Selective laser melting equipment with reciprocating type conveying rail

A technology of selective laser melting and conveying track, which is applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., which can solve the problems of inconvenient collection of metal powder, impact on the environment, and diffusion of metal powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

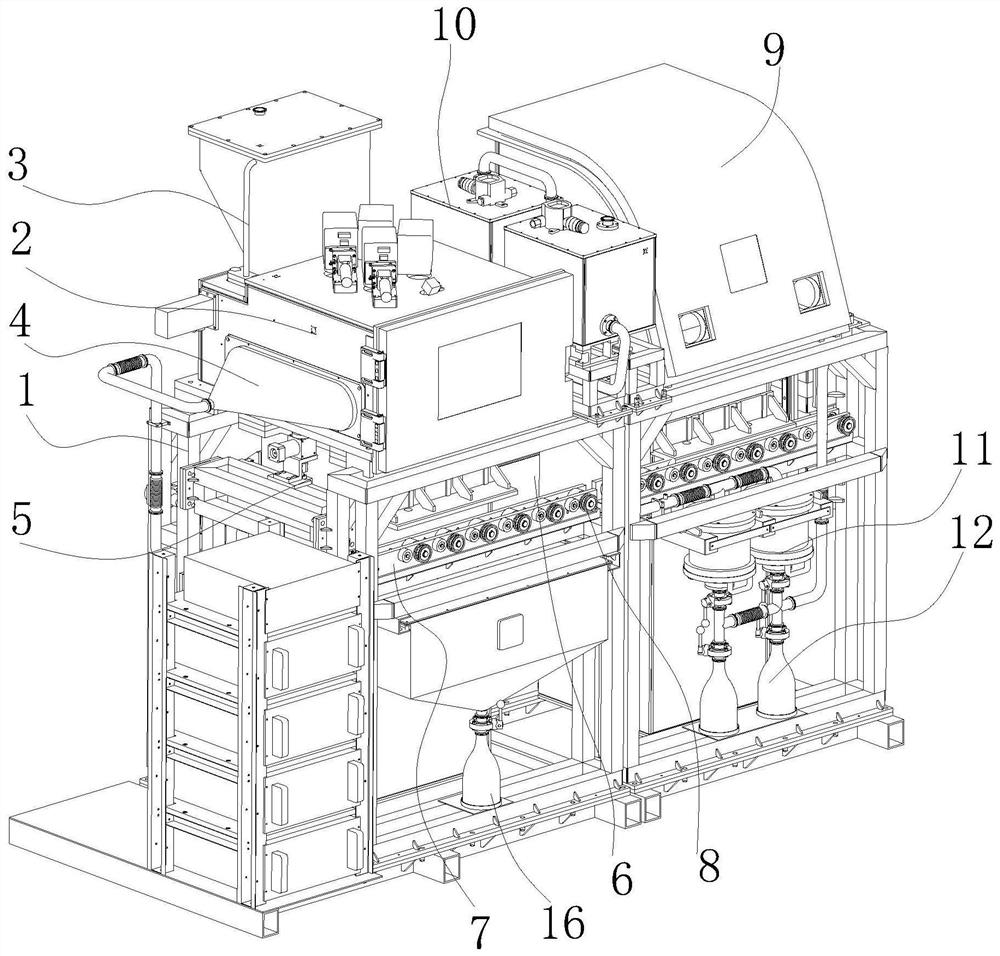

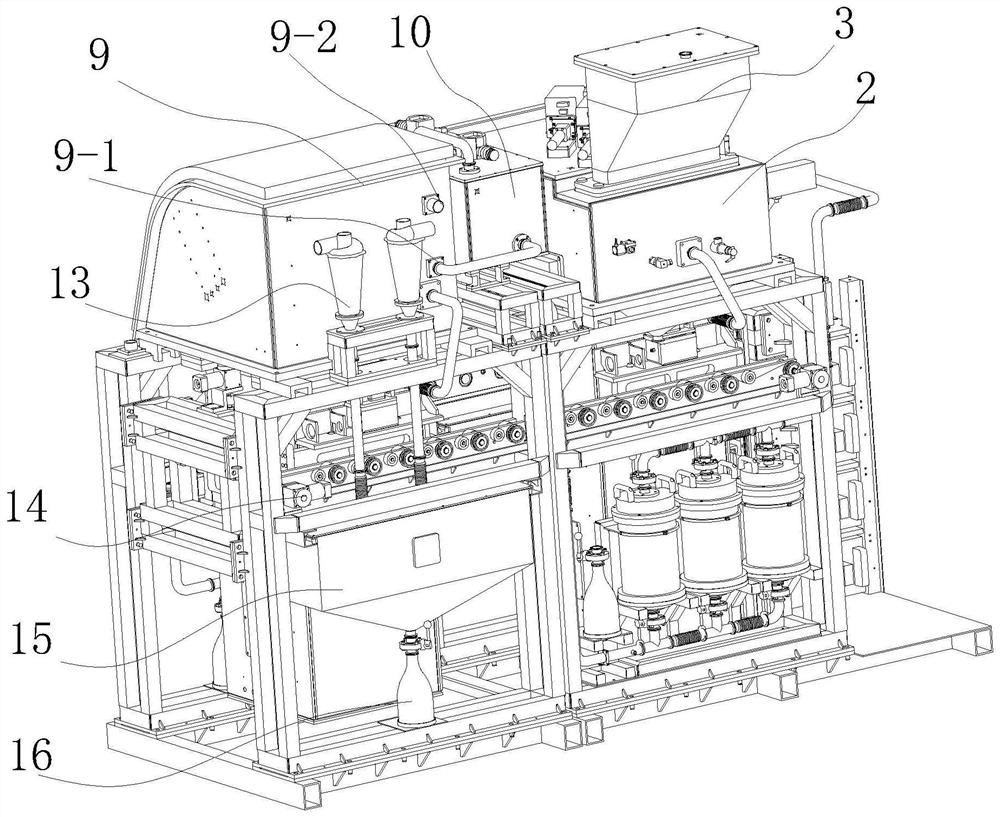

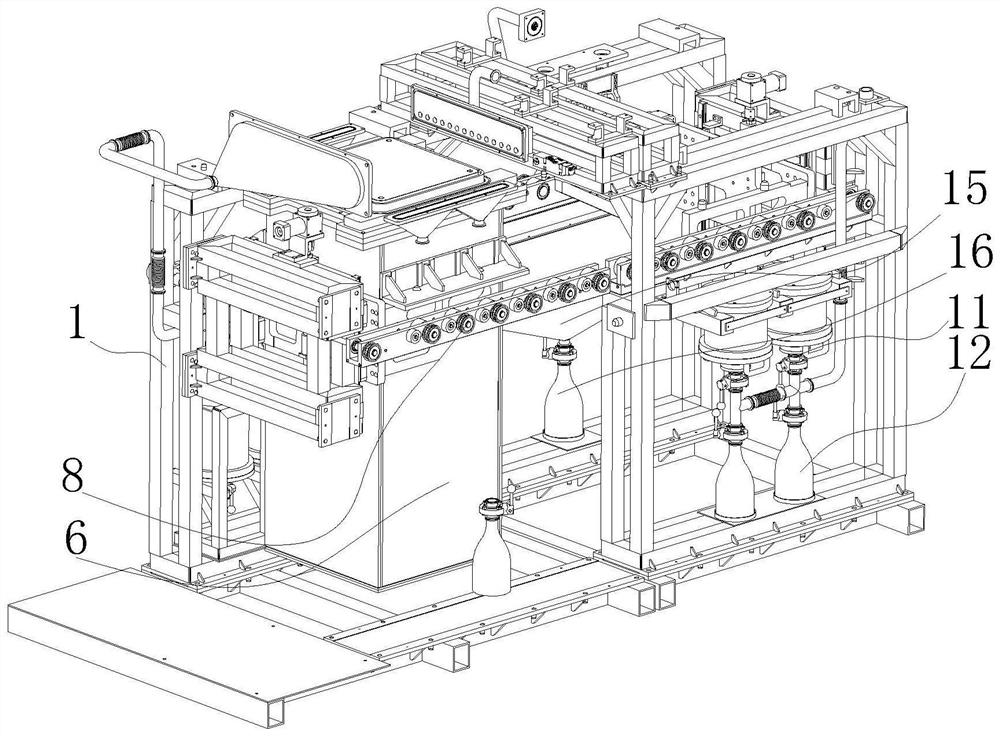

[0021] Such as Figure 1 to Figure 7 As shown, a selective area laser melting equipment with a reciprocating conveying track includes a frame 1 and a selected area laser melting equipment arranged on the frame 1, and the selected area laser melting equipment is composed of a material box arranged on the frame 1 , printing chamber 2, the print head on the printing chamber 2 and its printing platform 6. The printing platform 6 is located below the printing chamber 2 and can extend into the printing chamber 2. The material box 3 is located above the printing chamber 2 and is connected to the printing chamber. 2 connected, the frame 1 is located on the side of the printing chamber 2 and is provided with a cleaning chamber 9 for cleaning the powder on the surface of the three-dimensional model, and the lower ends of the printing chamber 2 and the cleaning chamber 9 are provided with a printing platform 6 extending The frame 1 is provided with a horizontal transmission mechanism for...

Embodiment 2

[0025] Such as Figure 1 to Figure 7As shown, a selective area laser melting equipment with a reciprocating conveying track includes a frame 1 and a selected area laser melting equipment arranged on the frame 1, and the selected area laser melting equipment is composed of a material box arranged on the frame 1 , printing chamber 2, the print head on the printing chamber 2 and its printing platform 6. The printing platform 6 is located below the printing chamber 2 and can extend into the printing chamber 2. The material box 3 is located above the printing chamber 2 and is connected to the printing chamber. 2 connected, the frame 1 is located on the side of the printing chamber 2 and is provided with a cleaning chamber 9 for cleaning the powder on the surface of the three-dimensional model, and the lower ends of the printing chamber 2 and the cleaning chamber 9 are provided with a printing platform 6 extending The frame 1 is provided with a horizontal transmission mechanism for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com