Guide wheel possessed die box for wire drawing machine

A technology of guide wheel and wire drawing machine, which is applied in the direction of wire drawing die, etc., can solve the problem of steel wire cutting and damage the mold box, and achieve the effect of ensuring wire drawing quality and good workshop environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

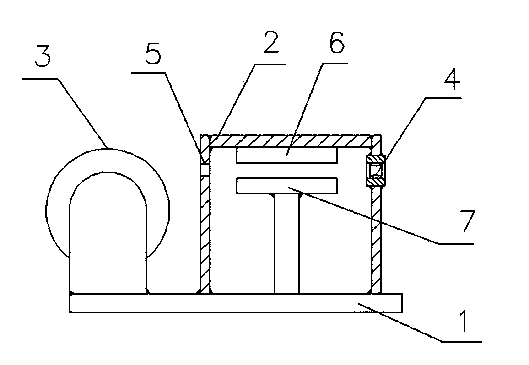

[0012] The present invention is described in detail below in conjunction with accompanying drawing:

[0013] refer to figure 1 , a mold box with guide wheels for a wire drawing machine, including a base 1, its special feature is: the base 1 is provided with a box body 2 and a guide wheel 3, and the guide wheel 3 is arranged at the rear end of the box body 2, The front panel of the box body 2 is provided with a through hole, the through hole is provided with a wire drawing die 4, and the rear panel is provided with an inlet hole 5, and the position of the wire inlet hole 5 is set opposite to the position of the wire drawing die 4. The tangent line of the groove at the top of the guide wheel 3 is aligned with the center of the wire inlet hole 5 . The inner side of the upper panel of the above-mentioned box body 2 is provided with an upper guide block 6 , and the bottom plate of the box body 2 is provided with a lower guide block 7 .

[0014] During use, the steel wire en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com