Chroming production equipment without chromium containing waste emission

A technology for waste discharge and production equipment, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems affecting the quality of the coating, water pollution, increase the production cost of enterprises, etc., to improve the recovery capacity of chromic acid, avoid environmental pollution, production Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment the present invention is described in further detail:

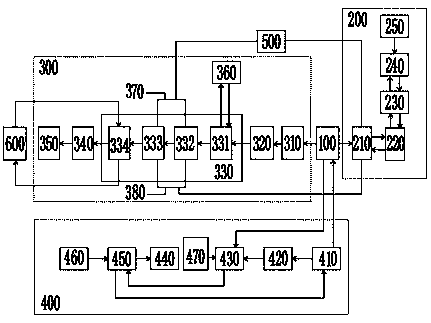

[0012] see figure 1 , the chrome-plating production equipment of the present invention comprises chrome-plating tank 100, cleaning device 200, chromic acid recovery device 300, waste treatment device 400, acid-resistant liquid pump 500 and chrome-plating room 600, and described chrome-plating tank 100 pipelines are respectively connected with cleaning device 200, The chromic acid recovery unit 300 is in communication with the waste treatment unit 400; the cleaning unit 200 includes a first-level cleaning tank 210, a second-level cleaning tank 220, a third-level cleaning tank 230, a fourth-level cleaning tank 240 and a water supply device 250, and its water supply device 250 Located above the four-stage cleaning tank 240; the chromic acid recovery device 300 includes a gas collection hood 310, a gas delivery device 320, a recovery tower 330, a centrifuge 340 and a neutralization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com