Clamp for quickly changing inner support of cylinder jacket

A technology for quick-change fixtures and cylinder liners, applied in the directions of clamping, manufacturing tools, supports, etc., can solve problems such as being unsuitable for small batch and multi-variety production lines, long time for tool replacement, affecting production efficiency, etc., to shorten production auxiliary time, Improve production efficiency, fast and convenient loading and unloading of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

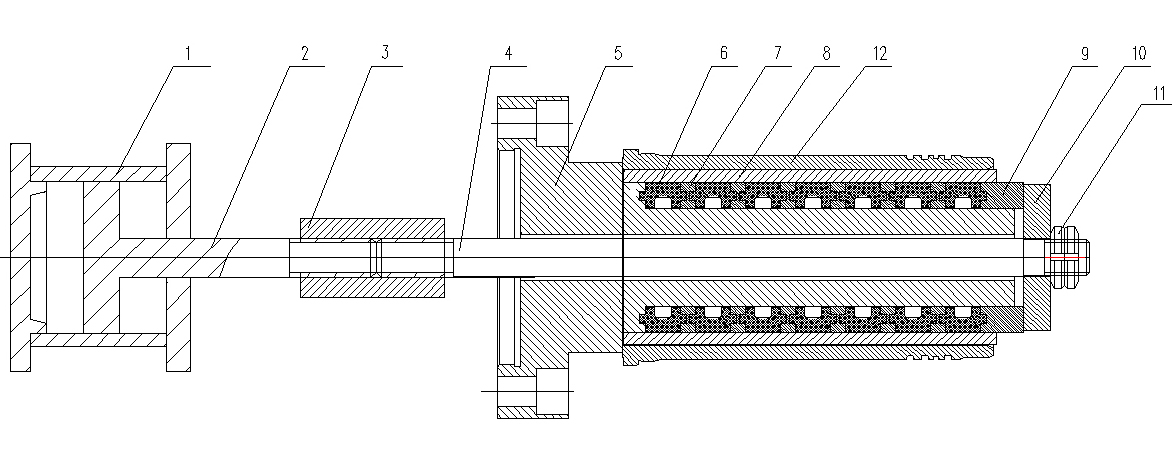

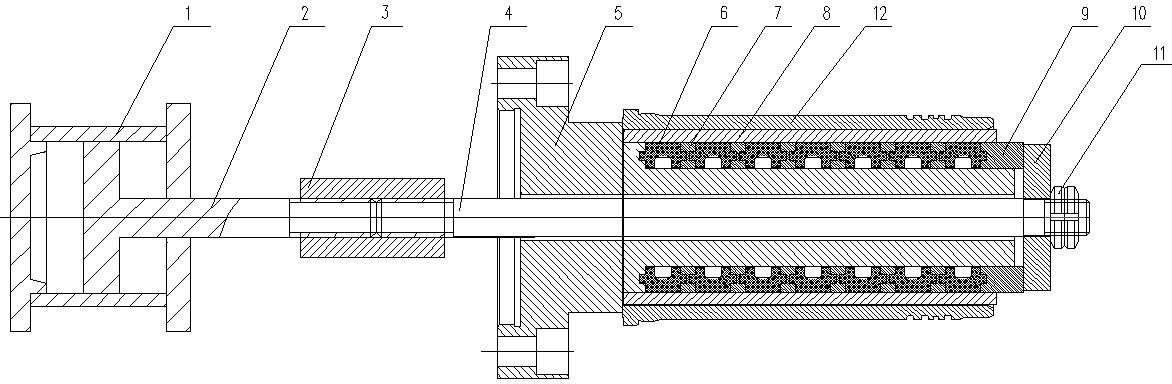

[0009] Example: such as figure 1 As shown, the cylinder liner internal support quick-change fixture includes a cylindrical body 5, in which a push-pull rod 4 is arranged, and an end cover 10 is arranged on the outside of the push-pull rod 4, and the outside of the end cover is fixed on the push-pull rod by a round nut 11. The inner side of the push-pull rod 4 is connected with the piston rod 2 of the hydraulic cylinder 1 through the connecting sleeve 3; the outer surface of the body 5 is sleeved with a hollow vulcanized rubber ring 6 and a spacer ring 7, and a spacer is set between every two adjacent hollow vulcanized rubber rings 6 ring 7, the inner side of the hollow vulcanized rubber ring 6 is provided with a gap; the innermost hollow vulcanized rubber ring 6 is set against the step of the body 5, and the outside of the outermost hollow vulcanized rubber ring 6 is provided with a push ring 9, and the outside of the push ring 9 is connected to The end cover 10 is set against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com