Railway bearing inner race mold retaining quenching device

A technology of railway bearings and quenching devices, which is applied in the direction of quenching devices, manufacturing tools, heat treatment equipment, etc., can solve the problems of extended production auxiliary time, narrow space, difficult adjustment, etc., achieve excellent quenching quality, reasonable structure, and improve the working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

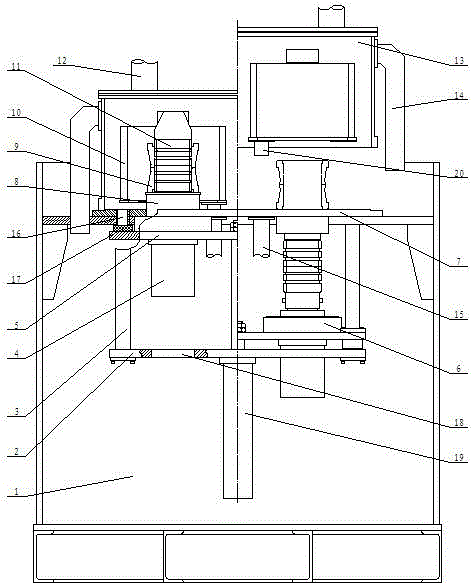

[0019] In the figure: 1—oil tank, 2—fixed plate, 3—guiding column, 4—mold cylinder, 5—supporting plate, 6—mold seat, 7—workbench, 8—workpiece supporting seat, 9—workpiece to be quenched, 10 - fuel injection ring, 11 - quenching mold, 12 - exhaust pipe, 13 - quenching oil cover, 14 - overflow pipe, 15 - oil inlet pipe, 16 - oil drain hole, 17 - gasket, 18 - mold cylinder hole, 19—supporting plate oil cylinder, 20 oil inlets.

[0020] Such as figure 1 As shown, the left side of the center line is the quenching station during the quenching process, and the right side of the center line is the pick-and-place workpiece station during the quenching process. The workbench 7 is horizontally installed in the oil tank 1, the guide column 3 is fixed on the lower plane of the workbench, the fixed plate 2 is installed at the lower end of the guide column, and the bracket that can move up and down along the guide column is installed between the fixed plate and the workbench. Plate 5, a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com