Pin wedge grafting type hole machining tool capable of being replaced in on-machine mode

A technology of hole processing and cutting tools, which is applied in the field of pin-wedge hole processing tools, which can solve the problems of low replacement efficiency and complicated disassembly procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

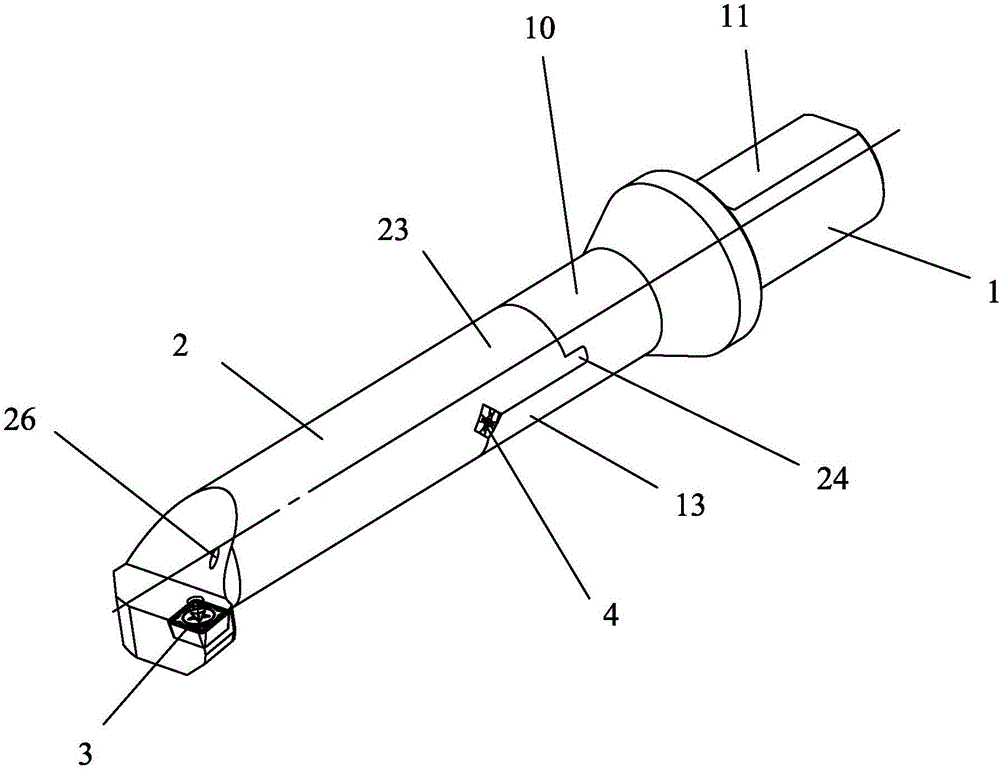

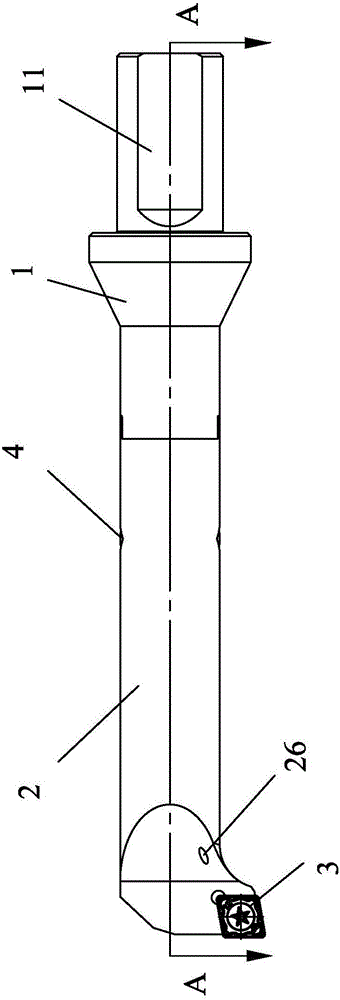

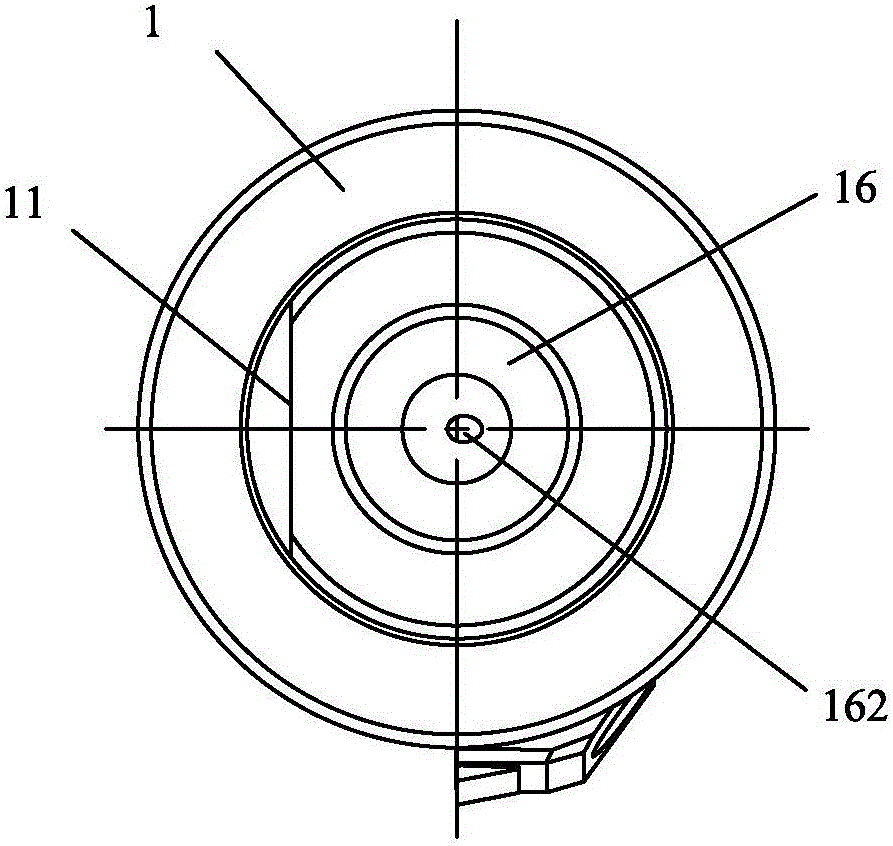

[0045] see Figure 1 to Figure 23 As shown, a kind of on-machine replaceable pin-wedge type hole machining tool of the present invention includes:

[0046] The cutter body part 1, one end of the cutter body part 1 is provided with a side fixing plane 11 for connecting with the machine tool spindle interface, and the other end of the cutter body part 1 protrudes outward along the central axis with a cylindrical anti-bending shaft 12, A section of the inner side of the cylindrical anti-bending shaft 12 is attached to a roughly semicircular first annular wall 13, and the peripheral surface of the other end of the main body 10 of the cutter body part 1 is provided with a first groove 14 opening along the axial direction , the cylindrical anti-bending shaft 12 is provided with a first through hole 15 penetrating along the radial direction; wherein, the main body 10 of the cutter body part 1 means that the cutter body part 1 does not include the cylindrical anti-bending shaft 12 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com