Extrusion forming and packaging machine and system for forming and packaging garbage

A technology of extrusion molding and forming machine, which is applied in the field of domestic garbage processing and packaging system, can solve the problems of long-term and unavoidable secondary pollution, and achieve a good effect on the environment of the processing workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Further explanation is made below in conjunction with accompanying drawing:

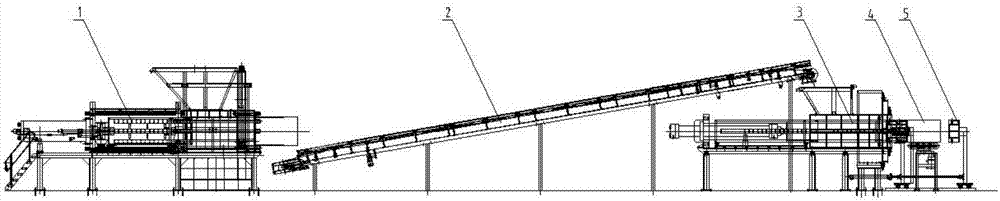

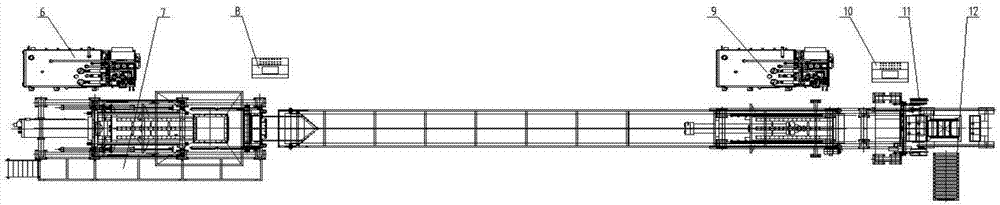

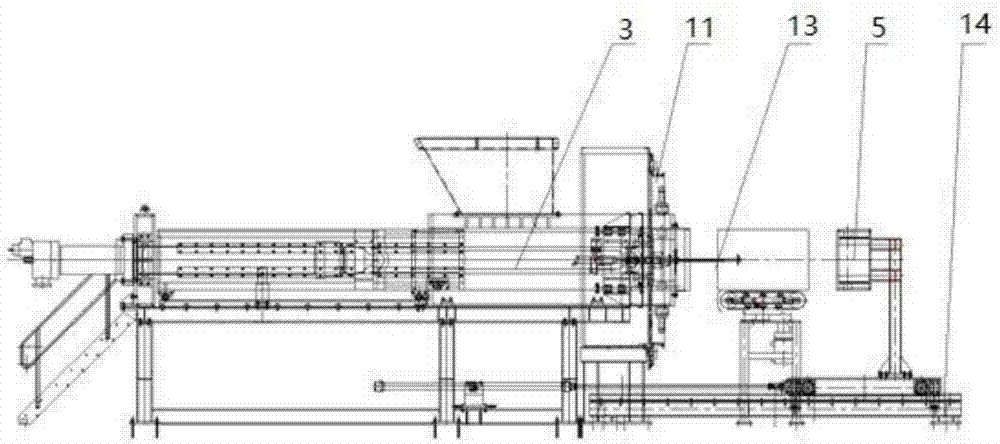

[0041] See attached figure 1 , figure 2 The garbage extruder 1 squeezes the household garbage under the drive of the hydraulic system 6 of the extrusion machine, and the molded household garbage is transported to the extrusion molding machine of the extrusion packaging machine 3 through the belt conveyor 3 .

[0042] Extrusion forming baler 3 comprises extrusion forming machine and wrapping film baler 11; Belt conveyor 3 at first moves the house refuse after the extrusion on the feeding hopper of extrusion forming machine, and extrusion forming machine presses on the hydraulic pressure of baler. Driven by the system 9, the domestic garbage is extruded again, and the back pressure head 5 and the extrusion head of the extrusion molding machine cooperate with each other and sent to the rotary belt conveyor 4 of the stretch film baler, and then the stretch film baler 11 pairs of formed Domestic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com