Process for producing polyester film

A manufacturing method and polyester film technology, applied in printed circuit manufacturing, multi-layer circuit manufacturing, electrical components, etc., can solve the problems of equipment investment, epoxy resin denaturation, increase in processing procedures, etc., and achieve accurate manufacturing plate thickness accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

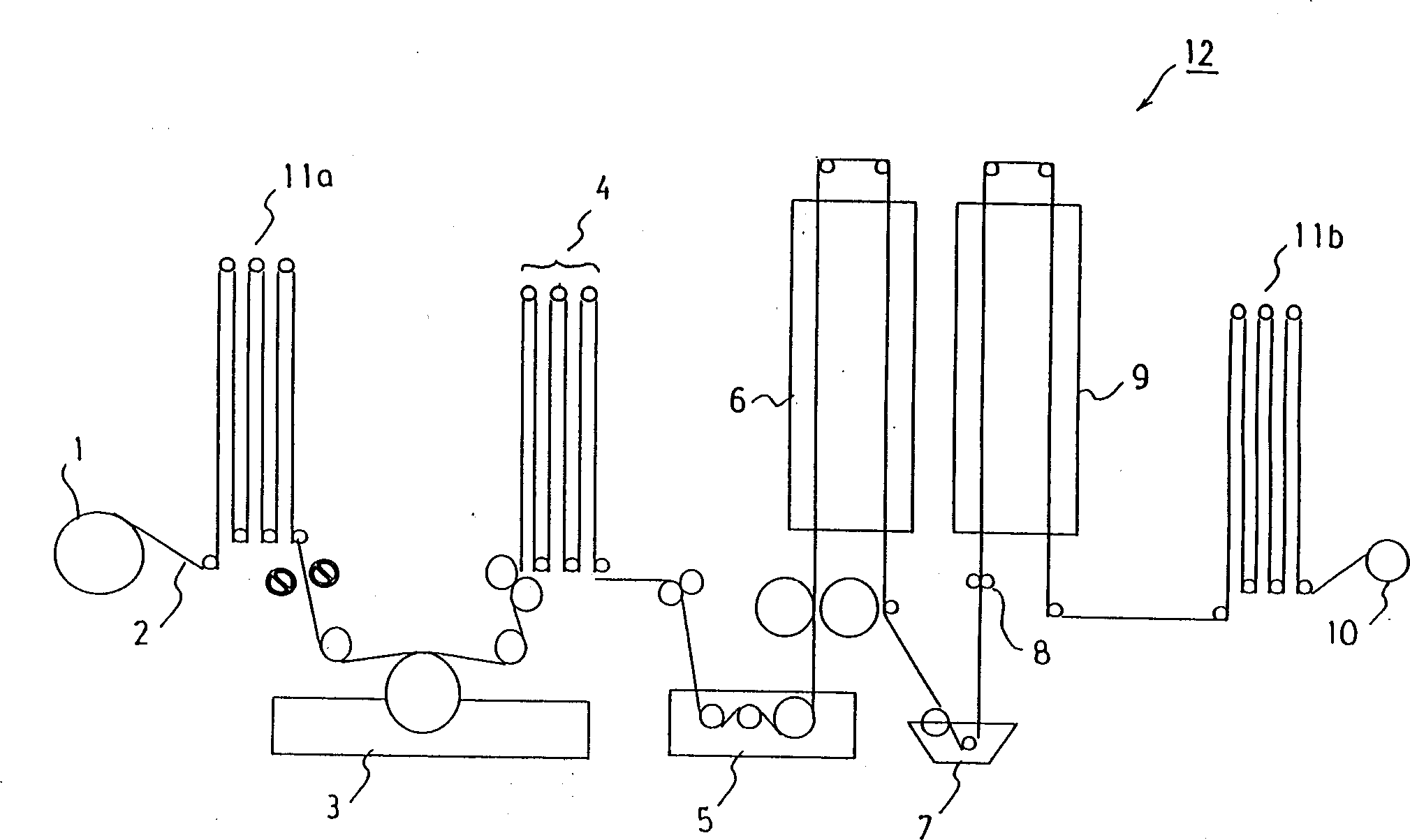

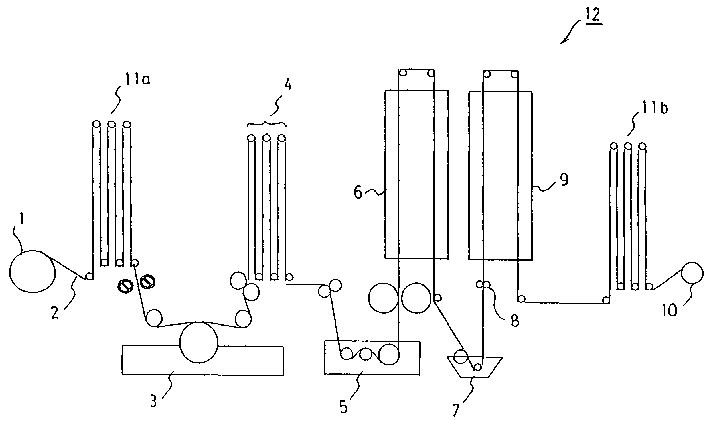

[0030] use figure 1 The polyester film manufacturing device shown is made of a polyester film composed of an inner layer impregnated with epoxy resin in a commercially available glass fiber woven cloth and an outer layer coated with epoxy resin on both sides of the inner layer. film.

[0031] In 100 parts by weight of methyl ethyl ketone, 70 parts by weight of a bisphenol A epoxy resin having an epoxy equivalent of about 450 and 30 parts by weight of a novolac epoxy resin with an epoxy equivalent of about 190 were dissolved. Add the solution of dissolving 3 parts by weight of dicyandiamide and 0.15 parts by weight of 2-phenol-4-methylimidazole in 20 parts by weight of dimethylformamide to this solution, stir and mix, and prepare the epoxy resin for glass weaving Varnish (I).

[0032] 35 parts by weight of bisphenol A type epoxy resin of about 450 epoxy equivalents, 35 parts by weight of bisphenol A type epoxy resins of about 2000 of epoxy equivalents, and about 210 of ep...

Embodiment 2

[0037] Except that the epoxy resin varnish (I) is replaced in the (d) process, and the epoxy resin varnish (II) is used to form the outer layer b, the rest are the same as in Example 1, and the inner layer a and the inner layer A prepreg consisting of an outer layer b formed on both sides of layer a. As a result, the reaction rate of the inner layer a was 86%, and that of the outer layer b was 52%. Comparative example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com