Constant-temperature drinking device

A constant temperature and inner cavity technology, applied in the field of metal processing and daily necessities, can solve the problems of not very long service life and not very high fatigue strength of 304 stainless steel, and achieve the effect of high efficiency and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

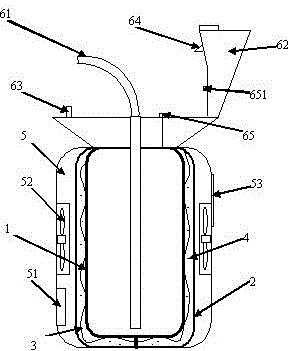

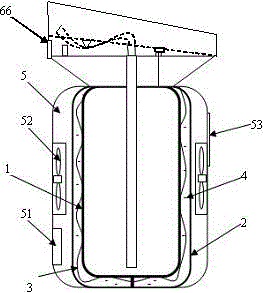

[0033] A constant temperature drinking device, comprising an inner cavity, an outer cavity, a functional cavity and a capping device;

[0034] The inner cavity, the outer cavity and the functional cavity are all concentric cylindrical configurations with an open upper end.

[0035] The inner cavity is made of improved 304 stainless steel, and the improved 304 stainless steel is calculated by mass percentage: C: 0.05%, Si: 0.58%, Mn: 1.5%, Ni: 10.2%, Cr: 19.5% , Cu: 3.9%, RE: 0.018%, the balance is Fe and unavoidable impurities; after the improved 304 stainless steel is formed into an inner cavity, it is also coated with a high temperature and fatigue resistance coating outside the inner cavity , the coating consists of Ni powder by mass percentage: 6.9%, Cr powder: 8.2%, Si powder: 1.8%, Mn powder: 23.9%, La 2 o 3 Powder: 1.38%, C powder: 0.68% and the rest of Fe powder are vacuum-dried by ball milling, and then laser cladding is applied to the outside of the inner cavity of...

Embodiment 2

[0052] A constant temperature drinking device, comprising an inner cavity, an outer cavity, a functional cavity and a capping device;

[0053] The inner cavity, the outer cavity and the functional cavity are all concentric cylindrical configurations with an open upper end.

[0054] The inner cavity is made of improved 304 stainless steel, and the improved 304 stainless steel is calculated by mass percentage: C: 0.032%, Si: 0.35%, Mn: 1.21%, Ni: 8.6%, Cr: 18% , Cu: 3.2%, RE: 0.011%, the balance is Fe and unavoidable impurities; after the improved 304 stainless steel is formed into an inner cavity, it is also coated with a high-temperature fatigue-resistant coating outside the inner cavity , the coating consists of Ni powder by mass percentage: 2.8%, Cr powder: 6.1%, Si powder: 1.2%, Mn powder: 21.2%, La 2 o 3 Powder: 1.12%, C powder: 0.31% and the rest of Fe powder are vacuum-dried by ball milling, and then laser cladding is applied to the outside of the inner cavity of the i...

Embodiment 3

[0071] A constant temperature drinking device, comprising an inner cavity, an outer cavity, a functional cavity and a capping device;

[0072] The inner cavity, the outer cavity and the functional cavity are all concentric cylindrical configurations with an open upper end.

[0073] The inner cavity is made of improved 304 stainless steel, and the improved 304 stainless steel is calculated by mass percentage: C: 0.038%, Si: 0.39%, Mn: 1.3%, Ni: 9.2%, Cr: 18.5% , Cu: 3.5%, RE: 0.015%, the balance is Fe and unavoidable impurities; after the improved 304 stainless steel is formed into an inner cavity, it is also coated with a high-temperature fatigue-resistant coating outside the inner cavity , the coating consists of Ni powder by mass percentage: 3.9%, Cr powder: 6.8%, Si powder: 1.5%, Mn powder: 22%, La 2 o 3 Powder: 1.2%, C powder: 0.51% and the rest of Fe powder are vacuum-dried by ball milling, and then laser cladding is applied to the outside of the inner cavity of the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com