Safety protection system for numerical control horizontal single-sided motor base boring machine

A technology of safety protection and seat boring machine, which is applied to maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc. The effect of stabilization, reduction of sensation level, and improvement of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

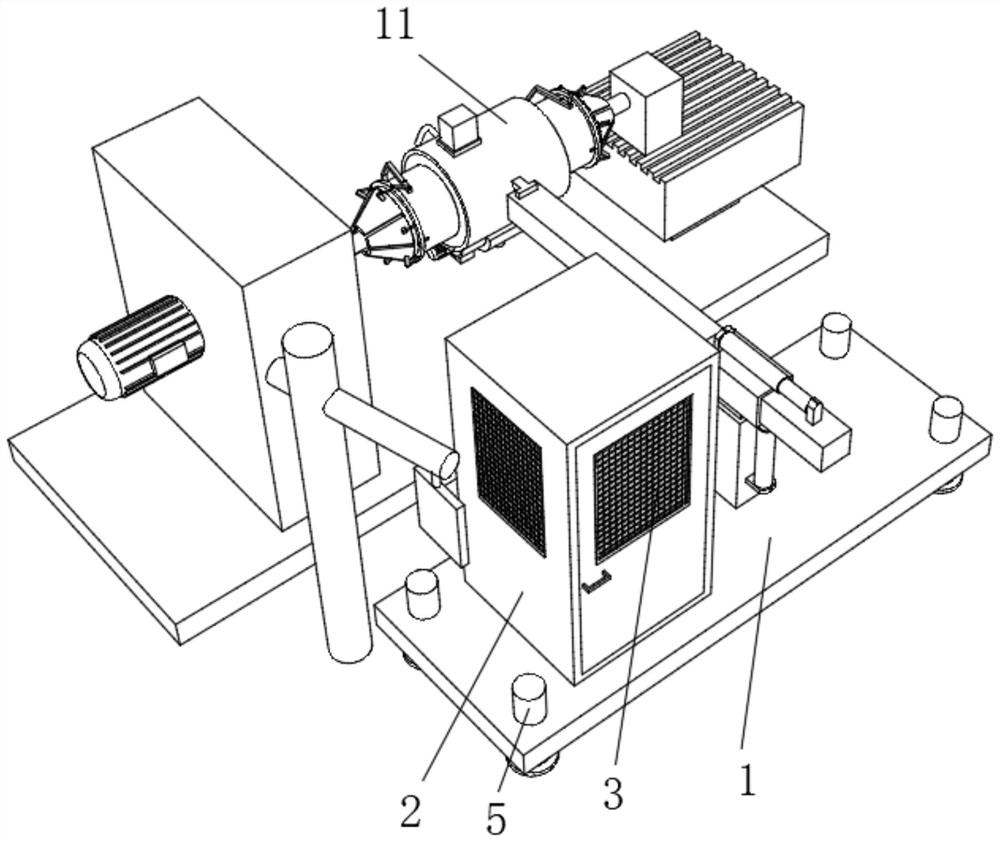

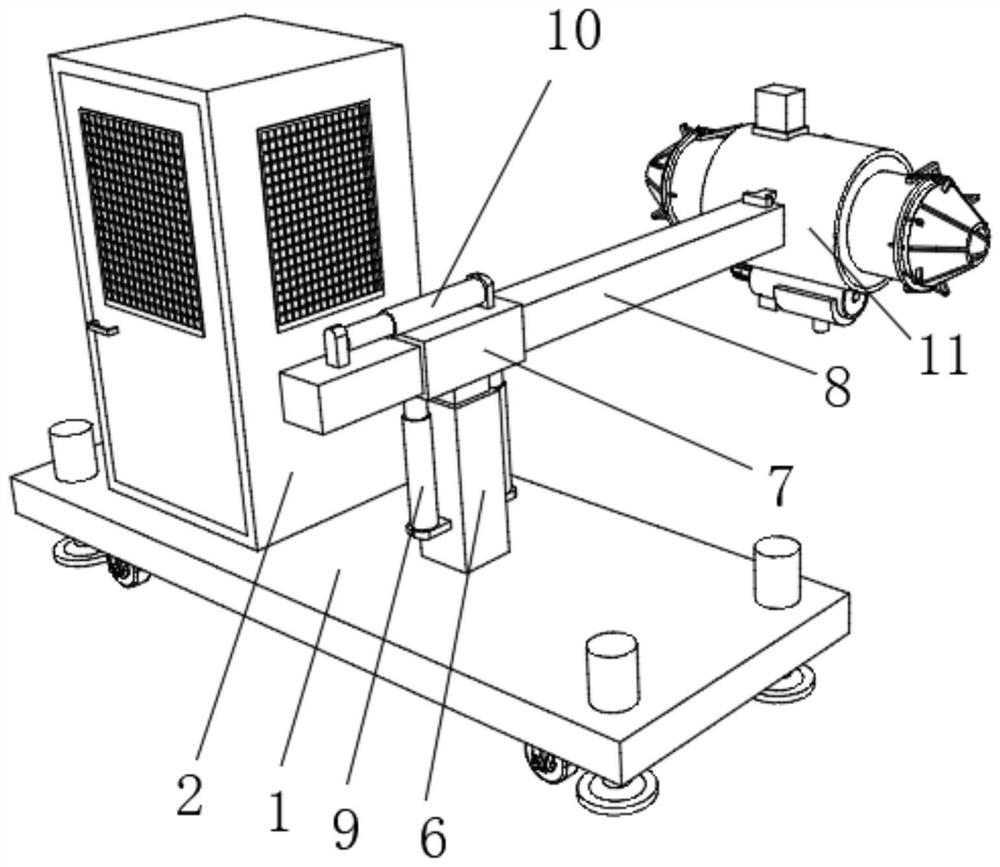

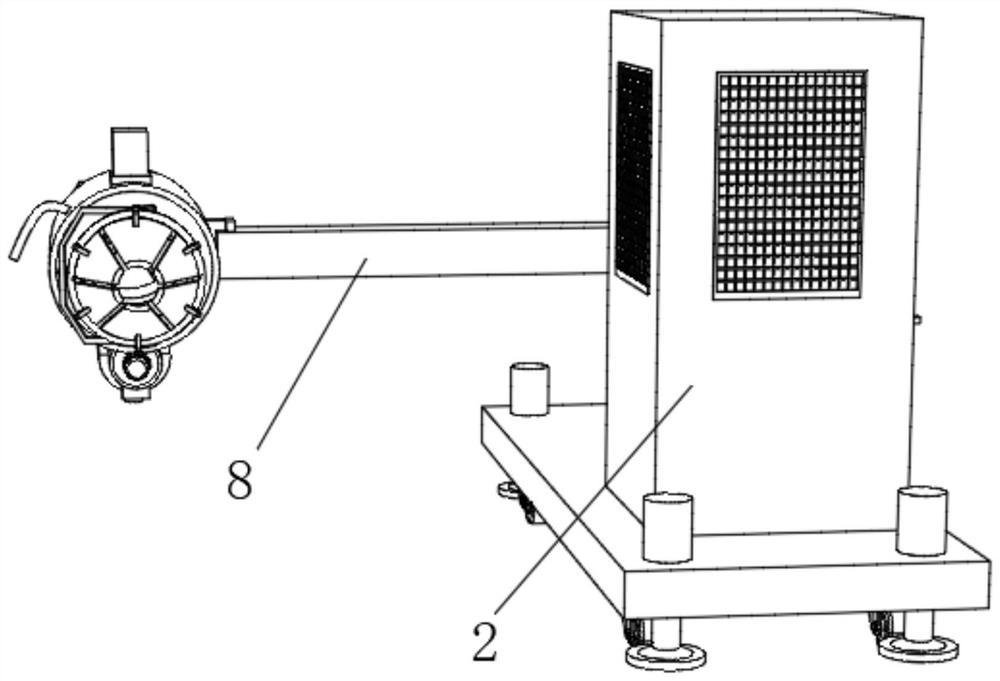

[0034] like Figure 1-9As shown, the embodiment of the present invention provides a safety protection system for a CNC horizontal single-sided motor bed boring machine, including a moving seat 1 and a wrapping cavity 11, a protection room 2 is provided on the left side of the top of the moving seat 1, and the three sides of the protection room 2 The window and the window of the front sealed door are equipped with protective components 3. The protective room 2 can prevent workers from being exposed to the outside, avoid the problem of being disturbed by machine noise, and also reduce the risk of accidents in the workshop, creating a good production environment. The protective room 2 There is a console 4 inside, and the console 4 is integrated with a video screen monitoring system, which can observe the processing situation. The middle part of the top of the mobile seat 1 is fixedly connected to the base 6, and the upper side of the base 6 is slidingly connected to the lifting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com