Mounting for a rotating shaft with sealing ring

A sealing ring and bearing technology, applied in the direction of rotating bearings, bearings, bearing components, etc., can solve the problem of delayed replacement of parts, and achieve the effect of good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

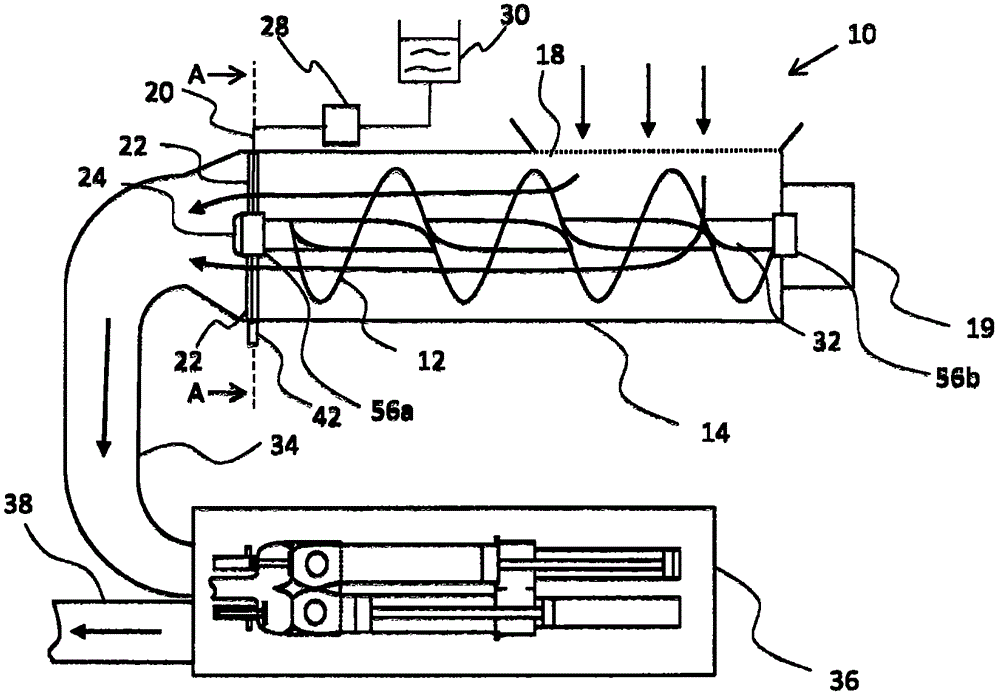

[0029] figure 1 Shown is a viscous material pump with a screw conveyor 10 and a schematically shown two-cylinder piston pump 36 , in which viscous material to be conveyed (“conveying medium”) is conveyed via an inlet 18 to Screw conveyor 10 supply. In this figure, the flow direction of the viscous material is shown by arrows. The screw conveyor 10 conveys and compresses the viscous material by means of a screw conveyor drive 19 which drives a shaft 32 on which one or more screw screws 12 are arranged. The viscous material is fed from the outlet of the screw conveyor 10 through the discharge section 34 to a double cylinder piston pump 36 in which the bearing 56a for supporting the shaft 32 is located, which sucks the viscous material and pumps the viscous material at high The pressure is pumped into the delivery tube 38 . another bearing in figure 1 Marked by 56b.

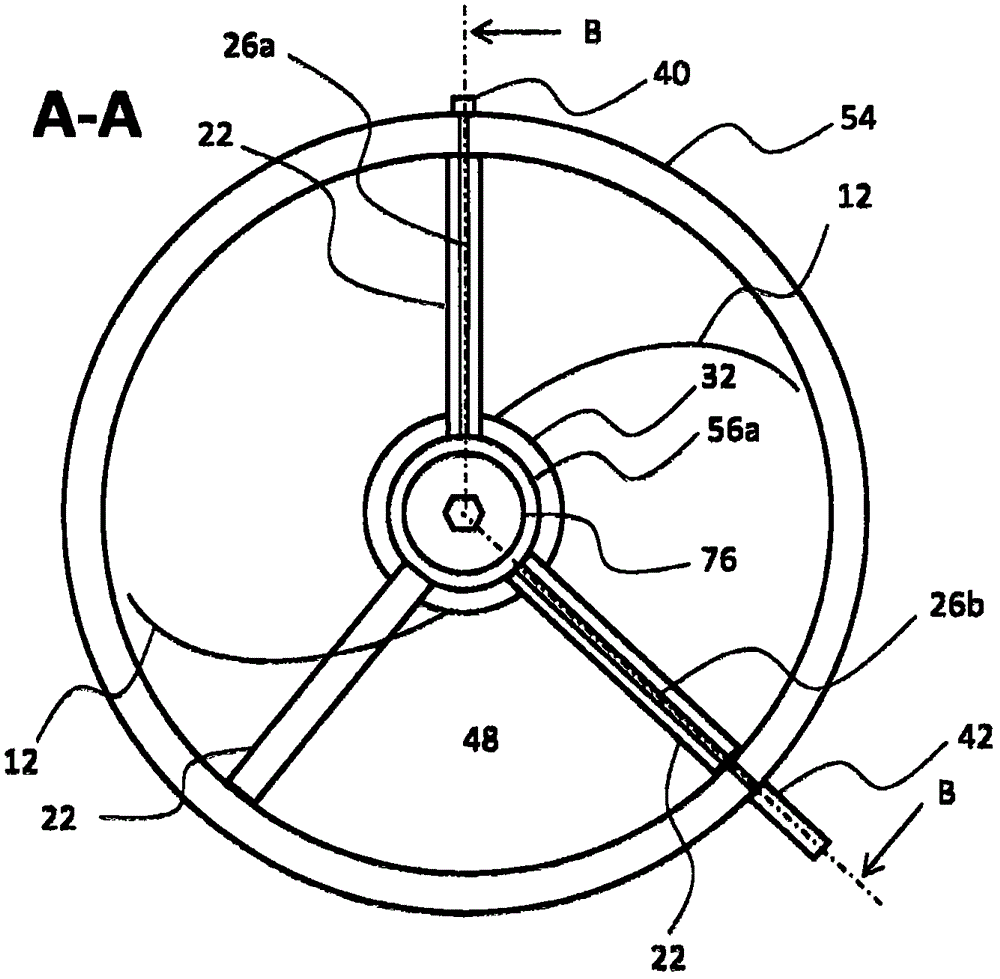

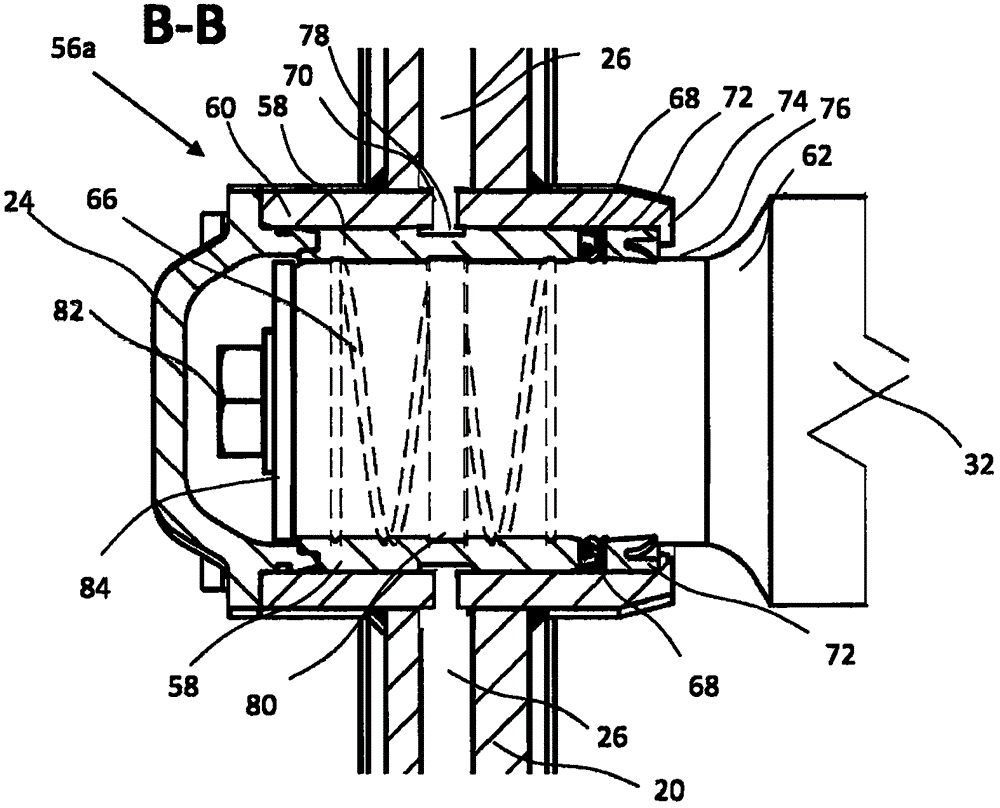

[0030] The bearing 56 a is fixed at the center of the outlet-side opening of the screw conveyor 10 by means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com