Desorption device for saxitoxin in macroporous resin and method of desorption device

A technology for shellfish toxin and pore adsorption, which is applied in the field of desorption of shellfish toxin and shellfish toxin desorption device in macroporous adsorption resin. Achieve the effect of avoiding residue and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

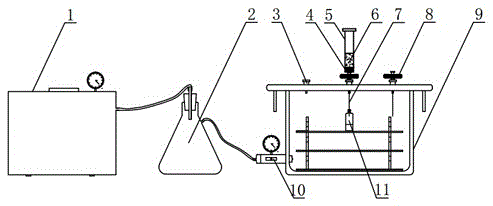

Embodiment 1

[0028] The target shellfish toxins in this embodiment are mainly fat-soluble shellfish toxins, such as OA, DTXs, PTXs, GYM, etc. Put the resin bag containing 3g of macroporous adsorption resin HP20 into the seawater 5 meters deep from the sea surface to absorb the fat-soluble shellfish toxin in the seawater, and take the resin bag back after 10 days. Put 12 resin bags in 500mL ultra-pure water, soak them 3 times, 5min each time, to remove salt and impurities; transfer the soaked macroporous adsorption resins to be desorbed into 30mL glass syringes 5 to form The macroporous adsorption resin layer 6 to be desorbed; open the vacuum pump 1, adjust the vacuum control valve 10, and carry out suction filtration until even if the vacuum degree inside the 12-hole solid-phase extraction instrument 9 is increased, the macroporous adsorption resin layer 6 to be desorbed Until no water flows out; close the vacuum pump 1, place the sample bottle 11 on the support in the solid-phase extracti...

Embodiment 2

[0030]The target shellfish toxin in this example is domoic acid toxin (DA). Put the resin bag containing 8g of macroporous adsorption resin SP207 into the seawater at a depth of 7 meters from the sea surface to adsorb DA toxin in the seawater, and take the resin bag back after 7 days. Place the resin bag in 1000mL ultrapure water, soak it twice, each time for 10min, to remove salt and impurities; transfer the soaked macroporous adsorption resin to be desorbed to a 50mL glass syringe 5 to form a desorbed Macroporous adsorption resin layer 6; open the vacuum pump 1, adjust the vacuum control valve 10, and perform suction filtration until even if the vacuum inside the solid phase extraction instrument 9 is increased, the macroporous adsorption resin layer 6 to be desorbed does not flow out; Turn off the vacuum pump 1, place the sample bottle 11 on the support in the solid phase extraction instrument 9, adjust the height of the support so that the guide needle 7 extends into the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com