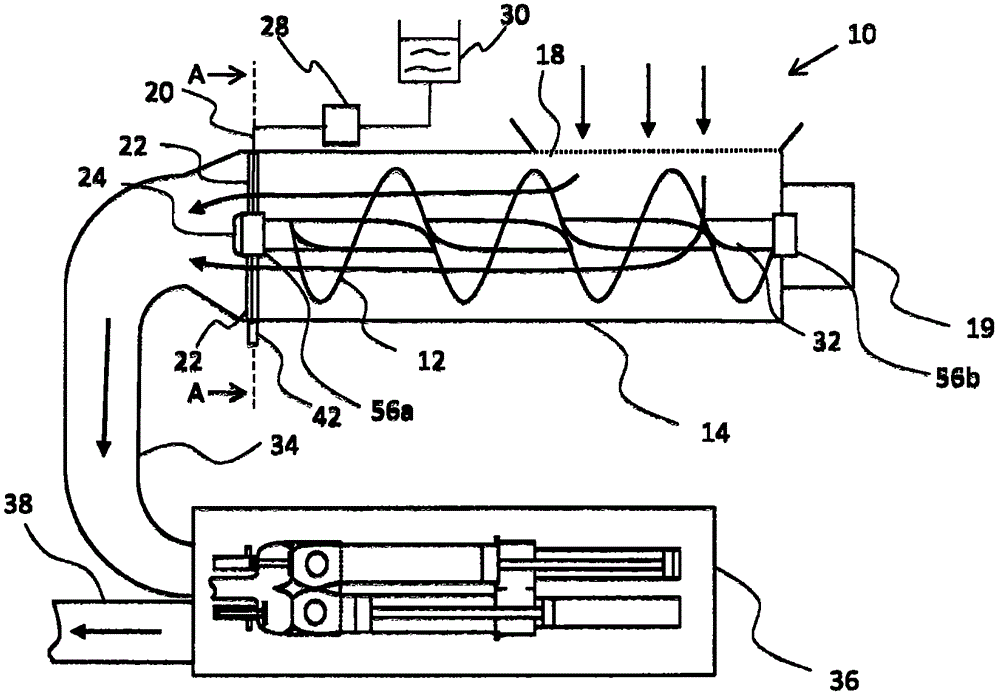

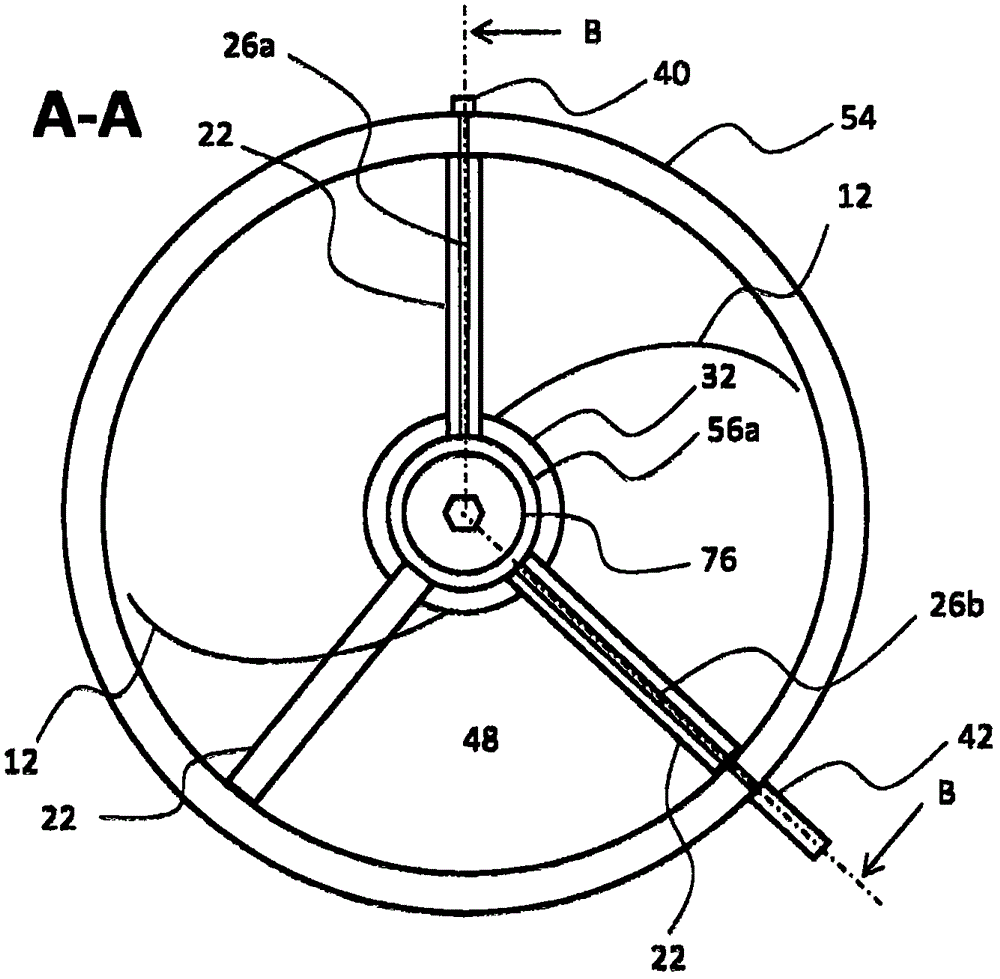

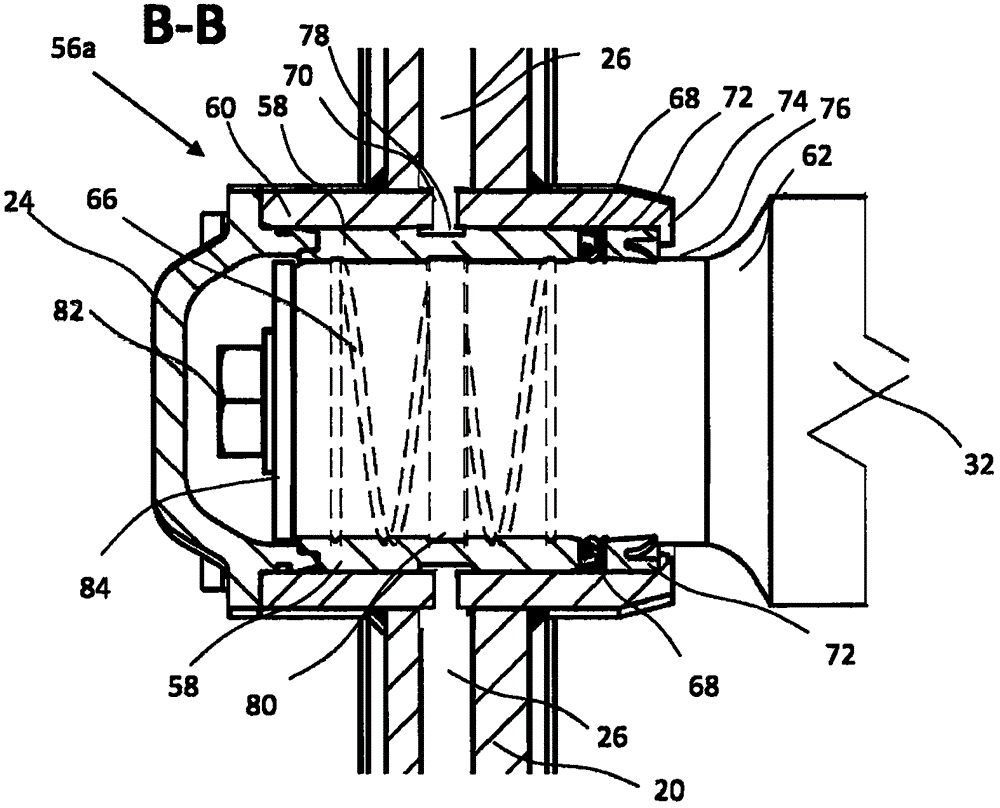

Mounting for a rotating shaft with sealing ring

ActiveCN106233012AGood sealingImprove sealingSpecific fluid pumpsPump componentsScrew conveyorEngineering

The invention relates to a bearing (56a, 56b) for mounting a rotating shaft (76) comprising a bearing housing (60) with an opening for accommodating a shaft (76) to be mounted, an inwardly oriented peripheral retaining collar (74) arranged on the edge of the opening, a bearing bush (58) arranged in the bearing housing (60), and a sealing ring (72) arranged in the bearing housing (60) between the bearing bush (58) and the retaining collar (74), which sealing ring abuts the rotating shaft (76) in a sealing manner. According to the invention, the sealing ring (72) has a sealing lip (72c) angled away from the bearing bush (58), oriented axially and tapering to a point at its free end, which sealing lip forms a contact surface of the sealing ring (72) on the shaft (76) to be mounted. The invention can be used in particular in conveying devices for high-density materials, e.g. in a screw conveyor, in which the sealing of the bearing is to be guaranteed against a conveyed medium penetrating from outside.

Owner:FRIEDRICH WILH SCHWING GMBH

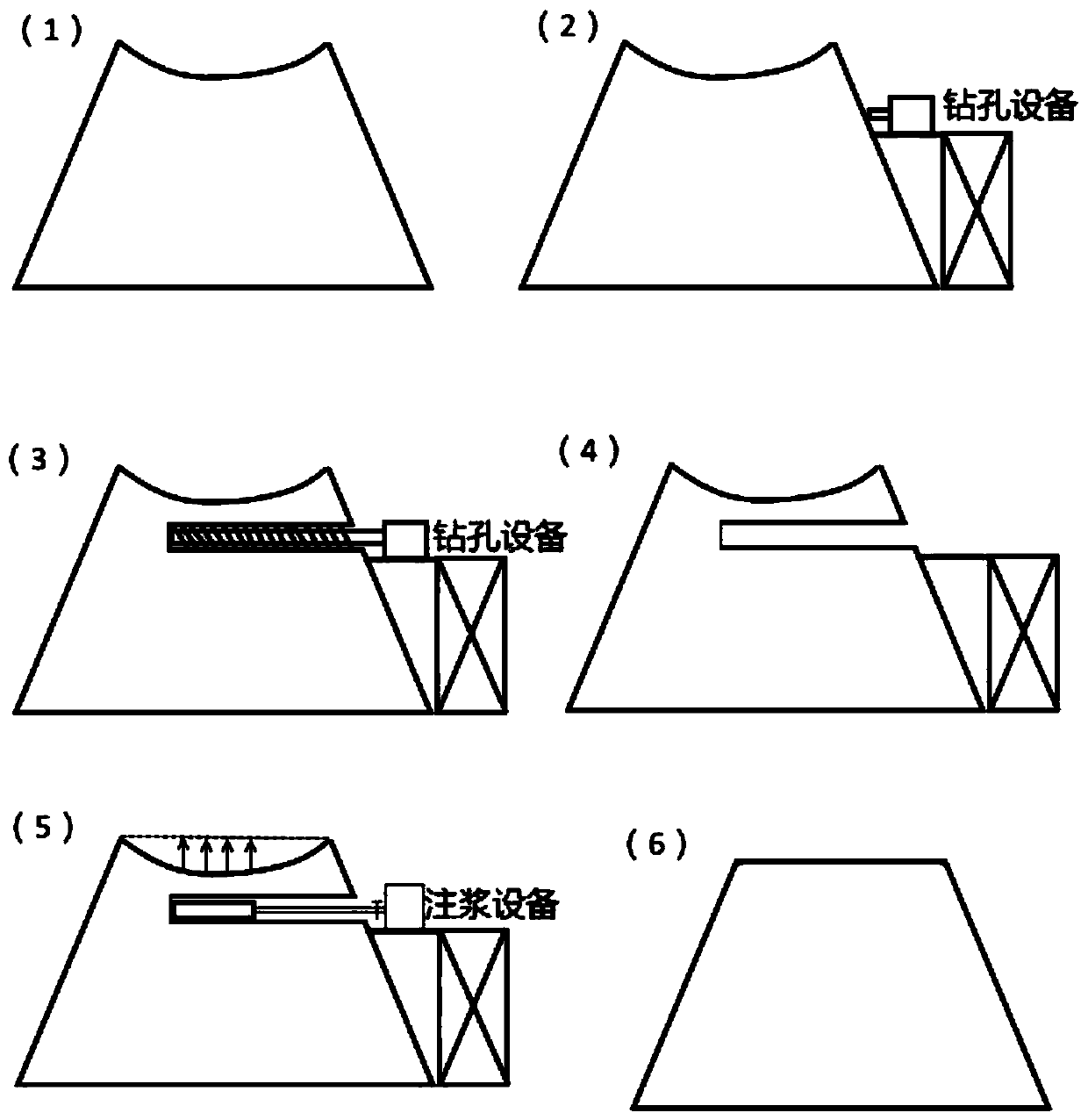

Roadbed settlement treatment method

The invention belongs to the technical field of road construction, and particularly relates to a roadbed settlement treatment method. The method specifically comprises the steps of (1) building a roadbed slope workbench, and putting construction equipment in place, wherein the construction equipment comprise drilling equipment and grouting equipment; (2) conducting radial drilling on the roadbed slope through the drilling equipment according to the roadbed settlement position; (3) putting a settlement compensation device into the hole; and (4) injecting high-pressure grout into the settlementcompensation device through the grouting equipment, wherein the volume of the settlement compensation device is expanded, the settlement part is jacked up, settlement compensation is completed after the high-pressure grout is solidified, and roadbed settlement is eliminated. The core of the method is punching, device placement, grouting expansion and extrusion lifting. The method is a brand-new technology, the traditional concept of mainly reinforcing is changed, the concept of compensating settlement to offset settlement is proposed for the first time, and meanwhile, a brand-new airbag deviceis adopted for construction and is proposed for the first time in related fields.

Owner:陕西融创交通科技有限公司

Liquid spray gun

InactiveCN106111379AChange pressureChange sizeSpray nozzlesLiquid spraying apparatusAir pumpEngineering

The invention discloses a liquid spray gun. The liquid spray gun comprises a spray head shell, a spray cap, a nozzle, a liquid channel and a gas channel; one side of the front end of the spray head shell is detachably provided with the nozzle; the outer side of the nozzle is connected with the spray cap through a screw thread; an opening communicating with a nozzle orifice of the nozzle is formed in the front end of the spray cap; and the nozzle respectively communicates with the liquid channel and the gas channel. According to the liquid spray gun disclosed by the invention, the distance between the opening in the front end of the spray cap and the nozzle orifice of the nozzle is regulated through the screw thread, so that the pressure of a liquid sprayed by the nozzle and the volume of the sprayed liquid are changed, and the sprayed liquid is good in atomized quality and uniform in spray, and no liquid drops flow out; both the spray cap and the nozzle can be dismounted, so that the spray cap and the nozzle are conveniently replaced, and the inside liquid channel is conveniently cleaned; a liquid cup is replaceably connected so that the liquid spray gun disclosed by the invention can be suitable for spraying for different purposes; and an air pump shell is detachably connected with the spray head shell, so that the liquid spray gun is conveniently carried, and the inside channels are conveniently cleaned.

Owner:NINGBO HAOSHENG PNEUMATIC MACHINERY

Drip-irrigation maintenance method for shield work shaft lining wall

InactiveCN110486035AReduce workloadAvoid Wall Maintenance InterruptionsUnderground chambersTunnel liningMaintenance modeWater pipe

Owner:CCCC FIRST HARBOR ENG +1

Process for producing polyester film

InactiveCN1374189ANot easy to produceNo outflowCircuit susbtrate materialsMultilayer circuit manufactureEpoxyPolyester

The invention provides a method for producing a polyester film, the method sequentially carries out (a) the process of immersing the glass fiber matrix material in a solvent; (b) the process of immersing the glass fiber matrix material impregnated with the solvent in an epoxy resin; (c) the process of heating the glass fiber matrix material impregnated with epoxy resin; (d) the process of further impregnating the glass fiber matrix material impregnated and cured with epoxy resin in epoxy resin; (e) heating the impregnated The glass fiber matrix material process of epoxy resin, the reaction rate of the inner layer epoxy resin is more than 85%, and the reaction rate of the outer layer epoxy resin is less than 60%. As a result, the laminated board or multilayer circuit board after molding has excellent board thickness accuracy, and a prepreg film excellent in formability can be stably and reliably produced.

Owner:SUMITOMO BAKELITE CO LTD

Liquid retaining bag

A liquid retaining bag comprises two outer membranes, two inner membranes, a storage area, a discharging way, bent portions, inlets, an outlet and a tearing part, wherein the bent portions, the inlets and the outlet are arranged in the discharging way. The storage area is formed by connecting the two outer membranes by means of heat sealing, the two inner membranes are positioned between the two outer membranes, the two outer membranes are connected with the inner outer membranes by means of heat sealing to form the discharging way or the discharging way is connected with the inner membranes by means of heat sealing to form between the two inner membranes, the inlets and the outlet are formed by means of heat sealing of the inner faces of the two inner membranes in a disconnected manner, the tearing part is positioned on the lateral sides of the inner membranes and the outer membranes, and the tearing part is exposed outside the outlet of the discharging way after being separated from the two inner membranes. When the two outer membranes is extruded by external force, the outer membranes are extruded by liquid to be opened outward so that the inlets of the discharging way can be opened automatically, the liquid flows into the bent portions of the discharging way through the inlets and flows out through the outlet. When the external force is relieved, the liquid flows back to the storage area through the bent portions, reaction suction force is generated during dropping, the two inner membranes in the bent portions are mutually attached due to the suction force to close the discharging way, and the liquid stops flowing and cannot flow out of the bag.

Owner:KUNSHAN AIRBAG PACKING CORP

Constant-temperature drinking device

InactiveCN106551589AGuaranteed temperatureReduce the temperatureMetallic material coating processesDrinking vesselsEngineeringThermal water

Owner:嘉兴日昌汽车配件股份有限公司

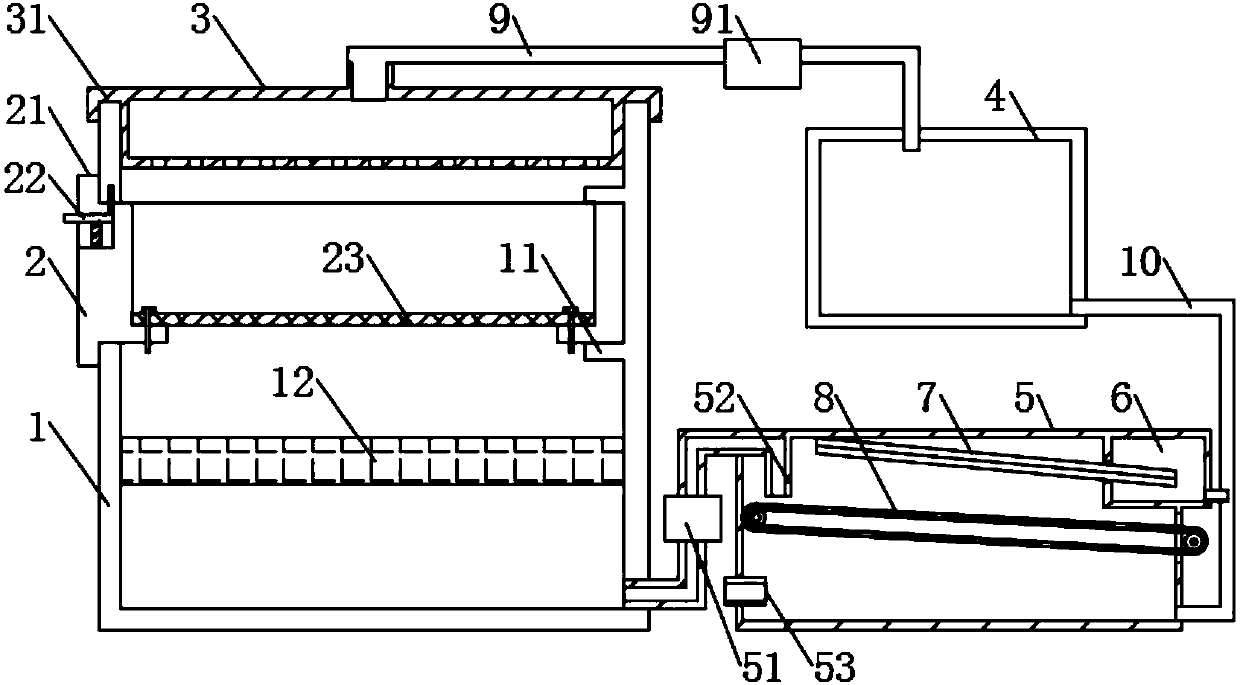

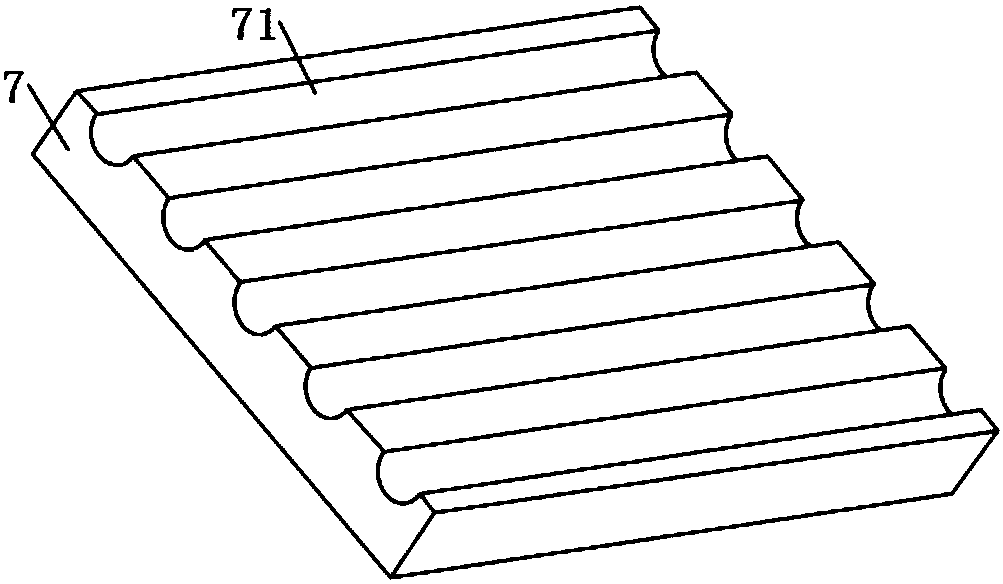

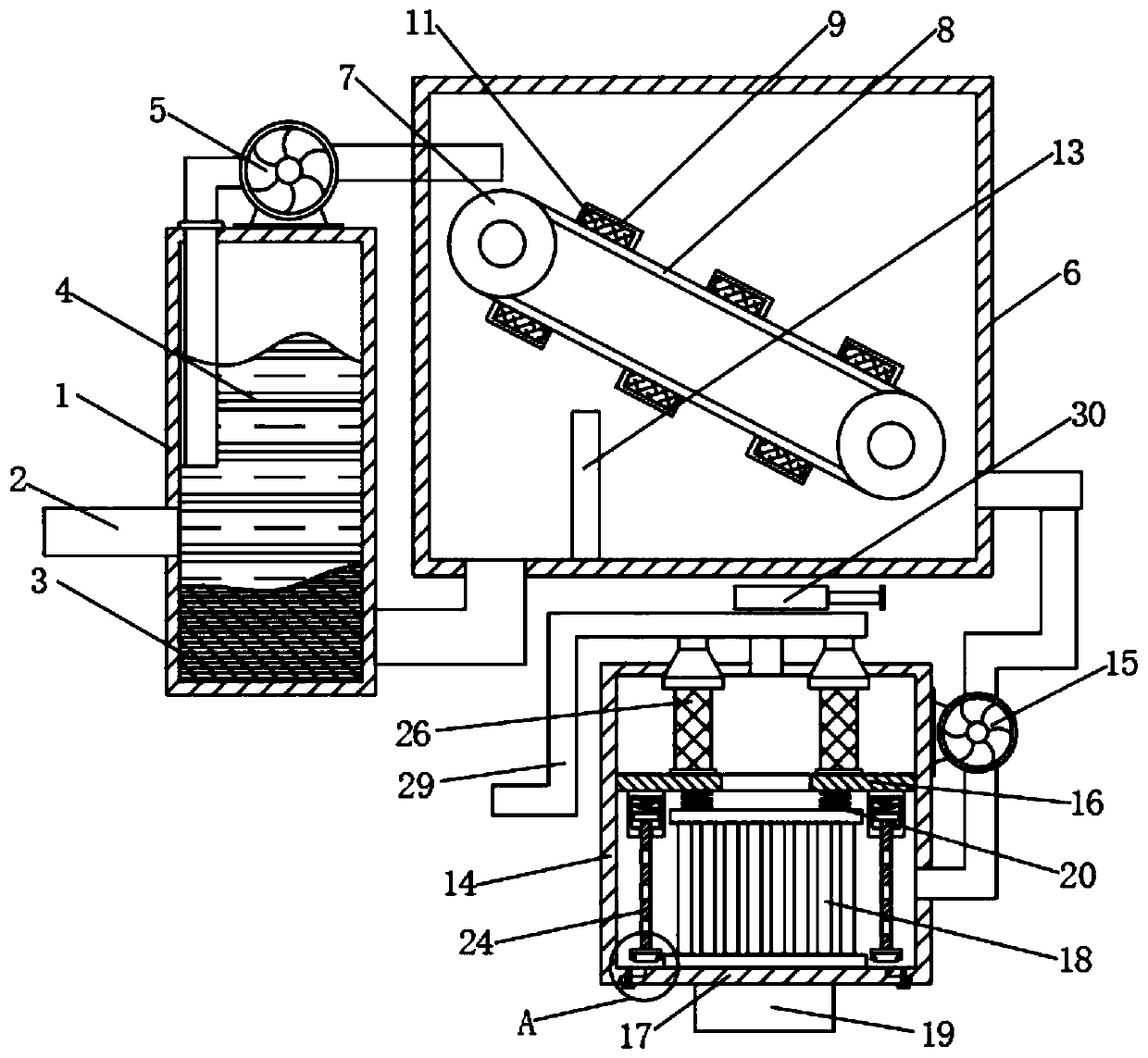

Small-scale domestic sewage treatment equipment

InactiveCN111423014AImprove filtering effectEasy to handleTreatment involving filtrationMultistage water/sewage treatmentSludgeTransmission belt

The invention relates to the technical field of domestic sewage treatment, and discloses small-scale domestic sewage treatment equipment. The equipment comprises a first box body, a second box body and a third box body, wherein the side wall of the first box body is fixedly connected with a sewage input pipe; a first pump body is fixedly mounted at the top end of the first box body; the output endof the first pump body is connected to the side wall of the second box body through a pipeline; and two rotating wheels are rotatably arranged in and connected with the second box body, a transmission belt is installed on the side walls of the two rotating wheels, an angle of 45 degrees is formed between the transmission belt and a horizontal plane, a fixed frame is fixedly connected to the outerwall of the transmission belt, and first filter screens are arranged at the front end and the rear end of the fixed frame. According to the small-scale domestic sewage treatment equipment, impuritiesand sludge can be well filtered, the situation that the filtering effect of the filter screens is poor due to gradual accumulation of filtered impurities is avoided, the using period of a filtering device is guaranteed to be long, and the size of a sewage filtering flow can be changed through the pump body.

Owner:钱进

Chroming production equipment without chromium containing waste emission

The invention discloses chroming production equipment without chromium containing waste emission. A chroming groove, a cleaning device, a chromic acid recycling device, a waste treatment device, an acid resisting liquid pump and a chroming chamber are included. The chroming groove communicates with the cleaning device, the chromic acid recycling device and the waste treatment device through a pipeline. The chromic acid recycling device comprises a gas collecting hood, a gas conveying device, a recycling tower, a centrifuge machine and a neutralization tower. The waste treatment device comprises a center groove, a circulation liquid pump, a filter, a recycling box, a filter press and an air pump. The acid resisting liquid pump is arranged on a pipeline between a first-level cleaning grooveand the recycling tower. The chroming chamber is connected with the recycling tower through a pipeline. According to the chroming production equipment, through the chroming groove, the cleaning device, the chromic acid recycling device, the waste treatment device, the acid resisting liquid pump and the chroming chamber, material balance can be controlled, and chrome containing waste water is not generated; and in the chromic acid recycling device, the character that cooling is conducted on chrome mist for adsorption of chromic acid is utilized, the chromic acid recycling capability is improved, and gas emission reaches the standard.

Owner:黄蕊

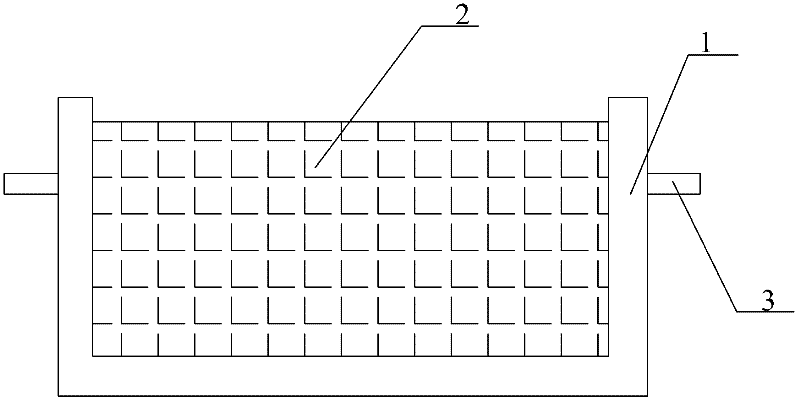

Sandbox for molding front cover of automobile

InactiveCN102363206ANo outflowThere will be no safety accidents caused by burnsMoulding flasksSocial benefitsEconomic benefits

The invention relates to a sandbox for molding a front cover of an automobile. The sandbox is characterized in that: the sandbox comprises a box body; the top of the box body has an open structure; and a coarse sand layer is filled in the box body. The sandbox of the invention, which has the advantages of simple structure and convenient usage and allows deficiencies of present production technologies to be overcome and production safety and raw material saving to be furthest guaranteed, has good economic benefits and social benefits.

Owner:解华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com