Small-scale domestic sewage treatment equipment

A domestic sewage and treatment equipment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of impurity filtration treatment, poor filter effect and short service life and other issues to achieve the effect of ensuring the cycle of use, improving the treatment effect, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

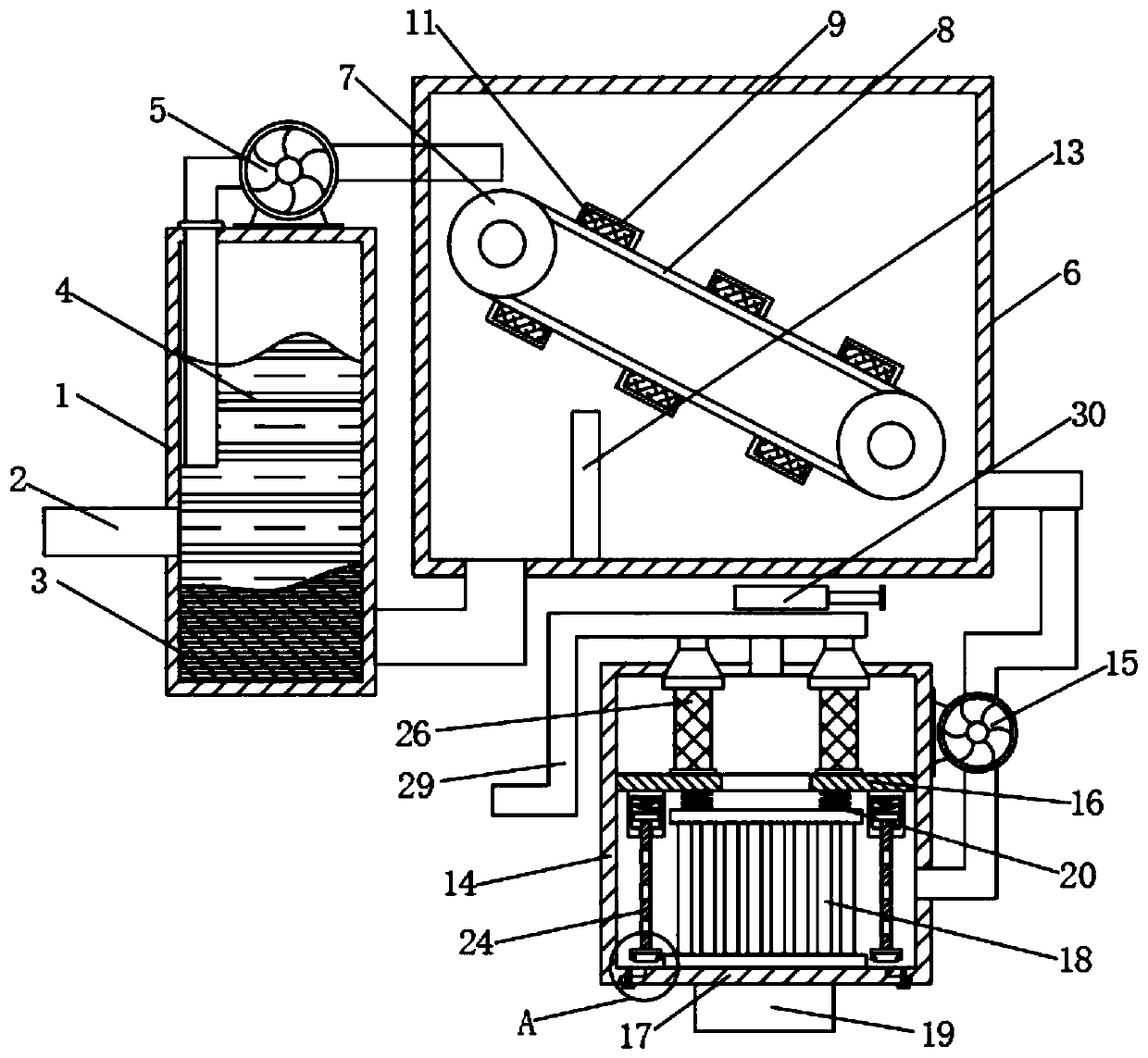

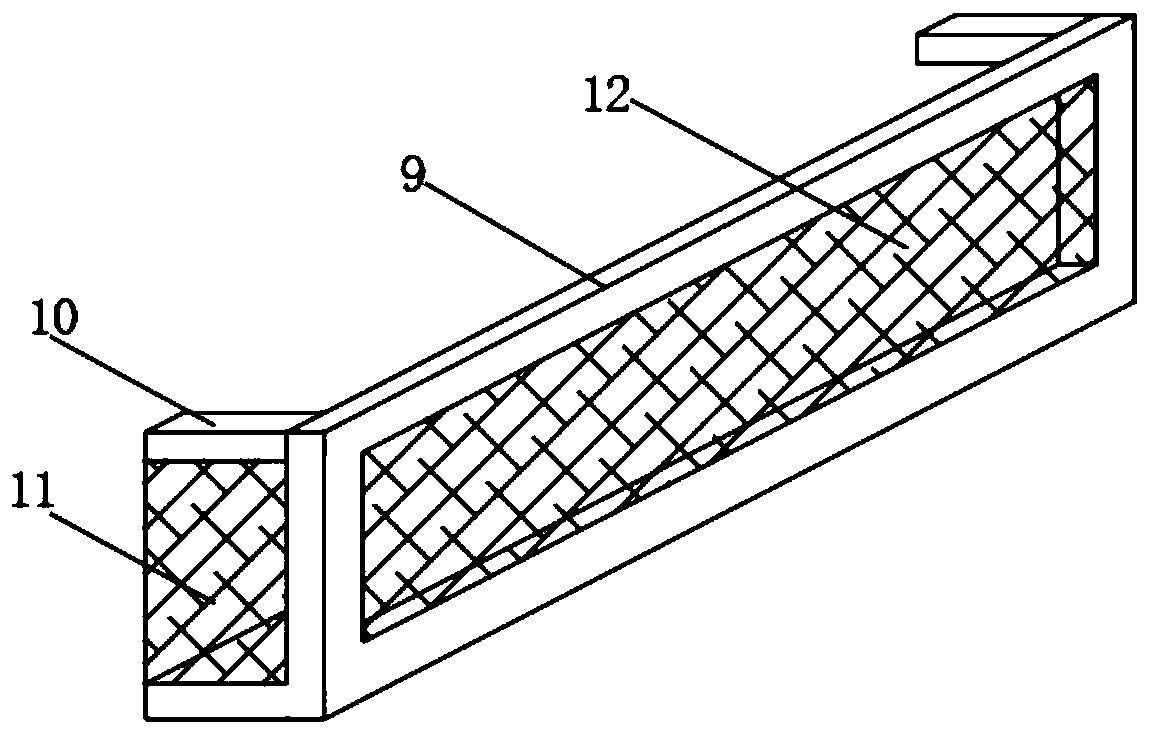

[0027] see Figure 1-5, a small-scale domestic sewage treatment equipment, including a first box 1, a second box 6 and a third box 14, the side wall of the first box 1 is fixedly connected with a sewage input pipe 2, the first box The top of 1 is fixedly installed with the first pump body 5, and the output end of the first pump body 5 is connected to the side wall of the second box body 6 through pipelines, and the second box body 6 is rotatably connected with two rotating wheels 7, and the two rotating wheels 7 The side wall is equipped with a transmission belt 8, and the transmission belt 8 is set at a forty-five angle with the horizontal plane, the outer wall of the transmission belt 8 is fixedly connected with a fixed frame 9, and the front and rear ends of the fixed frame 9 are provided with the first filter screen 11, and the fixed frame 9 The right side is provided with a second filter screen 12, the bottom end of the second box body 6 is fixedly connected with a partit...

Embodiment 2

[0030] see Figure 1-5 On the basis of Example 1, a further improvement is made: the bottom end of the first box 1 is provided with a sedimentation layer 3, the top of the sedimentation layer 3 is provided with a sewage layer 4, and the input pipeline of the first pump body 5 is connected to the second The inside of a box body 1, and the pipeline is located in the sewage layer 4; the upper side of one end of the fixed frame 9 is fixedly connected with the connecting rod 10, and the upper side of the first filter screen 11 is fixedly connected with the lower end of the connecting rod 10.

[0031] In this embodiment, by using the first tank 1 to divide the sewage into the sediment layer 3 and the sewage layer 4, the first pump body 5 can be used to extract the water in the sewage layer 3, and the connecting rod 10 can be used to ensure the first filtration. The installation strength of the net 11.

Embodiment 3

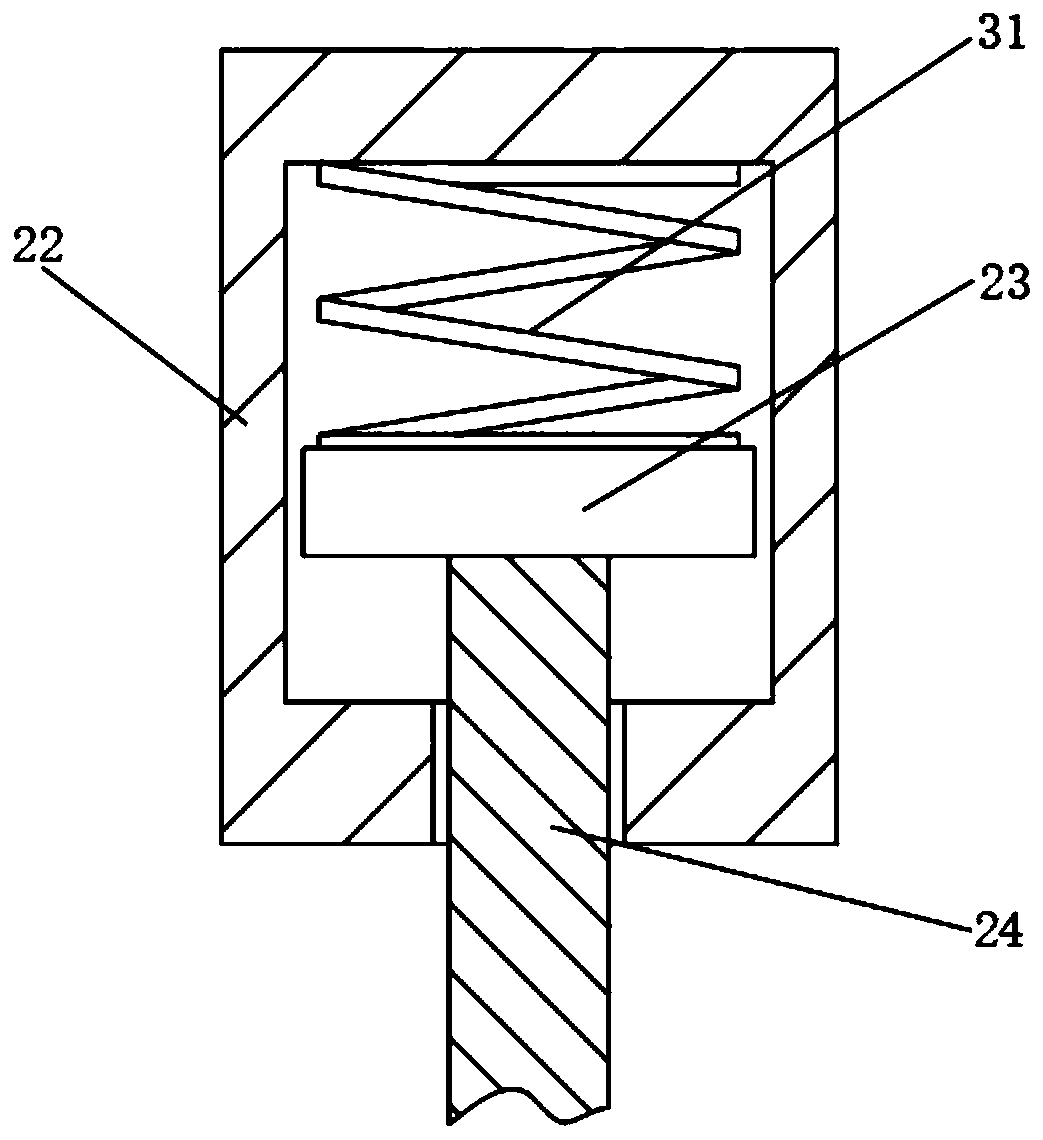

[0033] see Figure 1-5 , on the basis of Embodiment 1, a further improvement has been made: the first support spring 20 is fixedly installed on both sides of the top of the aeration pipe 18, and the top of the first support spring 20 is supported on the bottom end of the connecting plate 16; the second box 6. An installation pipe is fixedly installed on one side of the bottom end, and the installation pipe is connected to the side wall of the first box body 1; the partition plate 13 is located at one-third of the horizontal distance between the two rotating wheels 7; the top of the third box body 14 is fixedly connected to There is an installation pipe, and a medicine injector 30 is fixedly installed on the side wall of the installation pipe.

[0034] In this embodiment, the first support spring 20 can be used to support the aeration pipe 18 to ensure that the aeration pipe 18 shakes after installation, and the sludge and sundries can be transported to the first box 1 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com