Quick constant-temperature control method for secondary water use of gas water heater

A gas water heater and constant temperature control technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve problems affecting the user's bathing experience, and achieve the effect of improving the bathing experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

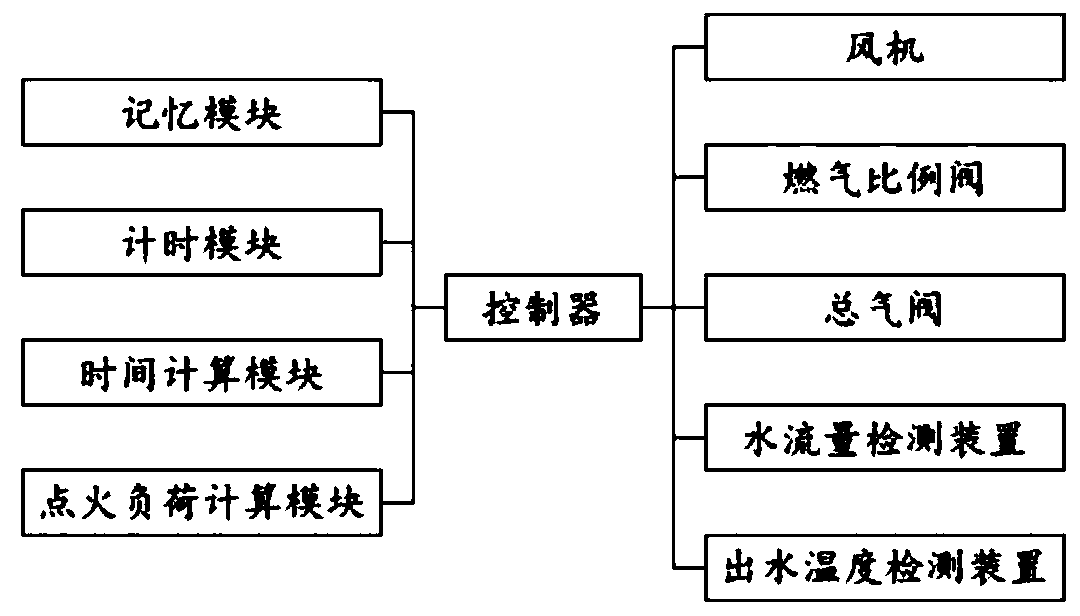

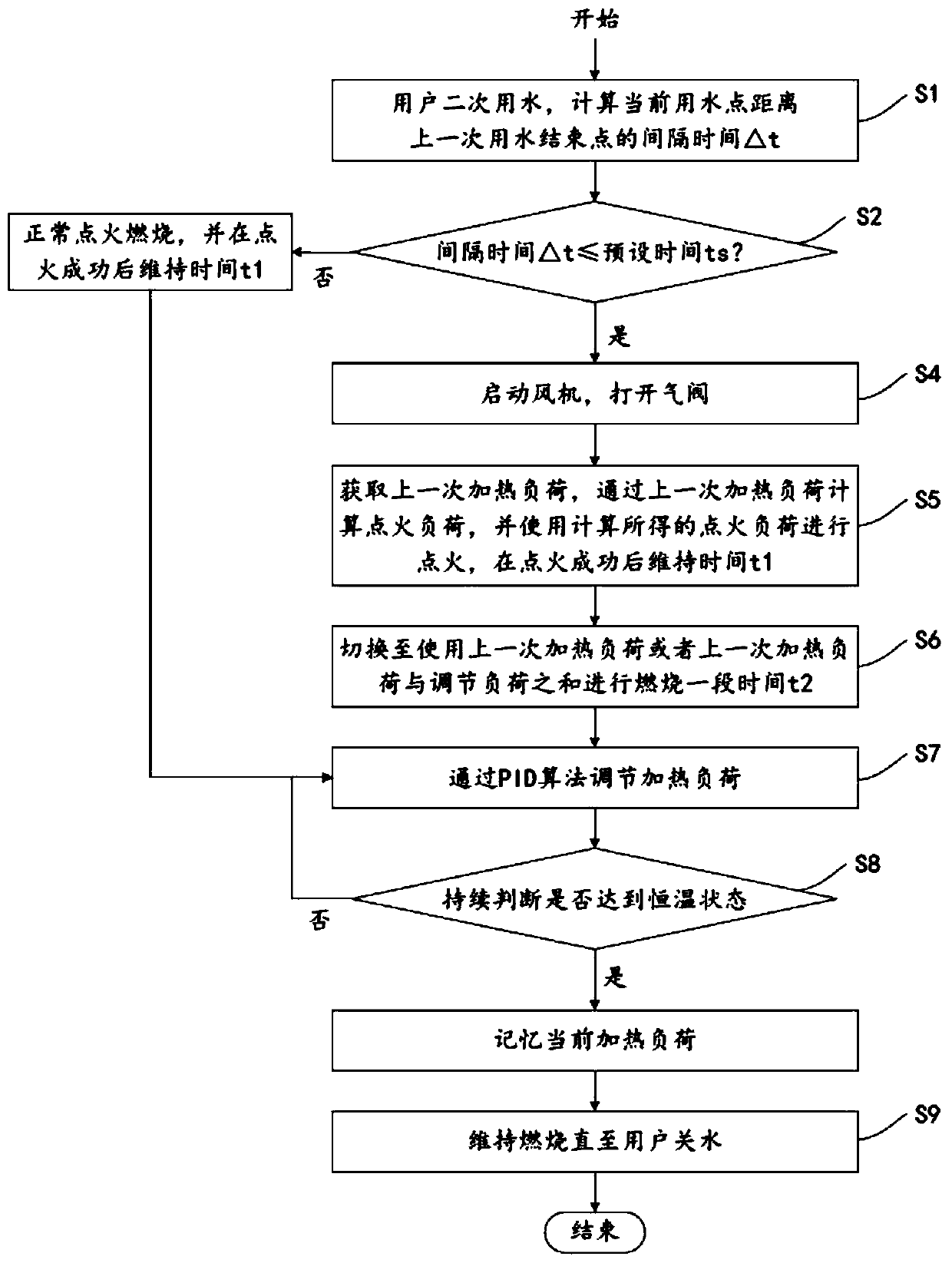

[0034] Such as figure 1 As shown, a method for rapid constant temperature control of the secondary water of a gas water heater in this embodiment, the gas water heater includes a controller, a memory module and a timing module, and the memory module and the timing module are respectively electrically connected to the controller. During the user's bathing process, when the gas water heater reaches a constant temperature state after normal ignition and combustion for the first time and before the user turns off the water halfway, the memory module memorizes the first heating load when the first normal ignition and combustion reaches a constant temperature state, and stores the stored load. The heating load for the first time is stored in the controller; when the user turns off the water halfway, the timing module records the end point of the first water use, and stores the recorded end point of the first water use in the controller.

[0035] Such as Figure 1-2 As shown, the co...

Embodiment 2

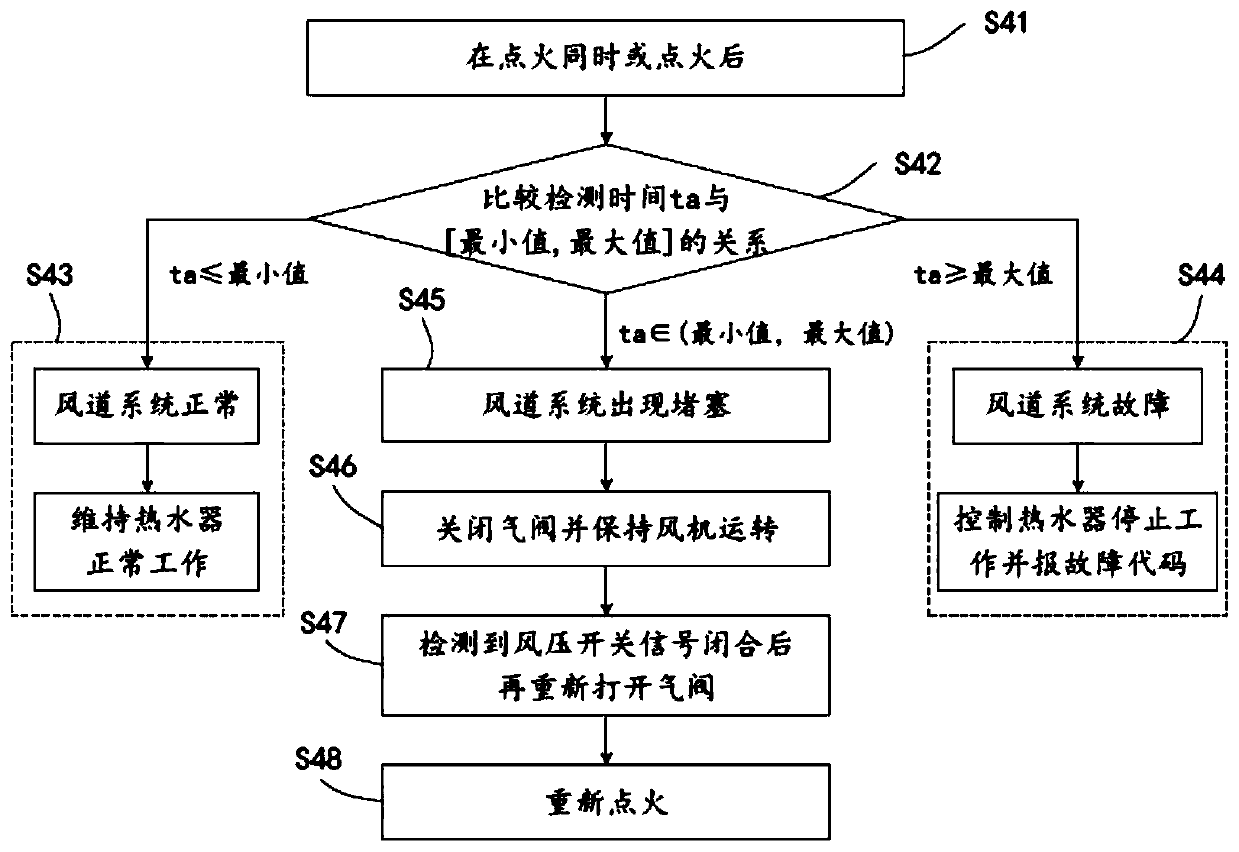

[0058] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the control method also includes step S3: judging whether the user's current water demand is the same as the previous water demand, and if so, enter step S4; After success, maintain the time t1 and then enter step S7.

[0059] Specifically, a water flow detection device is provided on the water inlet pipe of the gas water heater, and the water flow detection device is electrically connected with the controller for detecting the water flow rate of the water inlet pipe. Water demand includes preset target temperature and incoming water flow when starting the water heater. When the interval time △t≤preset time ts is determined, the water flow detection device samples the current water flow rate of the water inlet pipe, and the controller obtains the preset target temperature of the last water use and the water flow rate of the last water intake, and judges the current preset target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com