Large-power turning and milling composite machine tool

A compound machine tool and high-power technology, applied in the field of machine tools, can solve the problems of inability to realize high-power machining, inability to install large tools, and many times of workpiece clamping, so as to reduce the workshop area and equipment maintenance costs, and improve machining Accuracy, the effect of reducing the number of clamping times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

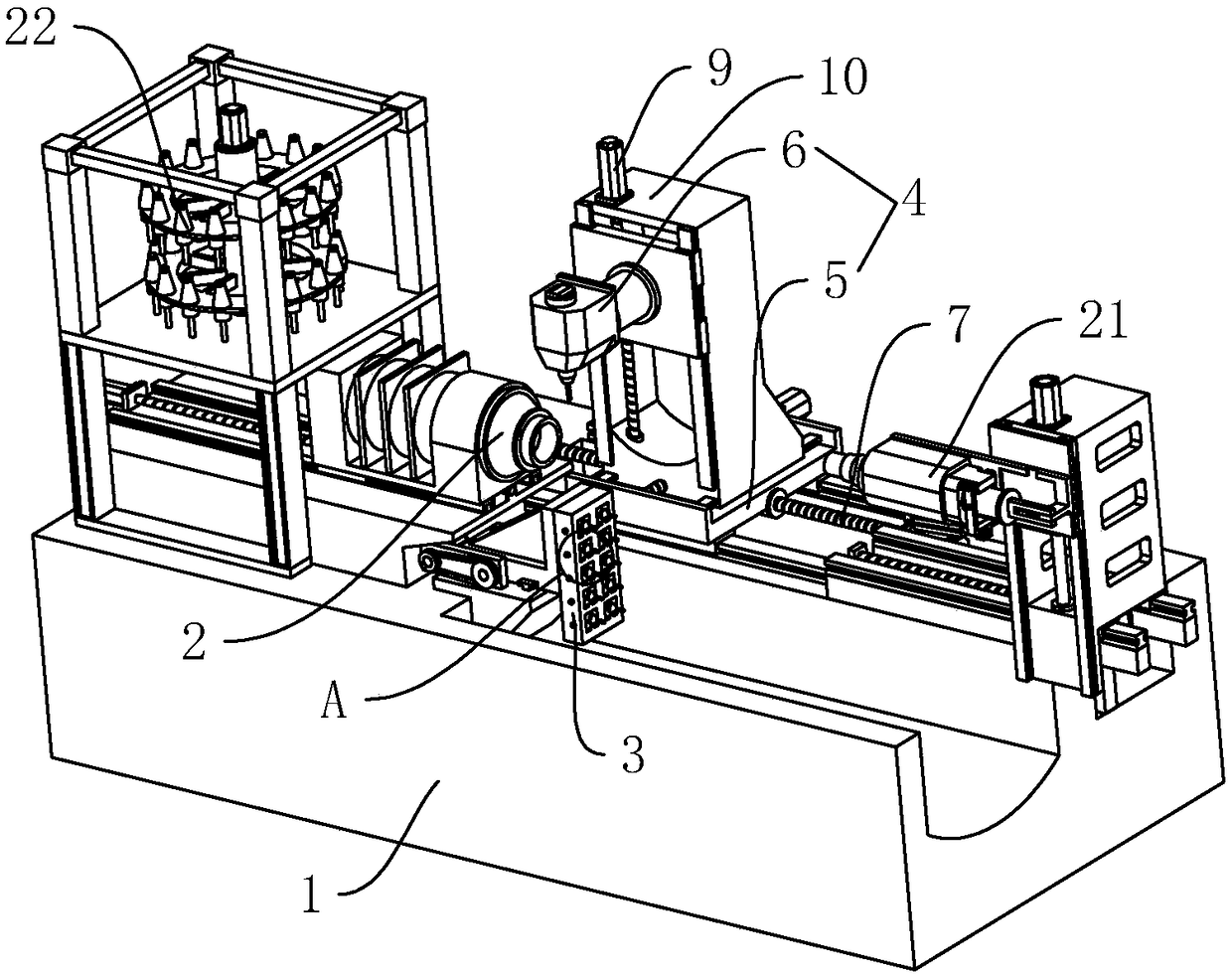

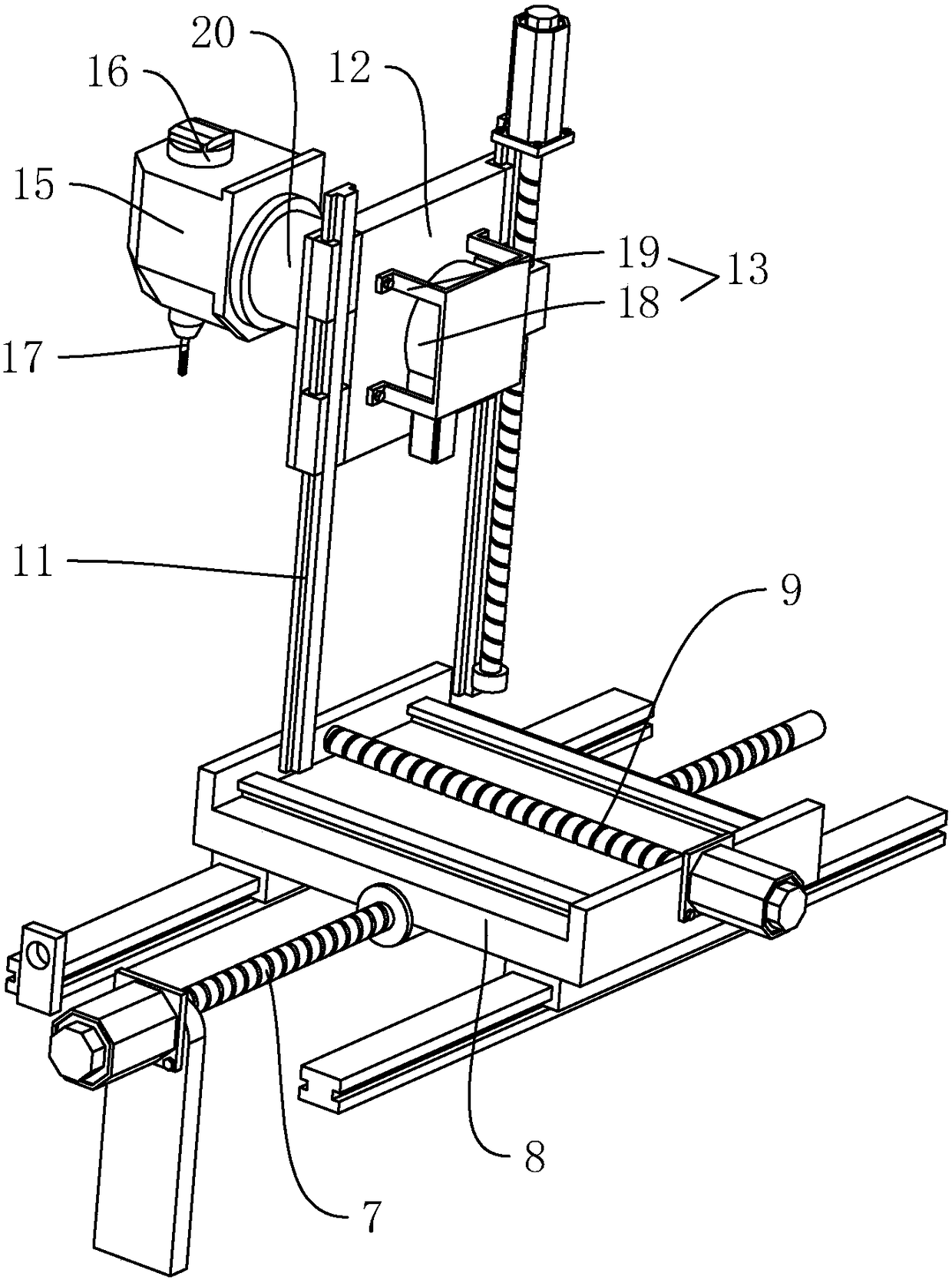

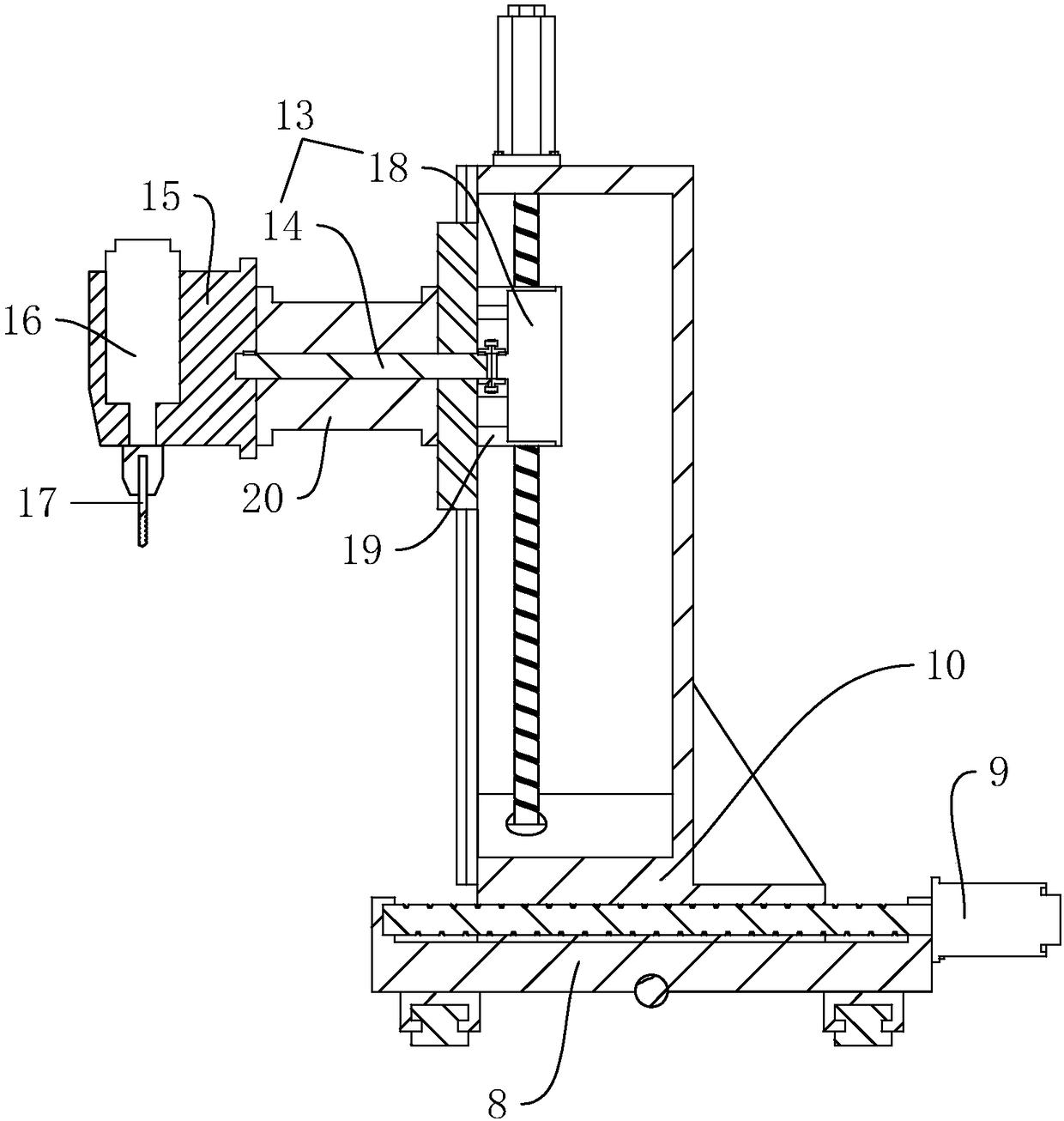

[0035] A high-power turning and milling compound machine tool, such as figure 1As shown, it includes a bed 1 and a main shaft 2 which is slidably arranged on the bed 1 through a screw, and the main shaft 2 can move along its axial direction, and also includes a back tool post 3 which is arranged on one side of the main shaft 2, and which is arranged on the other side of the main shaft 2. The milling device 4 on one side, the milling device 4 includes the drive mechanism 5 that is arranged on the bed 1 and the milling mechanism 6 that is arranged on the drive mechanism 5 in rotation, and the countershaft mechanism 21 is also provided on the bed 1; when the workpiece is processed , the workpiece is first clamped by the spindle 2, and then the driving mechanism 5 drives the milling mechanism 6 to move axially along the spindle 2 to the position correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com