Patents

Literature

49results about How to "Reduce production auxiliary time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

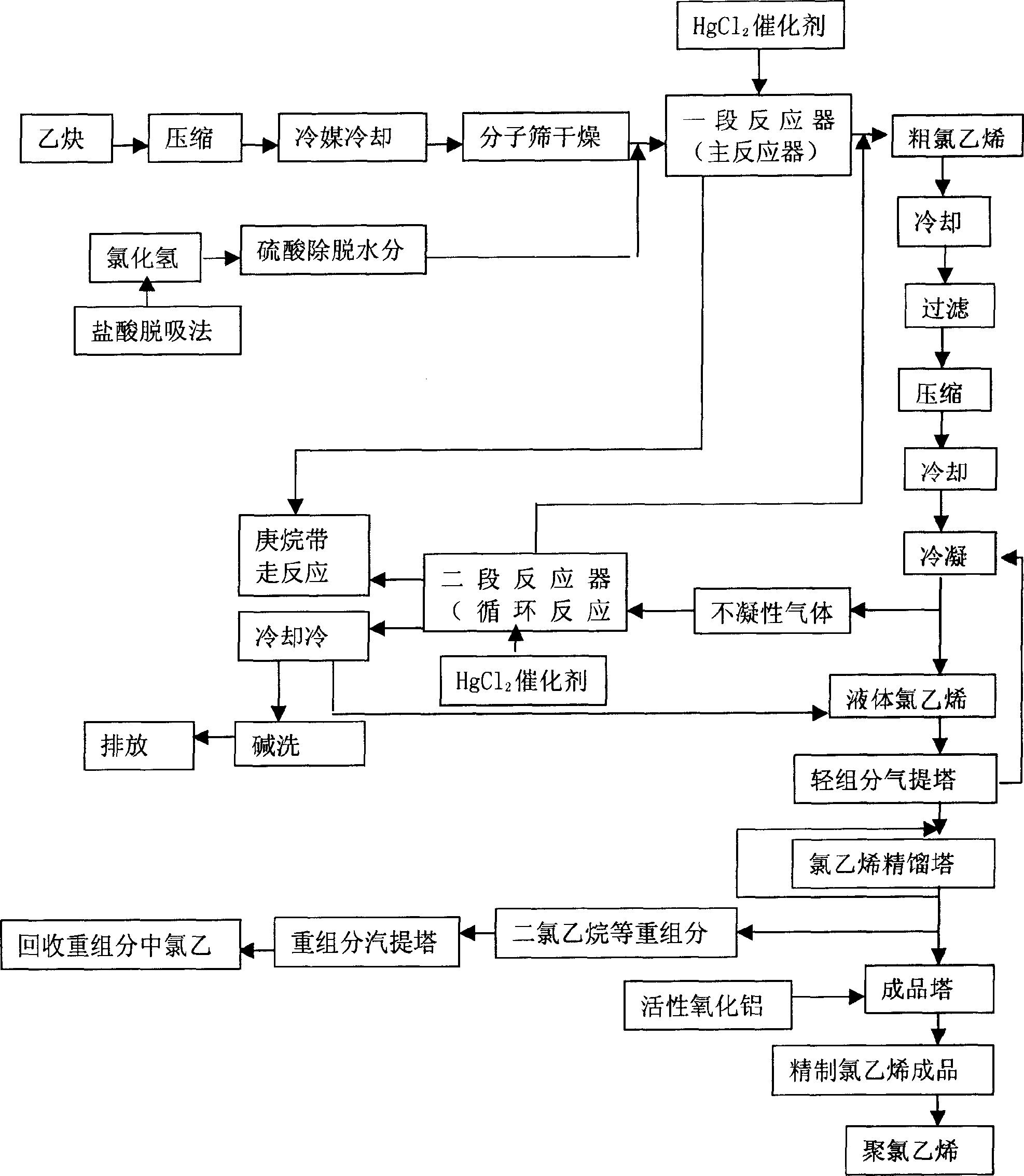

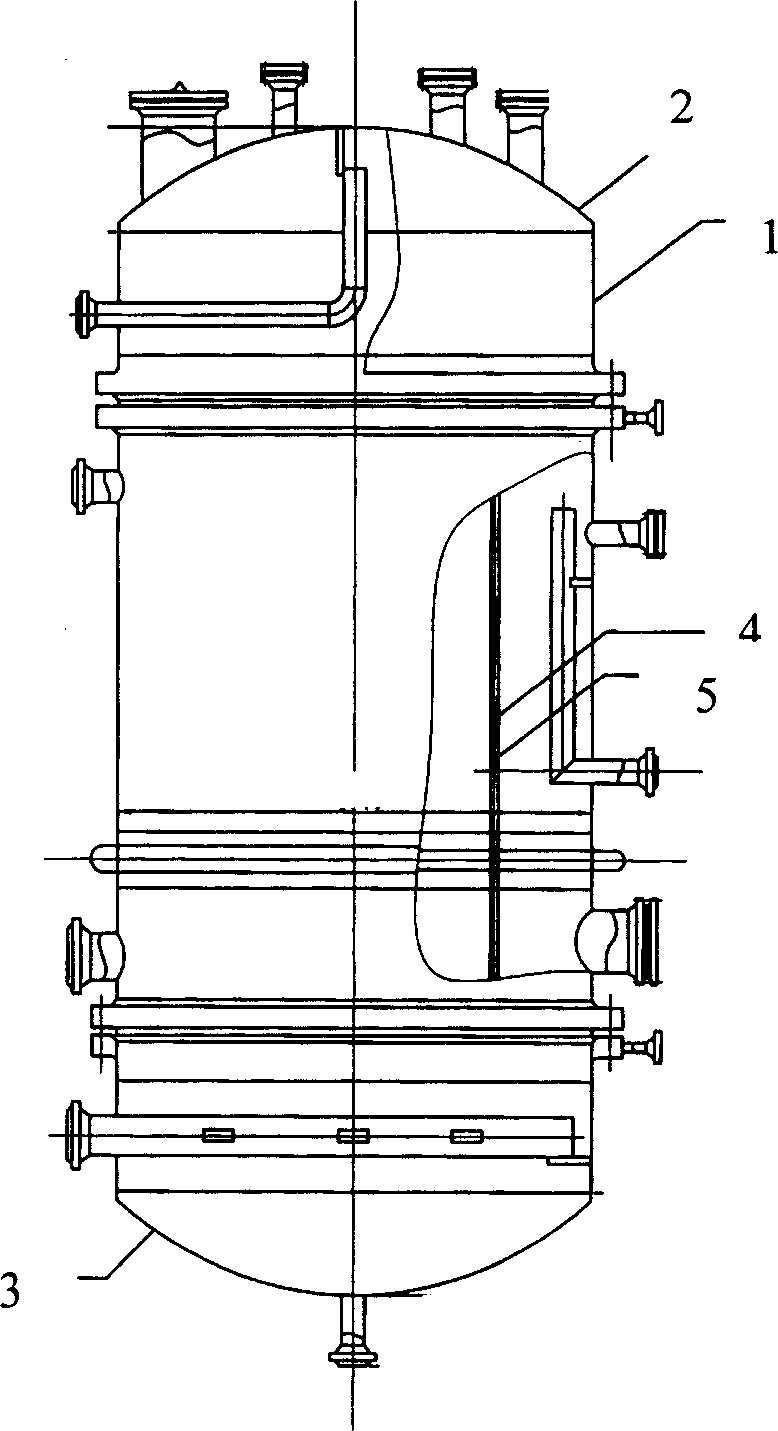

Process for producing vinyl chloride by acetylene method and dedicated device for realizing same

InactiveCN1884241ASmooth responseAvoid corrosionPreparation by halogen halide additionSewage treatmentUltimate tensile strength

The invention discloses a new method of chloroethylene through acetylene method and specific equipment, which comprises the following steps: disposing raw material gas strictly; reacting two-segment compensation; recycling heptane; cooling; radiating; providing specific catalyst and reactor to synthesize chloroethylene; disposing effluent with mercury to obtain high-purity chloroethylene monomer.

Owner:刘大军

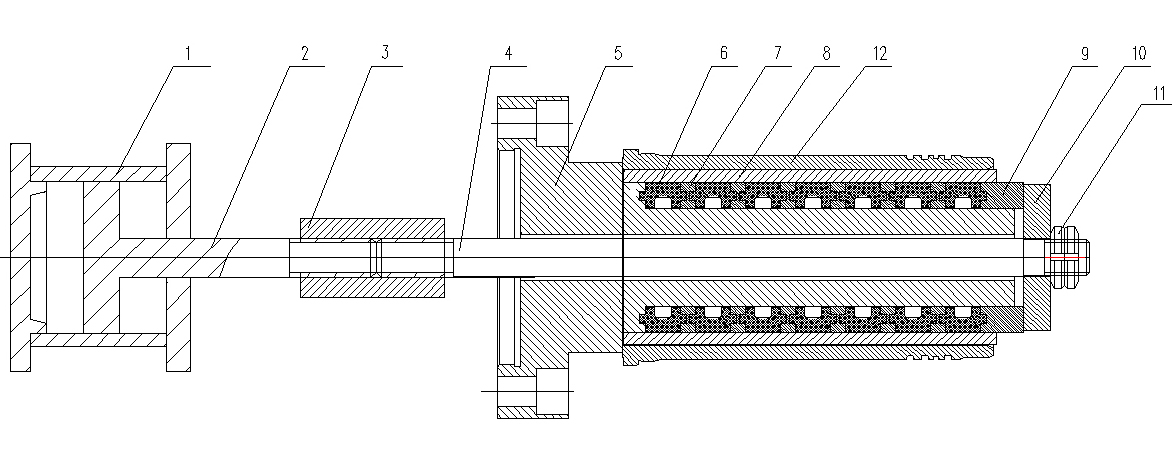

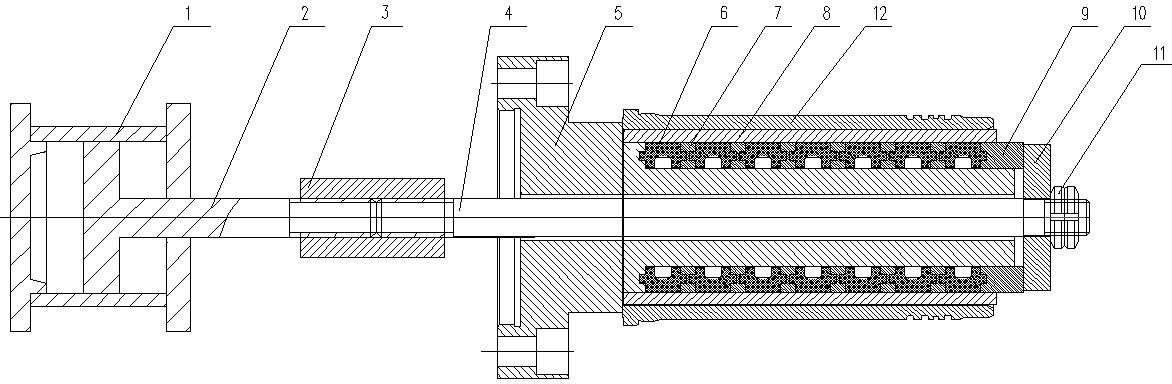

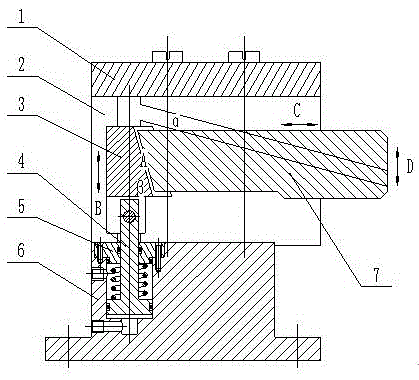

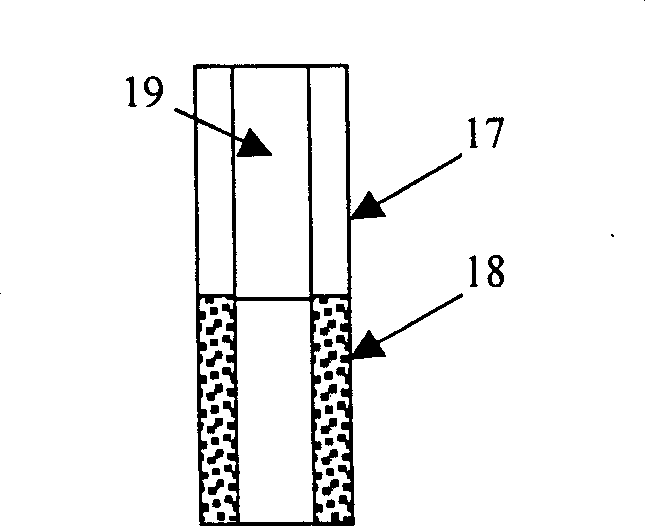

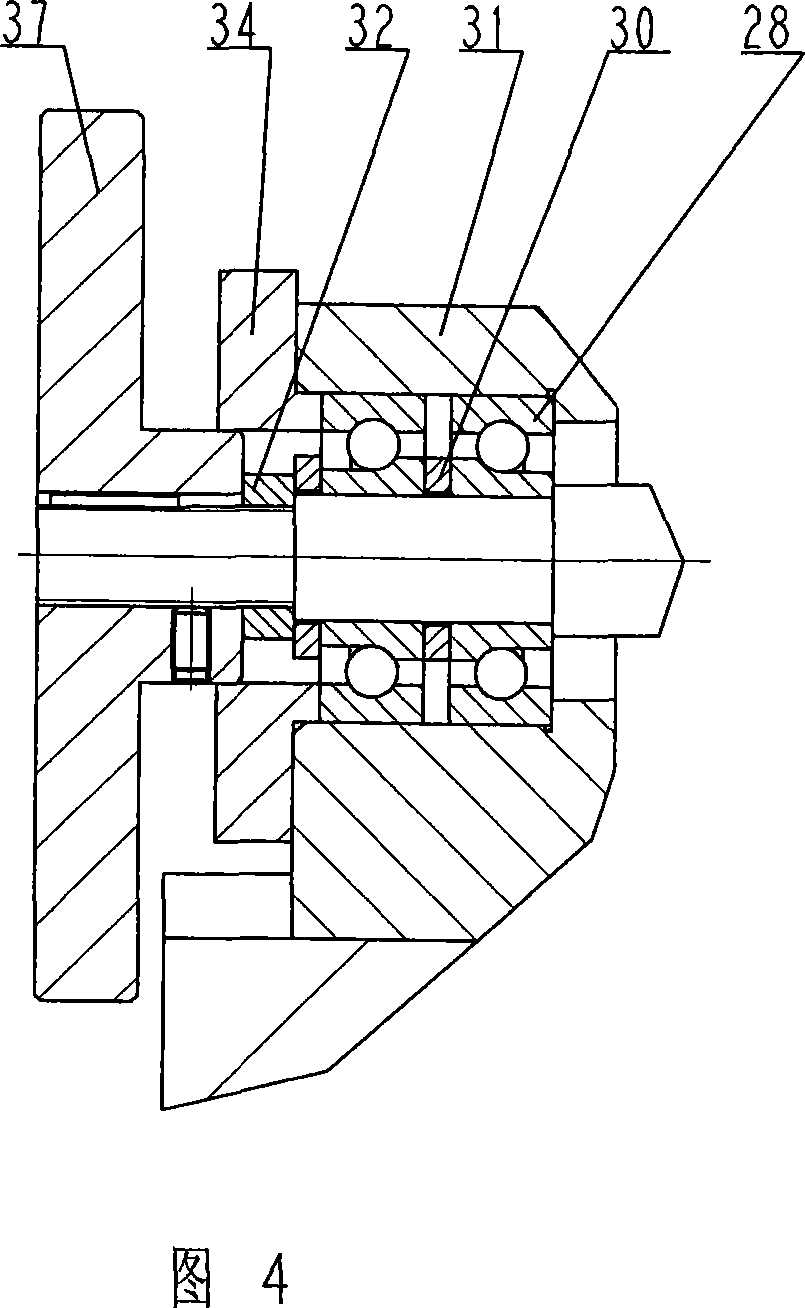

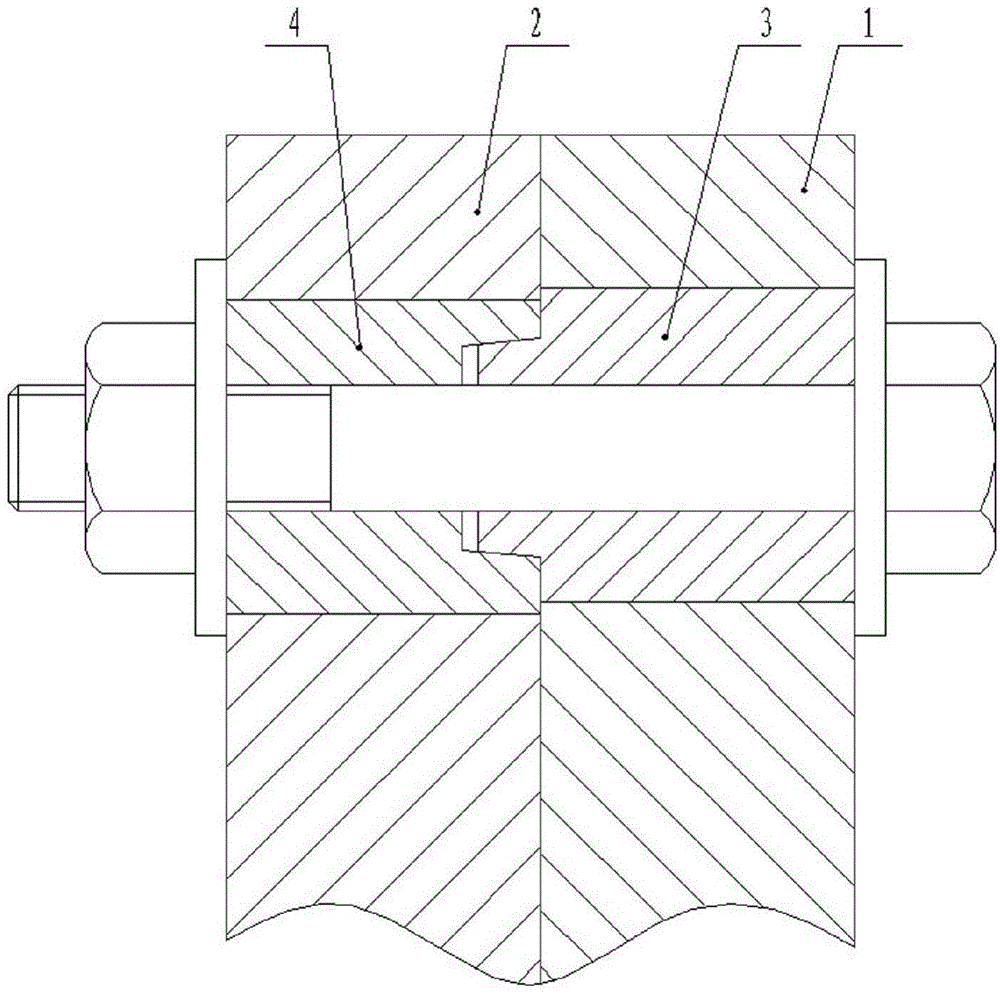

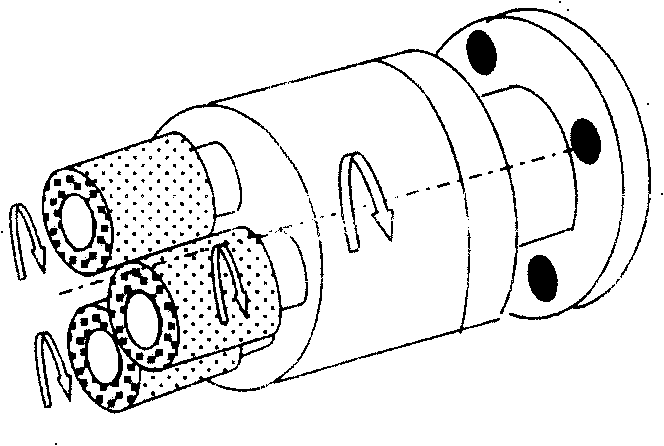

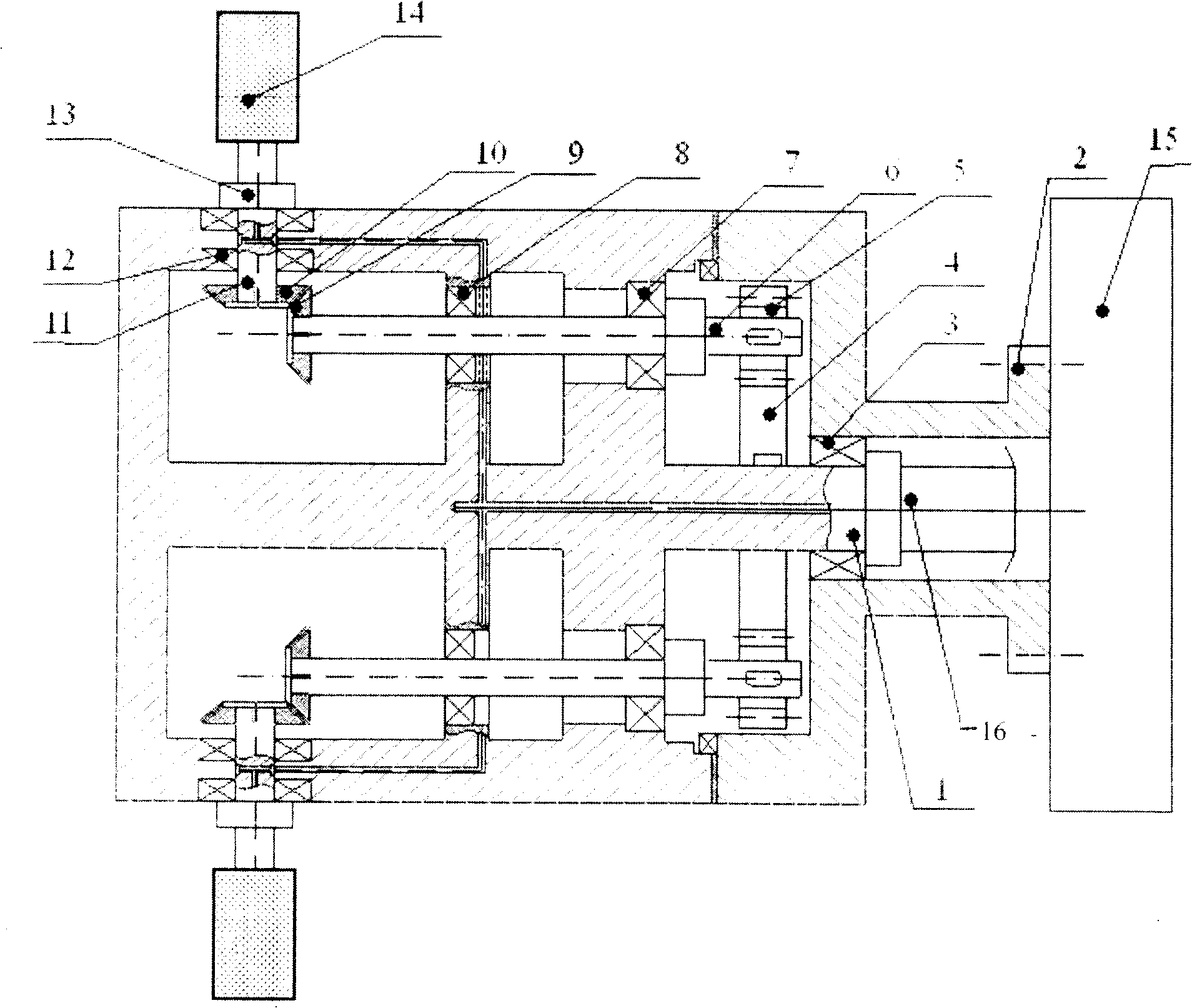

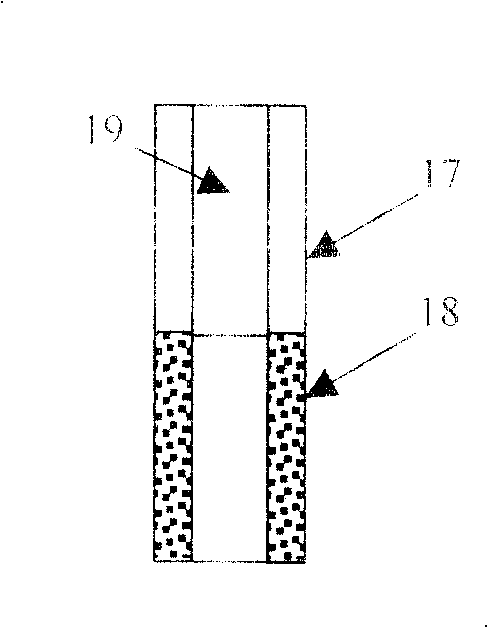

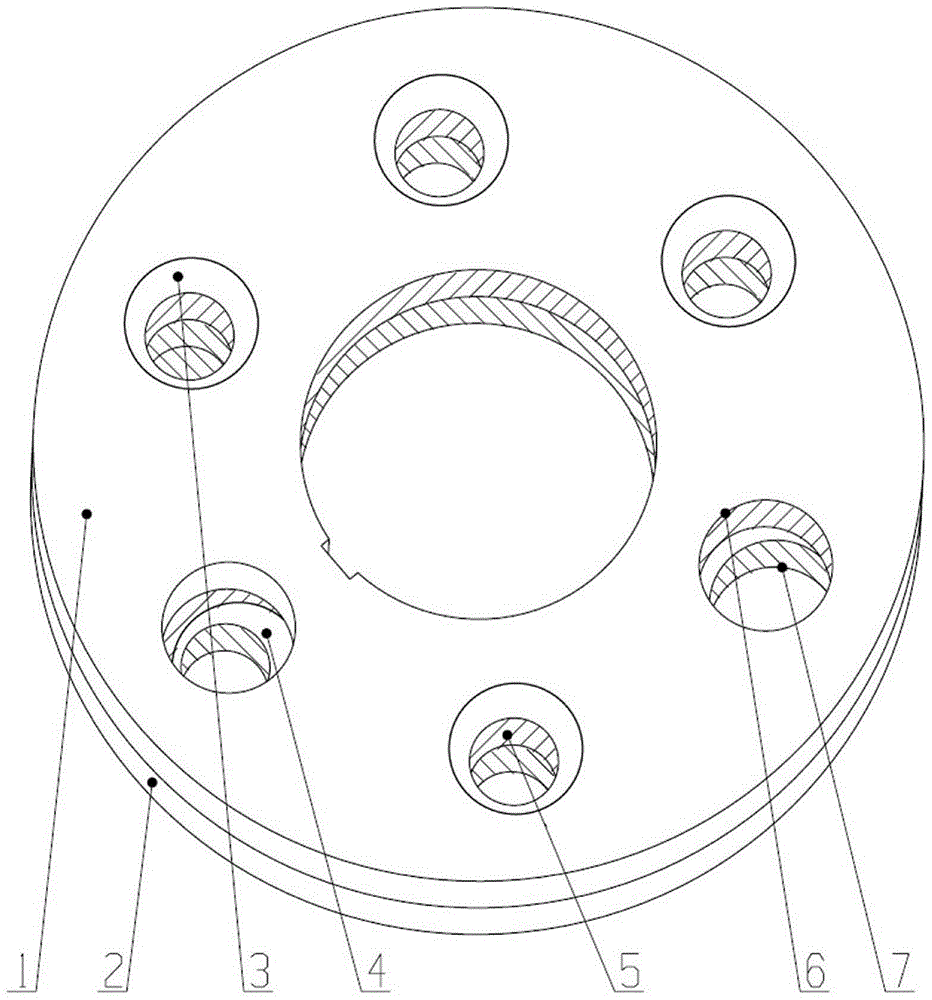

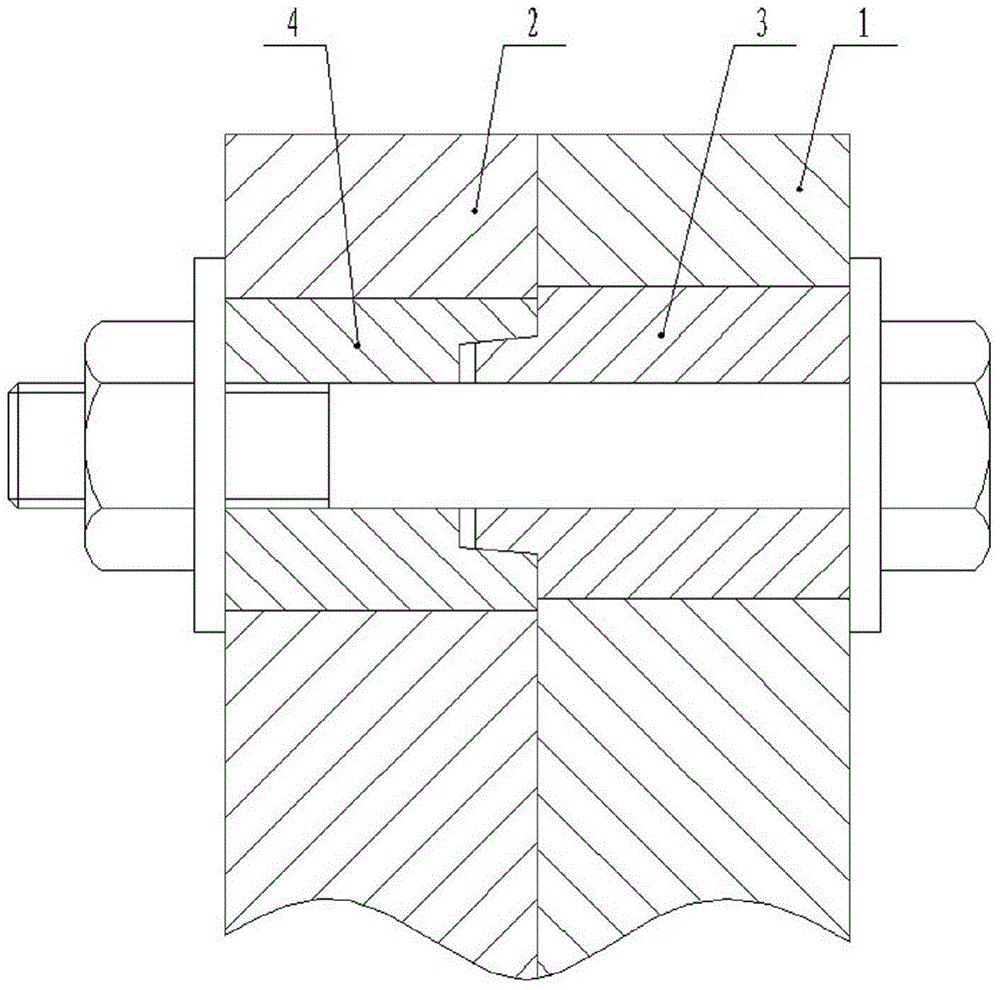

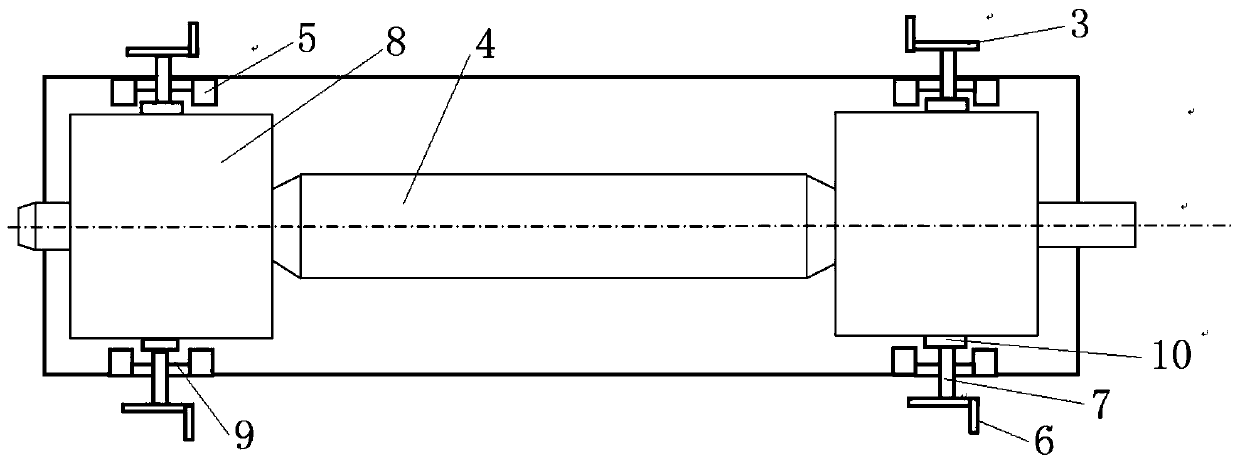

Clamp for quickly changing inner support of cylinder jacket

InactiveCN102059561AQuick changeReduce production auxiliary timePositioning apparatusMetal-working holdersPush and pullRubber ring

The invention discloses a clamp for quickly changing an inner support of a cylinder jacket. The clamp comprises a cylindrical body, wherein an axial passage is formed in the centre of the cylindrical body; a push-and-pull rod is arranged in the body; an end cover is arranged on the outer side of the push-and-pull rod; the inner side of the push-and-pull rod is connected with a piston rod of a hydraulic oil cylinder through a connecting sleeve; hollow vulcanized rubber rings and distance rings are sleeved on the outer surface of the body; one distance ring is arranged between every two adjacent hollow vulcanized rubber rings; a notch is formed on the inner side of each hollow vulcanized rubber ring; the hollow vulcanized rubber ring at the innermost end is tightly adhered to a step of the body; a push ring is arranged on the outer side of the hollow vulcanized rubber ring at the outermost end; the outer side of the push ring is tightly adhered to the end cover; spring random sleeves are sleeved on the outer surfaces of the hollow vulcanized rubber rings and the distance rings; and air cylinder sleeves are sleeved on the outer surfaces of the spring random sleeves. By the clamp, workpieces are quickly and conveniently assembled and disassembled; and when the line of production is changed, a tool can be quickly changed, the production auxiliary time can be shortened and the production efficiency can be improved so as to reduce the production cost.

Owner:ZYNP GRP

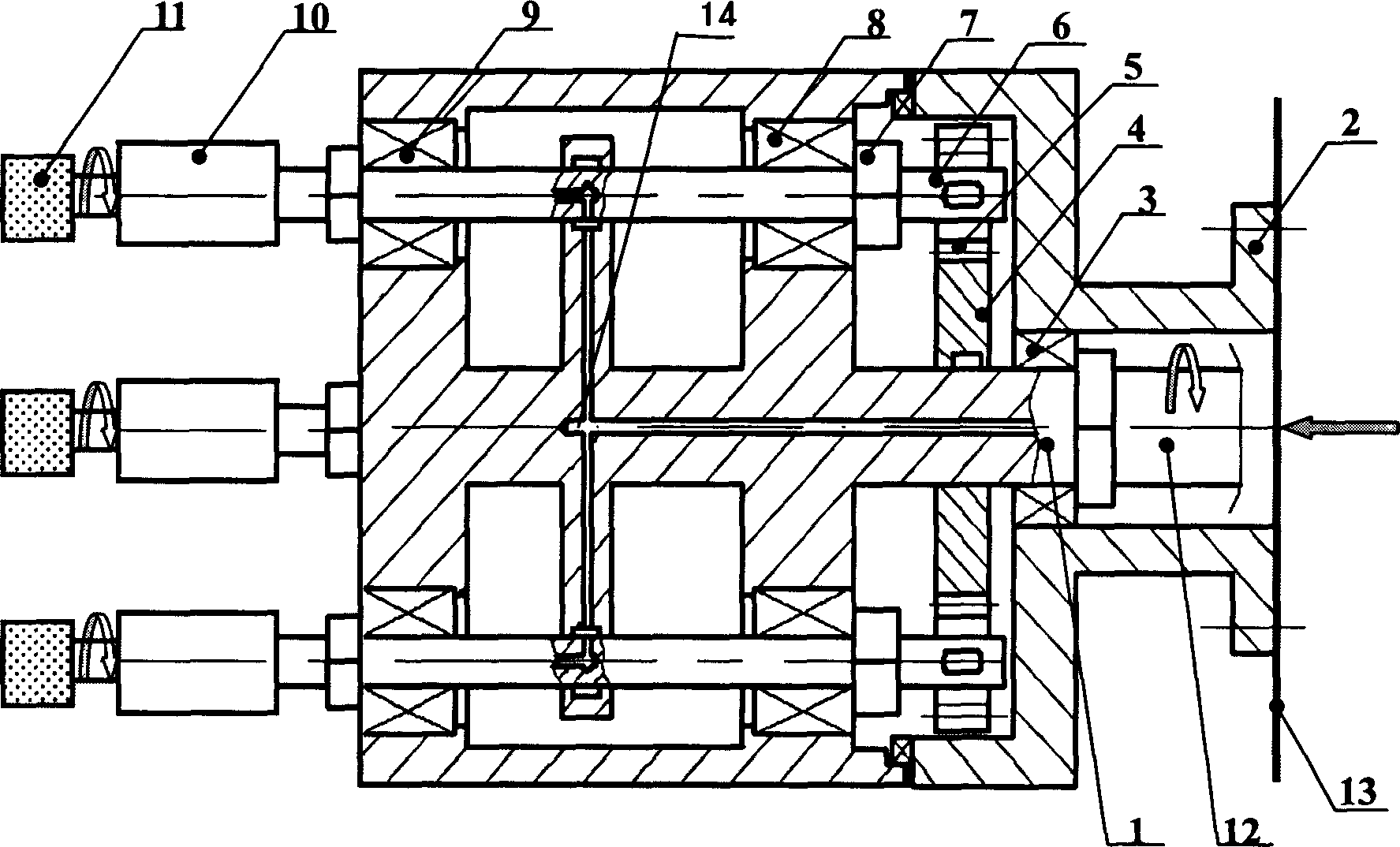

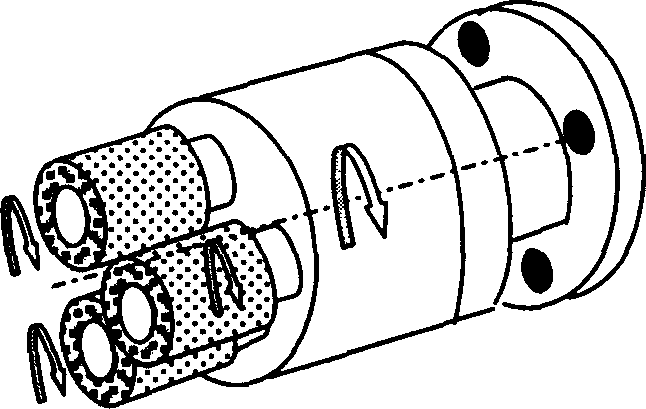

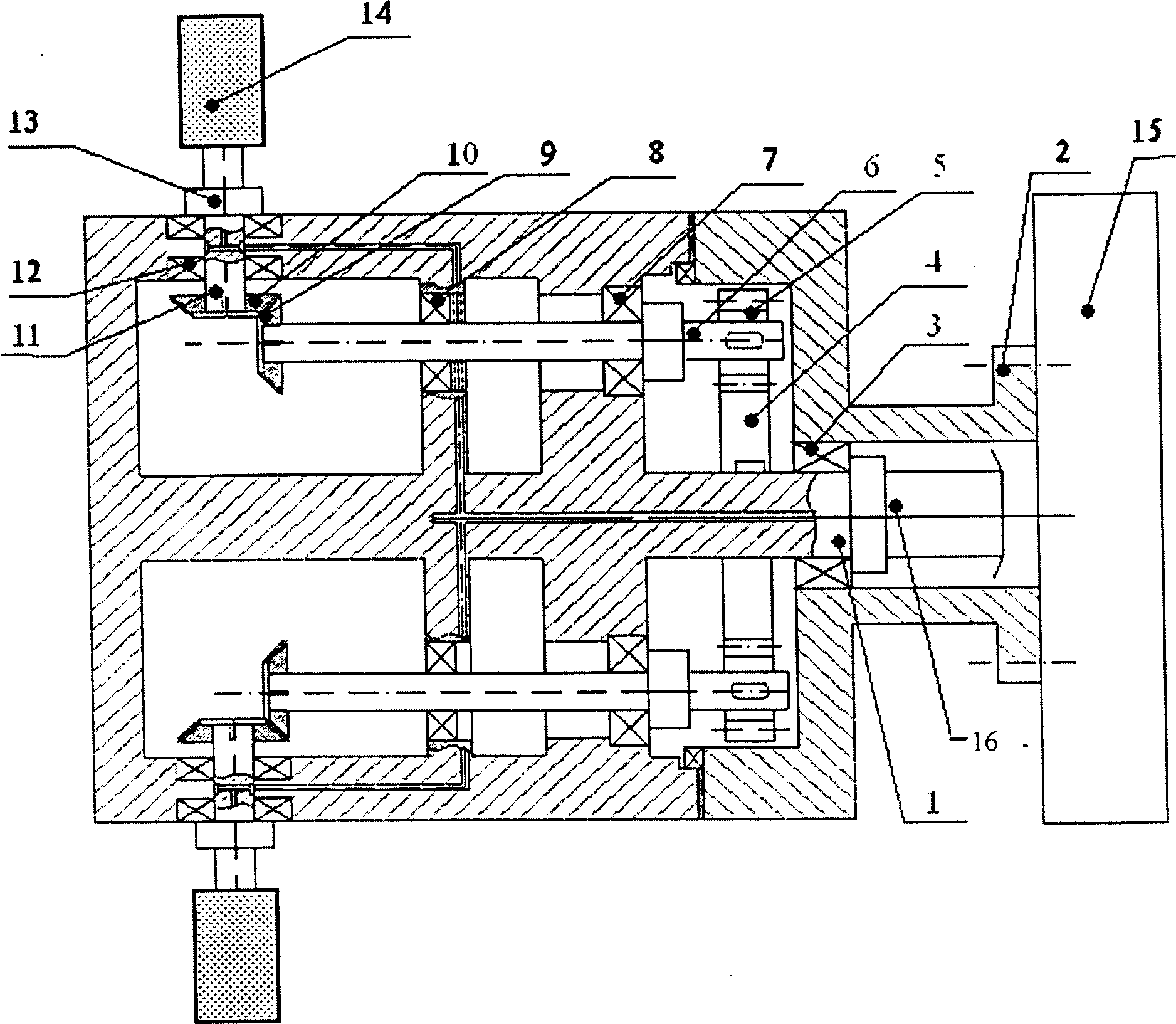

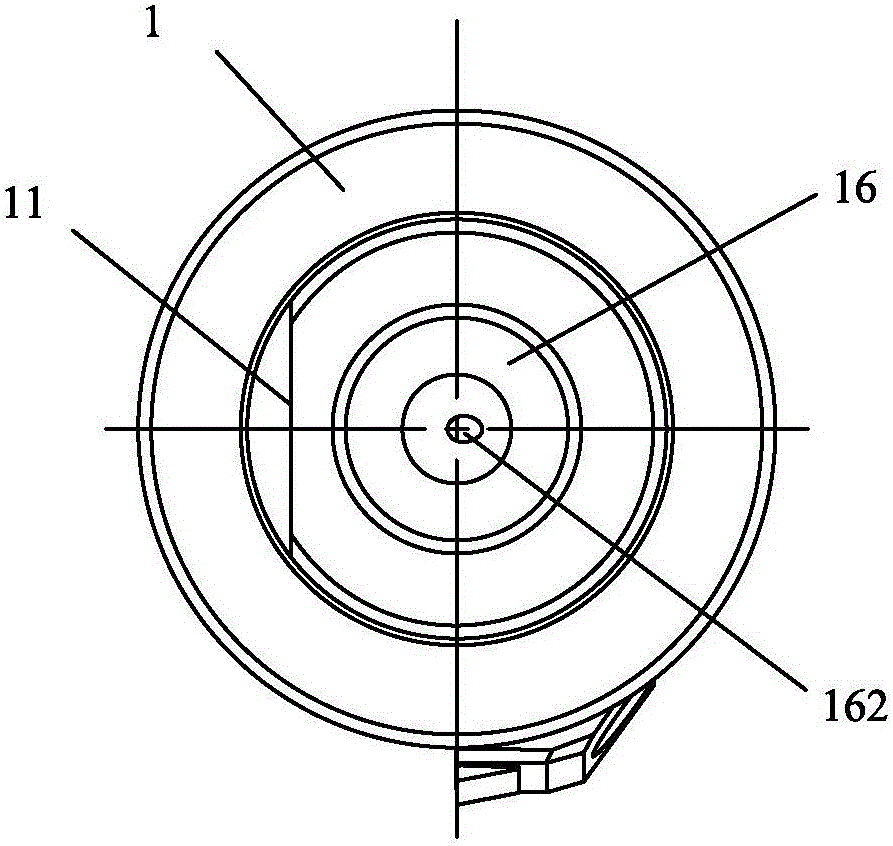

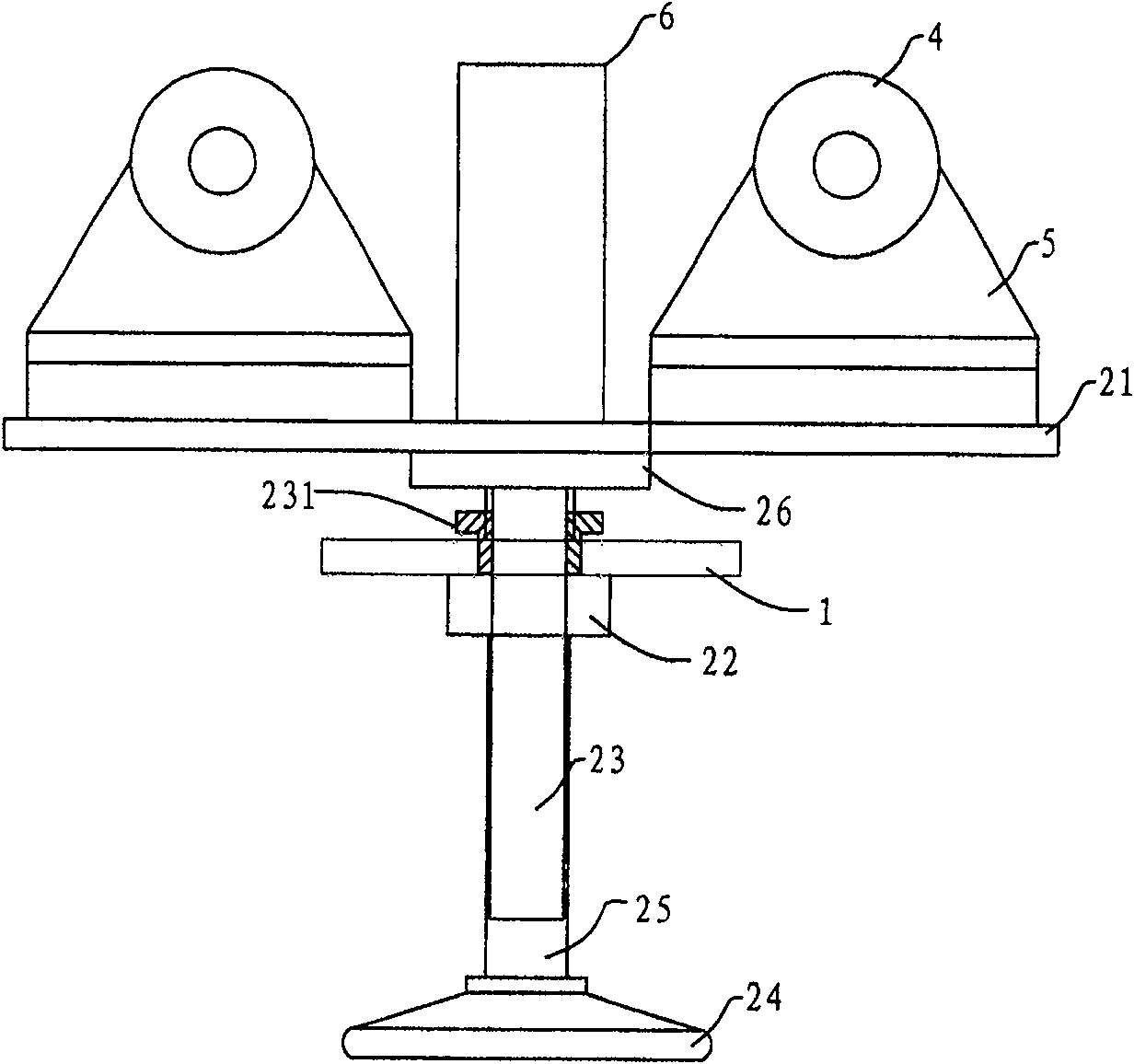

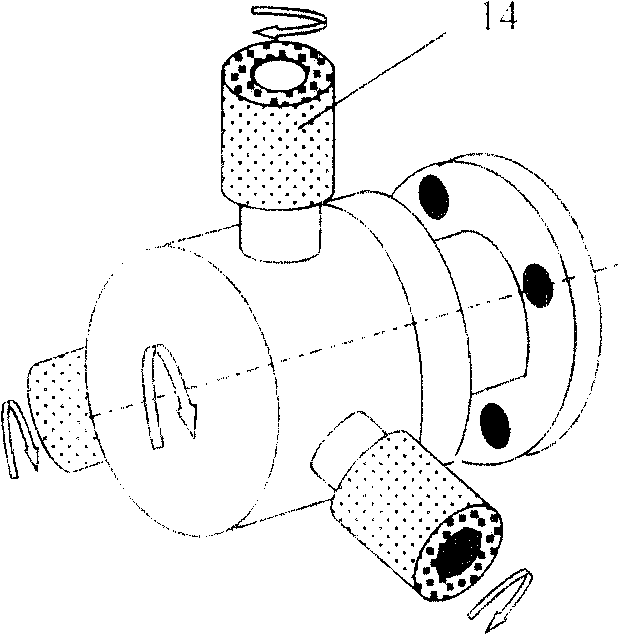

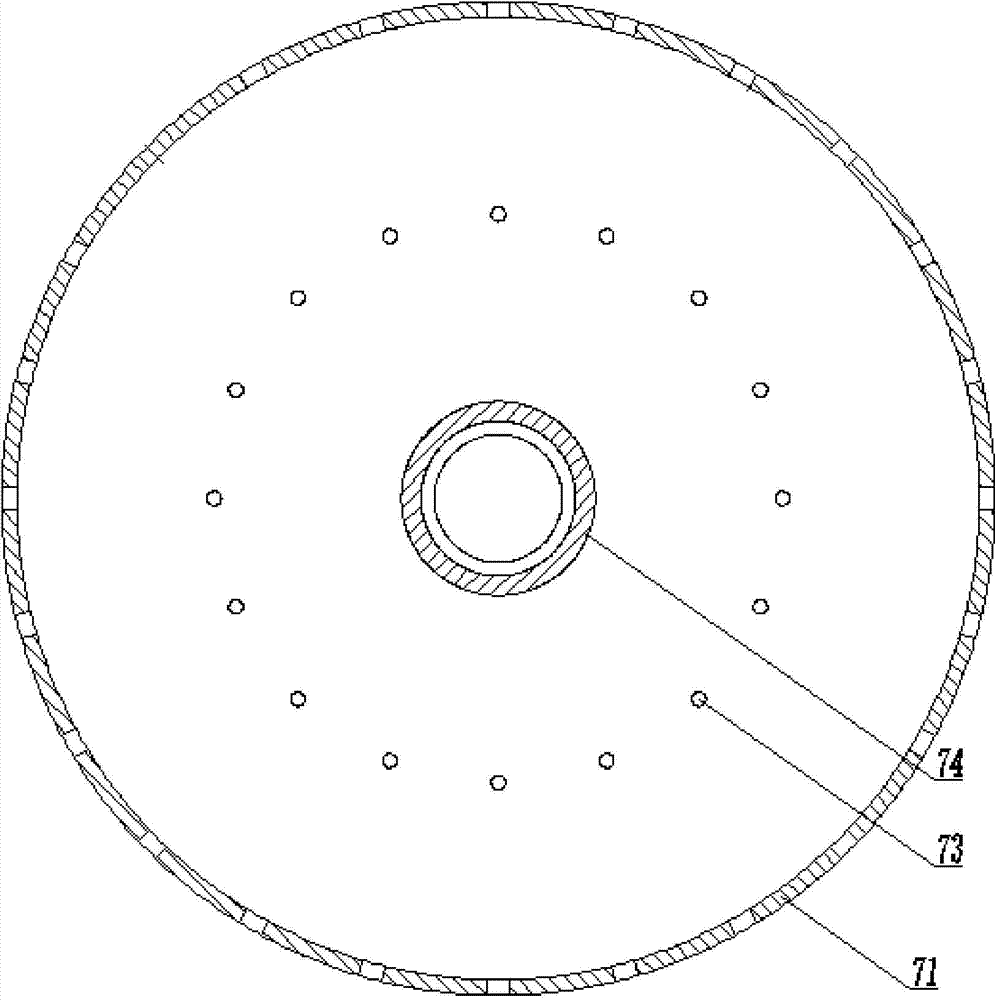

Planetary framework diamond abrasive tools

InactiveCN1836845AAvoid loweringMaintain sharpnessGrinding machinesMetal working apparatusDrive shaftGear wheel

The planetary mechanism diamond grinding tool is one workpiece grinding diamond grinding wheel apparatus with great grinding width, high efficiency, low cost and grinding wheel without needing trimming measure and tool. It has planetary gear mechanism, spring clamp sleeve, cooling pipeline, fixing and connecting casing and rotating casing. The planetary gear mechanism is provided with bearing, sun gear, planetary gear, nut, bearing and pressurized cooling liquid inflow pipeline. The rotating casing is connected to the driving shaft integrally, the bearing is set between the driving shaft and the fixing and connecting casing, the sun gear is set on the driving shaft for rotation, the planetary gear is connected to the sun gear, the spring clamp sleeve is set in the output end of the planetary shaft, the cooling liquid inflow pipeline is set in the axial center of the driving shaft and has one end connected to the built-in cooling pipeline inside the rotating casing.

Owner:XIAMEN UNIV

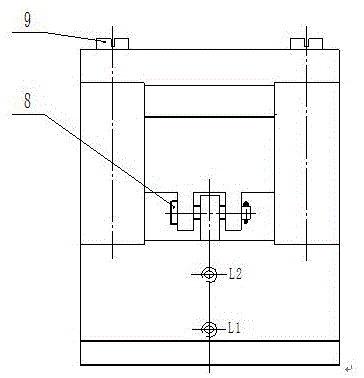

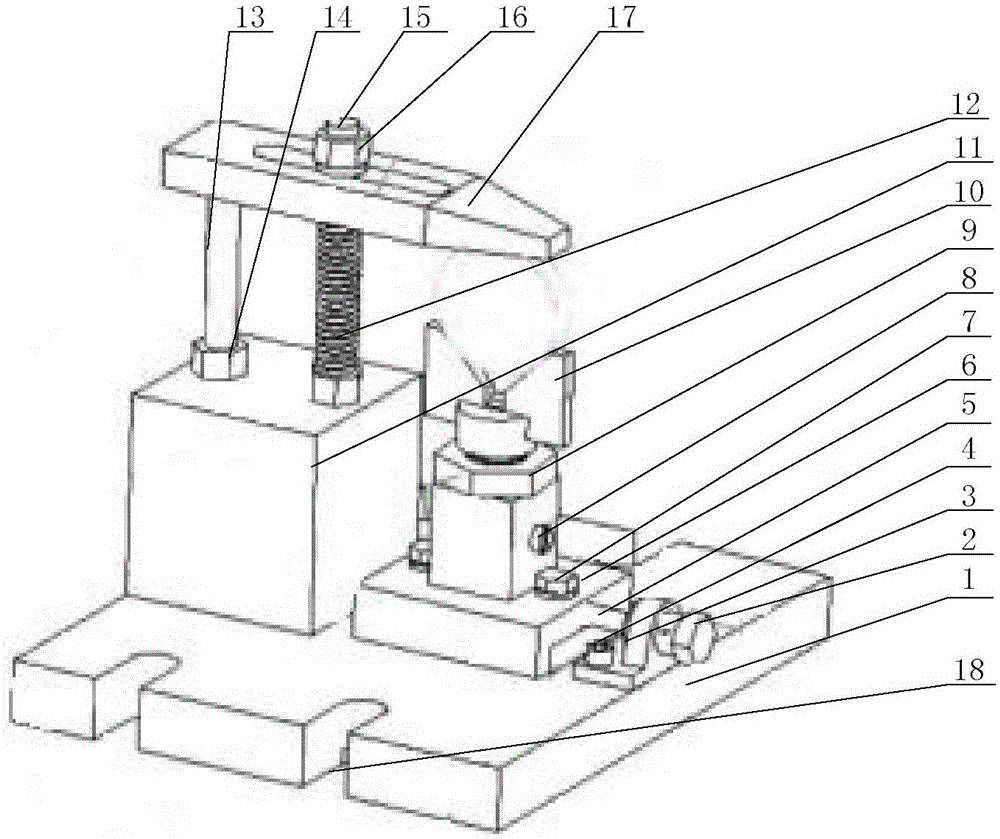

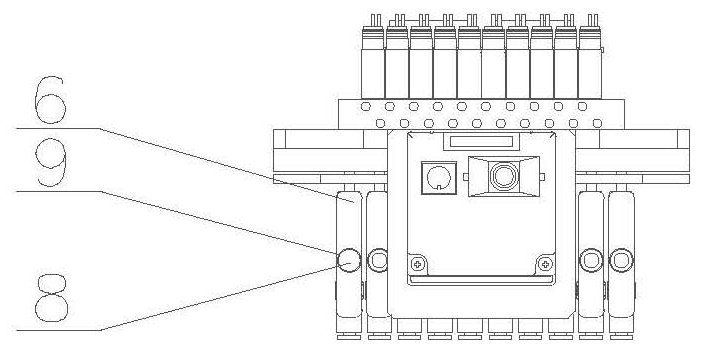

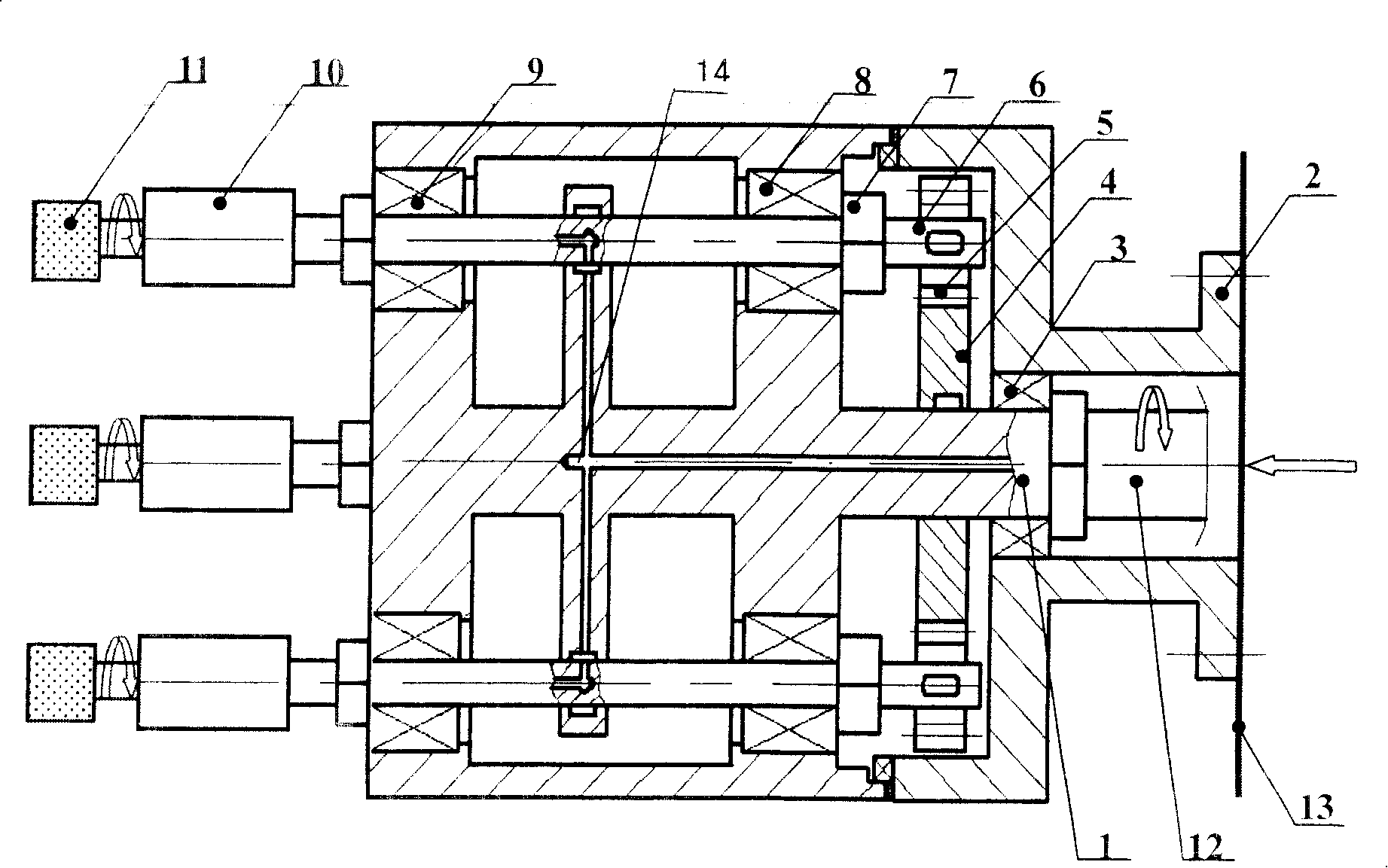

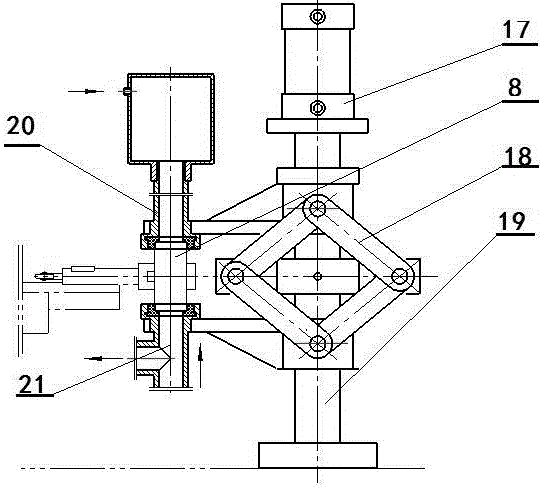

Mold clamping device

ActiveCN105562519AQuick installationQuick loading and unloadingShaping toolsServomotorsPistonEngineering

The invention discloses a mold clamping device. A sliding block and a clamping block of the mold clamping device are connected through an oblique surface with a dovetail section. The two side faces of the sliding block are each provided with a guiding boss, and the guiding bosses are matched with vertical guiding grooves in side plates. The two side faces of the clamping block are each provided with an oblique guiding boss, and the oblique guiding bosses are matched with oblique guiding grooves in the side plates. A piston installed on a base drives the sliding block to move up and down along the vertical guiding grooves in the two side plates installed on the base. Under the action of the oblique surface, the clamping block is pushed by the sliding block to move leftwards and rightwards and move upwards and downwards synchronously along the oblique guiding grooves in the side plates. A mold can be clamped and loosened through the up-down movement of the clamping block. According to the mold clamping device, the clamping force is converted by means of the oblique surface, and a good self-locking function is achieved; hydraulic driving is adopted, the clamping force is uniform and stable, and stepless adjustment of the clamping force can be achieved according to the size of the mold.

Owner:CHONGQING TECH & BUSINESS UNIV

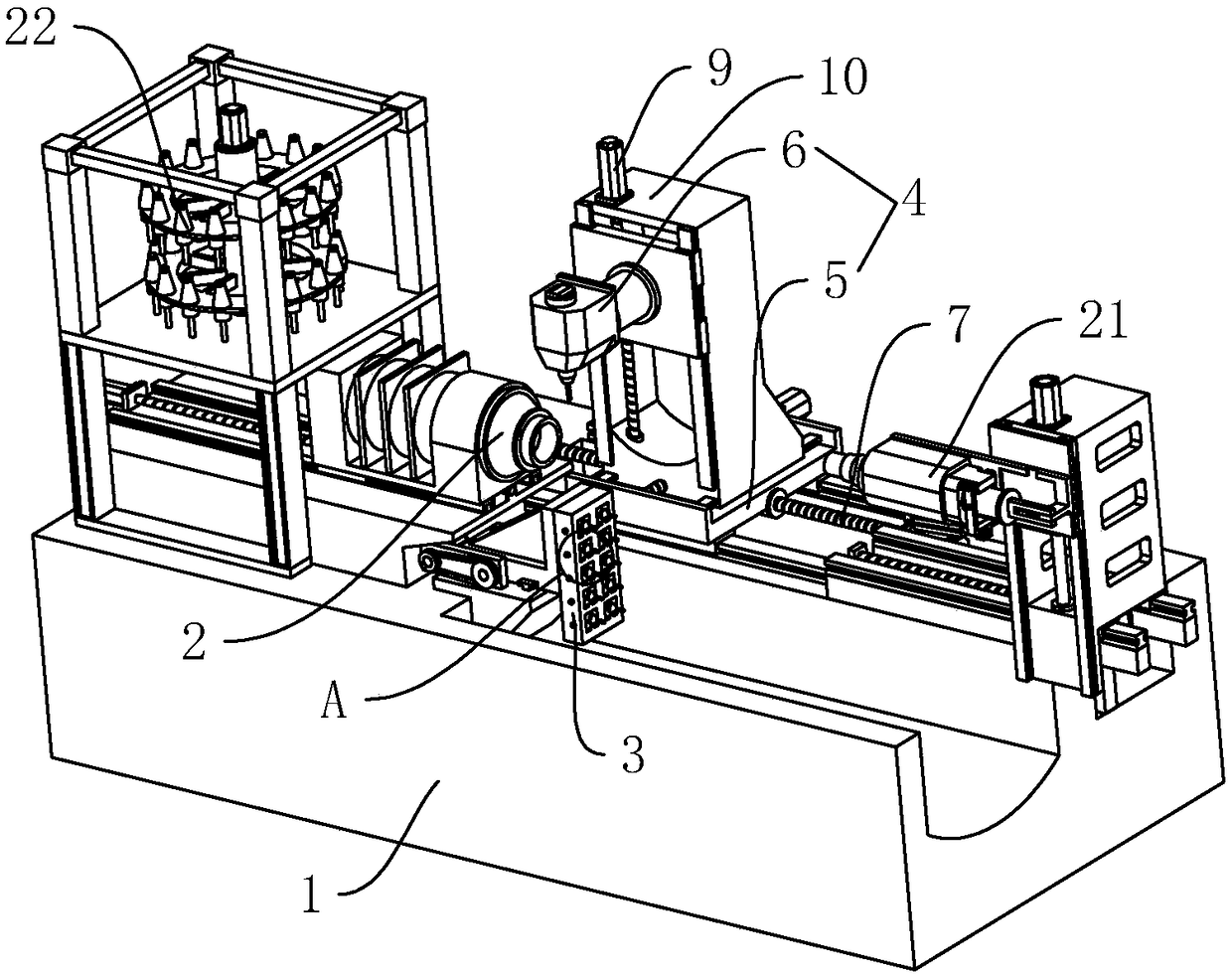

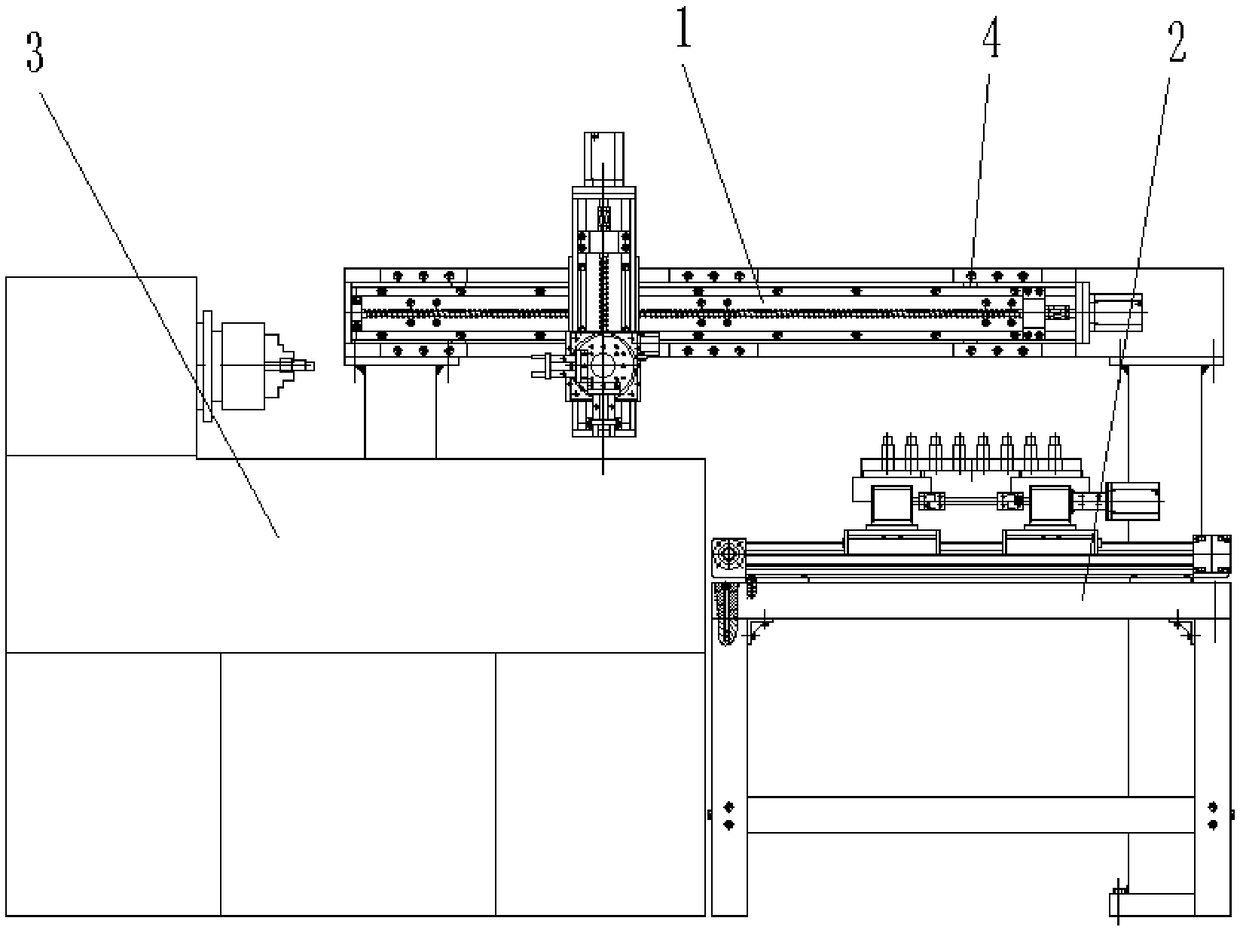

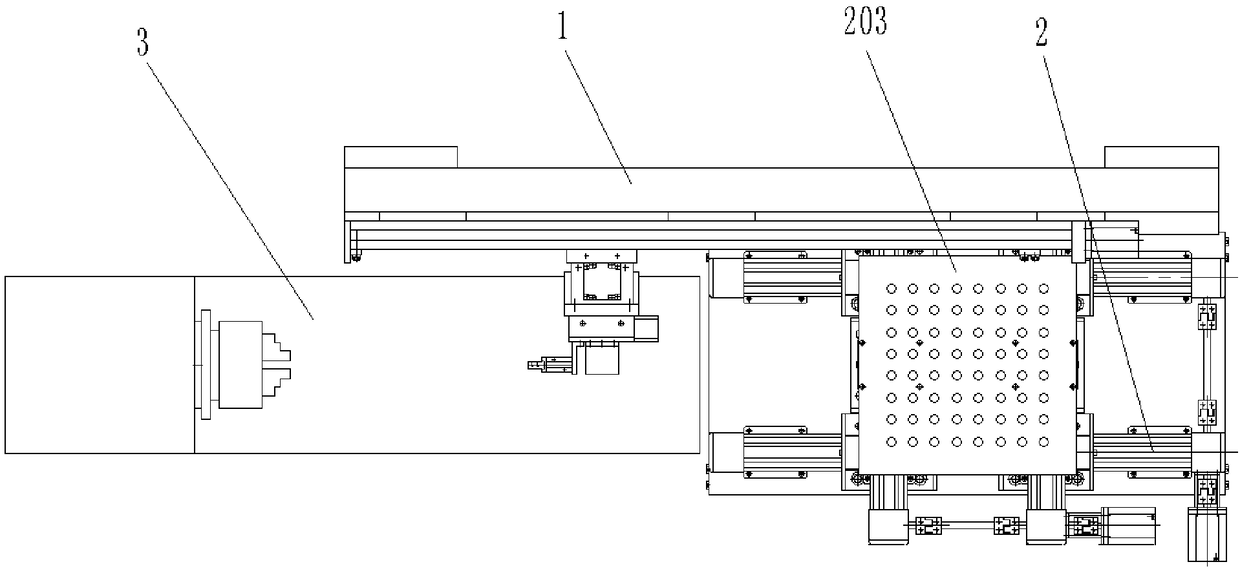

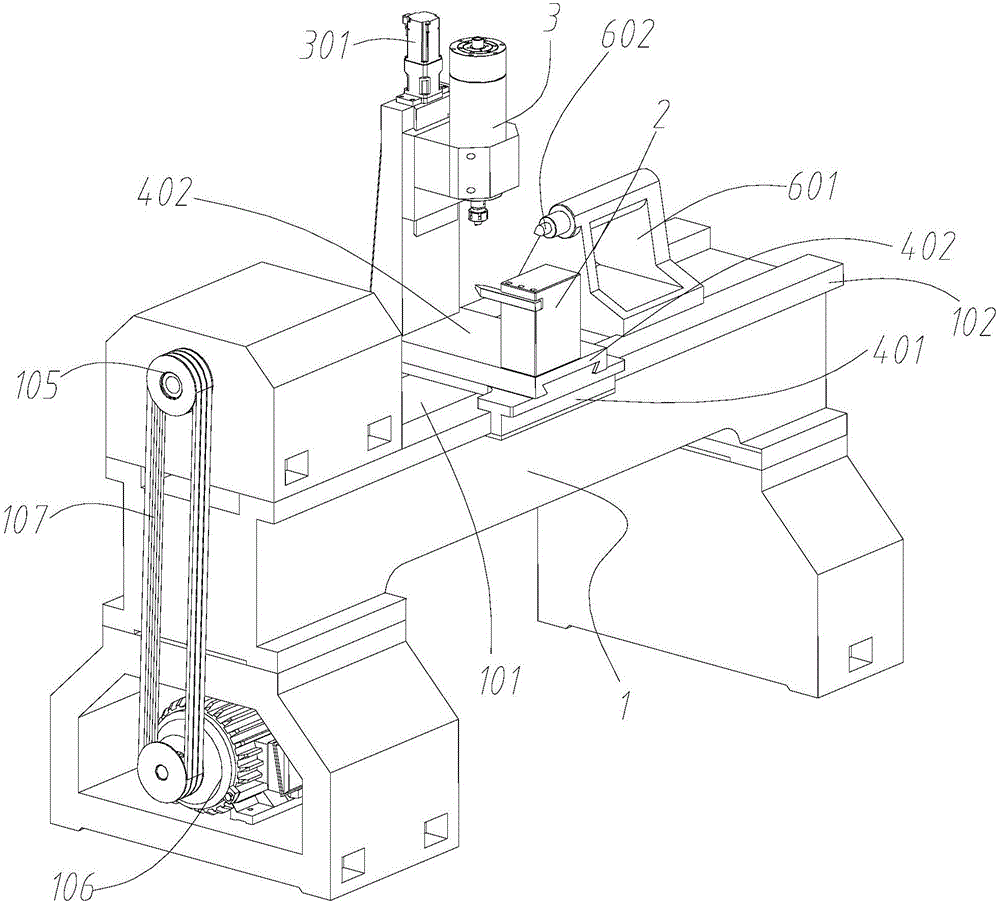

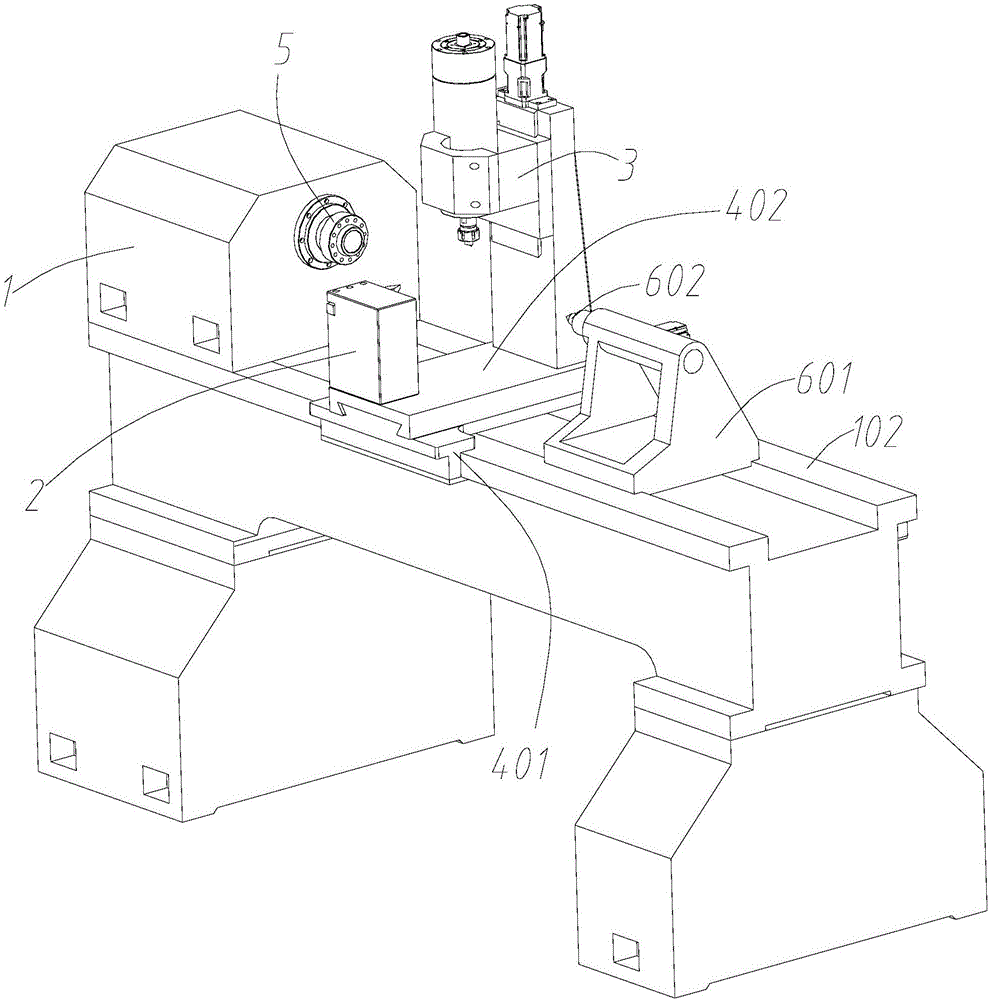

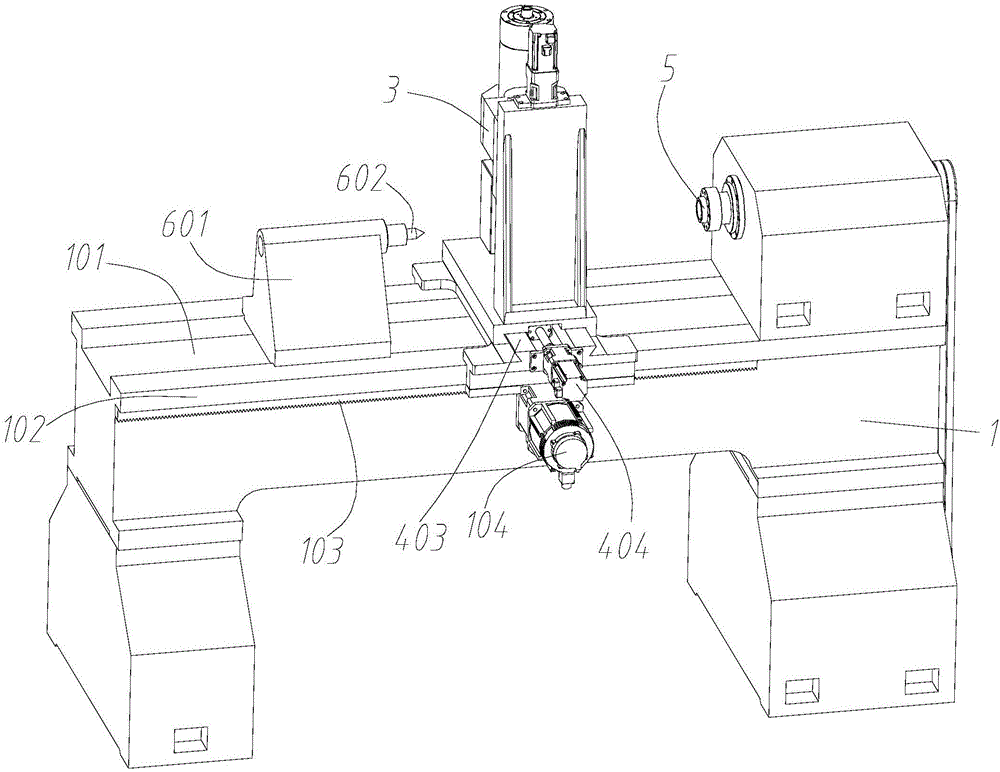

Large-power turning and milling composite machine tool

PendingCN108555602AIncrease productivityReduce production auxiliary timeOther manufacturing equipments/toolsProcessing accuracyMachine tool

The invention discloses a large-power turning and milling composite machine tool, belongs to the technical field of machine tools, and aims to solve a problem in a traditional composite machine tool that a milling device is only used for auxiliary machining. The key point of the technical scheme is that the large-power turning and milling composite machine tool comprises a lathe bed, a main shaftinstalled on the lathe bed, a back face knife table installed at one side of the main shaft, and the milling device installed at the other side of the main shaft. The milling device comprises a driving mechanism and a milling mechanism rotatably installed on the driving mechanism. The large-power turning and milling composite machine tool is capable of, through installing the milling device with aB-axis on the lathe bed, and enabling the milling device to be rotated in multiple degrees, completing the milling and machining of a complicated workpiece by cooperating with the main shaft, effectively shortening a product manufacturing process chain, improving production efficiency, reducing a clamping frequency of the workpiece, and effectively improving machining precision, and further has the advantages of reducing floor area, and reducing production cost.

Owner:津上精密机床(浙江)有限公司

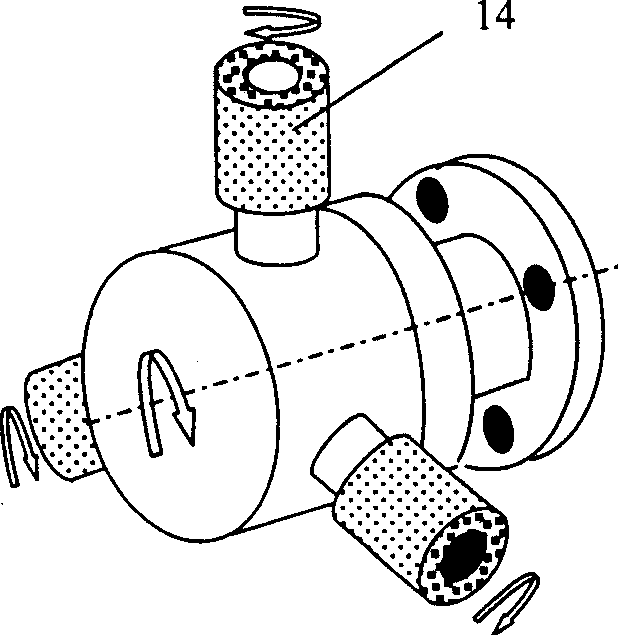

Radial diamond abrasive tool with planet mechanism

InactiveCN1843699AAvoid cloggingAvoid loweringGrinding machine componentsGrinding machinesGear wheelGrinding wheel

The invention relates to a radial planet diamond grinder, especially providing a diamond grinding wheel work-piece, with wider grinding width, high efficiency, lower cost and continuous operation. Said planet device comprises a bearing, a sun wheel, planet wheels, taper gear wheel, grinding main axle, nut, and a pressure refrigerating liquid inlet tube. The end of rotational frame is integrated with the inlet of driving axle; the inlet of driving axle is connected to the rotational axle of machine tool; a bearing is arranged between the driving axle and the fixed connecting frame; the top of fixed connecting frame is connected to the machine tool; the driving axle is mounted with sun wheel; the planet gear wheel is connected to the sun wheel; the planet axle drives the taper gear wheel to drive the grinding main axle; the grinding head spring is clamped on the output end of grinding main axle; the refrigerating liquid inlet tube is at the axes of driving axle and connected to the internal refrigerating tube of rotational frame; the refrigerating liquid flows to the clamp end of grinding spring that connecting to the grinding main axle, to enter into the middle hole of grinding head.

Owner:XIAMEN UNIV

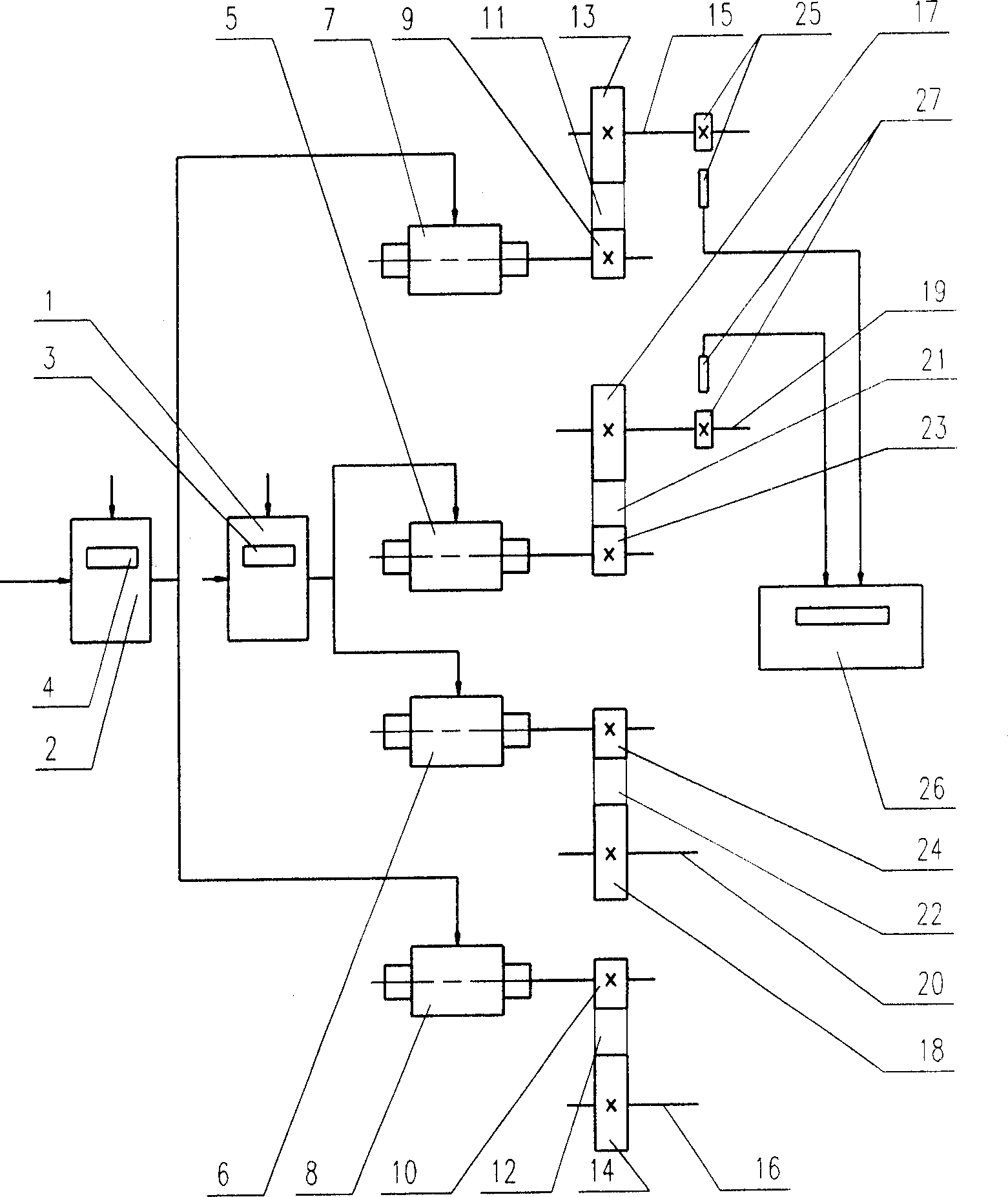

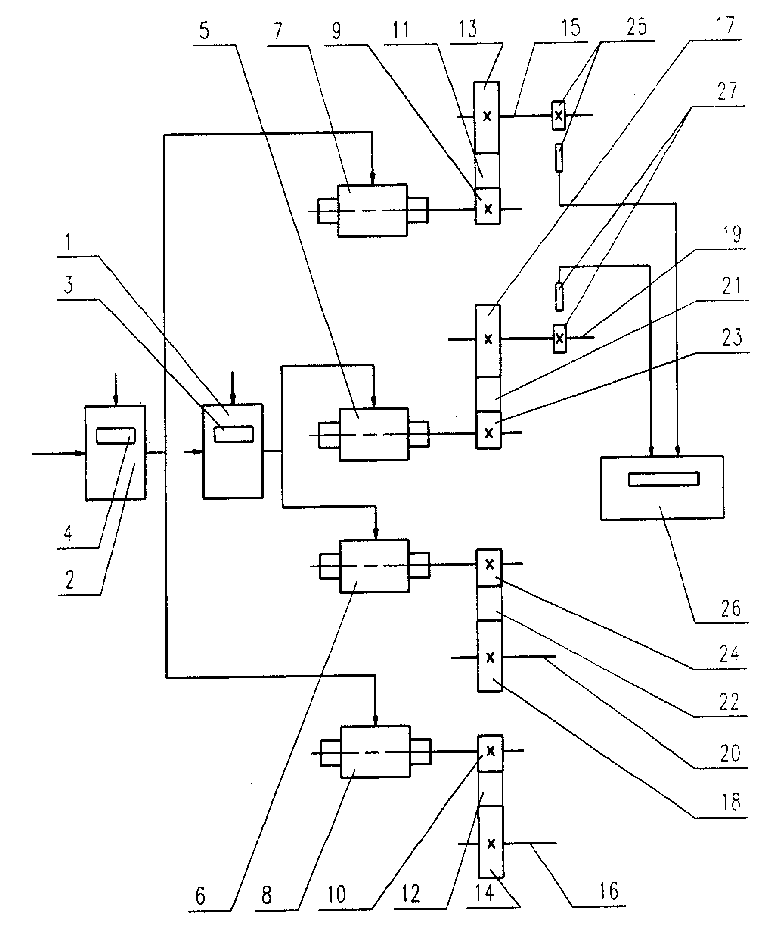

Yarn inserting and cotton feeding transmission mechanism for rotary-cup spinning machine

InactiveCN1361316AInnovative designSimple structureContinuous wound-up machinesYarnFrequency changer

The yarn inserting and cotton feeding transmissino mechanism includes a yarn inserting speed controller comprising yarn inserting speed controlling frequency converter and yarn inserting speed programmer; and a cotton feeding speed controller comprising cotton feeding speed controlling frequency converter and cotton feeding speed programmer as well as independent right and left yarn inserting roller transmission mechanism, yarn inserting roller speed sensor, cotton feeding roller speed sensor and parameter display instrument. The output of the yarn inserting speed controlling frequency converter is connected to the input of the yarn inserting motor; and the yarn inserting roller speed sensor has output connected to the parameter display instrument.

Owner:BEST MACHINE BUILDING YUCI DEVPT ZONE

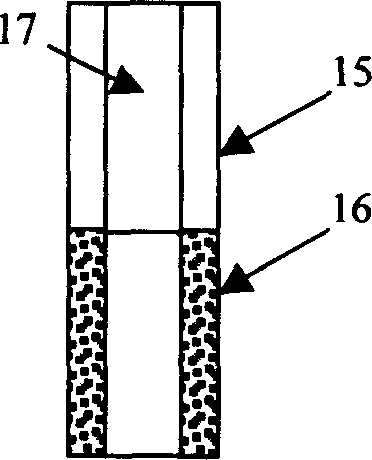

Preparation method of diamond film coating layer bearing supporter

ActiveCN1718853AEliminate negative effectsImprove adhesionBearing componentsChemical vapor deposition coatingHigh densityAlloy substrate

A process for preparing the bearing holder with coated diamond film layer includes such steps as removing Co from the surface of hard alloy substrate, roughing, decarbonizing, reducing, adding adhesion promoter to reacting gas, preparing the diamond film by CVD process while controlling its technological parameters by 3 stages to sequentially generate high-density layer, polycrystal layer and superfine micro crystal layer, and adhering said substrate onto the surface of steel holder.

Owner:SHANGHAI JIAO TONG UNIV +1

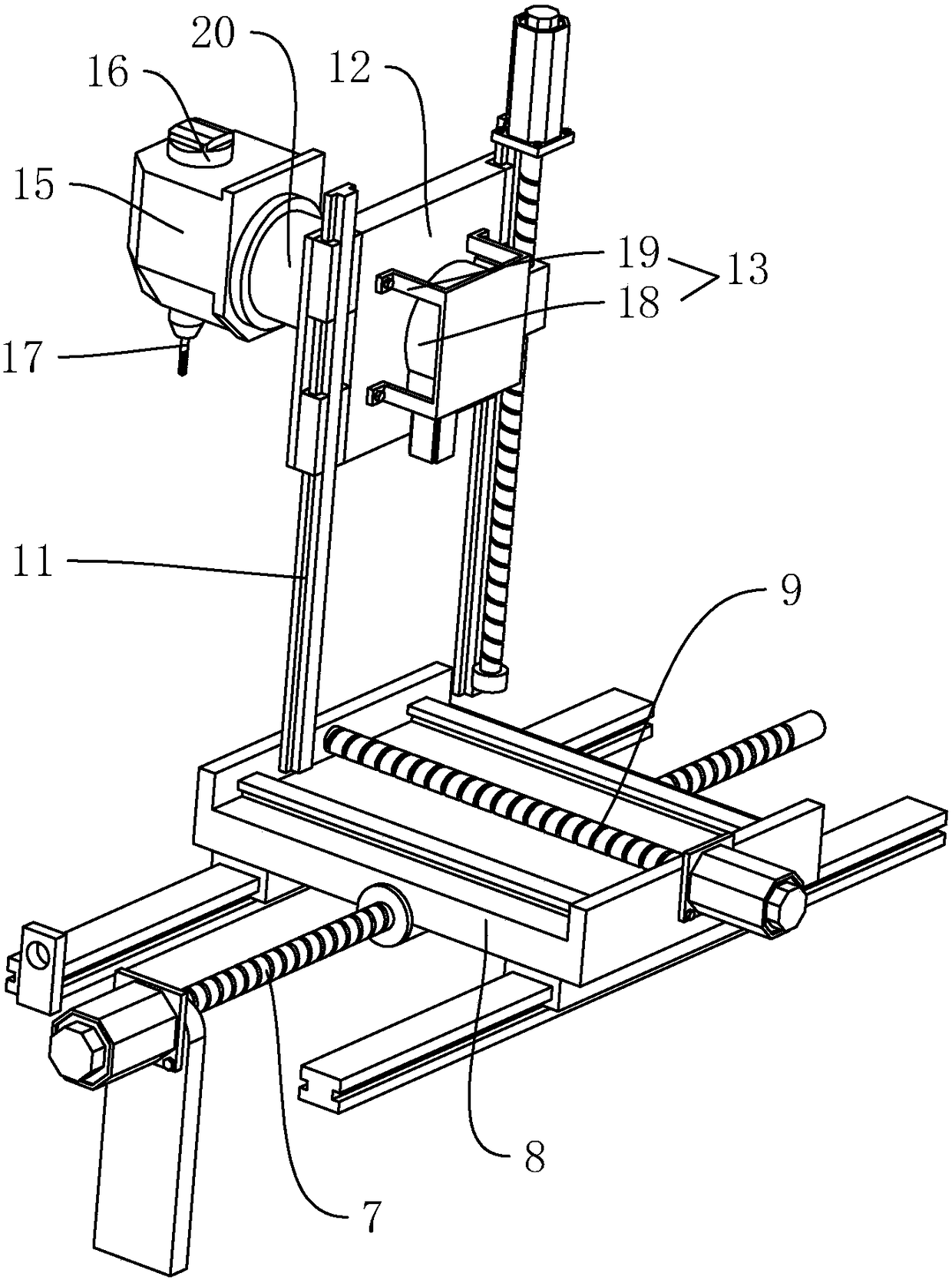

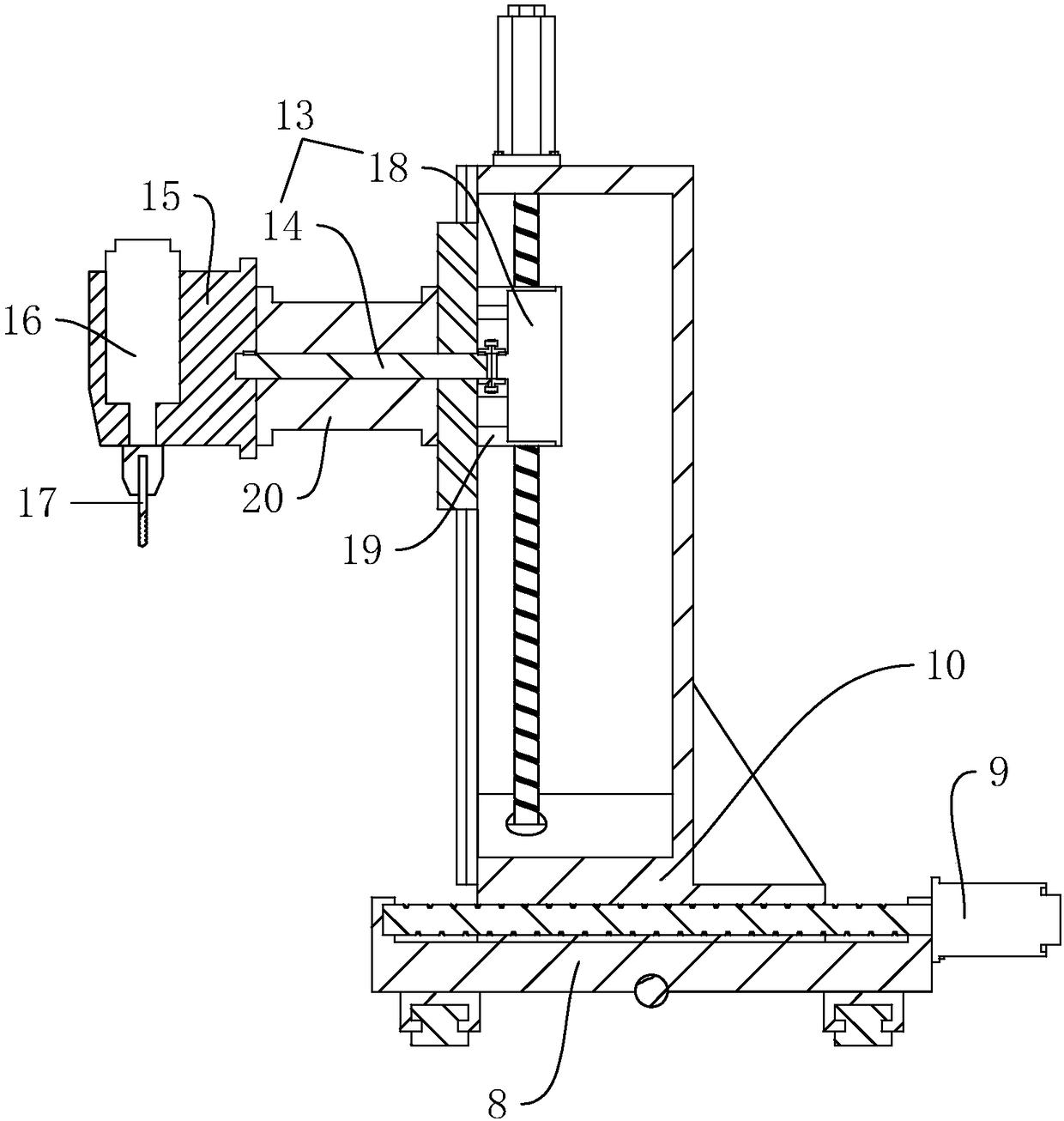

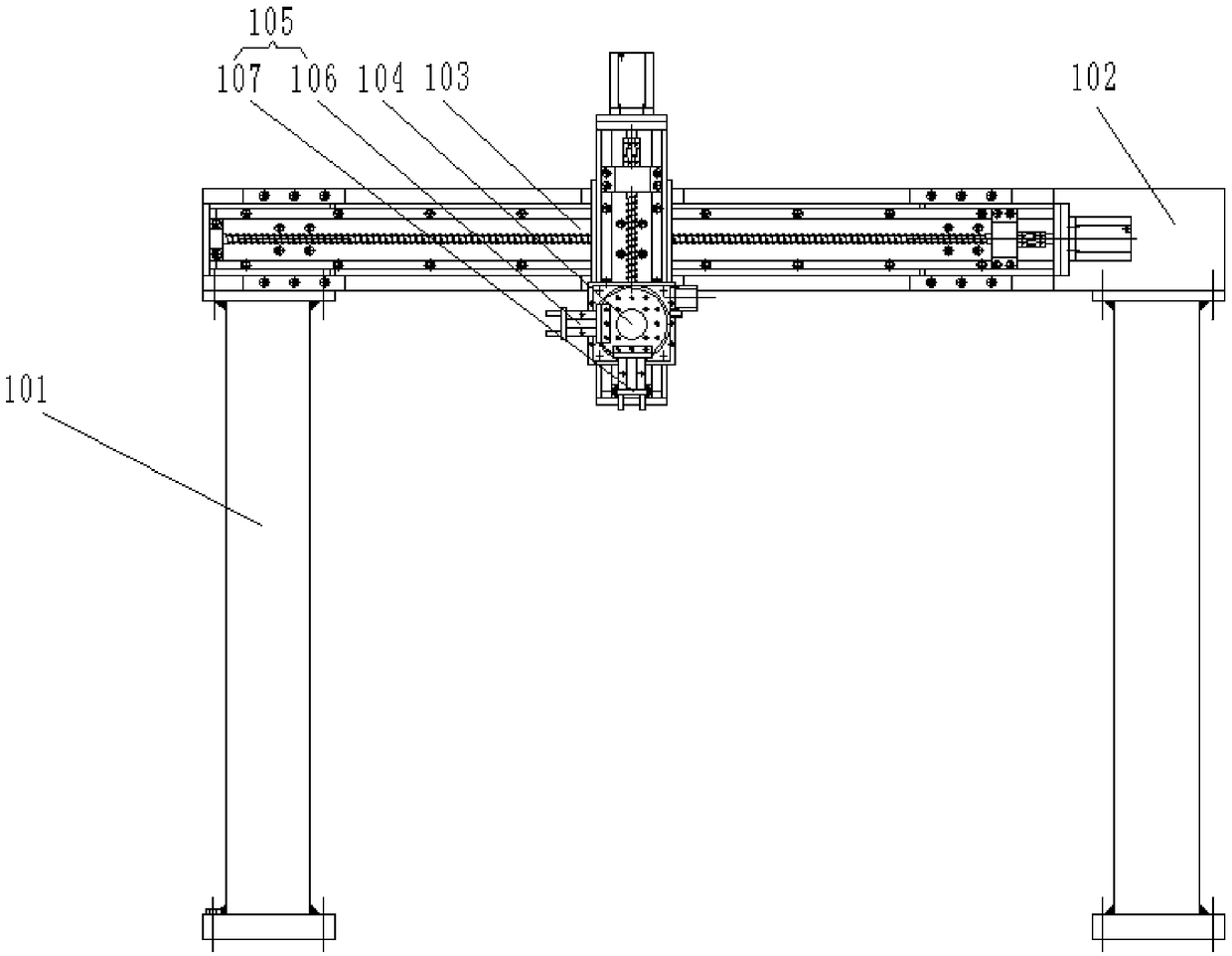

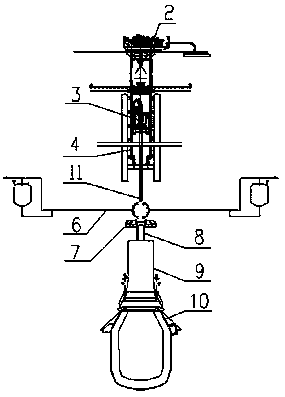

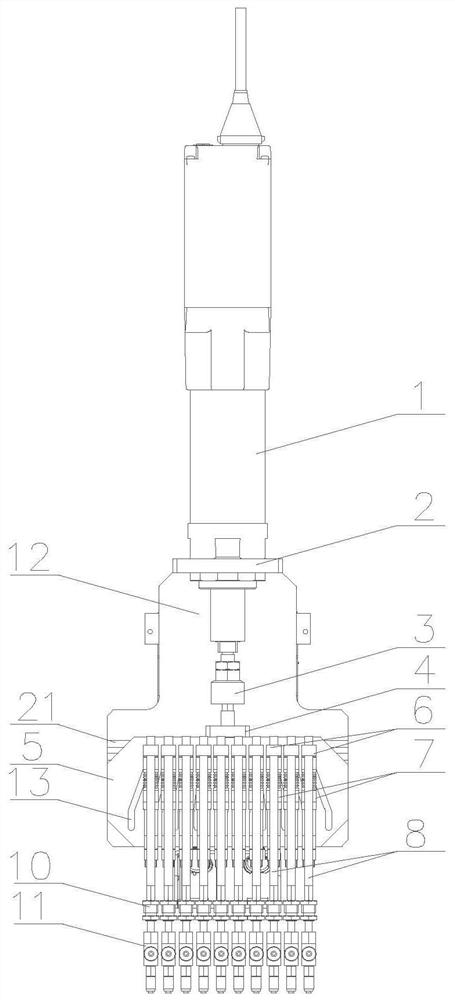

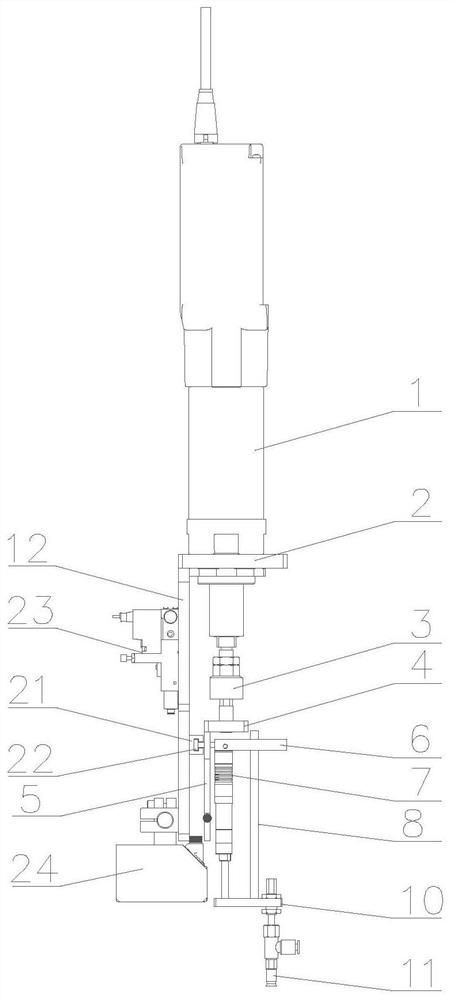

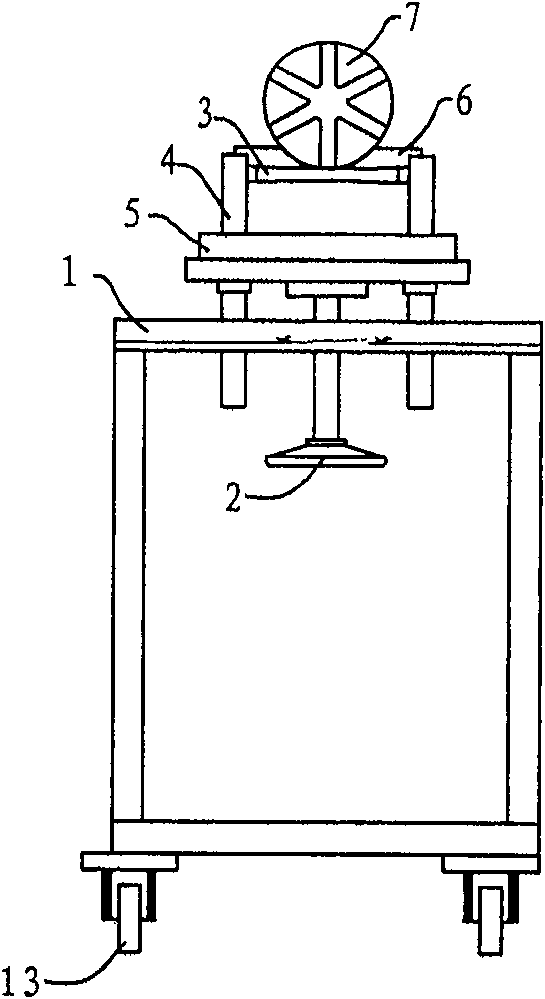

Automatic loading and unloading device of digital controlled lathe

PendingCN109249038AReduce production auxiliary timeIncrease productivityAutomatic workpiece supply/removalMetal working apparatusDigital controlMachining process

The invention provides an automatic loading and unloading device of a digital controlled lathe, and belongs to the technical field of mechanical manufacturing equipment. The automatic loading and unloading device of the digital controlled lathe comprises a manipulator system and a charging tray system, wherein the digital controlled lathe is arranged on one side of the charging tray system; and the manipulator system is arranged on the surface, which faces the charging tray system, of the digital controlled lathe. By the automatic loading and unloading device of the digital controlled lathe, during loading and unloading, continuous loading and unloading in a machining process of the digital controlled lathe can be realized through two gas claws of the manipulator system, the production auxiliary time is greatly shortened, and the production efficiency is improved effectively; according to the automatic loading and unloading device of the digital controlled lathe, the same system deviceis formed by the manipulator system and the charging tray system; and the automatic loading and unloading device of the digital controlled lathe is simple in structure, compact in overall arrangementand low in cost, and the occupied area is saved effectively.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Slit gauge

ActiveCN101059327AGuaranteed stabilityReduce production auxiliary timeUsing mechanical meansMechanical engineeringPiston ring

The invention belongs to a piston ring flexibility detecting device, in particular to a slit ruler. The inventive slit ruler comprises two detecting plates which can move relatively. The invention is characterized in that one side of a base is mounted with a fixed support, while another side is mounted with a movable support, the fixed support and the movable support are parallel, the two detecting plates are respectively mounted at the inner side of the fixed support and the movable support, the movable support is sliding connected on the base, and a pushing device for pushing the movable support is arranged between the movable support and the base. The invention can effectively resolve problem as frequent exchange, reduce producing time, make device with general service and reduce cost.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

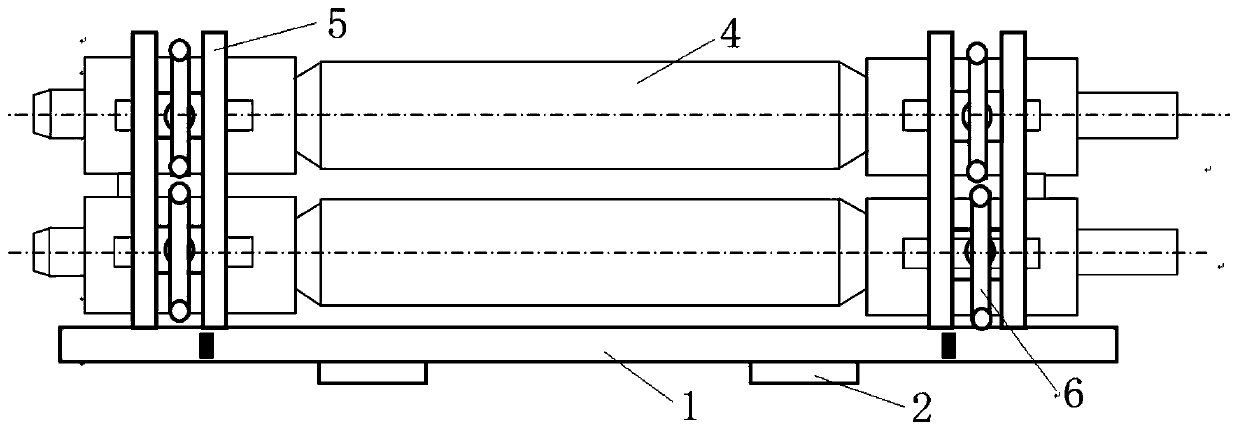

On-line exchanging bearing construction method for cold rolling electroplating and continuous annealing set sinking roller

ActiveCN101085656AReduce downtimeIncrease productivityCharge manipulationConveyor partsContinuous annealingElectroplating

The invention relates to the cold forging plating or continuous annealing bearing changing method. It dismantles the seal hood to get out of the seal active and static rings, installs the chain block on the steel structure or slot welding hanger to tie the roller, opening the bearing cover, dismantling the round nut and its stop cushion, dismantle the bearing base bolt, pulling down the bearing base and dismantle and clean it, installing the new bearing into the base and put it back, applying oil to the bearing to put back the round nut stop cushion, nut and bearing cover, adjusting the verticality of the depositing roll, and the mechanical seal to install the outside hood. It simplifies the procedure, reduces maintenance 2-3 hours, reduced in assisting time in production, and increased in productivity.

Owner:中国二十冶金建设有限公司

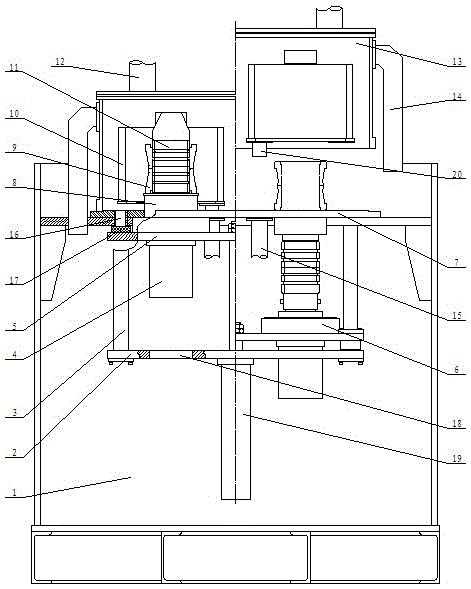

Railway bearing inner race mold retaining quenching device

ActiveCN104357624AReasonable structureIncrease the level of automationFurnace typesHeat treatment furnacesProduction lineFuel tank

The invention relates to a quenching device, and particularly to a railway bearing inner race mold retaining quenching device. The device comprises an oil tank, a worktable mounted inside the oil tank, a quenching mold mounted on the worktable and an quenching oil cover mounted at the upper part of the oil tank, and is characterized in that a fixing plate, a guiding rod and a supporting plate form an overall frame below the worktable; the quenching mold is mounted on the supporting plate; the quenching mold moves up to be inserted into an inner hole of a quenched workpiece and is used for implementing a quenching process in a closed quenching space formed by the quenching oil cover and the worktable. The quenching mold can move up to the surface of the worktable, so the mold is quite convenient, safe, clean and rapid to install and regulate, and the mold installation and regulation time is greatly shortened; compared with the prior art, the device can be used for reducing the production assistance time by more than 80%; meanwhile, no oil liquid overflows during the quenching process, and the device is environmentally friendly and quite applicable to ancillary use of large-batch thermal treatment production lines.

Owner:NINGXIA MACHINERY RES INST

A method for avoiding converter oxygen lance sticking steel slag

ActiveCN106591531BReduce replacement frequencyExtend your lifeManufacturing convertersSlagSpray coating

Owner:HEBEI IRON AND STEEL

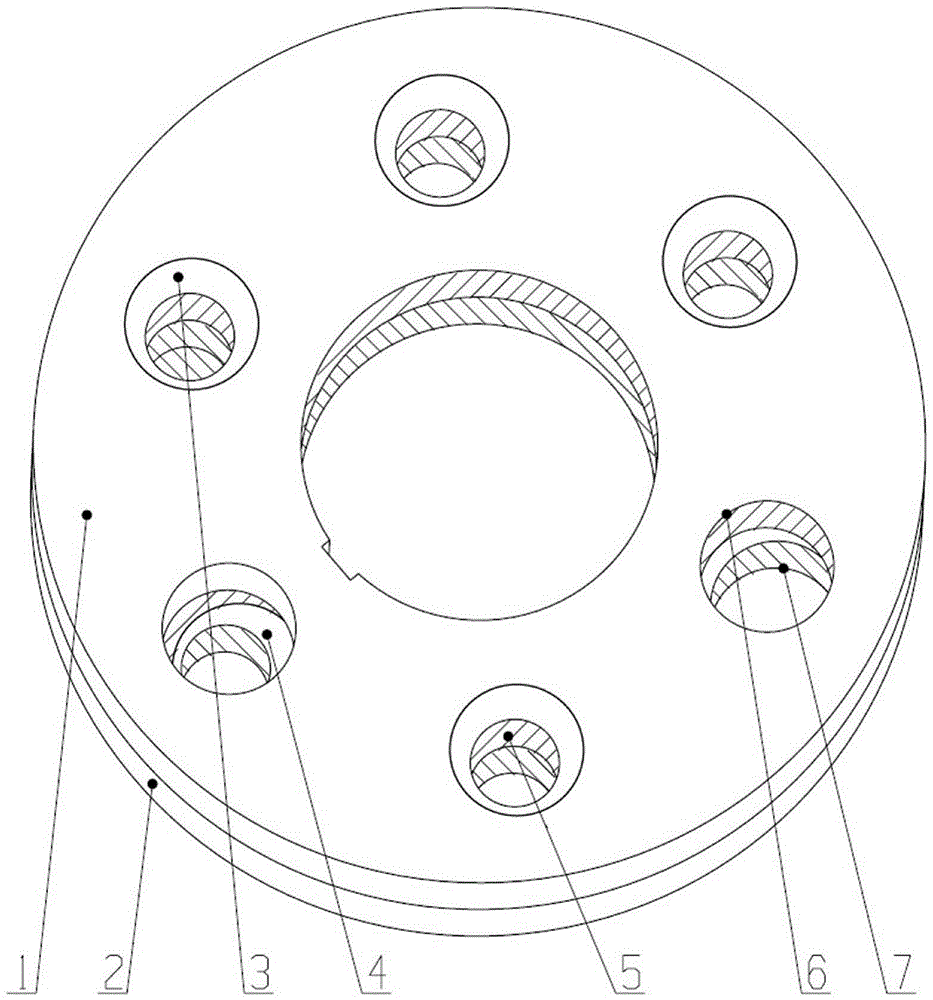

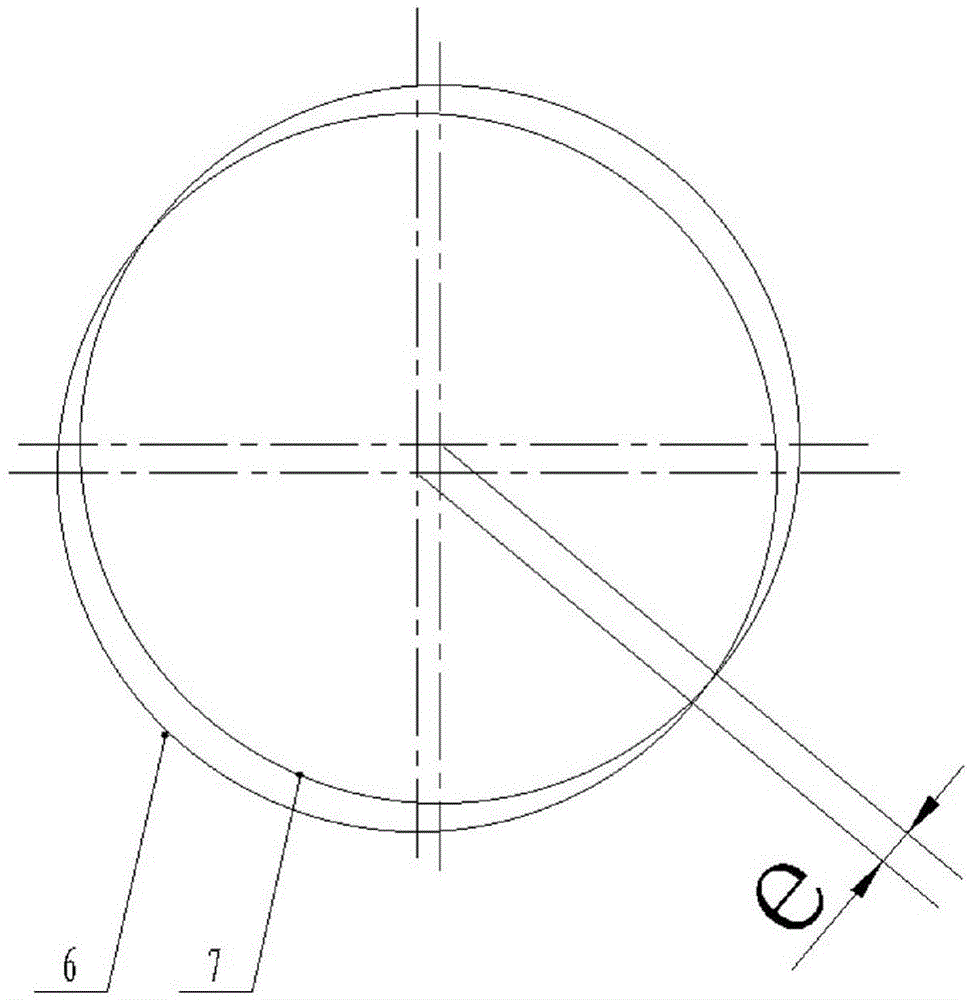

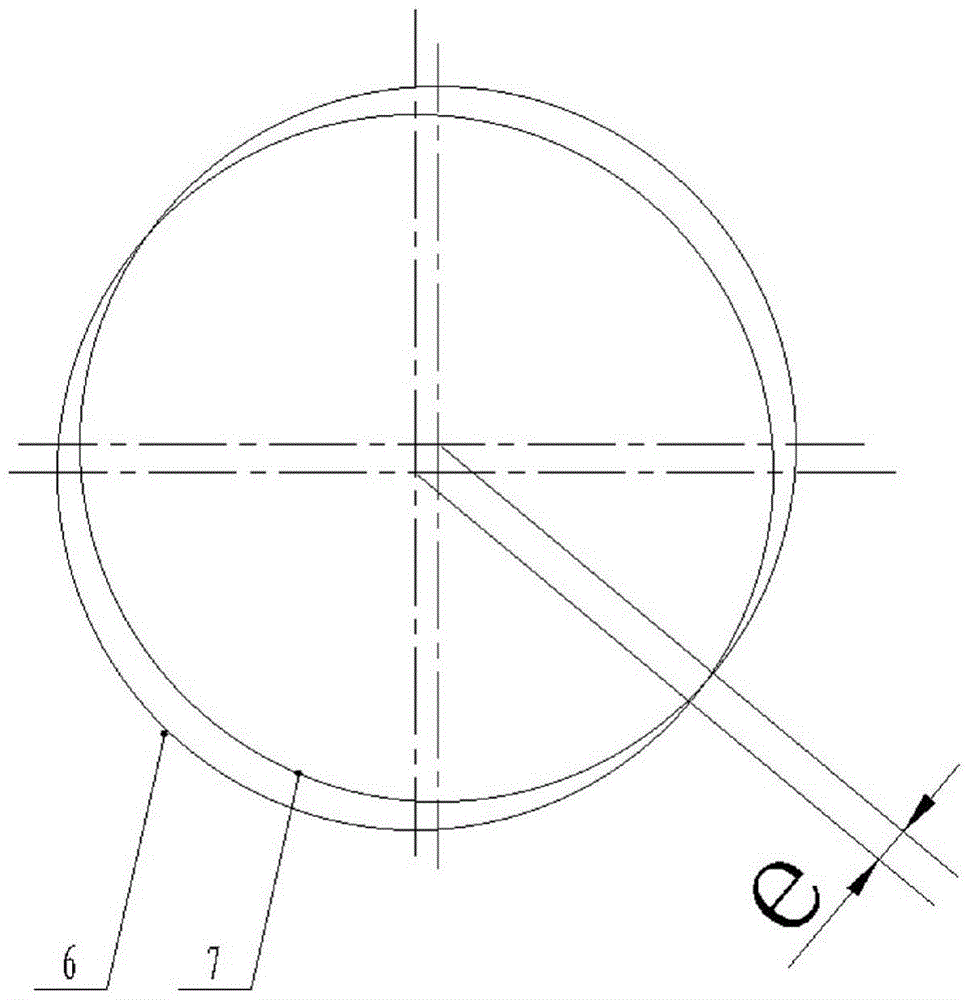

Deviation rectification device for reamed bolt holes and manufacturing method of deviation rectification device

ActiveCN104148875AEasy to replaceQuick and easy re-use when replacing partsMetal working apparatusEngineeringBolt connection

The invention discloses a deviation rectification device for reamed bolt holes and a manufacturing method of the deviation rectification device, and aims to provide a tool for reamed hole bolt connection, wherein the tool is short in maintenance time, low in maintenance intensity, economical and practical. The deviation rectification device comprises a part I and a part II which need to be connected through reamed bolts, holes A are formed in the part I, an eccentric bushing A is installed in each hole A, an eccentric hole is formed in the center of each eccentric bushing A, holes B are formed in the part II, an eccentric bushing B is installed in each hole B, an eccentric hole is formed in the center of each eccentric bushing B, the distance between the center of each hole A and the center of the corresponding hole B is set as e, the distance between the center of the corresponding eccentric hole and the center of the outer circle of each eccentric bushing A and the distance between the center of the corresponding eccentric hole and the center of the outer circle of each eccentric bushing B are g, the value of g is greater than or equal to 0.5e and is less than or equal to e, the end face of one end of each eccentric bushing A is provided with a tapered concave platform consistent with the axis of the corresponding eccentric hole, and the end face of one end of each eccentric bushing B is provided with a tapered convex platform matched with the tapered concave platform of the corresponding eccentric bushing A. The deviation rectification device for the reamed bolt holes and the manufacturing method of the deviation rectification device are suitable for manufacturing of the parts connected through the reamed bolts and particularly suitable for maintenance of the parts connected through the reamed bolts.

Owner:GUANGXI YUFENG GRP

Broach spline milling clamp

InactiveCN106514355ASimple structureEasy to manufacturePositioning apparatusMetal-working holdersEngineeringMachining

The invention discloses a broach spline milling clamp. The broach spline milling clamp comprises a base. A support and a fixing block are mounted on the base. A double-headed screw penetrates the support, one end of the double-headed screw is connected with a sliding block, and the other end of the double-headed screw is connected with a left-right adjusting nut. A vertical adjusting nut is mounted on the upper portion of the sliding block. A V-shaped supporting frame is mounted above the vertical adjusting nut. A supporting rod and a stud are mounted on the fixing block. One end of a pressing plate is connected with the supporting rod, and the other end of the pressing plate penetrates the stud and is fixed through a locking nut. A spring is mounted on the stud. A nut is mounted on the supporting rod. The broach spline milling clamp is simple in structure, convenient to manufacture, convenient to maintain and use, capable of achieving quick and precise positioning through up-down left-right adjustment and capable of achieving machining of small-batch varieties of products, the machining precision of a broach is guaranteed, the production auxiliary time is saved, and the production efficiency is improved.

Owner:ANHUI RUITAI AUTO PARTS

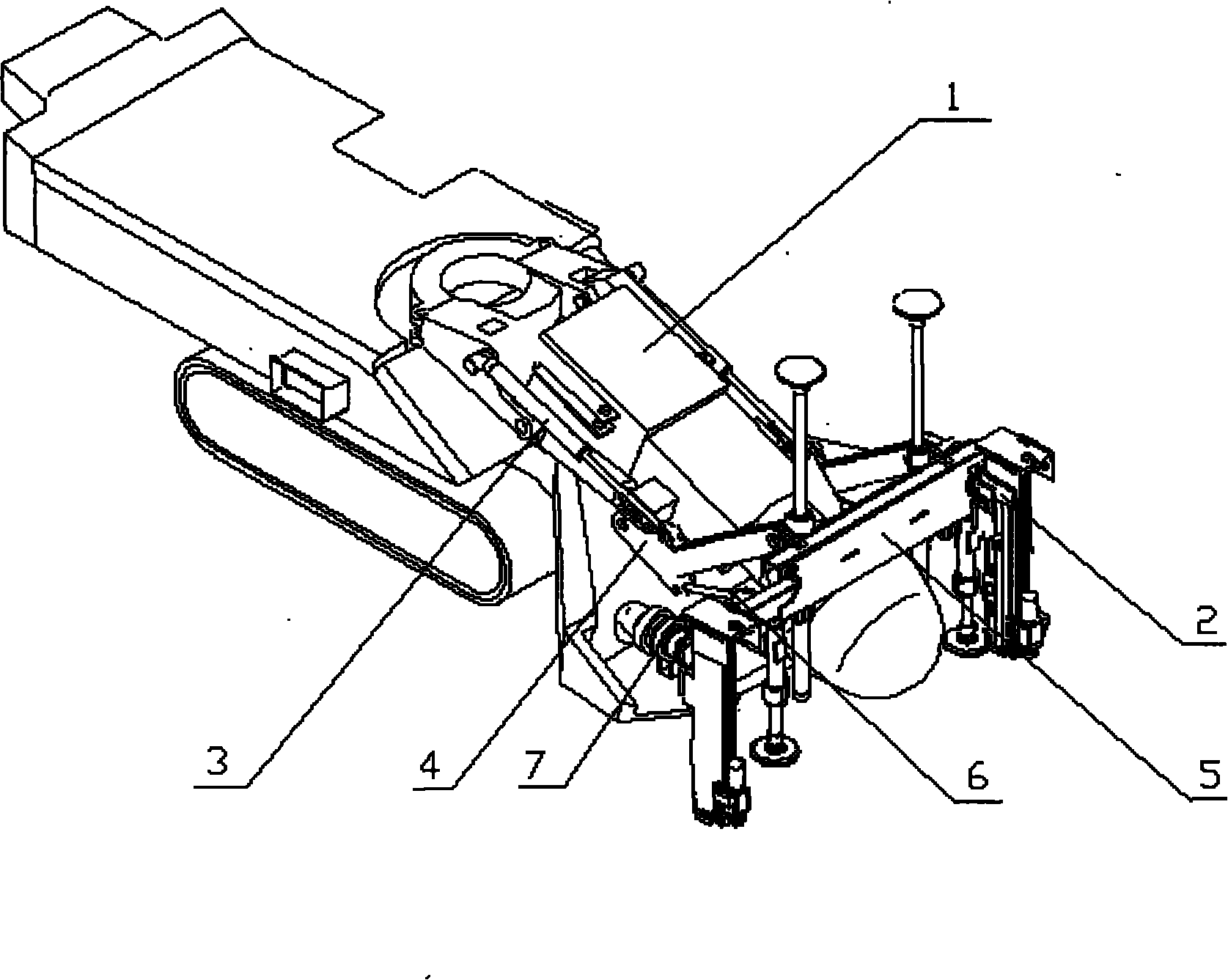

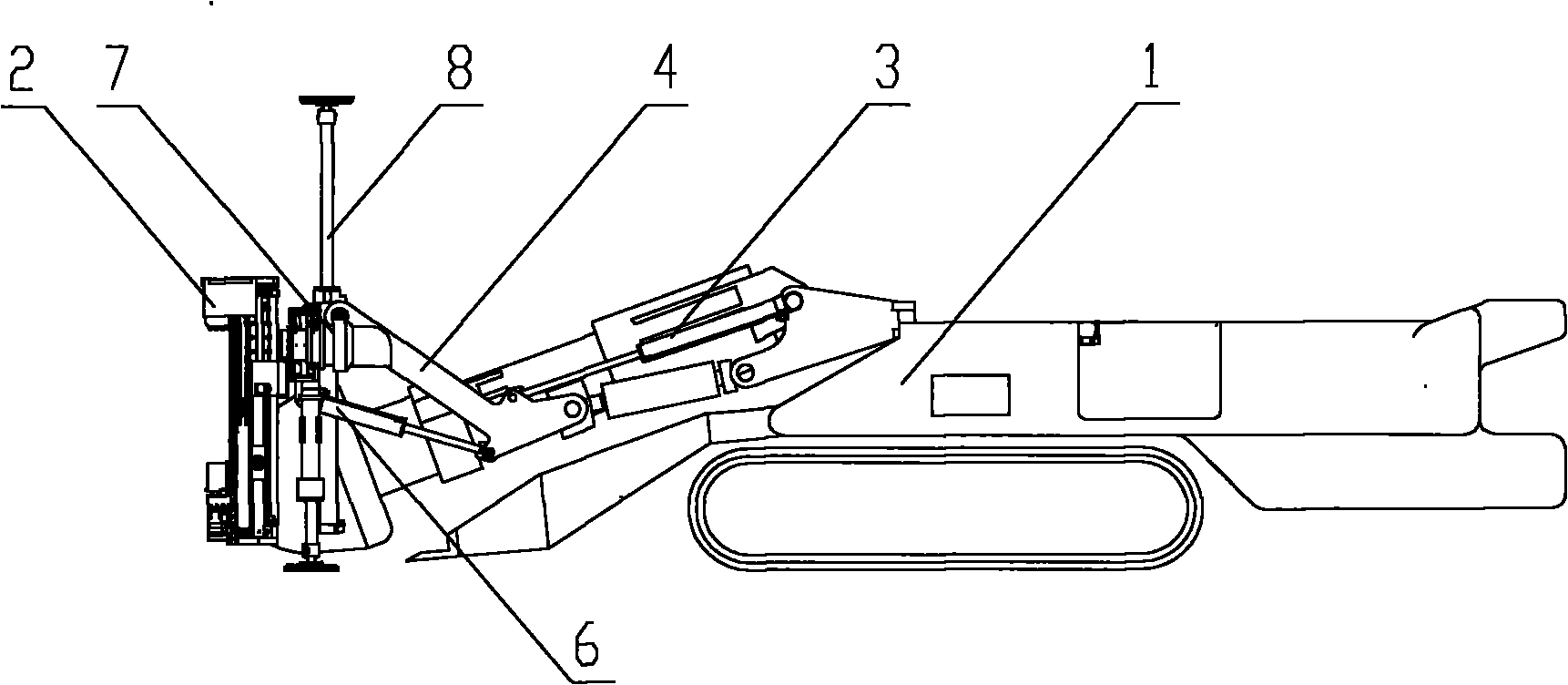

Development machine

The invention discloses a development machine, comprising a development machine body (1) as well as a supporting device (2) and a driving device (3) for driving the supporting device (2) to move; wherein the supporting device (2) is arranged at the front part of the development machine body (1), and the supporting device (2) can be in supported position under the action of the driving device (3). The development machine provided by the invention can widen application range thereof while ensuring use cost to be low, and meanwhile the time required by supporting is reduced, the labor intensity of workers is reduced, and the work efficiency is improved.

Owner:PANJI BRANCH OF FINLAY COAL DRESSING ENG & TECH BEIJING CO LTD

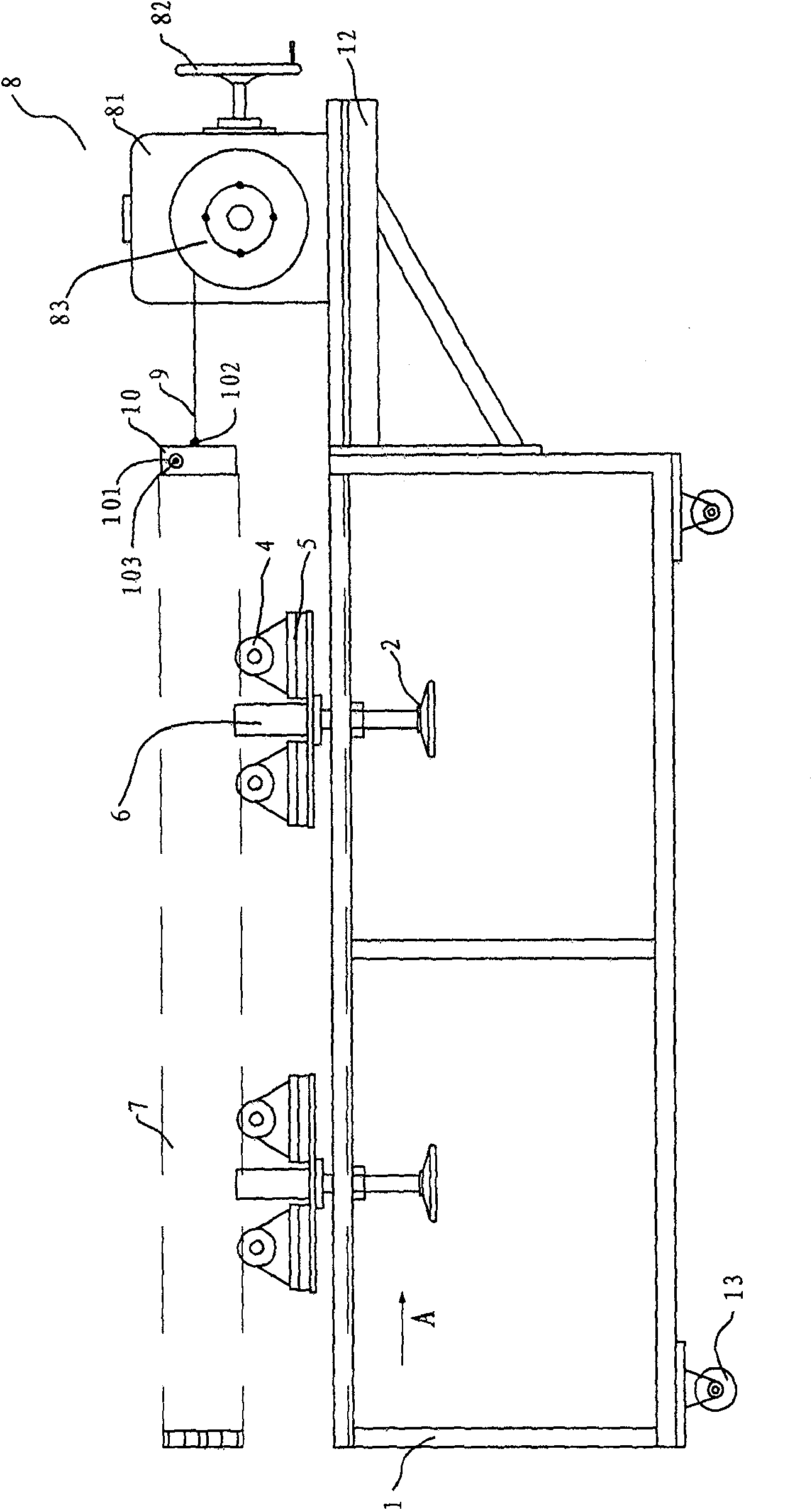

Combined carpentry machining equipment

The invention relates to combined carpentry machining equipment which comprises a body. The body is provided with a machining platform. The machining platform is provided with a clamping device for clamping a workpiece. A movable rack which can move along the body is arranged on the machining platform. A first cutter holder for mounting a machining cutter and a second cutter holder for mounting milling and drilling cutters are arranged on the movable rack. The clamping device can rotate to drive the workpiece on the clamping device to rotate. A fixing device for limiting the rotation of the clamping device is further arranged on the clamping device. The clamping device is provided with an online detecting device for detecting the rotation moment of the clamping device. The combined carpentry machining equipment has the advantages that functions such as turning, milling and drilling are added to the combined carpentry machining equipment, all or most machining procedures can be completed after one-step clamping, and a product manufacturing process chain is shortened greatly; production auxiliary time caused by clamping change is reduced, manufacturing cycle and waiting time of tool clamps are reduced, production efficiency can be increased evidently, clamping times are reduced, and machining precision is increased.

Owner:ZHONGSHAN MLTOR CNC TECH CO LTD

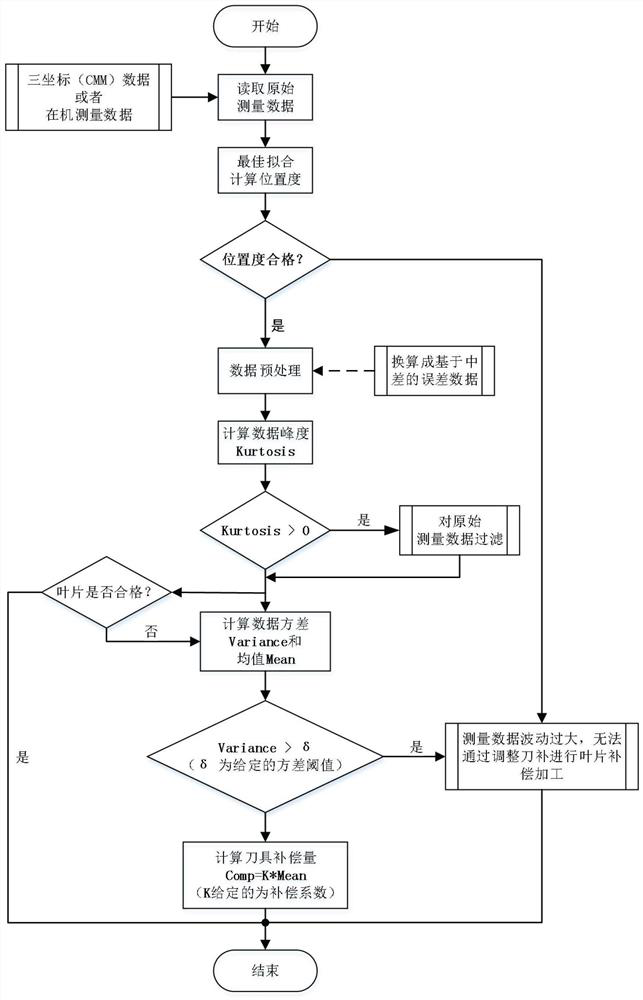

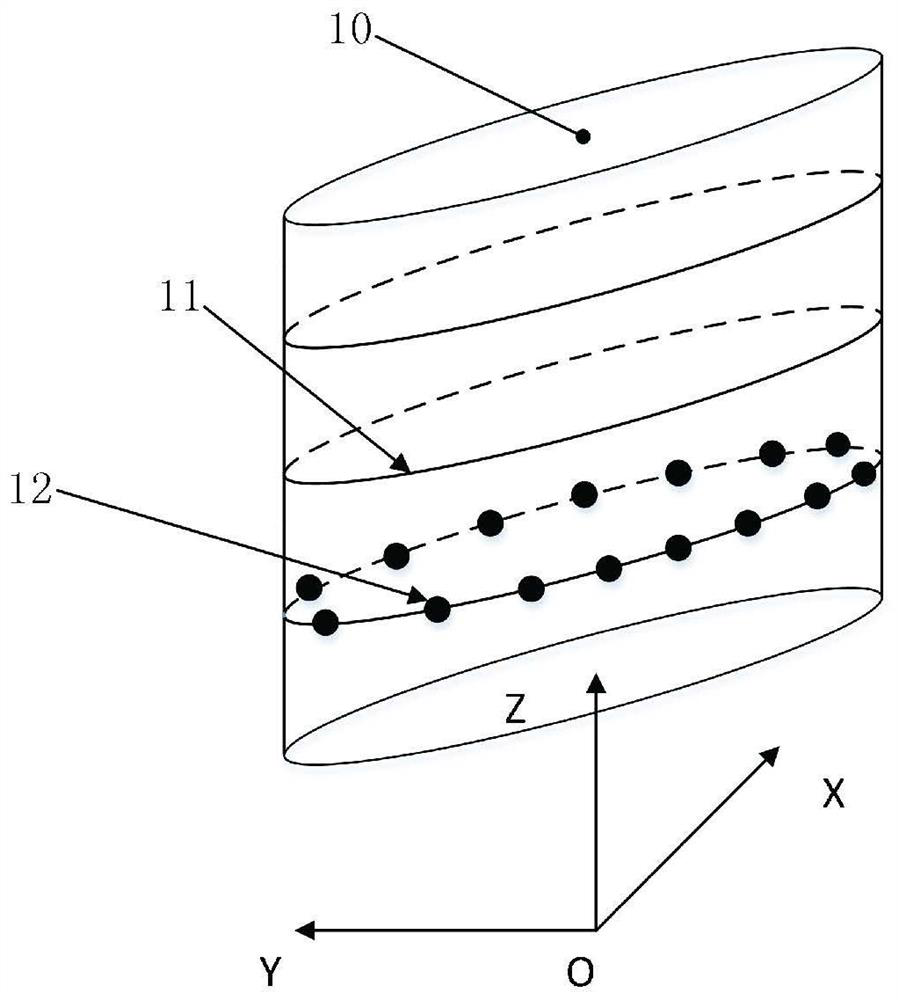

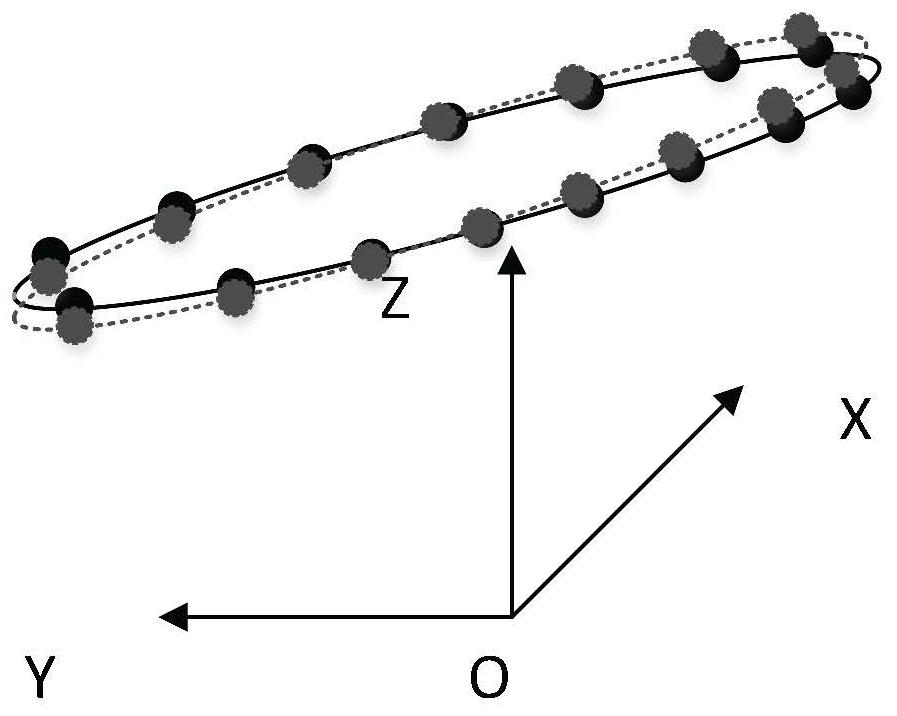

Blade machining cutter compensation amount calculation method and system

PendingCN114266014AReduce production auxiliary timeImprove machining accuracyComplex mathematical operationsAlgorithmMachining process

The invention discloses a blade machining cutter compensation amount calculation method, which comprises the following steps of: selecting a group of measurement points on a blade section line, and acquiring actual position data of each measurement point; fitting to obtain the location degree of the cross section corresponding to the cross section line; judging whether the location degree meets a tolerance requirement or not; calculating the error of each measuring point to obtain a group of error data, and calculating the kurtosis of the error data; performing statistical filtering on the error data to enable the kurtosis of the error data after statistical filtering to meet the requirement; judging whether the blade profile contour is qualified or not; calculating the variance of the error data meeting the kurtosis requirement; judging whether the variance meets a variance threshold value or not; and the cutter compensation amount is calculated according to the compensation coefficient and the mean value of the error data meeting the kurtosis requirement. According to the method, the blade machining state and the cutter compensation amount can be accurately obtained in the blade finish machining stage, and the production auxiliary time in the blade machining process can be remarkably shortened while the machining quality is effectively guaranteed.

Owner:苏州千机智能软件有限公司

Plate-spring forming quenching hardened die and application thereof

ActiveCN103614533AReduce in quantityLow costFurnace typesHeat treatment furnacesWaste productEngineering

The invention relates to a plate-spring forming quenching hardened die and an application thereof. The plate-spring forming quenching hardened die is characterized in that standardized and serialized quenching hardened dies are adopted in the plate-spring quenching process, and the corresponding quenching hardened die with the quenching curvature closest to that of a plate spring is selected according to the quenching curvature of the plate spring. The quenching hardened dies used in the plate-spring quenching process is normalized and serialized, and all the quenching hardened dies are prepared only by one time, so that the total number of the quenching hardened dies is greatly reduced, the technical design is simplified, the cost of the quenching hardened dies is saved, the management of the quenching hardened dies is facilitated, the quenching hardened die selecting adjustment time is shortened, the production efficiency is improved, the stability of the quality of a product is guaranteed, and the reject loss caused by misuse of the quenching hardened dies is avoided.

Owner:SHANDONG AUTOMOBILE SPRING FACTORY ZIBO CO LTD

Chip suction device capable of automatically adjusting space

PendingCN112607417ANo human intervention requiredReduce production auxiliary timeConveyor partsAuto regulationControl theory

A chip suction device capable of automatically adjusting the space comprises a support, and a lifting driving mechanism, a space adjusting mechanism and a suction mechanism are installed on the support. The space adjusting mechanism comprises a comb plate, a space adjusting assembly and multiple steering engine assemblies, multiple hollowed-out grooves are formed in the comb plate, the space adjusting assembly comprises a limiting groove and multiple connecting shafts, the limiting groove is fixed to the support, one ends of the connecting shafts are clamped in the limiting groove, and the other ends of the connecting shafts penetrate through the hollowed-out grooves in the comb plate and are then fixed to the steering engine assemblies. The numbers of the hollowed-out grooves, the connecting shafts and the steering engine assemblies correspond to one another. The suction mechanism comprises a containerized vacuum generator and multiple suction cups, the suction cups are installed below the steering engine assemblies correspondingly, and multiple gas suction ports of the containerized vacuum generator communicate with air outlets of the suction cups through gas pipes correspondingly. The lifting driving mechanism is used for driving the comb plate to move up and down. The space between the suction cups can be adjusted, the chip suction device can adapt to chips of different specifications, the production auxiliary time is saved, and the production efficiency is improved.

Owner:QINGDAO SIASUN ROBOT & AUTOMATION CO LTD

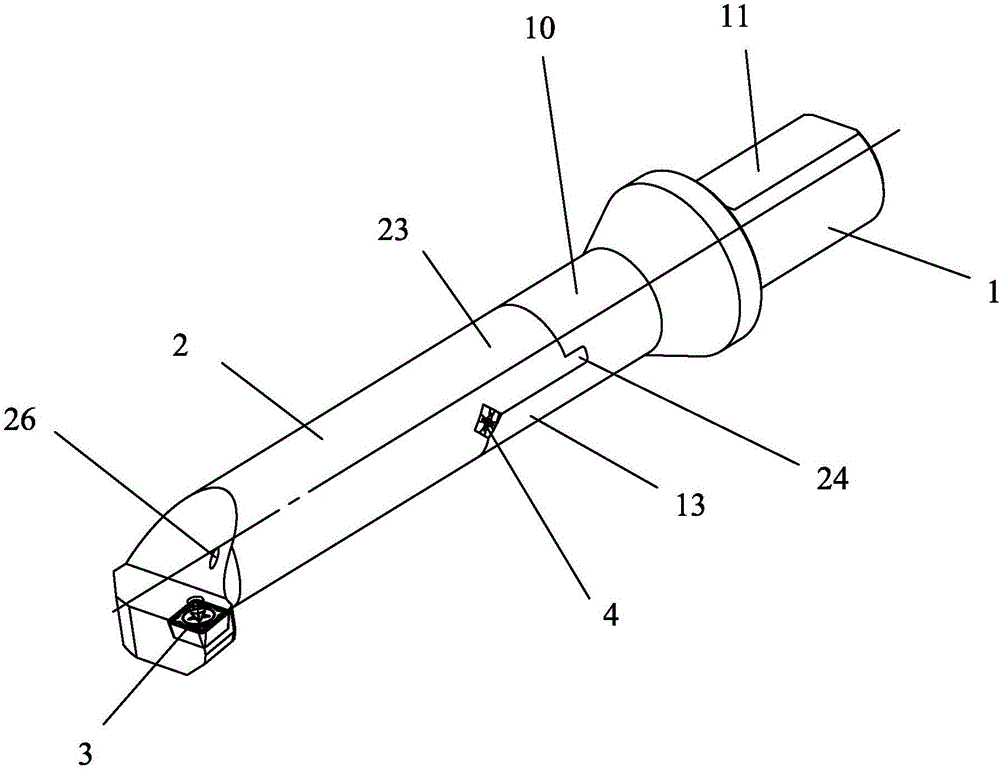

Pin wedge grafting type hole machining tool capable of being replaced in on-machine mode

ActiveCN105834463AImprove installation efficiencyReduce production auxiliary timeBoring barsEngineeringButt joint

The invention discloses a pin wedge grafting type hole machining tool capable of being replaced in an on-machine mode. The pin wedge grafting type hole machining tool comprises a tool body part, a tool body cutting part and a pin body. The other end of the tool body part is provided with a cylindrical anti-bending shaft, a first groove and a first through hole penetrating in the radial direction. The other end of the tool body cutting part is provided with a cylindrical anti-bending hole, a first convex body and a second groove penetrating in the radial direction. When the other end of the tool body part is in butt joint with the other end of the tool body cutting part, the cylindrical anti-bending shaft and the first groove of the tool body part are matched with the cylindrical anti-bending hole and the first convex body of the tool body cutting part respectively, and the pin body is inserted into the first through hole of the tool body part and the second groove of the tool body cutting part at the same time. The pin wedge grafting type hole machining tool solves the problems that an existing hole machining tool is complex in disassembling process, low in replacing efficiency and the like, and the purposes of greatly improving tool installation efficiency and shortening production non-cutting time can be achieved on the basis that tool performance is not lowered.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

Device for changing roller

ActiveCN100577314CReduce investmentFlexible roll changeMetal rolling stand detailsMetal rolling arrangementsMechanical engineeringWork safety

The roll changer includes one frame, one roll connecting mechanism, one traction mechanism, and several parallel elevating mechanisms with height regulation. The roll connecting mechanism is connected through a traction rope to the traction mechanism; and the elevating mechanisms have in the top one V-shaped support block to limit the transverse motion of the roll and one roll shaft for facilitating the traction of the roll, with the roll shaft capable of rotating being set on the elevating mechanism and coaxially with the support block. The present invention has the advantages of high work efficiency, high safety and saving in manpower.

Owner:NINGBO BAOXIN STAINLESS STEEL

Planetary framework diamond abrasive tools

InactiveCN100436063CAvoid loweringMaintain sharpnessGrinding machinesMetal working apparatusDrive shaftGear wheel

The planetary mechanism diamond grinding tool is one workpiece grinding diamond grinding wheel apparatus with great grinding width, high efficiency, low cost and grinding wheel without needing trimming measure and tool. It has planetary gear mechanism, spring clamp sleeve, cooling pipeline, fixing and connecting casing and rotating casing. The planetary gear mechanism is provided with bearing, sun gear, planetary gear, nut, bearing and pressurized cooling liquid inflow pipeline. The rotating casing is connected to the driving shaft integrally, the bearing is set between the driving shaft and the fixing and connecting casing, the sun gear is set on the driving shaft for rotation, the planetary gear is connected to the sun gear, the spring clamp sleeve is set in the output end of the planetary shaft, the cooling liquid inflow pipeline is set in the axial center of the driving shaft and has one end connected to the built-in cooling pipeline inside the rotating casing.

Owner:XIAMEN UNIV

Radial diamond abrasive tool with planet mechanism

InactiveCN100413647CAvoid cloggingAvoid loweringGrinding machine componentsGrinding machinesGear wheelEngineering

The invention relates to a radial planet diamond grinder, especially providing a diamond grinding wheel work-piece, with wider grinding width, high efficiency, lower cost and continuous operation. Said planet device comprises a bearing, a sun wheel, planet wheels, taper gear wheel, grinding main axle, nut, and a pressure refrigerating liquid inlet tube. The end of rotational frame is integrated with the inlet of driving axle; the inlet of driving axle is connected to the rotational axle of machine tool; a bearing is arranged between the driving axle and the fixed connecting frame; the top of fixed connecting frame is connected to the machine tool; the driving axle is mounted with sun wheel; the planet gear wheel is connected to the sun wheel; the planet axle drives the taper gear wheel to drive the grinding main axle; the grinding head spring is clamped on the output end of grinding main axle; the refrigerating liquid inlet tube is at the axes of driving axle and connected to the internal refrigerating tube of rotational frame; the refrigerating liquid flows to the clamp end of grinding spring that connecting to the grinding main axle, to enter into the middle hole of grinding head.

Owner:XIAMEN UNIV

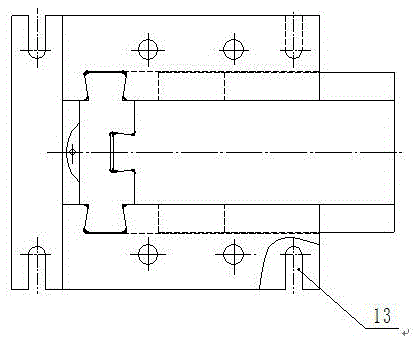

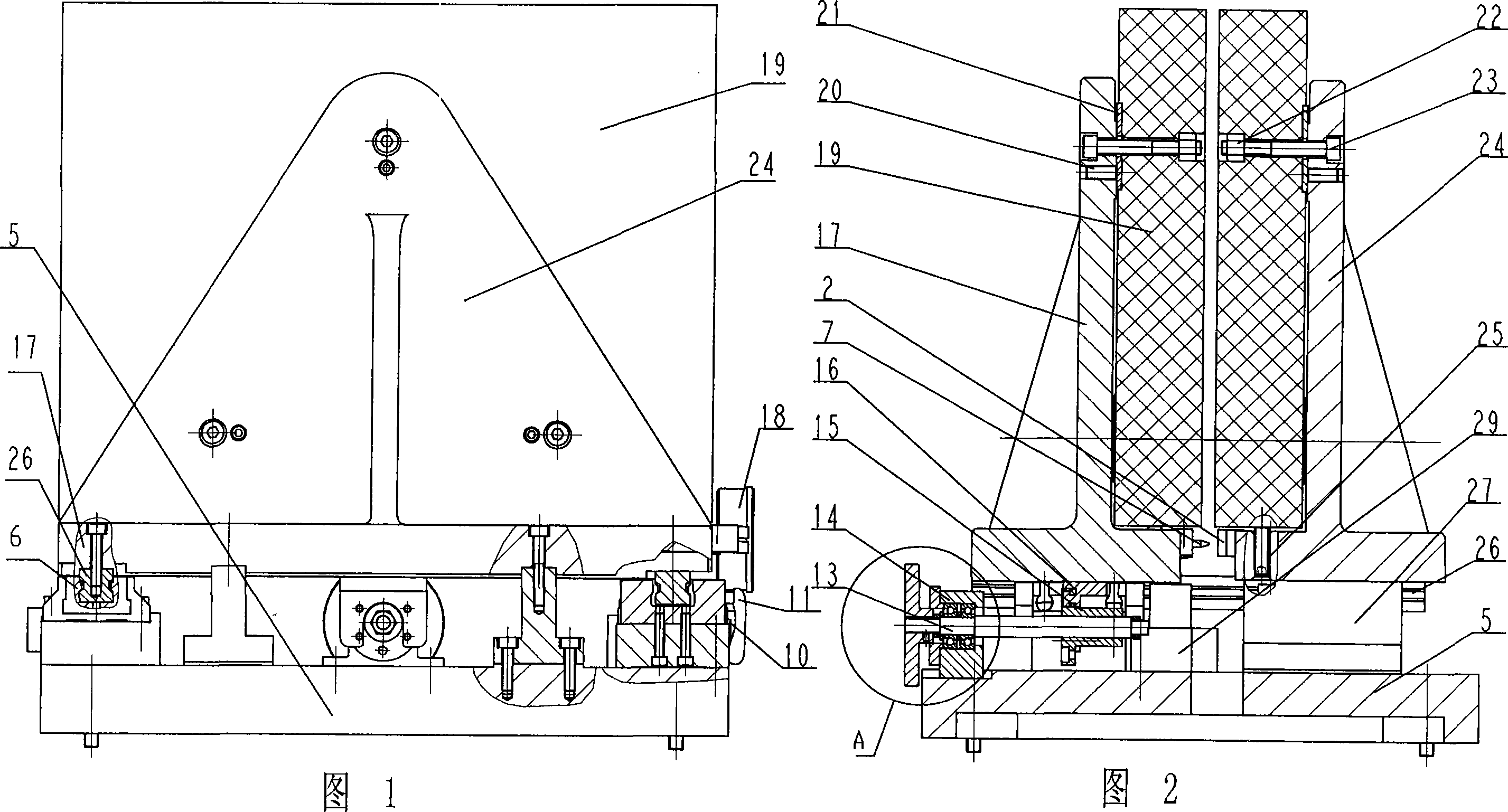

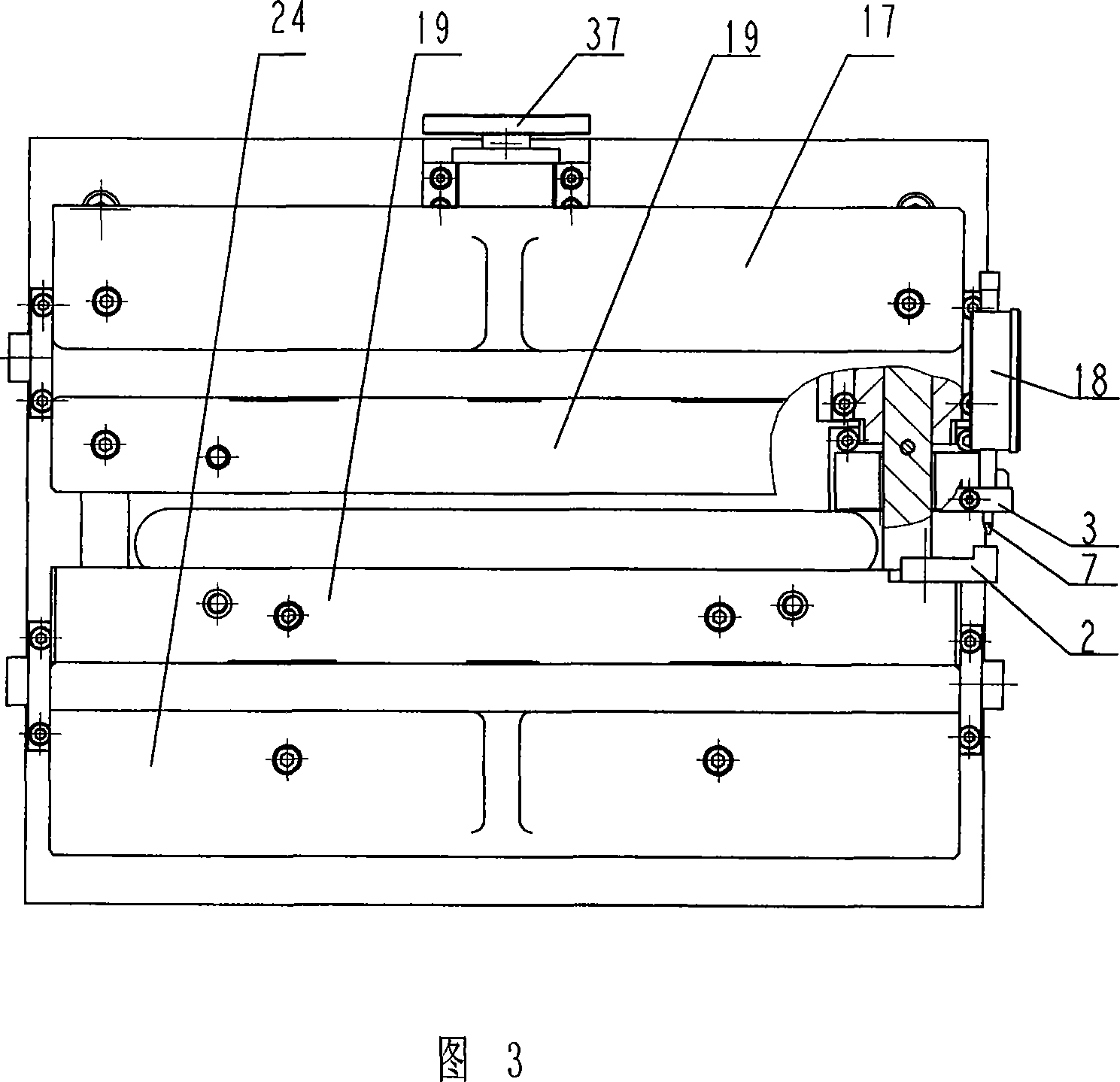

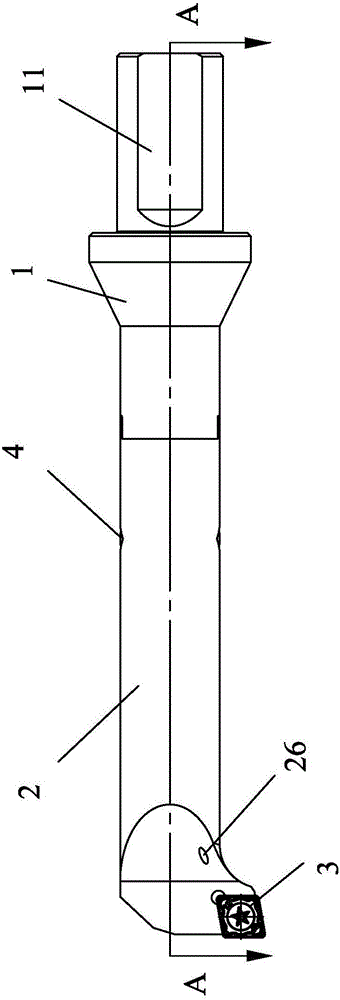

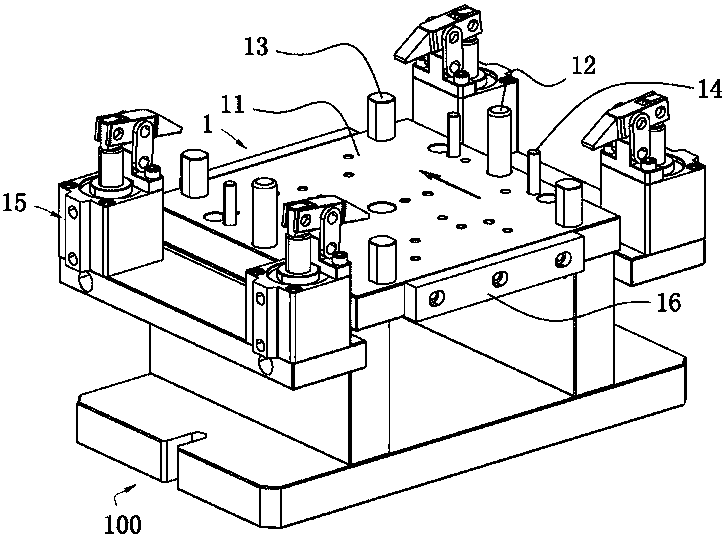

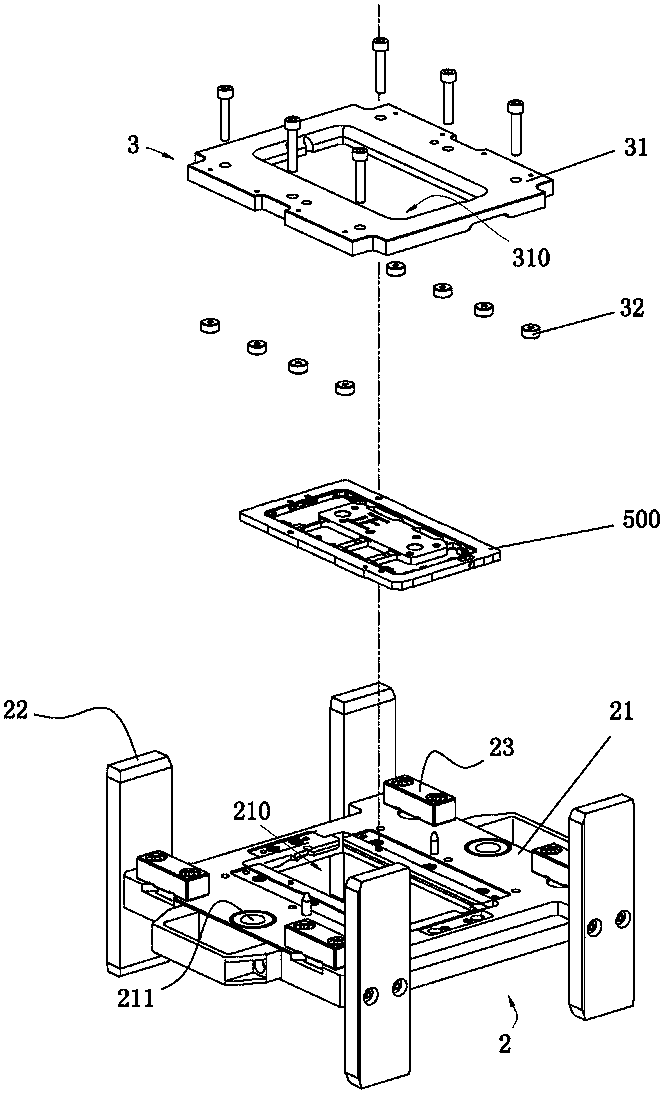

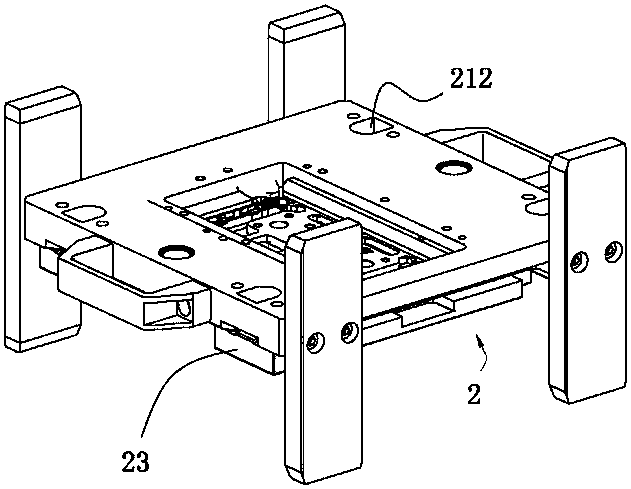

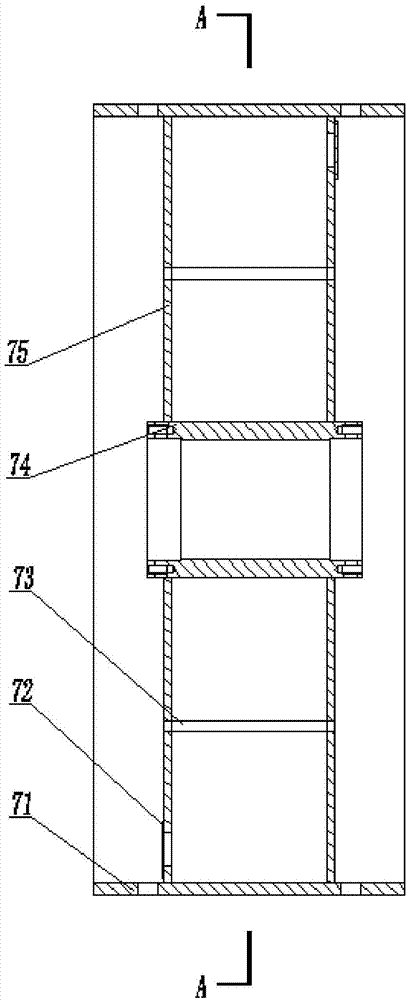

A fixture that realizes the processing of complex workpieces in one clamping

InactiveCN105500068BShorten the timeReduce production auxiliary timePositioning apparatusMetal-working holdersNumerical controlEngineering

The invention discloses a fixture with a function of completing machining of a complex workpiece by one-time clamping. The fixture is applicable to a fourth shaft of a numerically-controlled machine tool to realize multi-surface machining of the complex workpiece by one-time clamping. The fixture comprises a base datum plate structure, an auxiliary clamp and a cover plate component, the auxiliary clamp is used for realizing quick combination with the base datum plate structure, and the cover plate component is disposed in the auxiliary clamp. The fixture is ingenious in design and reasonable in structure, and machining of front and back faces and side faces of the workpieces can be realized by one-time clamping. In addition, the scheme for solution of clamping techniques is provided to realize that workpiece replacement time and production auxiliary time can be shortened in a complex workpiece machining process, workpiece clamping precision is guaranteed, and improvement of production efficiency is promoted. Furthermore, high efficiency and low labor intensity in use of the fixture can be realized beneficially.

Owner:东莞市精誉自动化科技有限公司

Deviation correction device for reaming bolt holes and manufacturing method thereof

ActiveCN104148875BAchieve connectionReduce labor intensityMetal working apparatusEngineeringBolt connection

The invention discloses a deviation rectification device for reamed bolt holes and a manufacturing method of the deviation rectification device, and aims to provide a tool for reamed hole bolt connection, wherein the tool is short in maintenance time, low in maintenance intensity, economical and practical. The deviation rectification device comprises a part I and a part II which need to be connected through reamed bolts, holes A are formed in the part I, an eccentric bushing A is installed in each hole A, an eccentric hole is formed in the center of each eccentric bushing A, holes B are formed in the part II, an eccentric bushing B is installed in each hole B, an eccentric hole is formed in the center of each eccentric bushing B, the distance between the center of each hole A and the center of the corresponding hole B is set as e, the distance between the center of the corresponding eccentric hole and the center of the outer circle of each eccentric bushing A and the distance between the center of the corresponding eccentric hole and the center of the outer circle of each eccentric bushing B are g, the value of g is greater than or equal to 0.5e and is less than or equal to e, the end face of one end of each eccentric bushing A is provided with a tapered concave platform consistent with the axis of the corresponding eccentric hole, and the end face of one end of each eccentric bushing B is provided with a tapered convex platform matched with the tapered concave platform of the corresponding eccentric bushing A. The deviation rectification device for the reamed bolt holes and the manufacturing method of the deviation rectification device are suitable for manufacturing of the parts connected through the reamed bolts and particularly suitable for maintenance of the parts connected through the reamed bolts.

Owner:GUANGXI YUFENG GRP

Working roll transferring rack

InactiveCN111098283ASimple structureEasy to carryWork holdersWork tools storageWork rollRolling chassis

The invention relates to the technical field of working roll assembling, in particular to a working roll transferring rack. The working roll transferring rack comprises a chassis, fixtures are arranged on the chassis, and working roll bearing boxes are installed on the two sides of working rolls; the working roll bearing boxes are clamped among the fixtures; each fixture comprises positioning blocks, a rocker and a lead screw, and a connecting rod is fixedly arranged between the corresponding two positioning blocks; each connecting rod is provided with a cut-through through hole used for allowing the corresponding lead screw to penetrate; the lead screws and the positioning blocks are located on the inner sides of the rockers, the lead screws are fixed to the centers of the rockers, and cushion blocks are fixedly connected to the ends, close to the working roll bearing boxes, of the lead screws; and the cushion blocks are used for clamping the working roll bearing boxes. According to the working roll transferring rack, the structure is simple, carrying is convenient, travelling crane lifting does not need to wait, the production auxiliary time of a rolling mill is shortened, therefore, the transferring efficiency is improved, and higher safety and stability are achieved in the transferring process.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Die holding quenching device for railway bearing inner ring

ActiveCN104357624BReasonable structureIncrease the level of automationFurnace typesHeat treatment furnacesProduction lineFuel tank

The invention relates to a quenching device, and particularly to a railway bearing inner race mold retaining quenching device. The device comprises an oil tank, a worktable mounted inside the oil tank, a quenching mold mounted on the worktable and an quenching oil cover mounted at the upper part of the oil tank, and is characterized in that a fixing plate, a guiding rod and a supporting plate form an overall frame below the worktable; the quenching mold is mounted on the supporting plate; the quenching mold moves up to be inserted into an inner hole of a quenched workpiece and is used for implementing a quenching process in a closed quenching space formed by the quenching oil cover and the worktable. The quenching mold can move up to the surface of the worktable, so the mold is quite convenient, safe, clean and rapid to install and regulate, and the mold installation and regulation time is greatly shortened; compared with the prior art, the device can be used for reducing the production assistance time by more than 80%; meanwhile, no oil liquid overflows during the quenching process, and the device is environmentally friendly and quite applicable to ancillary use of large-batch thermal treatment production lines.

Owner:NINGXIA MACHINERY RES INST

A double-width plate iron water mill

InactiveCN103447121BIncreased crush strengthImprove productivityGrain treatmentsRenewable energy source integrationFault rateFlange

The invention discloses a double-plate type iron water-powered roller. The double-plate type iron water-powered roller comprises a runner wheel framework assembly and an edge-runner pan and is characterized in that the runner wheel framework assembly comprises a hub, double plates and a rim, which are welded to form one body, wherein a hollow structure is formed between the two plates, connecting rods are circumferentially welded and distributed on the plates, a block combined wheel flange lining plate is arranged at the outer side of the rim in a fastening manner by a bolt and a nut, a spring is arranged on the bolt at the inner side of the rim in a sheathed manner and is arranged between the rim and the nut, and the edge-runner pan and the runner wheel framework assembly are made of an iron material. The double-plate type iron water-powered roller has high production efficiency, low power consumption, a low equipment fault rate and little part abrasion.

Owner:凤阳县三友矿山机械设备有限公司 +1

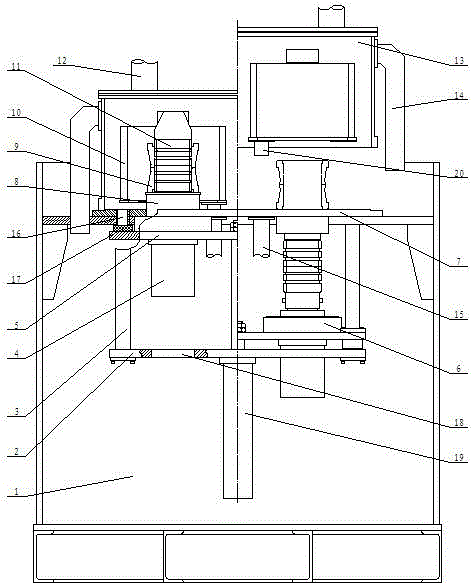

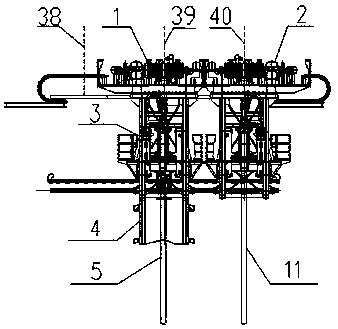

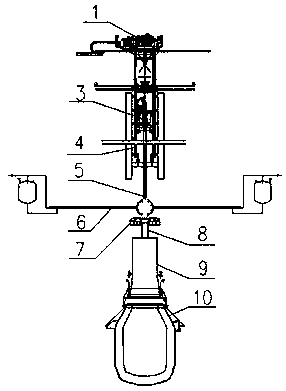

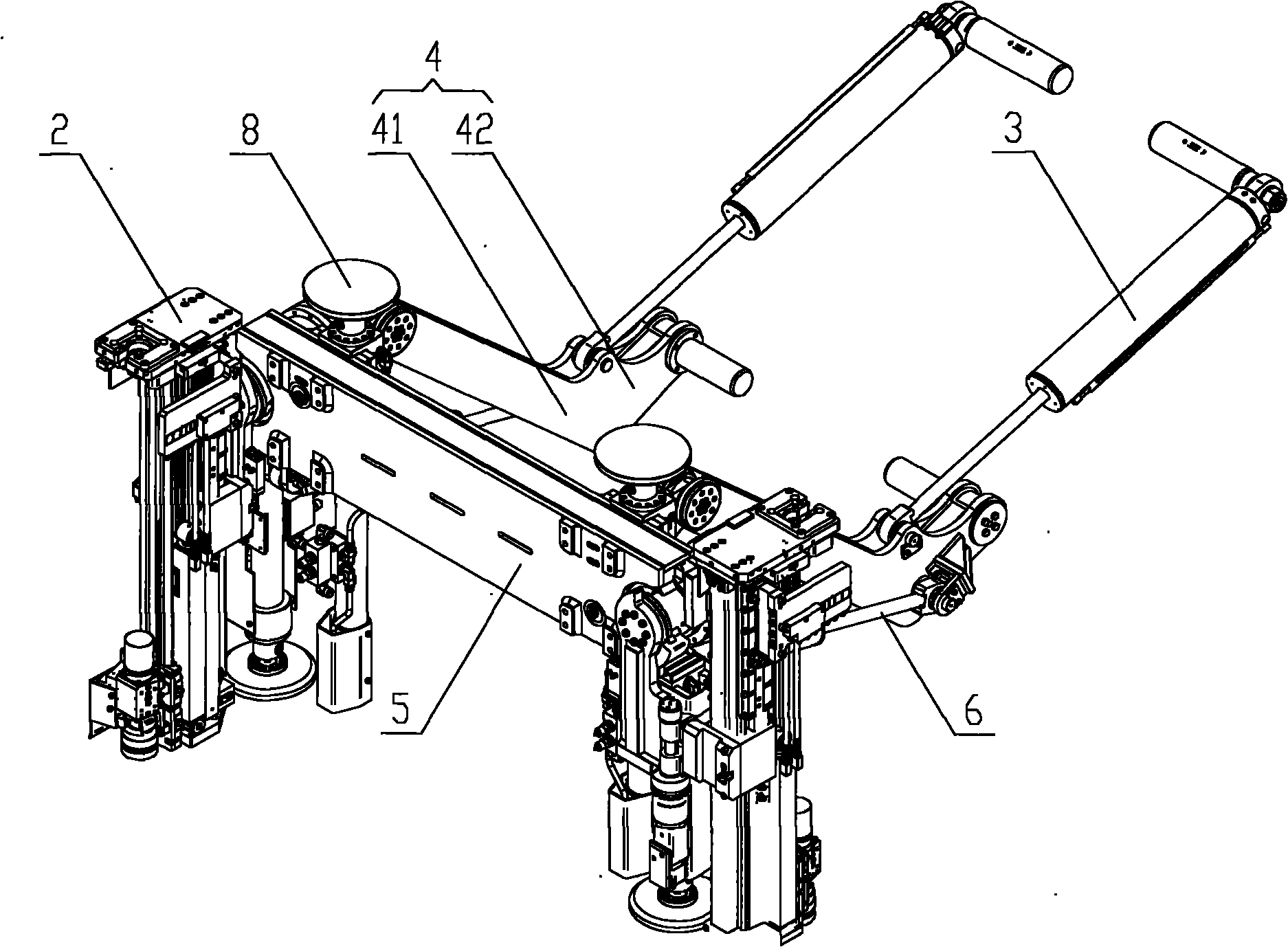

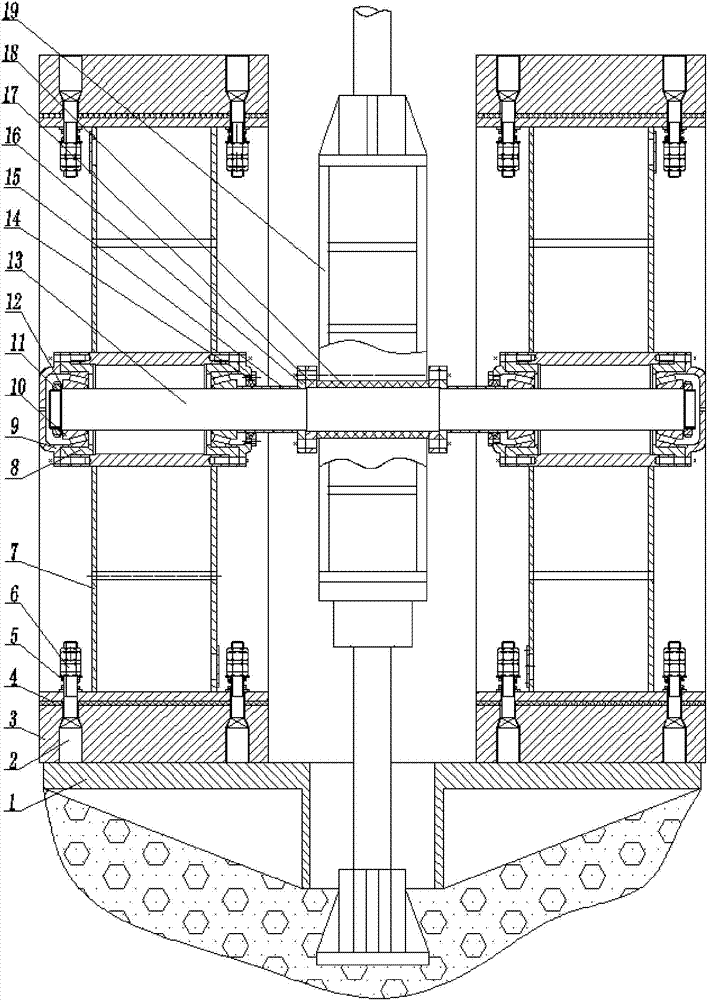

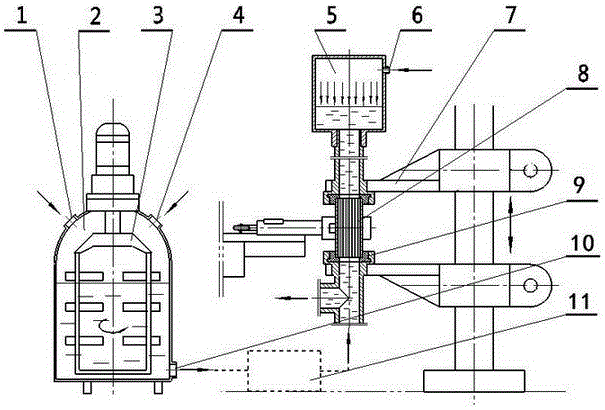

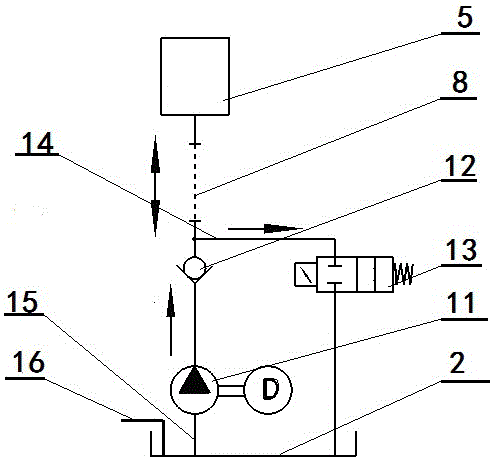

A catalyst automatic coating device for honeycomb exhaust pipe

ActiveCN103752465BGuaranteed uniformityAccurate settingLiquid surface applicatorsCoatingsControl systemAgricultural engineering

The invention discloses an automatic coating device of a honeycomb exhaust pipe catalyst. The automatic coating device is composed of a material storage system, a pressure control system and a rapid interface device; the material storage system is mainly composed of a storage cabin and a stirrer; the pressure control system is mainly composed of a quantitative injection pump, a discharging pipe, a one-way valve, an electromagnetic valve, a backflow pipe and a pressure-retaining cabin; and the rapid interface device is mainly composed of a rapid joint mechanism, a double-upright-post frame, a stress-applying lever system, a sealing base assembly and a cylinder. By means of application of the automatic coating device of the honeycomb exhaust pipe catalyst disclosed by the invention, constancy and homogeneity of the coating amounts of coatings are ensured; the product quality accords with enterprise standard requirements; the labour intensity of first-line operators is greatly lightened; and the production efficiency is effectively increased.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com