Automatic loading and unloading device of digital controlled lathe

A technology of automatic loading and unloading, CNC lathe, applied in the direction of automatic in/out of workpieces, metal processing mechanical parts, metal processing, etc., can solve the problems of low work efficiency, low work efficiency, large floor space, etc. The effect of production auxiliary time, space saving and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

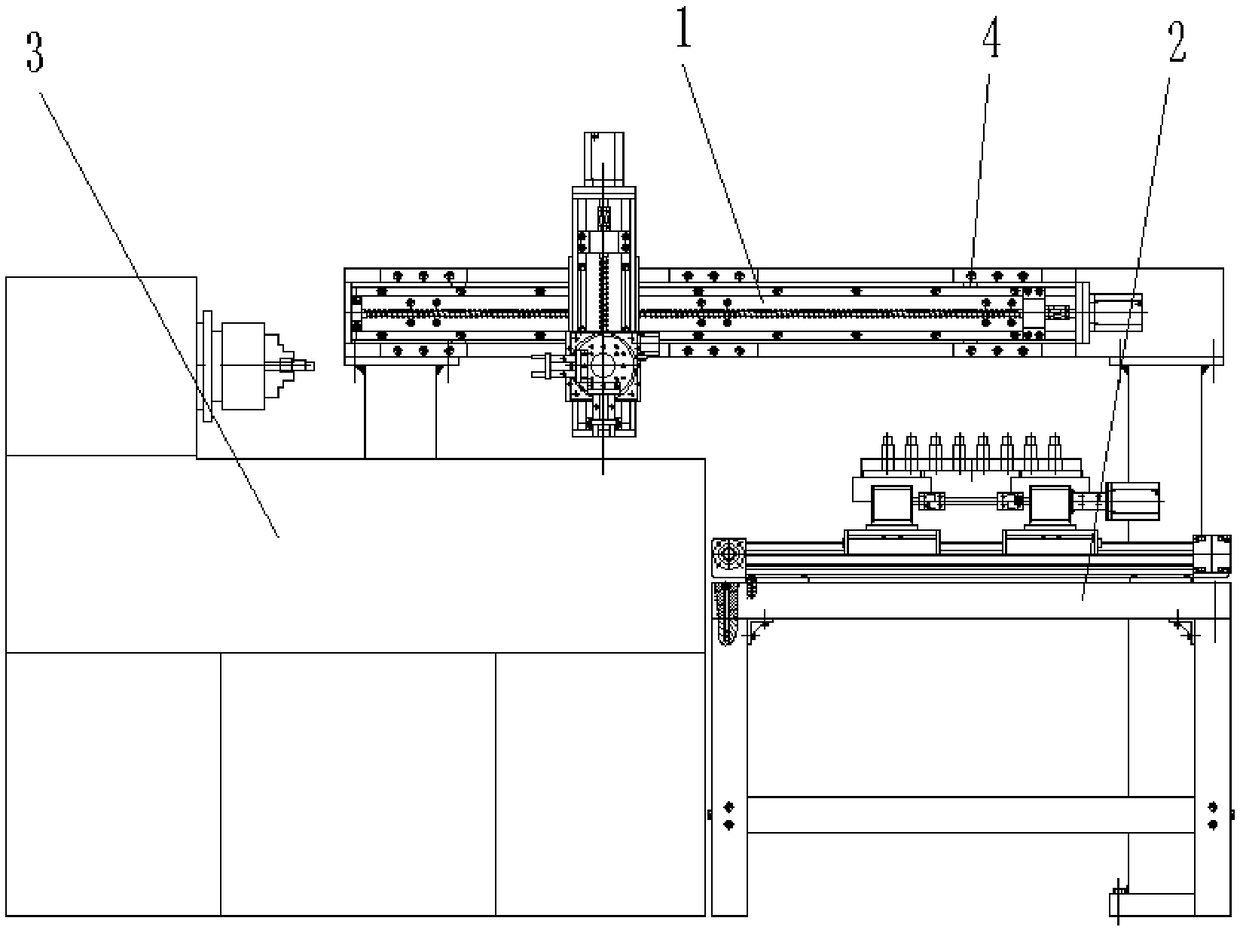

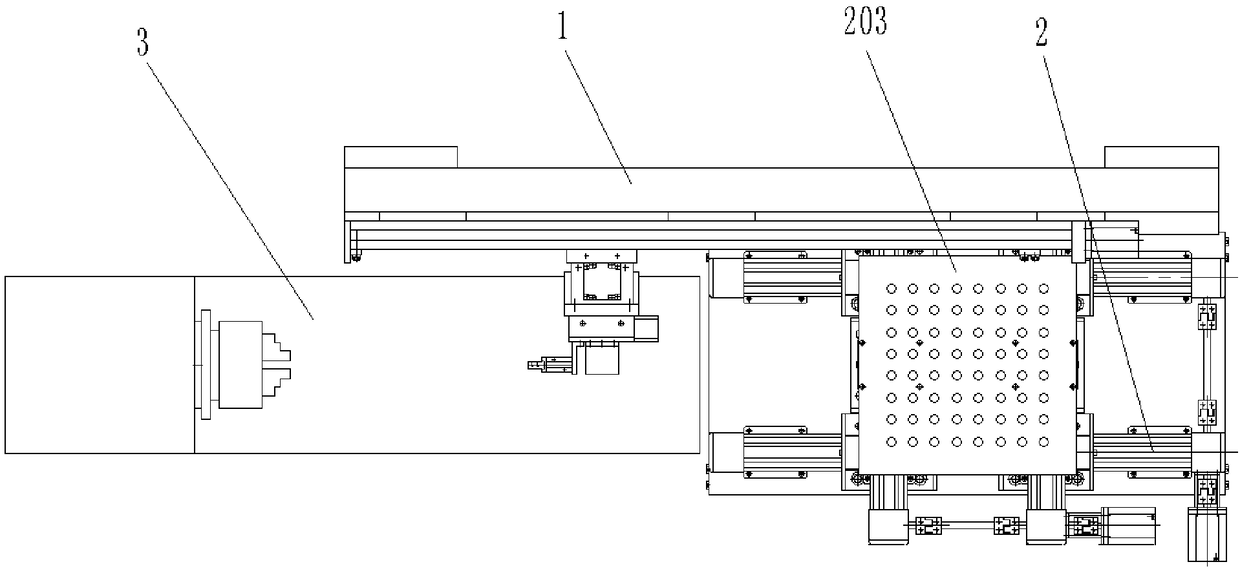

[0020] Such as Figure 1-Figure 4 As shown, an automatic loading and unloading device for a CNC lathe, including a manipulator system 1 and a loading tray system 2, a CNC lathe 3 is provided at one end of the loading tray system 2, and a manipulator system 1 is provided directly opposite the CNC lathe 3 and the loading tray system 2 .

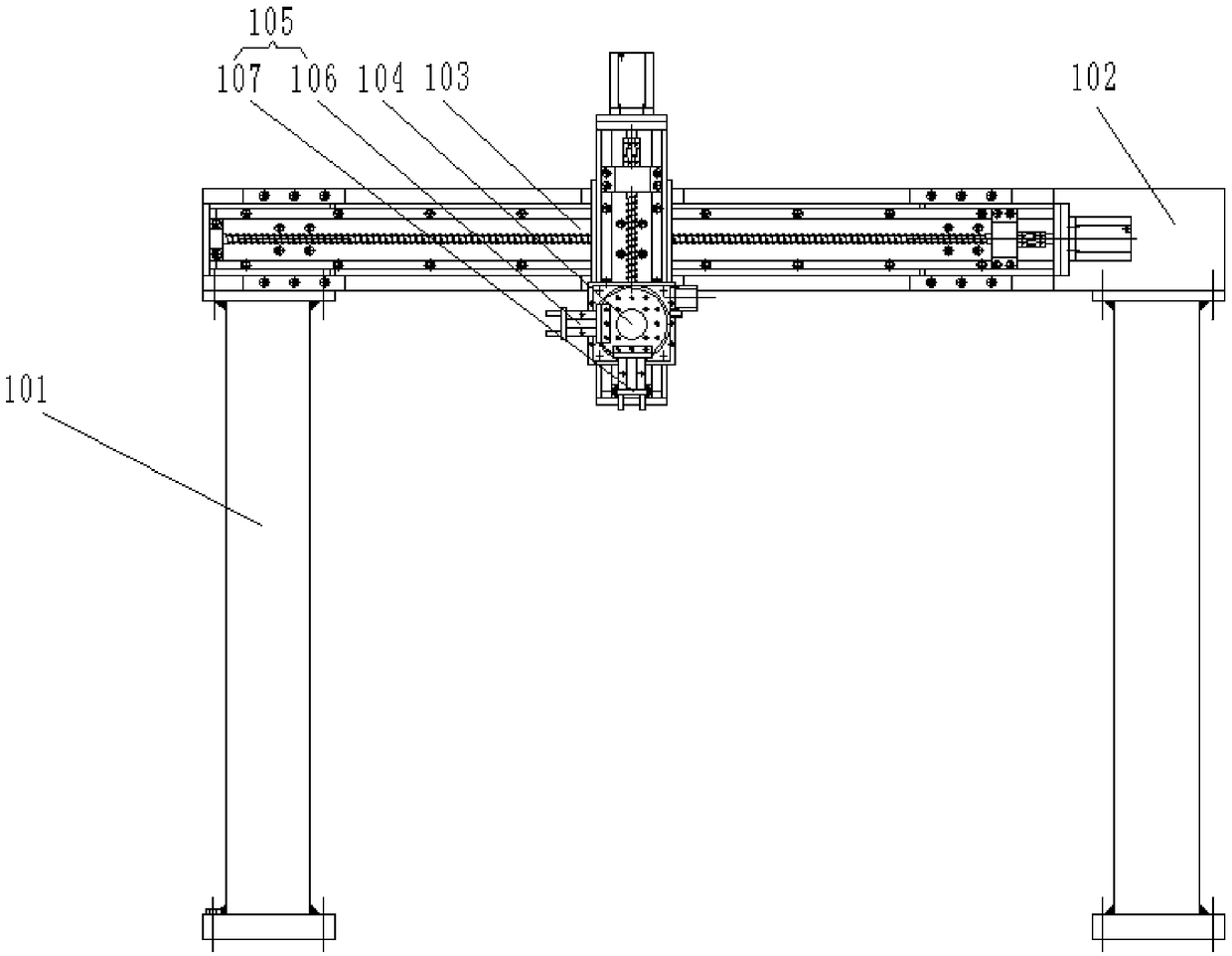

[0021] The manipulator system 1 includes a beam frame 101, the top of the two beam frames 101 is provided with a beam 102, and the front side wall of the beam 102 is provided with a cross-shaped screw slide module 103, and the cross-shaped screw slide module 103 passes through The horizontal slide table and the front end of the beam 102 are fixedly installed, and the ends of the cross-shaped screw slide table module 103 vertical slide table and the horizontal slide table are all provided with limit switches 4, and the setting of the limit switch 4 ensures that the vertical slide table or the horizontal slide table The slide table will not exce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com