Liquid retaining bag

A liquid and stop-flow technology, applied in the field of liquid container structure, can solve the problems of pollution, waste, lack of stop-flow function, etc., and achieve the effects of convenient use and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

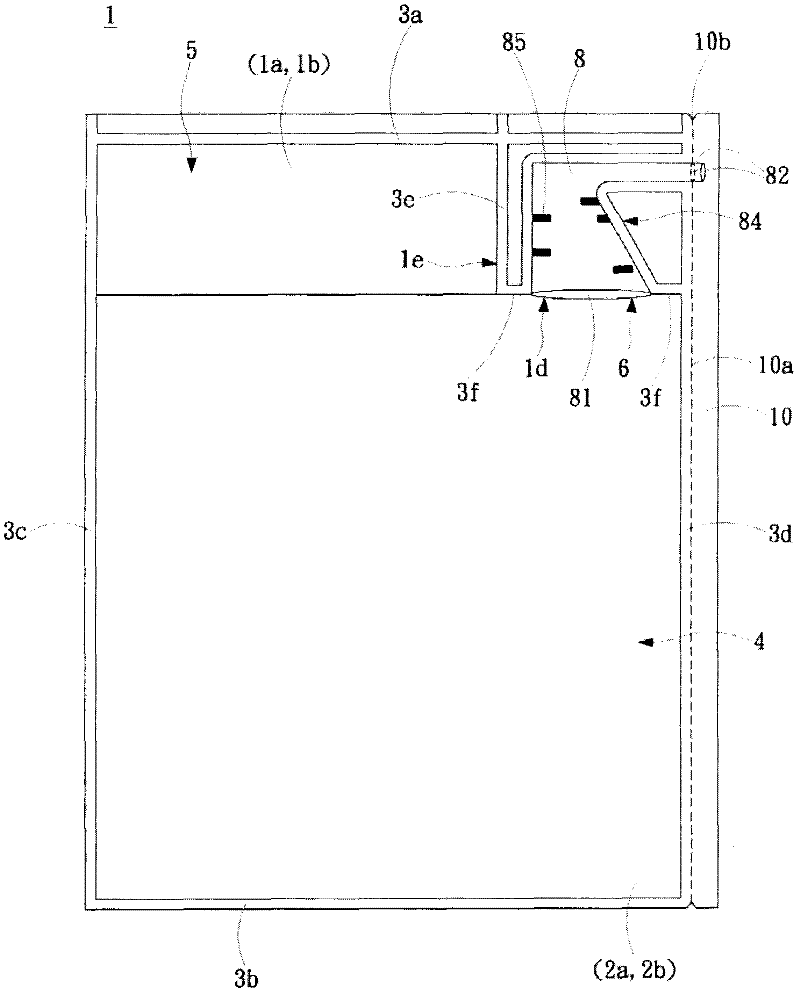

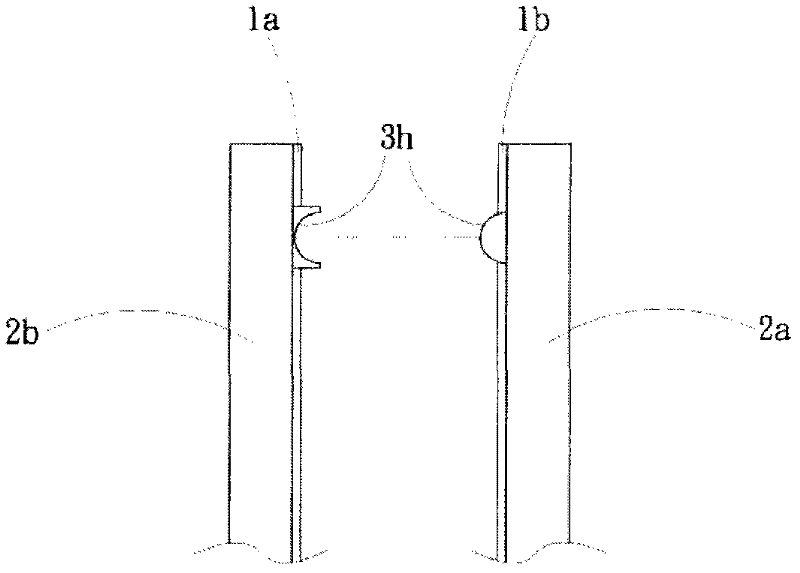

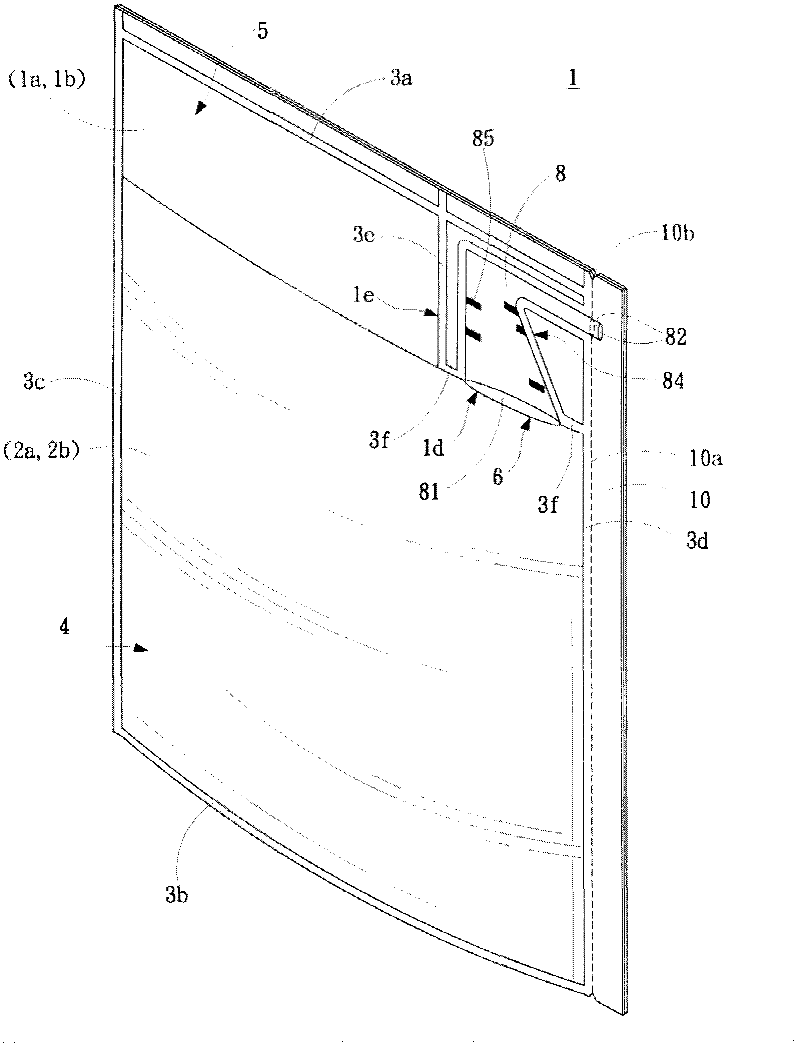

[0077] Figure 3A shows the second embodiment of the present invention: the inner membrane vertical stop structure

[0078] Two narrower inner films are placed vertically on one side of the two outer films, and the upper sections of the four films are simultaneously heat-sealed. The heat-sealing lines 3b, 3c, 3d, and 3f form a liquid-containing bag 1, and The bag body is divided into: filling area 5, discharging area 8, storage area 4, and heat sealing line 3e. A discharge channel is formed in the discharge area and includes at least an inlet 81, a curved portion 84 and an outlet 82. When the inlet 81 and the outlet 82 are heat-sealed, a baffle is applied to the inner surfaces of the two inner films 1a and 1b or a heat-resistant sealing material is pre-coated so that the inner surfaces of the two inner films 1a and 1b are not adhered to the inner surfaces during heat sealing. However, the two inner films 1a, 1b and the two outer films 2a, 2b opposed to each other are heat-sealed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com