A double-width plate iron water mill

A width plate and iron technology, applied in the field of double width plate iron water mill, can solve the problems of reduced productivity, low manufacturing and assembly precision, high wear rate of grinding wheel, etc. The effect of reducing the change of fluctuation range and reducing the range of productivity change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in combination with specific embodiments.

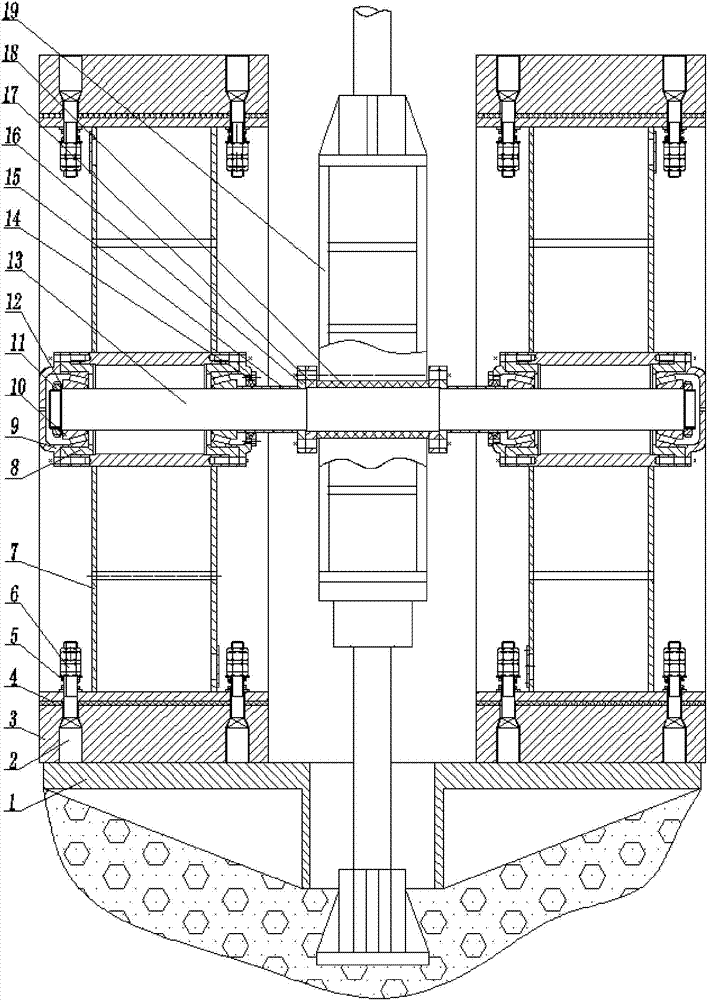

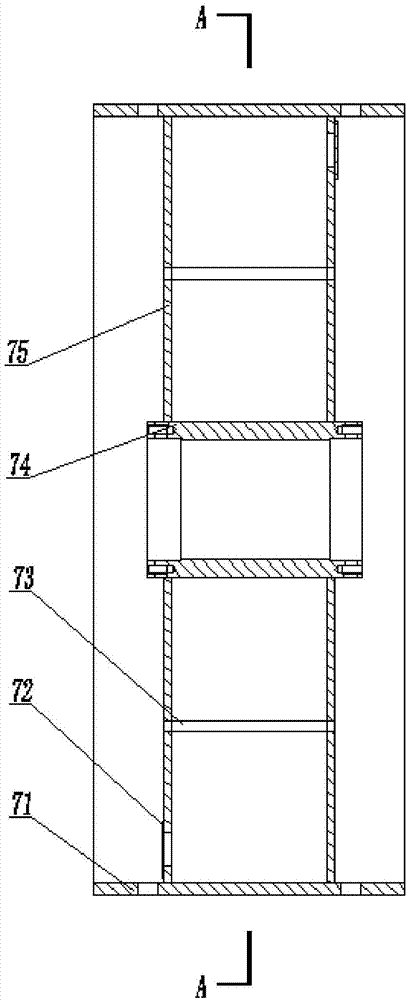

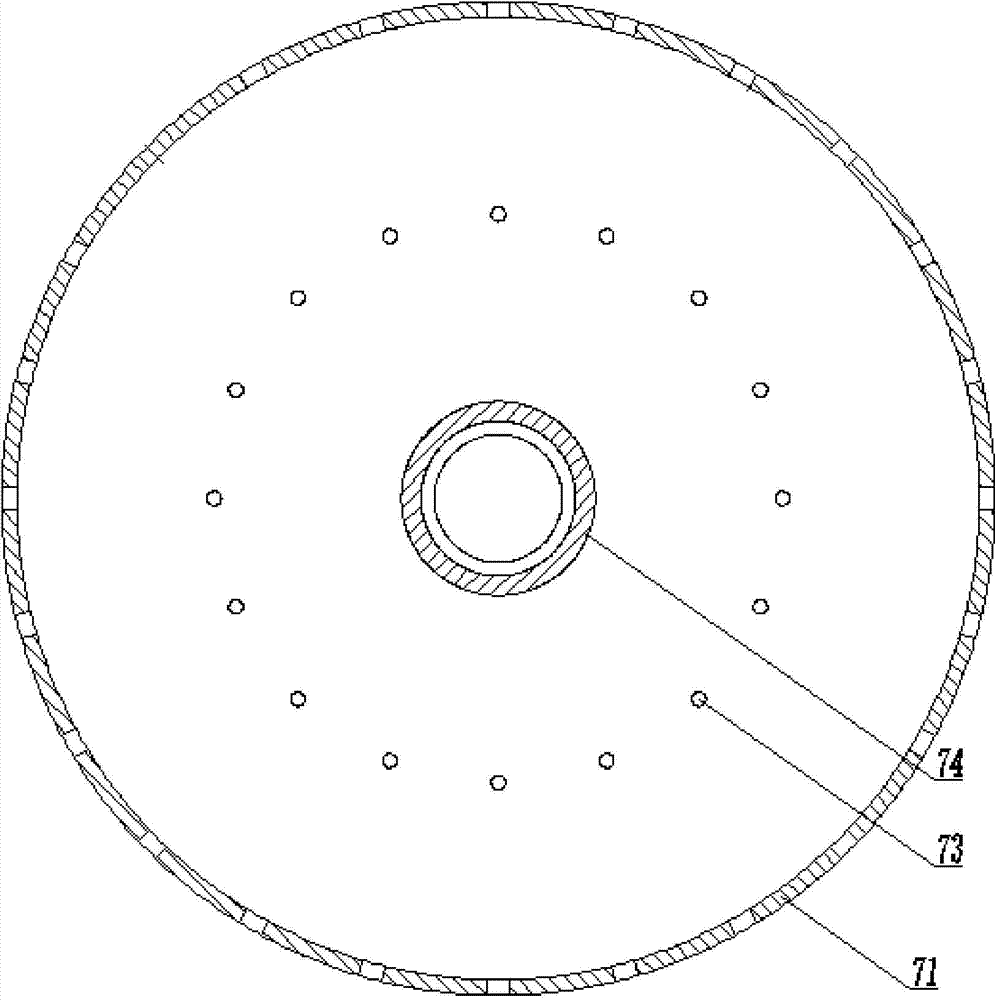

[0033] A double-width iron water mill, comprising a roller frame assembly 7 and a mill plate 1, the roller frame assembly 7 includes a welded integral hub 74, a web 75, and a rim 71, and the web 75 is a double-width board structure, the space between the two panels 75 is a hollow structure, the upper circumference of the panel 75 is welded with connecting rods 73; On the rim 71, the bolt 2 inside the rim 71 is covered with a spring 5, and the spring 5 is located between the rim 71 and the nut 6; the grinding plate 1 and the grinding wheel frame assembly 7 are all made of iron materials.

[0034] The hub 74 adopts a thick-walled seamless steel pipe to be formed by cutting.

[0035] The web 75 is provided with a feed hole, a discharge hole and an orifice cover plate 72, and the orifice cover plate 72 is assembled on the feed hole and the discharge hole by bolts.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com