A method for avoiding converter oxygen lance sticking steel slag

A converter oxygen lance and oxygen lance technology are applied in the field of preventing the converter oxygen lance from sticking to steel slag, and in the field of converter steelmaking, which can solve the problem of difficulty in effectively removing the oxygen lance sticking slag, etc., so as to reduce labor intensity and maintenance cost, improve the ratio, and reduce replacement. The effect of frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

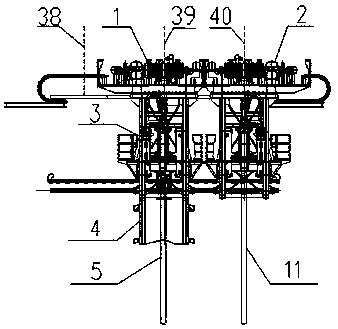

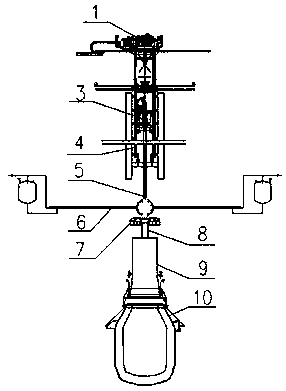

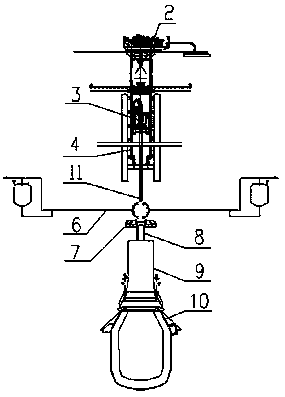

Image

Examples

Embodiment

[0039] Oxygen blowing steelmaking oxygen lance 11 blowing is completed, when the slag is good, the oxygen lance hardly sticks to steel, when the condition of molten iron or semi-steel is not good, a thin layer of steel slag mixture usually sticks to the outer tube of the oxygen lance, with a thickness of 1 mm to 5mm, length 1m to 2m, if this oxygen blowing steelmaking oxygen lance 11 sticking to the thin layer of steel slag continues to be used to blow nitrogen and splash slag to protect the furnace, then the thin layer of steel slag will be covered with 10mm to 30mm thick slag, This kind of steel slag mixture is difficult to fall off automatically in the next furnace of oxygen blowing steelmaking, and it will continue to stick to the steel slag mixture with a thin layer of steel slag. If the same oxygen lance is used continuously, the steel slag mixture will become stickier and longer. , the more sticky and thicker, after the fifth heat of steel was smelted, the oxygen lance c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com