Automatic impurity removing system for CNC engraving and milling machine for part machining

A technology for parts processing and engraving machine, which is applied in the field of automatic impurity removal system, can solve the problems of a large amount of dust, dust drift, and pollution of staff and workshop environment in the engraving machine, so as to protect the health, improve the treatment effect and protect the environment. The effect of the workshop environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

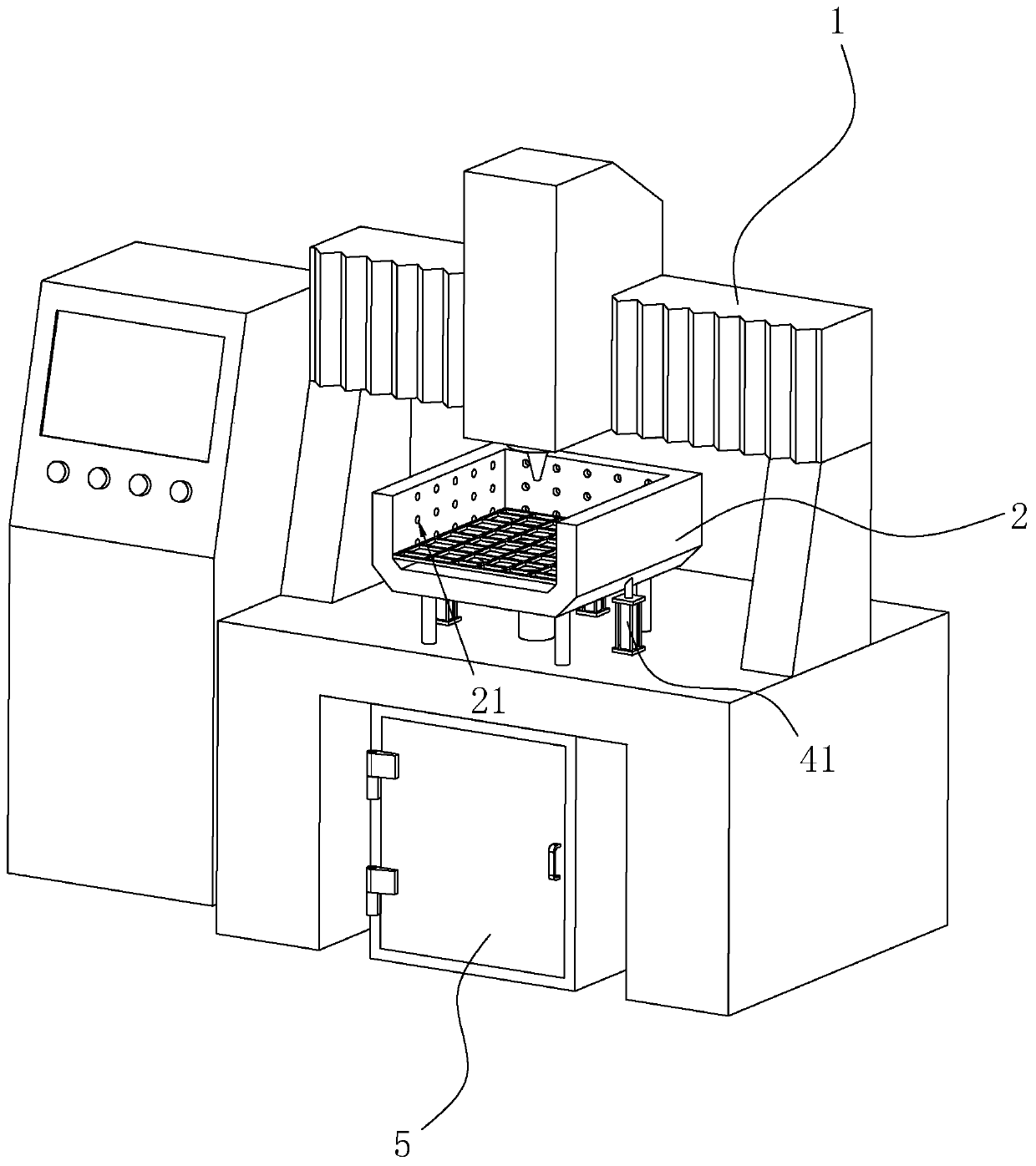

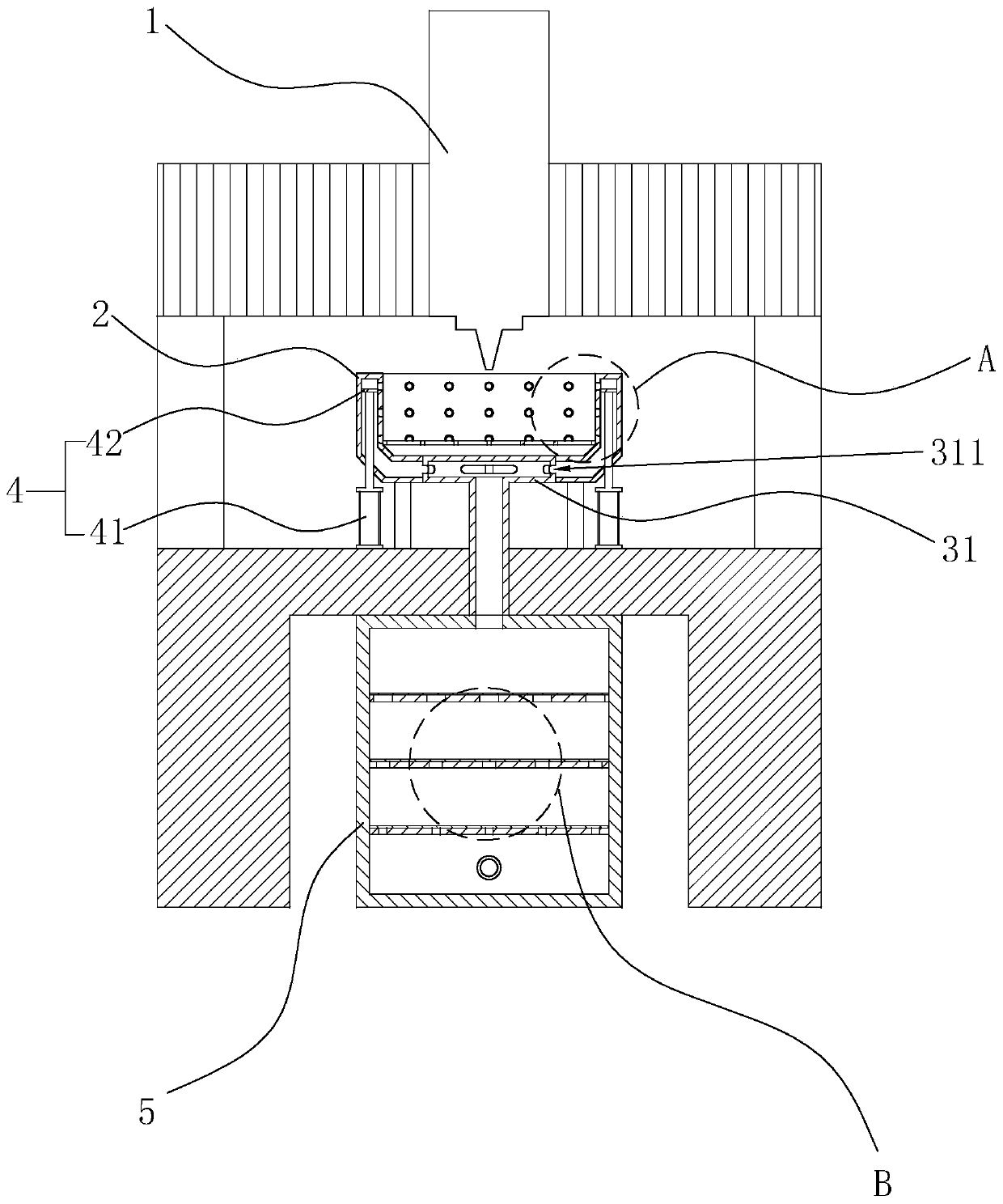

[0032] combine figure 1 and figure 2 , an automatic impurity removal system for a Jingdiao machine used for parts processing, including a Jingdiao machine body 1, the Jingdiao machine body 1 is provided with a cover body 2 for dust removal, a dust suction device 3, a scraping device 4 and a collection Box 5, compared with the situation that the Jingdiao machine in the prior art is not provided with an automatic impurity removal system, the present invention achieves the effect of protecting the health of the staff and a good workshop environment.

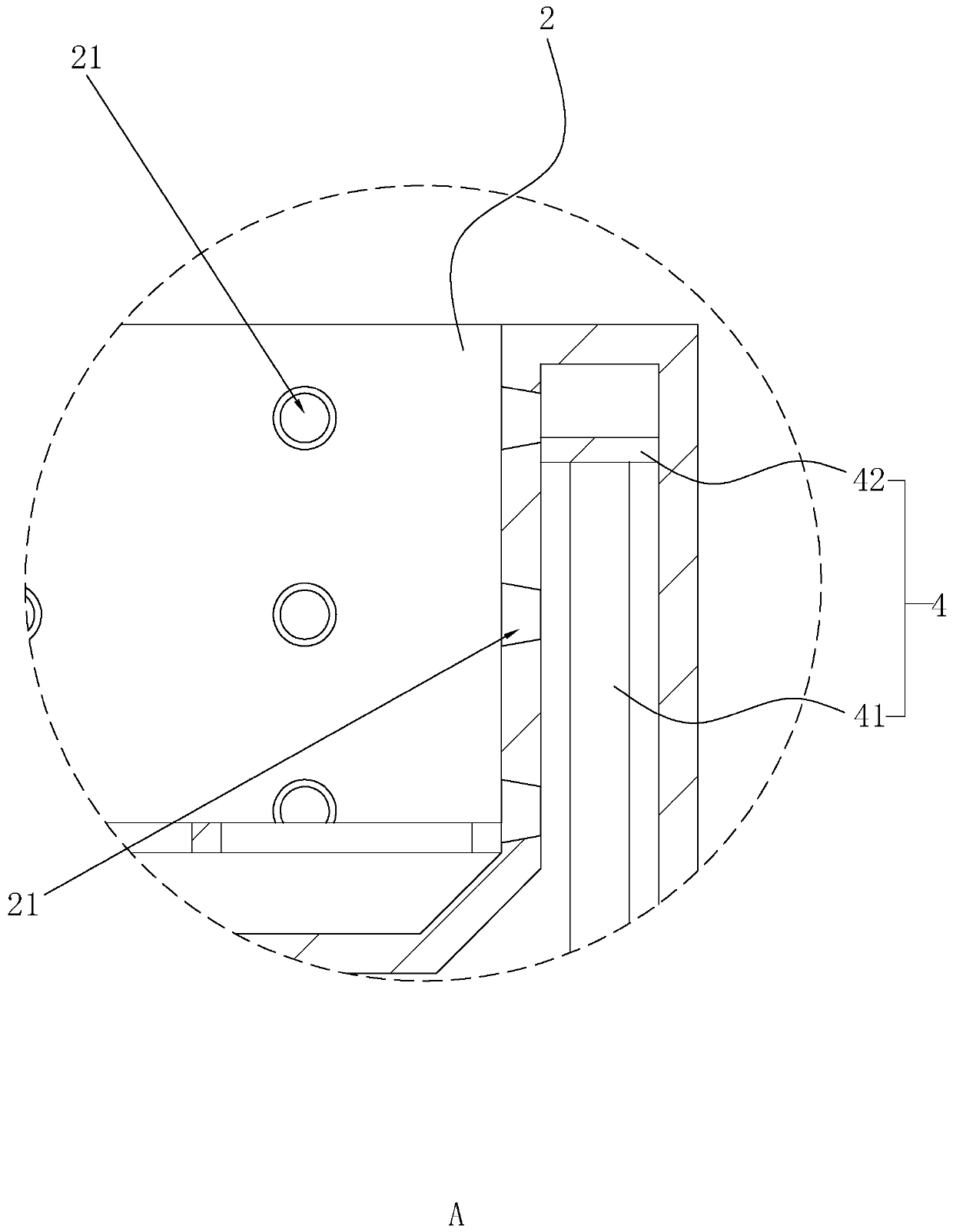

[0033] combine figure 2 and image 3 , the cover body 2 is placed around the head of the engraving machine body 1, the inside of the cover body 2 is hollow, and the inner wall of the cover body 2 is provided with a dust suction hole 21 for absorbing dust, and the dust suction hole 21 is defined by the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com