Sandbox for molding front cover of automobile

A front cover and sandbox technology, which is applied in mold boxes, casting molding equipment, metal processing equipment, etc., can solve problems such as waste of raw materials, safety accidents, mold scalding, etc., to avoid material waste, save manpower and material resources, The effect of easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

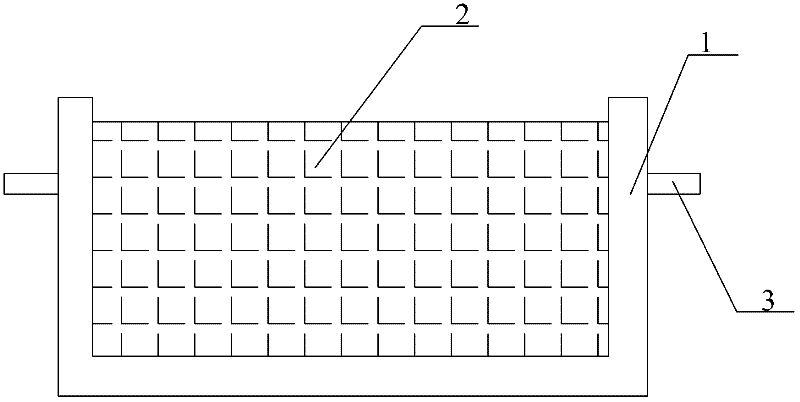

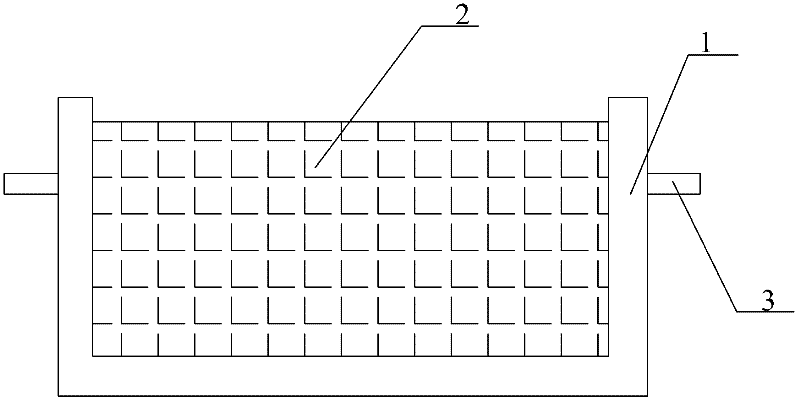

[0011] Such as figure 1 As shown, a sandbox for forming an automobile front cover includes a box body 1, the top of which is an open structure, and the inside of the box body 1 is filled with a coarse sand layer 2. Lifting handles 3 are arranged on the outer sides of the box body 1 .

[0012] When it is necessary to inject molten iron into the mould, first bury the mold in the coarse sand layer 2 in the box body 1, because the gap between the coarse sand in the coarse sand layer 2 is large, the exhaust and heat dissipation effect is good, even if the mold is scalded Even if the molten iron is broken, there will be no outflow of molten iron, and the coarse sand layer 2 is tightly pressed. After the molten iron is injected into the mold, even if the mold is broken, there will be a certain forming effect. It not only ensures that the safety accident of hot metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com