Slit gauge

A technology of slit gauges and mobile brackets, applied in the field of slit gauges, can solve the problems of cumbersome replacement, reduce production auxiliary time, and reduce costs, and achieve the effects of ensuring stability, reducing production auxiliary time, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

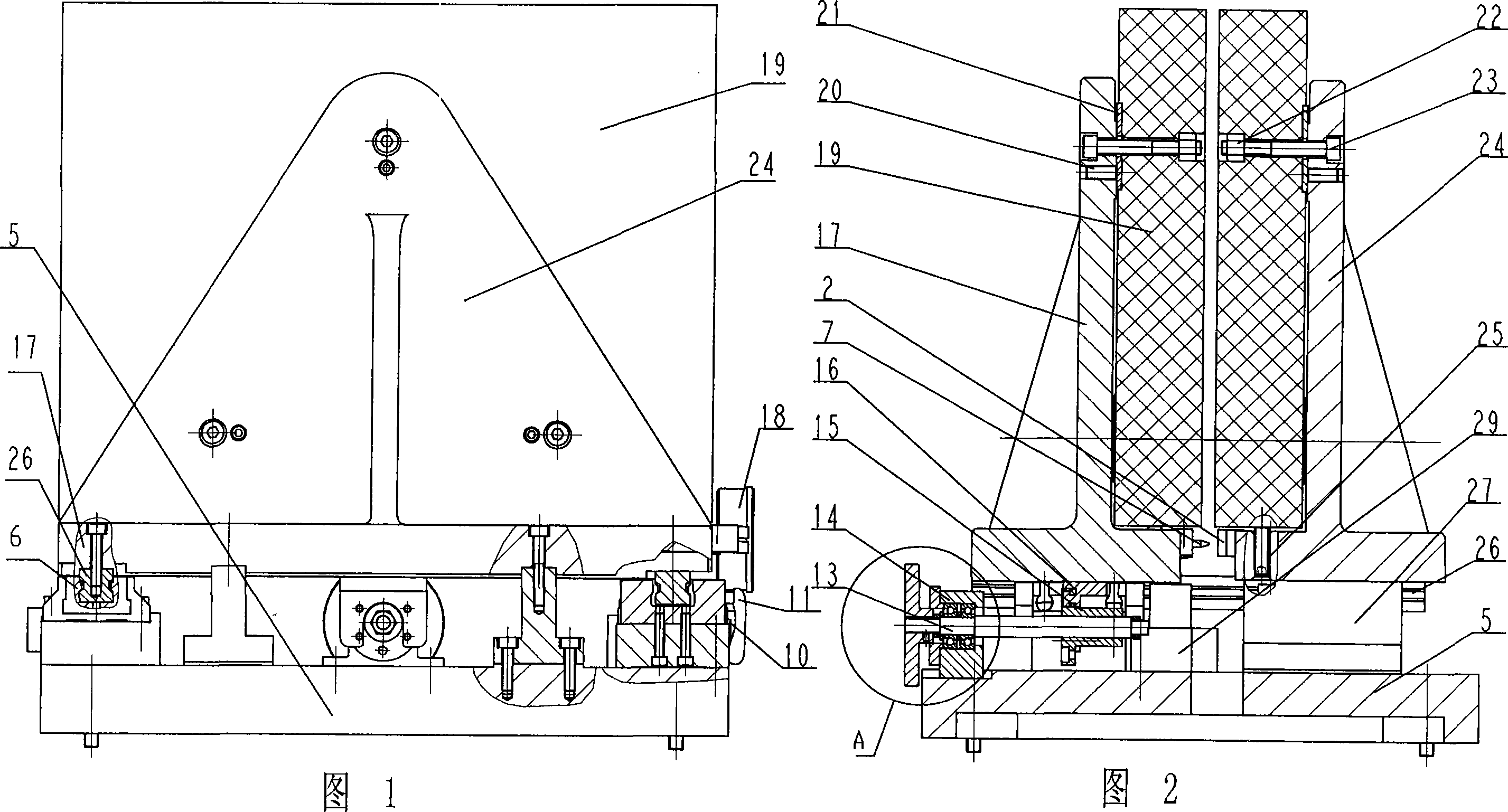

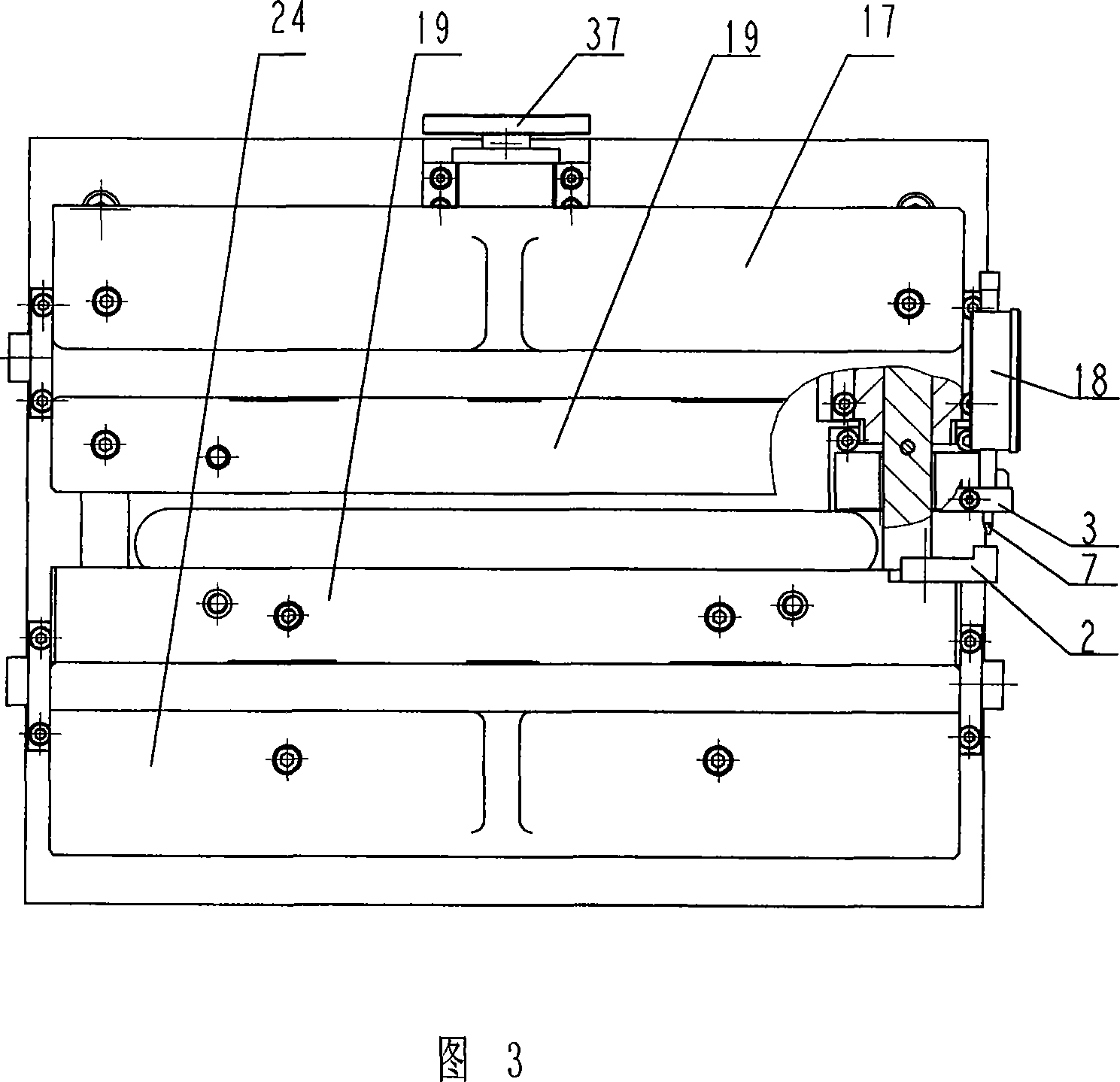

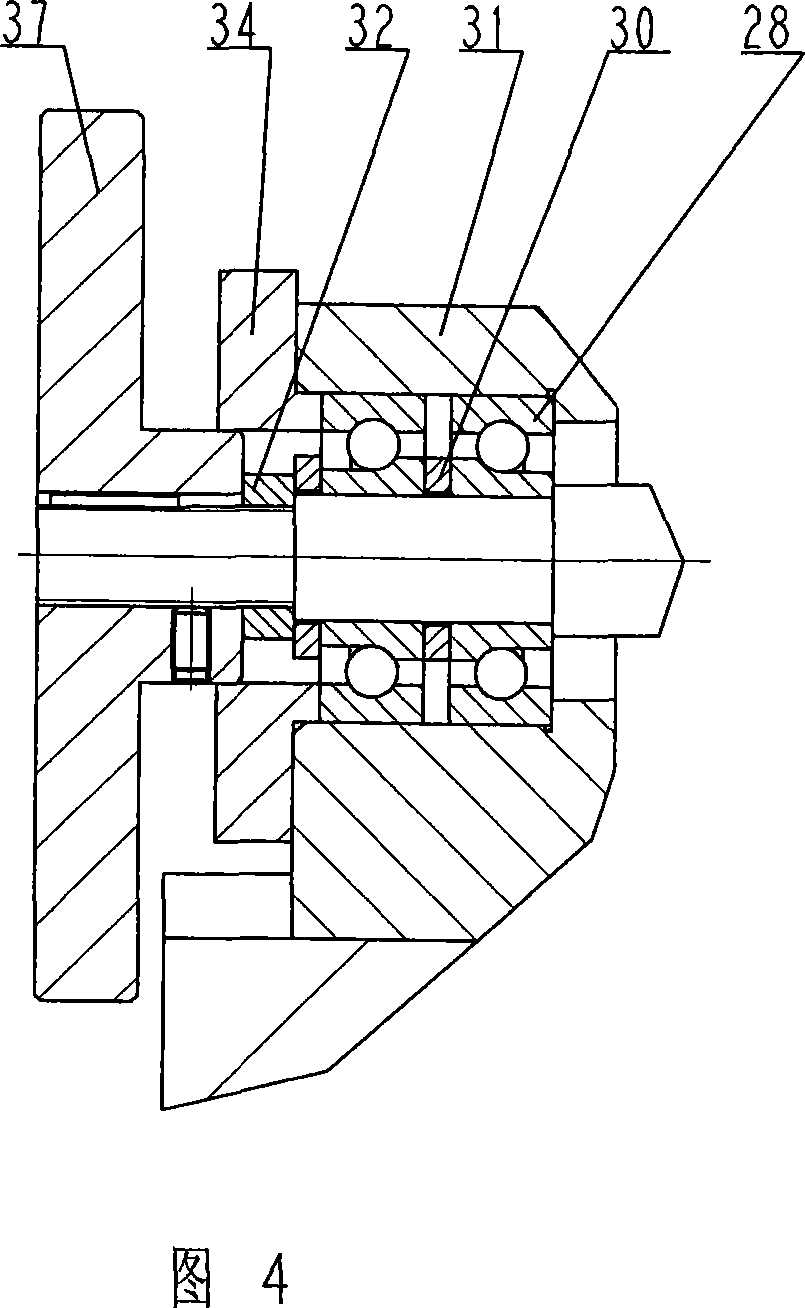

[0016] In the figure: 1. Left locking block; 2. Reference block; 3. Guide frame; 4. Right locking block; 5. Base; 6. Guide rail; 7. Thimble; 10. Press block; 11. Handle; 12. Screw; 13, screw; 15, nut; 16, transmission bracket; 17, mobile bracket; 18, dial indicator; 19, detection plate; 20, positioning pin; 21, gasket; 22, nut; 23, bolt ; 24, fixed bracket; 25, screw; 26, slider; 27, the support of the fixed bracket, used to install the fixed bracket on the base; 28, the bearing; 29, the locking block support, used to connect and lock Block and base; 30, washer; 31, bearing seat; 32, nut; 34, bearing cover; 37, handwheel.

[0017] As shown in the figure: a fixed bracket 24 is installed on one side of the base 5, and a mobile bracket 17 is installed on the other side. The fixed bracket 24 and the mobile bracket 17 are parallel to each other, and two detection plates 19 are respectively installed on the fixed bracket 24 and the mobile bracket 17. The inner side; the mobile brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com