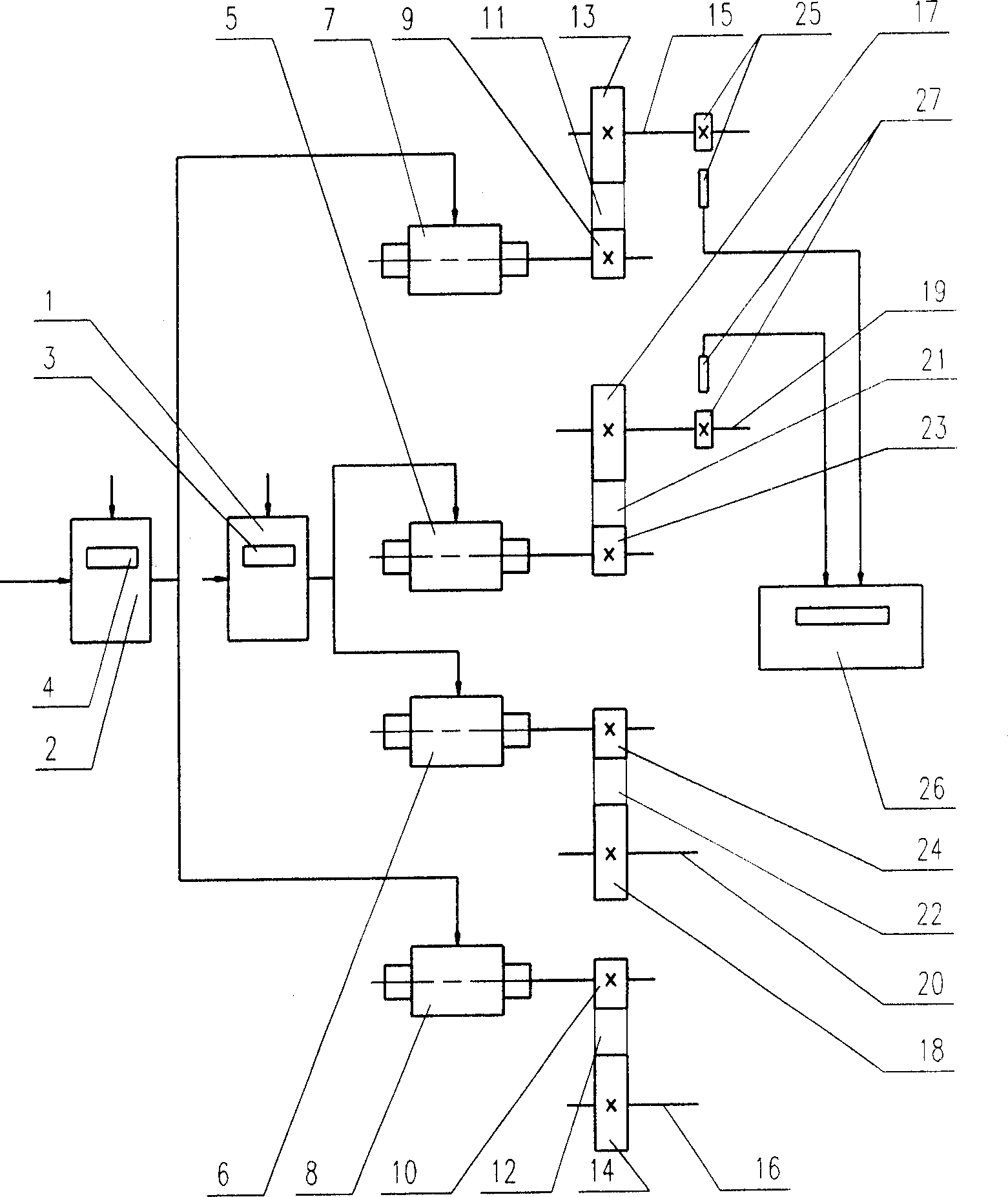

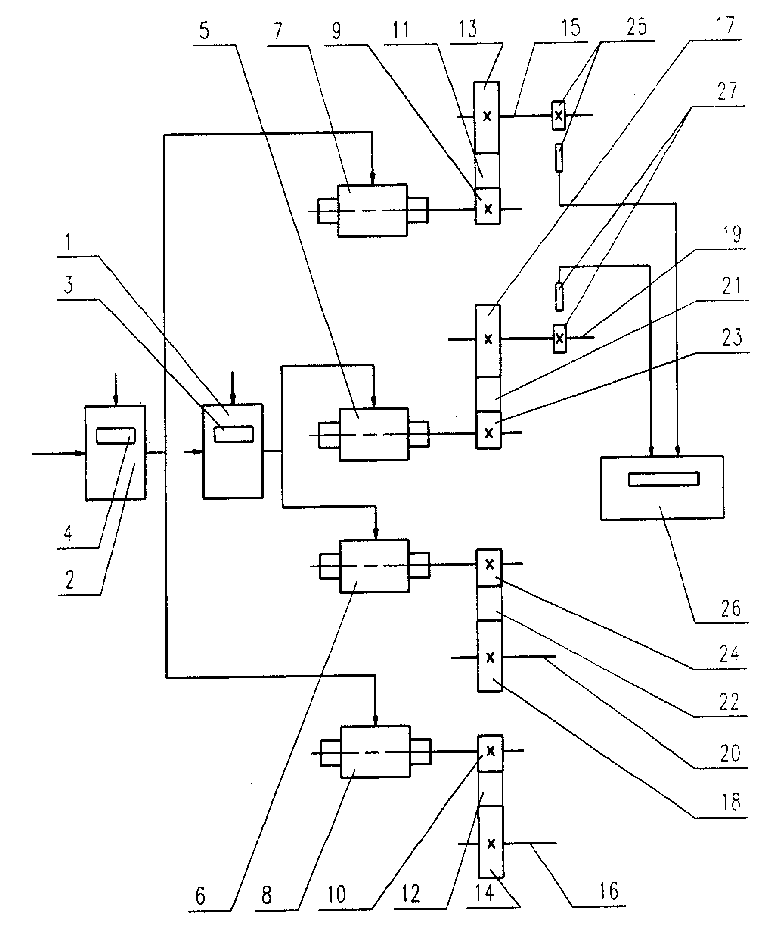

Yarn inserting and cotton feeding transmission mechanism for rotary-cup spinning machine

A rotor spinning machine and transmission device technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., which can solve the problems of complex transmission mechanism design, high failure rate of gearboxes, and inconvenient maintenance and other problems, to achieve the effect of reducing maintenance and production auxiliary time, simplifying the transmission mechanism, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0014] As described in the accompanying drawings, the yarn drawing and cotton feeding transmission device of the rotor spinning machine in this embodiment includes a yarn drawing speed control device composed of a yarn drawing speed control frequency converter 1 and a yarn drawing speed programmer 3 and a Cotton-feeding speed control frequency converter 2 and cotton-feeding speed programmer 4 constitute the cotton-feeding speed control device, wherein it also includes the yarn-drawing roller transmission device on the left and right sides independent of each other, the cotton-feeding roller transmission device on the left and right sides independent of each other, Yarn drawing roller speed sensor 27, cotton feeding roller speed sensor 25 and parameter display instrument 26; the left and right sides of the independent yarn drawing roller transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com